Difference between revisions of "Case studies for pretreatment"

m |

m |

||

| Line 57: | Line 57: | ||

In 2017, the City of Fridley used grant money from the Mississippi Watershed Management Organization (MWMO) to retrofit curb bump-outs with bioswales to treat stormwater runoff and provide multiple benefits (e.g., traffic control, stormwater treatment, and improved aesthetics) to the neighborhood. Rock-lined filter strips provide pretreatment at the curb cutout before stormwater entered the bioswale (Figure 3). The rock filter strip treats stormwater runoff that enters the bioswale by dissipating the flow to minimize erosion and remove sediment from the runoff via filtration and settling (Figure 4). This design reduces the TSS load to the bioswale, which allows the bioswale to function as designed and minimize costly maintenance. | In 2017, the City of Fridley used grant money from the Mississippi Watershed Management Organization (MWMO) to retrofit curb bump-outs with bioswales to treat stormwater runoff and provide multiple benefits (e.g., traffic control, stormwater treatment, and improved aesthetics) to the neighborhood. Rock-lined filter strips provide pretreatment at the curb cutout before stormwater entered the bioswale (Figure 3). The rock filter strip treats stormwater runoff that enters the bioswale by dissipating the flow to minimize erosion and remove sediment from the runoff via filtration and settling (Figure 4). This design reduces the TSS load to the bioswale, which allows the bioswale to function as designed and minimize costly maintenance. | ||

| − | <gallery caption="Images of rock filter strip" widths="250px"> | + | <gallery caption="Images of rock filter strip. Click on image to enlarge." widths="250px"> |

File:Fridley figure 1.png|alt=rock filter strip image|Rock Filter Strip at Curb Cut Bioswale Installed Along 3rd Street [City of Fridley, 2018] | File:Fridley figure 1.png|alt=rock filter strip image|Rock Filter Strip at Curb Cut Bioswale Installed Along 3rd Street [City of Fridley, 2018] | ||

File:Fridley figure 2.png|alt=rock filter strip image|Rock Filter Strip Treating Stormwater Runoff [MWMO, 2019] | File:Fridley figure 2.png|alt=rock filter strip image|Rock Filter Strip Treating Stormwater Runoff [MWMO, 2019] | ||

Revision as of 19:55, 23 May 2019

This page is in development

Filter strips

City of Burnsville - vegetated filter strip pretreatment

- Location: Neighborhood surrounding Crystal Lake in Burnsville, Minnesota

- Owners: Homeowners

- Designer: Barr Engineering

- Contractor: Mike’s Lawn and Landscape

- Year of Completion: 2004

- Pretreatment Practice: Filtration and settling

- Practice Description: Vegetated filter strip

- Design Features: The vegetated filter strip design filters stormwater runoff which minimizes erosion risks and filters out sediment prior to entering the rain gardens.

- Downstream Best Management Practice (BMP) Benefitting from Pretreatment: Rain garden

- Total Drainage Area and Land Use: 5.3 acres (primarily residential)

- Construction Cost: $8.00 per square foot (rain garden)

- Pollutant Removal: Vegetated filter strips provide 90 percent stormwater runoff volume reductions

- Is the Site Publicly Accessible: No

- Contact: Barr Engineering (kleuthold@barr.com)

Design summary

In 2002, the City of Burnsville worked with Barr Engineering to design rain gardens in a residential neighborhood surrounding Crystal Lake to reduce the pollutant runoff into the lake. Using city funding and a grant from the Metropolitan Council, 17 raingardens were installed along a street near Lake Crystal (Figure 1) as part of a stormwater retrofit study [Land and Water Magazine, 2004]. Vegetated filter strips provide stormwater pretreatment between the curb cutout and rain garden (Figure 2). The vegetated filter strip treats stormwater runoff that enters the raingarden by dissipating the flow to minimize erosion and remove sediment from the runoff via filtration and settling into the vegetation. This design reduces the total suspended solids (TSS) load to the rain garden and allows the rain garden to function as designed and minimize costly maintenance that results from sedimentation.

