Difference between revisions of "Case studies for pretreatment"

m |

m |

||

| Line 251: | Line 251: | ||

[[File:St paul figure 3.png|300px|left|thumb|alt=safl baffle image|<font size=3>Location of Pretreatment Sump Manhole Relative to Infiltration Basin (WSB & Associates, 2011)</font size>]] | [[File:St paul figure 3.png|300px|left|thumb|alt=safl baffle image|<font size=3>Location of Pretreatment Sump Manhole Relative to Infiltration Basin (WSB & Associates, 2011)</font size>]] | ||

[[File:St paul figure 4.jpg|300px|thumb|alt=safl baffle image|<font size=3>Trash and Sediment Captured by Sump and SAFL Baffle at Beacon Bluff (Storm Water Solutions, 2015)</font size>]] | [[File:St paul figure 4.jpg|300px|thumb|alt=safl baffle image|<font size=3>Trash and Sediment Captured by Sump and SAFL Baffle at Beacon Bluff (Storm Water Solutions, 2015)</font size>]] | ||

| + | [[File:St paul figure 5.png|300px|thumb|left|alt=safl baffle image|<font size=3>SAFL Baffle in Empty Sump Manhole (Loucks Associates, 2013).</font size>]] | ||

On a former brownfield, the Saint Paul Port Authority took title of the 46.5-acre brownfield with the intention of redeveloping the site. The site drains a 144-acre area that flows into the Phalen Creek tunnel and, ultimately, to the Mississippi River without any stormwater treatment. Runoff from the watershed typically contained high levels of sediment and contaminants (Saint Paul Port Authority). Flows from the existing 45-inch storm pipe on Duchess Street were diverted onto the site, along with two other storm sewer outfalls, and into the new stormwater treatment system. The diverted flows first went through a SAFL Baffle then into an infiltration basin that can return the treated water via an overflow back to the Phalen Creek tunnel. | On a former brownfield, the Saint Paul Port Authority took title of the 46.5-acre brownfield with the intention of redeveloping the site. The site drains a 144-acre area that flows into the Phalen Creek tunnel and, ultimately, to the Mississippi River without any stormwater treatment. Runoff from the watershed typically contained high levels of sediment and contaminants (Saint Paul Port Authority). Flows from the existing 45-inch storm pipe on Duchess Street were diverted onto the site, along with two other storm sewer outfalls, and into the new stormwater treatment system. The diverted flows first went through a SAFL Baffle then into an infiltration basin that can return the treated water via an overflow back to the Phalen Creek tunnel. | ||

Revision as of 20:58, 23 May 2019

This page is in development

Contents

Filter strips

City of Burnsville - vegetated filter strip pretreatment

- Location: Neighborhood surrounding Crystal Lake in Burnsville, Minnesota

- Owners: Homeowners

- Designer: Barr Engineering

- Contractor: Mike’s Lawn and Landscape

- Year of Completion: 2004

- Pretreatment Practice: Filtration and settling

- Practice Description: Vegetated filter strip

- Design Features: The vegetated filter strip design filters stormwater runoff which minimizes erosion risks and filters out sediment prior to entering the rain gardens.

- Downstream Best Management Practice (BMP) Benefitting from Pretreatment: Rain garden

- Total Drainage Area and Land Use: 5.3 acres (primarily residential)

- Construction Cost: $8.00 per square foot (rain garden)

- Pollutant Removal: Vegetated filter strips provide 90 percent stormwater runoff volume reductions

- Is the Site Publicly Accessible: No

- Contact: Barr Engineering (kleuthold@barr.com)

Design summary

In 2002, the City of Burnsville worked with Barr Engineering to design rain gardens in a residential neighborhood surrounding Crystal Lake to reduce the pollutant runoff into the lake. Using city funding and a grant from the Metropolitan Council, 17 raingardens were installed along a street near Lake Crystal (Figure 1) as part of a stormwater retrofit study [Land and Water Magazine, 2004]. Vegetated filter strips provide stormwater pretreatment between the curb cutout and rain garden (Figure 2). The vegetated filter strip treats stormwater runoff that enters the raingarden by dissipating the flow to minimize erosion and remove sediment from the runoff via filtration and settling into the vegetation. This design reduces the total suspended solids (TSS) load to the rain garden and allows the rain garden to function as designed and minimize costly maintenance that results from sedimentation.

