Winter Parking Lot and Sidewalk Maintenance Manual

We are in the process of migrating the Winter Parking Lot and Sidewalk Maintenance manual to the Minnesota Stormwater Manual. Thus, this page is undergoing formatting, which we hope to complete by the end of February, 2016. You can access a pdf version of the maintenance manual here. Other changes and updates to information on salt management will be posted in the What's new page in the manual. Information on road salt and water quality can be found on MPCA's website

.

Contents

- 1 Background Information

- 2 Prepare for Winter Operations

- 3 Storage

- 4 Calibration

- 5 Materials

- 6 Speed of Melting

- 7 Testing

- 8 Take Action to Keep Surfaces Clear

- 9 Deicing/Anti-Icing Information

- 9.1 Anti-icing

- 9.2 Get started in anti-icing

- 9.3 Anti-icing Tips

- 9.4 Equipment

- 9.5 Deicing

- 9.6 Pre-wetting and Pretreating Salt and Sand

- 9.7 Guidelines for Pretreating Stockpiles

- 9.8 Treating the salt stockpile:

- 9.9 Treated Stockpile Application:

- 9.10 Guidelines for Pre-wetting

- 9.11 Traction

- 9.12 Advantages of sand (abrasives):

- 9.13 Disadvantages of sand:

- 9.14 Sweeping

- 10 Evaluate the effectiveness of actions

- 11 Application Rates for Reduced Environmental Impacts

- 12 Deicing Application Rate Guidelines for Parking Lots and Sidewalks

- 13 Application Rates for Reduced Environmental Impacts

- 14 Deicing Application Rate Guidelines for Parking Lots and Sidewalks

- 15 Instructions for using application rate table for calibrated spreaders

- 16 Results

- 17 References and Resources

- 18 Additional Resources

- 19 Appendix

Background Information

Good Business Choices

Customer service is the key to success. Best Management Practices (BMP) keep parking lots and sidewalks safe and also reduce environmental impacts. Educating customers on the proper methods of snow removal and ice control (and of the value of this approach) can create a good and long-standing relationship.

Customers want reliable service. Providing a well-planned and well-executed winter maintenance program will have a positive impact. Using the latest technologies will increase the abilty to provide reliable service.

Customers want to hire educated winter maintenance professionals. This maunal will provide the necessary information to increase staff knowledge on the best practices for winter maintenance.

Using the right amount of material at the right time, will save time and money.

Certification in Smart Salting is a good reflection on the professional and the organization.

Customers and the public want safe parking lots and sidewalks. Understanding the materials, weather and application rates, provide a head start on controlling icy, slippery parking lots, and sidewalks.

Clean and neat parking lots and sidewalks are important to the public. By using less material and increased winter sweeping, pedestrians will track less material into buildings and there will be less damage to flooring. Proper snow storage makes debris removal in the spring easier. Covered storage of deicers will reduce loss of material, protect water, and is more aesthetic. Using BMPs and lower application rates will keep parking lots and sidewalks looking neat.

Customers also want affordable snow and ice control. The use of sophisticated chemicals and equipment may require a larger budget up-front; however, these costs can be balanced by reduced on-going costs. Reducing the need for sweeping, floor and rug maintenance, parking lot striping, and snow and ice maintenance time will allow for cost savings.

Minnesotan’s value water resources and the protection of lakes, streams, and wetlands is important. Educating customers how sustainable winter maintenance protects water resources is necessary.

Using less material is an effective approach to protecting our water resources. It is difficult to recover salt or sand once applied.

Water and Environmental Impacts

- Only 2.5% of all of the water on this planet is freshwater (not saltwater). Of that, less than 1% is available for use. The majority of the freshwater is frozen in the glaciers (Freshwater Crisis n.d.).

- Water is recycled over long periods of time. There is a limited supply of water on this planet. Water is reused, recycled and dispersed as illustrated below from the Minnesota Department of Natural Resources (DNR), “Healthy Rivers: a Water Course” (Healthy Rivers 2004).

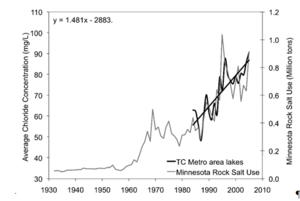

Chloride concentrations are increasing in many surface waters and groundwater across Minnesota.

- In the Twin Cities Metropolitan Area (TCMA), of surface water bodies tested, 39 are on the draft 2014 impaired waters list for chloride exceedances and 38 more are found to be at high risk as of July 2015. (MPCA 2015). Salts (chloride) dissolve in water and move with the water to nearby lakes, streams, and wetlands and also infiltrate into groundwater.

- Chloride is virtually a permanent pollutant that does not degrade and cannot be removed from surface waters. Once in the water, it continues to accumulate in the environment over time.

- Salt water is heavier than freshwater and may sink to the bottom of lakes. This may cause chemical stratification of the lake and loss of or changes in lake turn over (Stefan et al. 2008).

- Thirty percent of the 270 shallow aquifer monitoring wells tested in the TCMA exceeded the state chloride standard. (MPCA 2013).