Maintenance

The homeowners are responsible for performing routine maintenance such as weeding, raking, and removal of accumulated sediment for the filter strips and rain gardens. The elevation of the filter strip increases over time because of solids settling into the vegetation, so the City of Burnsville has removed the vegetated filter strips, removed the sediment, and replaced the filter strips every five to seven years. Over the 15-year lifespan of the project, filter strips have been replaced twice by the city.

Lessons learned

- Incorporate “drop waterfalls” at curb cutout to slow the speed and reduce erosion potential of the runoff entering the vegetated filter strip.

- Vegetated filter strips have performed as designed and prolonged the lifespan and reduced maintenance of the rain gardens

References

- Barr Engineering Company. (2006). Rain Garden Project Summary. Retrieved February 5, 2019, from City of Burnsville

- Land and Water Magazine. (2004, September). Burnsville Rainwater Gardens. Land and Water Magazine, 48(5), p. 47. Retrieved February 5, 2019, from Land and Water Magazine

City of Fridley - Rock-lined filter strip pretreatment

- Location: 3rd St. NE, Fridley, Minnesota

- Owners: City of Fridley, Mississippi Watershed Management Organization

- Designer: Wenck Associates/City of Fridley/Minnesota Nice

- Contractor: Minnesota Nice

- Year of Completion: 2017

- Pretreatment Practice: Filtration and settling

- Practice Description: Rock Filter Strip

- Design Features: The design filters stormwater runoff before entering bioswale to minimize erosion risk and filter out and settle sediment.

- Downstream BMP Benefitting from Pretreatment: Bioswale

- Total Drainage Area and Land Use: Approximately 3 acres total (residential)

- Construction Cost: $27,900

- Documented Maintenance Practices: Annual removal of trash and sediment. Plants replaced as needed.

- Pollutant Removal: Sediment/nutrients, trash

- Is the Site Publicly Accessible: Yes

- Contact: Marcy Bean, Mississippi Watershed Management Organization (mbean@mwmo.org); Jon Lennander, City of Fridley (jon.lennander@fridleymn.gov)

Design summary

In 2017, the City of Fridley used grant money from the Mississippi Watershed Management Organization (MWMO) to retrofit curb bump-outs with bioswales to treat stormwater runoff and provide multiple benefits (e.g., traffic control, stormwater treatment, and improved aesthetics) to the neighborhood. Rock-lined filter strips provide pretreatment at the curb cutout before stormwater entered the bioswale (Figure 3). The rock filter strip treats stormwater runoff that enters the bioswale by dissipating the flow to minimize erosion and remove sediment from the runoff via filtration and settling (Figure 4). This design reduces the TSS load to the bioswale, which allows the bioswale to function as designed and minimize costly maintenance.

- Images of rock filter strip. Click on image to enlarge.

Maintenance

The City of Fridley inspects the rock-lined filter strips and bioswales annually and relocate existing rock, add rock when needed, and inspect for buried rocks that may be causing damming at the inlet. If damming at the inlet is observed, the rock-lined filter strip can be cleaned, replaced, or an inlet structure can be added.

Lessons learned

- Only bid to contractors with demonstrated similar experience.

- Blocked inlets can cause stormwater to bypass the basin.

- Initial rocks in filter strips were too small, which resulted in rocks getting carried into the bioswale during larger rain events. Larger rocks were used to avoid this problem moving forward. Through trial-and-error the appropriate rock size was determined to be Class I riprap (3 – 6 inches in diameter).

- Regular maintenance has prolonged lifespan and function

- Delegating maintenance responsibilities to contractor results in more consistent maintenance and ultimately better results compared to resident-driven projects. The City of Fridley added three years of maintenance to the contractor’s responsibility to ensure maintenance is conducted and done correctly.

References

- City of Fridley. (2018, January). Fridley Community Connection. Retrieved February 15, 2019, from City of Fridley

- Mississippi Watershed Management Organization. (no date). Fridley Street Reconstruction. Retrieved February 5, 2019 from Mississippi Watershed Management Organization

Project Name

Project Overview

Narrative description of pretreatment project

- Project Location:

- Year Constructed:

- Type of Pretreatment Practice: (e.g., forebay, proprietary settling device, etc.)