Maintenance

The homeowners are responsible for performing routine maintenance such as weeding, raking, and removal of accumulated sediment for the filter strips and rain gardens. The elevation of the filter strip increases over time because of solids settling into the vegetation, so the City of Burnsville has removed the vegetated filter strips, removed the sediment, and replaced the filter strips every five to seven years. Over the 15-year lifespan of the project, filter strips have been replaced twice by the city.

Lessons learned

- Incorporate “drop waterfalls” at curb cutout to slow the speed and reduce erosion potential of the runoff entering the vegetated filter strip.

- Vegetated filter strips have performed as designed and prolonged the lifespan and reduced maintenance of the rain gardens

References

- Barr Engineering Company. (2006). Rain Garden Project Summary. Retrieved February 5, 2019, from City of Burnsville

- Land and Water Magazine. (2004, September). Burnsville Rainwater Gardens. Land and Water Magazine, 48(5), p. 47. Retrieved February 5, 2019, from Land and Water Magazine

City of Fridley - Rock-lined filter strip pretreatment

- Location: 3rd St. NE, Fridley, Minnesota

- Owners: City of Fridley, Mississippi Watershed Management Organization

- Designer: Wenck Associates/City of Fridley/Minnesota Nice

- Contractor: Minnesota Nice

- Year of Completion: 2017

- Pretreatment Practice: Filtration and settling

- Practice Description: Rock Filter Strip

- Design Features: The design filters stormwater runoff before entering bioswale to minimize erosion risk and filter out and settle sediment.

- Downstream BMP Benefitting from Pretreatment: Bioswale

- Total Drainage Area and Land Use: Approximately 3 acres total (residential)

- Construction Cost: $27,900

- Documented Maintenance Practices: Annual removal of trash and sediment. Plants replaced as needed.

- Pollutant Removal: Sediment/nutrients, trash

- Is the Site Publicly Accessible: Yes

- Contact: Marcy Bean, Mississippi Watershed Management Organization (mbean@mwmo.org); Jon Lennander, City of Fridley (jon.lennander@fridleymn.gov)

Design summary

In 2017, the City of Fridley used grant money from the Mississippi Watershed Management Organization (MWMO) to retrofit curb bump-outs with bioswales to treat stormwater runoff and provide multiple benefits (e.g., traffic control, stormwater treatment, and improved aesthetics) to the neighborhood. Rock-lined filter strips provide pretreatment at the curb cutout before stormwater entered the bioswale (Figure 3). The rock filter strip treats stormwater runoff that enters the bioswale by dissipating the flow to minimize erosion and remove sediment from the runoff via filtration and settling (Figure 4). This design reduces the TSS load to the bioswale, which allows the bioswale to function as designed and minimize costly maintenance.

- Images of rock filter strip. Click on image to enlarge.

Maintenance

The City of Fridley inspects the rock-lined filter strips and bioswales annually and relocate existing rock, add rock when needed, and inspect for buried rocks that may be causing damming at the inlet. If damming at the inlet is observed, the rock-lined filter strip can be cleaned, replaced, or an inlet structure can be added.

Lessons learned

- Only bid to contractors with demonstrated similar experience.

- Blocked inlets can cause stormwater to bypass the basin.

- Initial rocks in filter strips were too small, which resulted in rocks getting carried into the bioswale during larger rain events. Larger rocks were used to avoid this problem moving forward. Through trial-and-error the appropriate rock size was determined to be Class I riprap (3 – 6 inches in diameter).

- Regular maintenance has prolonged lifespan and function

- Delegating maintenance responsibilities to contractor results in more consistent maintenance and ultimately better results compared to resident-driven projects. The City of Fridley added three years of maintenance to the contractor’s responsibility to ensure maintenance is conducted and done correctly.

References

- City of Fridley. (2018, January). Fridley Community Connection. Retrieved February 15, 2019, from City of Fridley

- Mississippi Watershed Management Organization. (no date). Fridley Street Reconstruction. Retrieved February 5, 2019 from Mississippi Watershed Management Organization

Forebays

City of South St. Paul - Seidl's Lake stormwater retrofit

- Location: 1415 4th Street South, South St. Paul, Minnesota

- Owner: City of South St. Paul

- Designer: Dakota County Soil and Water Conservation District

- Contractor: G.L. Contracting

- Year of Completion: 2012

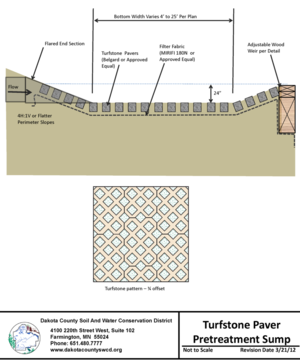

- Pretreatment Practice: Turfstone forebay

- Design Features: The design includes sediment forebay with level spreaders.