- Specific Practice: (e.g., rock inlet, name of proprietary device)

- Practice Owner:

- Practice Designer:

Design Considerations

- Design Cost:

- Design Year:

Narrative description of contributing drainage area, including description of land use

List of existing impairments and TMDLs that the BMP drains to

- Total Contributing Drainage Area (acres):

- Total Impervious Area (acres):

- Watershed Slope (%):

- Downstream Structural Best Management Practice:

- Design Pollutant Removal Performance:

Discussion of why that particular pretreatment system was chosen for that project location, specific rationale (e.g., site characteristics, ease of maintenance, etc.)

Description of sizing criteria used to design pretreatment practice

Construction Considerations

- Construction Cost:

- Construction Year:

Description of adverse site conditions/other construction challenges encountered during installation

Maintenance Considerations

List or description of types of maintenance practices used for the upkeep of the pretreatment system

- Maintenance Frequency:

- Maintenance Cost:

- Disposal Cost:

Description of maintenance challenges, discussion of ease of maintenance

Discussion of any additional maintenance considerations

Results

Discussion of how the performance was measured or estimated

- Measured or Estimated Pollutant Removal Performance:

For proprietary practices, did were the manufacturer claims met?

Discussion of lessons learned through the implementation of this pretreatment practice

Villa Park Stormwater Improvements - Preserver

Project Overview

Narrative description of pretreatment project

- Project Location: Roseville, MN

- Year Constructed:

- Type of Pretreatment Practice: Proprietary settling device

- Specific Practice: The Preserver

- Practice Owner:

- Practice Designer:

Design Considerations

- Design Cost:

- Design Year:

The total contributing drainage area to the Preserver was 242 acres, with 8 acres of direct drainage area. An estimated 30% of the direct drainage area to the Preserver was impervious (2.4 acres). The land use of the contributing drainage area was residential, with a mature tree canopy.

List of existing impairments and TMDLs that the BMP drains to

- Total Contributing Drainage Area (acres): 242

- Total Impervious Area (acres): ~30%

- Watershed Slope (%):

- Downstream Structural Best Management Practice: Irrigation cistern

- Design Pollutant Removal Performance:

Discussion of why that particular pretreatment system was chosen for that project location, specific rationale (e.g., site characteristics, ease of maintenance, etc.)

Description of sizing criteria used to design pretreatment practice

Construction Considerations

- Construction Cost:

- Construction Year:

Description of adverse site conditions/other construction challenges encountered during installation

Maintenance Considerations

List or description of types of maintenance practices used for the upkeep of the pretreatment system

- Maintenance Frequency:

- Maintenance Cost:

- Disposal Cost:

The mature tree canopy in the contributing drainage area contributed to heavy organic loads, including large debris. The total captured material would likely be greater with more frequent cleaning of the system - the sump was full approximately halfway through the monitoring period.

Discussion of any additional maintenance considerations

Results

Discussion of how the performance was measured or estimated

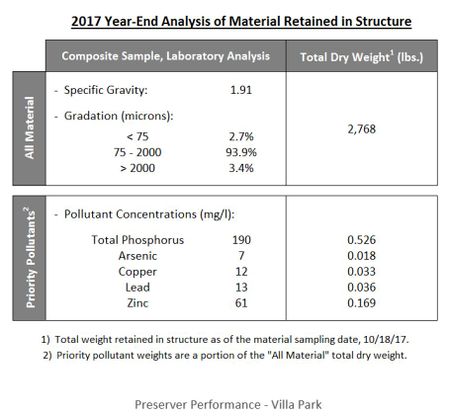

- Measured or Estimated Pollutant Removal Performance: 2,768 lbs of material captured by the pretreatment device, including:

- 0.526 lbs phosphorus

- Significant heavy metals

For proprietary practices, did were the manufacturer claims met?

Discussion of lessons learned through the implementation of this pretreatment practice