- Downstream BMP and receiving water benefitting from pretreatment: Iron-enhanced sand filter and Seidl’s Lake

- Total Drainage Area and Land Use: 15.5 acres (residential)

- Impervious Drainage Area: 5.68 acres

- Is the Site Publicly Accessible: Yes

- Contact & Email: Joe Barten (joe.barten@co.dakota.mn.us)

Design summary

The Seidl’s Lake Park was an area for potential stormwater improvements identified in the City of South St. Paul’s Comprehensive Stormwater Management Plan, developed to improve the water quality within the city (City of South St. Paul, 2012). In partnership with the Dakota County Soil and Water Conservation District, an iron-enhanced sand filter and pretreatment forebay were designed to improve water quality in Seidl’s Lake by treating an untreated 15.5-acre subwatershed.

Maintenance

In 2016, the pretreatment cell was excavated and found to have accumulated 6 cubic yards of sediment and organic materials.

Lessons learned

- The turfstone and weir design is successfully capturing large amounts of sediment.

- It is uncertain whether surface ponding in the pre-treatment area is due to underlying soils or caking of sediment at turfstone and fabric interface.

- With future forebay designs, particularly in areas with poor or compacted soils, consider including underdrains beneath the pretreatment cell which could help facilitate proper drainage and reduce surface ponding.

- With future forebay designs, could consider raising the elevation of the pretreatment area relative to the basin and installing screened leveling pipes that connect to the basin to reduce ponding in forebay.

- Consider manually vacuuming out turfstone to remove layer of fine sediment at paver surface and replace with washed sand during regular maintenance.

References

- City of South St. Paul. (2012, January). Stormwater Management Plan. Retrieved March 7, 2019, from City of South St. Paul

- Dakota County Soil and Water Conservation District. (2013, January 23). Seidls Retrofit. Retrieved March 07, 2019, from Dakota County Soil and Water Conservation District

City of Savage - Bluff Haven wet pond forebay

- Location: Hillsboro Avenue and McColl Drive, Savage, Minnesota

- Owner: City of Savage

- Designer: Westwood Professional Services

- Contractor: John Arthur Homes

- Year of Completion: 2018

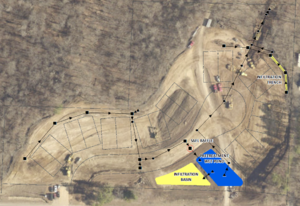

- Pretreatment Practice: Sump manhole, baffle, and wet forebay

- Practice Description: Sump manhole and St. Anthony Falls Laboratory (SAFL) baffle (or equivalent) with wet pond forebay treat stormwater runoff prior to discharge into an infiltration basin.

- Design Features: The design includes a sump manhole with SAFL baffle and a wet pond forebay which provides a treatment train approach to stormwater pretreatment. First, the SAFL Baffle retains sands and trash, then the forebay retains most of the silts and smaller organic material, prior to the stormwater entering the infiltration basin where the relatively clean water is infiltrated.

- Downstream BMP Benefitting from Pretreatment: Infiltration basin

- Total Drainage Area and Land Use: 6.8 acres, twin home development

- Total Impervious Area: 1.84 acre

- Is the Site Publicly Accessible: Yes

- Contact & Email: Jesse Carlson, City of Savage (JCarlson@ci.savage.mn.us)

Design summary

Water quality for the proposed 6.8-acre twin home development is provided by pretreatment and infiltration practices designed to infiltrate the water quality volume of 1.0 inch over the impervious area, utilizing an above ground infiltration basin and an underground infiltration rock trench. The pretreatment for the above ground infiltration basin is a wet basin with dead storage exceeding 25% of the water quality volume which is consistent with the Minnesota Stormwater Manual guidelines for pretreatment. Pretreatment of the underground infiltration rock trench is not required because only green space and disconnected roof runoff drains to the BMP [Westwood Professional Services, 2017].

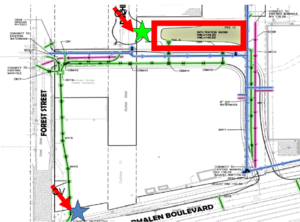

Site layout for the above ground infiltration basin and pretreatment is shown below, which treats approximately 4.4 acres of the proposed development.

Construction considerations

The stormwater BMP treatment train included an infiltration basin. Measures shall be taken during construction to protect this area during construction and after. Employ all appropriate erosion and sediment control BMPs and time the installation to prevent sediment from impacting the proposed infiltration basin.

Lessons learned

Steep bluff slopes and existing trees limited stormwater management locations due to City ordinance prohibiting disturbance of such areas during development. Care was taken to avoid concentrated flows down the bluff areas [City of Savage, 2017].

References

- City of Savage. (21 September 2017). Planning Commission Packet for Thursday September 21, 2017. Accessed March 3, 2019.

- Westwood Professional Services, Inc. (2017 August 11). Preliminary Storm Water Runoff Narrative. Savage, MN. Prepared for John Arthur Homes.

- Westwood Professional Services, Inc. (2018 March 8). Construction Plans for Grading, Sanitary Sewer, Water Main, Storm Sewer, and Streets for Bluff Haven. Savage, MN. Prepared for John Arthur Homes

Proprietary devices

City of Minnetonka - Libb's Lake Rain Guardian pretreatment

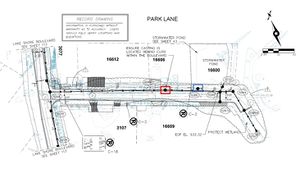

- Location: 16600 Park Lane, Minnetonka, Minnesota

- Owner: City of Minnetonka

- Designer: WSB & Associates

- Contractor: GMH Asphalt Corporation

- Year of Completion: 2016

- Pretreatment Practice: Proprietary Screening/Settling Device

- Practice Description: Sump manhole and Rain Guardian Turret pretreatment chamber

- Design Features: A biofiltration wetland was installed to alleviate the existing flooding concerns near Libb’s Lake and provide water quality treatment for the 2016 street reconstruction project.

- Downstream BMP and receiving water benefitting from pretreatment: Stormwater biofiltration area, as well as Libb’s Lake and Lake Minnetonka

- Total Drainage Area and Land Uses: Sump 2.2 acres, Rain Guardian 0.75 acre (estimated); Large lot residential; rolling flat topography

- Impervious Drainage Area: Sump 1.2 acres (estimated from Google Earth), Rain Guardian 0.15 acre (estimated)

- Design Cost: $6,000

- Construction Cost: $12,000 ($75,000 with stormwater biofiltration grading and plantings)

- Is the Site Publicly Accessible: Yes

- Contact: Philip Olson, City of Minnetonka (polson@eminnetonka.com)

Design summary

As a part of the City of Minnetonka’s 2016–2020 Capital Improvement Program, the 2016 Street Rehabilitation Project updated roadways, watermains, sanitary sewer pipes in the neighborhood around Libb’s Lake, near Grays Bay of Lake Minnetonka. The program also provided improved stormwater drainage and water quality treatment. Before this project, most of the stormwater runoff flowed overland directly to Libb’s Lake without treatment.

During the project design, challenges included developing viable stormwater treatment options while accounting for site conditions (e.g., a high groundwater table, rolling terrain, right-of-way limitations, and existing buildings with a history of flooding). To address these challenges, a pretreatment manhole sump was installed in-line along with a Rain Guardian Turret structure to capture stormwater runoff and provide pretreatment before entering a stormwater biofiltration area that discharges to Libb’s Lake (Figure 12).

The sump treats runoff that entered the system upstream, while the Rain Guardian Turret and stormwater biofiltration area treat overland flow from Park Lane. The Rain Guardian Turret chamber treats runoff before it enters the shallow stormwater wetland biofiltration area directly from the roadway and removes sediment, coarse debris, and trash (Figures 13 and 14). The pretreatment system captures 0.5 pound of total phosphorus and 576 pounds of TSS annually (WSB & Associates, 2015).

Maintenance

The sump manhole is vacuumed truck to remove deposited sediment and debris. Per the final feasibility study for this project, maintenance occurs twice annually at an estimated cost of $450 per year (WSB & Associates, 2015).

To maintain the designed functionality of the Rain Guardian Turret, the City of Minnetonka intends to clear debris from the top grate, remove debris from inside the chamber, and clean the filter wall. In addition to performing regular maintenance, markers are recommended to be placed at the inlet in the winter months to alert snow plows of their locations and prevent snow piles from forming on top of the practice (Anoka Conservation District).

Lessons learned

Because of the shallow nature of the storm sewer system, the Rain Guardian Turret was selected primarily for its minimal cover requirements to discharge stormwater from the reconstructed Park Lane into the new stormwater wetland. The Rain Guardian Turret has the added benefit of providing additional pretreatment, reducing maintenance needs, and increasing the lifespan of the stormwater wetland.

References

- Anoka Conservation District. (no date). Rain Guardian Maintenance Guide. Retrieved February 22, 2019

- WSB & Associates, Inc. (2015, October 5). Feasibility Report: 2016 Street Rehabilitation Project Libbs Lake Area. Prepared for City of Minnetonka.

- WSB & Associates, Inc. (2017, April). Record Drawings for 2016 Street Rehabilitation Project – Libbs Lake Area. Prepared for City of Minnetonka.

City of New Brighton - Environment21 V2B1 MODEL 4

- Location: Rice Creek Road and Long Lake Road, New Brighton, Minnesota

- Owner: City of New Brighton

- Designer: City of New Brighton

- Contractor: Central Landscaping, Inc.

- Year of Completion: 2005

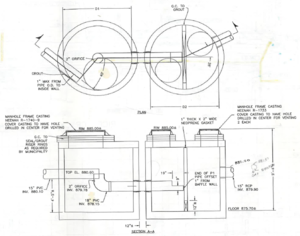

- Pretreatment Practice: Proprietary Hydrodynamic Separator

- Practice Description: Two Environment21 V2B1 Model 4 installed as part of 2005 street improvement project.

- Downstream receiving water benefitting from pretreatment device: Long Lake

- Total Drainage Area and Land Use: 1.8 and 4.2 acres (residential)

- Impervious Drainage Area: 1.44 and 1.89 acres, respectively

- Construction Cost: $40,526.62

- Is the Site Publicly Accessible: Yes

- Contact: Dustin Lind, City of New Brighton (Dustin.Lind@newbrightonmn.gov)

Design summary

As part of the City of New Brighton’s reconstruction of Rice Creek Road in 2005, proposed storm improvements included installing new storm sewer and treatment devices. The storm sewer ultimately discharges to Long Lake. Because the lake is impaired for nutrients, the Rice Creek Watershed District required stormwater treatment. The Environment21 V2B1 Model 4 treatment devices remove floatable debris and sediment from the storm sewer before discharging into Long Lake [Gulliver et al, 2007]. The V2B1 device is a pretreatment device and as such removes trash, sand, and gravels. This case study is an example of pretreatment without a downstream BMP, however pretreatment provided by the V2B1 device benefits the downstream Long Lake.

The system was designed for the 10-year design storm event with a peak intensity of 4.6 inches per hour, with the V2B1 Model 4 installed in-line with the new storm sewer. The Environment21 V2B1 Model 4 consists of two connected manholes, a 5-foot-diameter settling chamber and a 5-foot-diameter floatables trap (Figure 15). Based on the performance assessment, anticipated TSS removal is 65 percent [Fyten et al, 2008].

Maintenance

At part of the City’s MS4 program and documented on their MS4 form, twice a year in the spring and fall, the city-owned vacuum truck removes debris and sediment from structures. Debris and sediment are then hauled to a contained spoil pile (where the City stores possibly-contaminated soils) for testing. Barr Engineering conducts tests to determine if the soil is contaminated, then the soil is hauled to the appropriate location.

Lessons learned

The site was included as part of a field performance study on underground stormwater treatment devices by the University of Minnesota and the Minnesota Department of Transportation (Figure 16). The study found that the hydraulic conditions of the storm sewer system produced a backwater effect inside the treatment manholes during a runoff event, which results in a reduced velocity at the inlet pipe. Slower velocities may reduce the mixing energy and provide more opportunities for settling. However, coarse particles are unlikely to remain in suspension and may increase sediment deposition in the inlet pipes until a large event flushes the system [Gulliver et al, 2007].

Additional Environment21 V2B1 Model 4 case studies are available for the City of Fridley and the City of Wayzata from the manufacturer’s website.

References

- City of New Brighton. (2005, April 11). State Aid Project 147-020-32. Sheets 8-9 of 29.

- Fyten, A., Lueker, M., & Mohseni, O. (2008). Performance Assessment of the Environment21 V2B1 Model 4 for Removing Suspended Sediments from Stormwater. University of Minnesota, St. Anthony Falls Laboratory. Minneapolis: Environment21. Retrieved March 7, 2019

- Gulliver, J., Hozalski, R., Mohseni, O., & Wilson, M. (2007). Performance Assessment of Underground Stormwater Treatment Devices. University of Minnesota, Department of Mechanical Engineering. St. Paul: Minnesota Department of Transportation, Research Services Section. Retrieved March 7, 2019

City of St. Paul - Beacon Bluff SAFL Baffle pretreatment

- Location: Phalen Blvd., St. Paul, Minnesota

- Owner: City of St. Paul

- Designer: Loucks Associates

- Contractor: Blackstone Contractors, LLC

- Year of Completion: 2011

- Pretreatment Practice: Proprietary Screening/Settling

- Practice Description: SAFL Baffle

- Design Features: The design reduces the turbulence and scouring of high flows through a sump, which minimizes scouring. A garbage trap hood captures trash and other floatables at the outflow.

- Downstream BMP Benefitting from Pretreatment: Infiltration System

- Total Drainage Area and Land Use: 144 Acres, Residential and industrial

- Is the Site Publicly Accessible: Yes

- Contact & Email: Monte Hillman (mmh@sspa.com)

Design summary

On a former brownfield, the Saint Paul Port Authority took title of the 46.5-acre brownfield with the intention of redeveloping the site. The site drains a 144-acre area that flows into the Phalen Creek tunnel and, ultimately, to the Mississippi River without any stormwater treatment. Runoff from the watershed typically contained high levels of sediment and contaminants (Saint Paul Port Authority). Flows from the existing 45-inch storm pipe on Duchess Street were diverted onto the site, along with two other storm sewer outfalls, and into the new stormwater treatment system. The diverted flows first went through a SAFL Baffle then into an infiltration basin that can return the treated water via an overflow back to the Phalen Creek tunnel.

The SAFL baffle was is in a 6-feet deep with a 6-foot diameter sump designed to trap sand, trash, and floatables. The SAFL baffle is upstream of the infiltration basin and reduces scouring of previously deposited sediments in the sump by reducing turbulence during high flows. A trash hood (model 30R Snout from Best Management Products, Inc) installed on the outflowing pipe prevents trash and other floatables from leaving the sump. This design reduces the floatables and TSS load to the infiltration basin, allowing the practice to function as designed, maintain storage capacity of the system, and minimize costly maintenance (Storm Water Solutions, 2015).

Maintenance

The St. Paul Sewer Maintenance Division vacuums out the SAFL Baffle structure 3 times per year. During the first 4 months of use, 130 cubic feet (roughly 13,000 pounds) of sediment were removed. Even with the pretreatment, infiltration rates in the infiltration basin have been decreasing on an annual basis, likely due to sediment accumulation in the BMP. Maintenance conducted on the infiltration basin last fall noted the basin was still performing as an infiltration practice. Maintenance inspections have also found trash and floatables in the SAFL baffle (WSB & Associates, 2015).

Lessons learned

- The sump filled up more quickly than expected and clean outs were required three times per year. Planning ahead for additional maintenance in the first years after installation is recommended.

- The sediment collected contained a mix of sand, silt, and organic materials.

- Floatables and garbage were observed in the SAFL baffle during maintenance inspections in 2014.

References

- Blackstone Contractors, LLC. (2018, March). Beacon Bluff Stormwater Demonstration Area. Retrieved March 7, 2019 from Blackstone Contractors

- Loucks Associates. (2013). Next Generation Stormwater Management. Retrieved March 7, 2019, from American Planning Association Minnesota Chapter

- Saint Paul Port Authority. “Managing Stormwater for the Next Generation.” Saint Paul Historical. Retrieved March 7, 2019 from https://saintpaulhistorical.com/items/show/348

- Storm Water Solutions. (2015, August 27). St. Paul Stops Storm Water Sediment & Trash. Retrieved March 11, 2019 from Storm Water Solutions

- WSB & Associates, Inc. (2011). Beacon Bluff SAFL Baffle Installation.

- WSB & Associates, Inc. (2015, April). 2014 Stormwater Quality and Quantity Monitoring Program for the City of Saint Paul, Minnesota. Retrieved March 7, 2019, from City of St. Paul

Project Name

Project Overview

Narrative description of pretreatment project

- Project Location:

- Year Constructed:

- Type of Pretreatment Practice: (e.g., forebay, proprietary settling device, etc.)

- Specific Practice: (e.g., rock inlet, name of proprietary device)

- Practice Owner:

- Practice Designer:

Design Considerations

- Design Cost:

- Design Year:

Narrative description of contributing drainage area, including description of land use

List of existing impairments and TMDLs that the BMP drains to

- Total Contributing Drainage Area (acres):

- Total Impervious Area (acres):

- Watershed Slope (%):

- Downstream Structural Best Management Practice:

- Design Pollutant Removal Performance:

Discussion of why that particular pretreatment system was chosen for that project location, specific rationale (e.g., site characteristics, ease of maintenance, etc.)

Description of sizing criteria used to design pretreatment practice

Construction Considerations

- Construction Cost:

- Construction Year:

Description of adverse site conditions/other construction challenges encountered during installation

Maintenance Considerations

List or description of types of maintenance practices used for the upkeep of the pretreatment system

- Maintenance Frequency:

- Maintenance Cost:

- Disposal Cost:

Description of maintenance challenges, discussion of ease of maintenance

Discussion of any additional maintenance considerations

Results

Discussion of how the performance was measured or estimated

- Measured or Estimated Pollutant Removal Performance:

For proprietary practices, did were the manufacturer claims met?

Discussion of lessons learned through the implementation of this pretreatment practice

Villa Park Stormwater Improvements - Preserver

Project Overview

Narrative description of pretreatment project

- Project Location: Roseville, MN

- Year Constructed:

- Type of Pretreatment Practice: Proprietary settling device

- Specific Practice: The Preserver

- Practice Owner:

- Practice Designer:

Design Considerations

- Design Cost:

- Design Year:

The total contributing drainage area to the Preserver was 242 acres, with 8 acres of direct drainage area. An estimated 30% of the direct drainage area to the Preserver was impervious (2.4 acres). The land use of the contributing drainage area was residential, with a mature tree canopy.

List of existing impairments and TMDLs that the BMP drains to

- Total Contributing Drainage Area (acres): 242

- Total Impervious Area (acres): ~30%

- Watershed Slope (%):

- Downstream Structural Best Management Practice: Irrigation cistern

- Design Pollutant Removal Performance:

Discussion of why that particular pretreatment system was chosen for that project location, specific rationale (e.g., site characteristics, ease of maintenance, etc.)

Description of sizing criteria used to design pretreatment practice

Construction Considerations

- Construction Cost:

- Construction Year:

Description of adverse site conditions/other construction challenges encountered during installation

Maintenance Considerations

List or description of types of maintenance practices used for the upkeep of the pretreatment system

- Maintenance Frequency:

- Maintenance Cost:

- Disposal Cost:

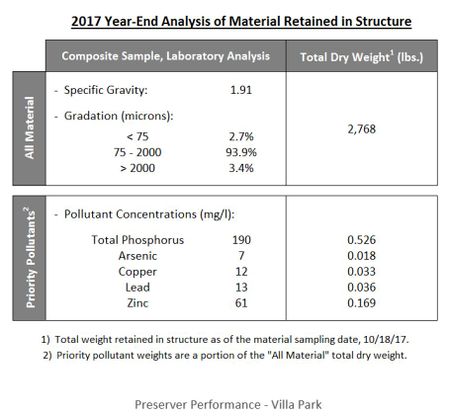

The mature tree canopy in the contributing drainage area contributed to heavy organic loads, including large debris. The total captured material would likely be greater with more frequent cleaning of the system - the sump was full approximately halfway through the monitoring period.

Discussion of any additional maintenance considerations

Results

Discussion of how the performance was measured or estimated

- Measured or Estimated Pollutant Removal Performance: 2,768 lbs of material captured by the pretreatment device, including:

- 0.526 lbs phosphorus

- Significant heavy metals

For proprietary practices, did were the manufacturer claims met?

Discussion of lessons learned through the implementation of this pretreatment practice