- About 75% of Minnesotans rely on groundwater for drinking water. The MPCA has found 30% of the shallow monitoring wells, often found in urban areas, have exceeded the state standard for salt levels. As water moves from shallow to deeper aquifers, the salt contamination could penetrate sources of drinking water (MPCA 2013).

- The average salt use in the TCMA based on purchasing records is 349,000 tons per year (Sander et al. 2007).

Deicers can be very damaging to both soil and vegetation. Efforts to keep salt off vegetation are needed: drive slower when applying deicers, turn down spinner speed to reduce spread pattern, use drop spreaders on sidewalks, store snow piles on hard surfaces, and reduce application rates. One source of information about salt-tolerant plants is the Plant Selector from Minnesota Department of Transportation.

Impacts of Materials

Abrasives and deicers cause problems to infrastructure, drainage, water, vegetation, and soils when used in large quantities. Abrasives: Winter Sand

- Runs off parking lots with water to the nearest storm drain entering lakes, wetlands, streams, and rivers.

- Fills in surface water bodies, accelerating the aging process.

- Covers habitat and disrupts the food chain.

- Irritates the gills of fish.

- Clogs and disrupts the flow of water in storm drain systems.

Deicers are not "environmentally safe" regardless of what the bag says.

Chlorides commonly used for deicing are Sodium Chloride (road salt), Magnesium Chloride, Calcium Chloride, and Potassium Chloride.

- Road salt is the least expensive and most widely used deicer.

- Salt is corrosive to steel.

- Some have corrosion inhibitors and anti-caking agents added that are often toxic.

- Frequently damage plants through contact or by interfering with soil properties.

- Salt can cause soil to lose its ability to retain water, leading to soil erosion.

- Excess salt can make soil more alkaline and compact, and less permeable, making it more difficult to store nutrients that plants need to grow.

- Cannot be removed by stormwater ponds or rain gardens.

- Cannot be removed from the lakes, wetlands and rivers.

- Are persistent pollutants and will not break down over time.

About one teaspoon of salt can pollute five gallons of water. This applies to all chloride containing deicers.

Acetates:

- Are non-chloride compounds.

- Are an organic substance.

- When added to water, compete with aquatic life for oxygen.

- Contribute nutrients which promote algal blooms in lakes and ponds.

- Most of the problems they cause in the water are relatively short term, but severe.

- Are usually safer for vegetation.

- Are less corrosive than salts.

- Have the potential to be treated by stormwater BMPs.

Acetates can have a high biological oxygen demand (BOD), and can contribute to oxygen depletion in soil and water. Use carefully.

Plant-based additives (beet, corn, molasses):

- These additives do not contribute chloride to water but contribute nutrients (fertilizer).

- Cause an increase aquatic plant and algae growth.

- Use up oxygen in the lake or water body as they decompose.

- Serious impacts but not as long-lasting as chloride.

One lb. of phosphorus encourages growth of up to 500 lbs. of algae. Phosphorus is in plant-based products.

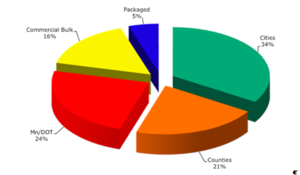

Twin Cities Metropolitan Area Chloride (TCMA) Management Plan

There are two primary sources of chloride to Minnesota water resources: 1) salt applied to roads, parking lots, and sidewalks for deicing; and 2) water softener brine discharges to municipal wastewater treatment plants (MPCA 2015). To address chloride impacts to Minnesota water resources, the MPCA worked with local stakeholders to develop a Chloride Manageme6nt Plan designed specifically to minimize chloride use across the seven counties of the metropolitan area. This plan is intended to be useful for all winter maintenance practices. The plan can be located on the MPCA’s website: http://www.pca.state.mn.us/programs/roadsalt.html

1 ton of rock salt ($50) causes greater than $1,450 in corrosion damage to bridges. (Sohanghpurwala 2008)

Fathead Minnows will die if exposed to chloride concentrations of 443 mg/l for more than 30 days (Axler n.d.)

Prepare for Winter Operations

Policies/Plans

Start now—develop a maintenance policy or plan that guides winter operations. A little planning and communication up-front can help achieve better results throughout the season.

- Develop a maintenance policy or plan.

- Review the maintenance policy with the crew.

- Inform customers of the maintenance policy.

- In the plan:

- list the key actions to take during a winter event

- list the order of these actions

- address the level of service

- consider customer expectations, the hours and use of the building, priority access points and environmental concerns in the policy

- spell out any additional strategies such as routes, chemicals, application rate ranges etc.

- Follow the plan.

- Document actions.

- Review and update the maintenance policy each year.

Our waters are threatened by contracts which are based on fees for material use. This encourages overuse of materials.

Reduce liability. Establish a maintenance policy and follow it.

Training

Reduce risk by having a solid written winter maintenance policy and training program that utilizes best management practices. Schedule training for supervisors, staff, and customers.

The MPCA has three Smart Salting training classes available:

- Level 1 Winter maintenance of roads

- Level 1 Winter maintenance of parking lots/sidewalks

- Level 2 winter maintenance training for supervisory staff

Check the MPCA website to find out about upcoming training opportunities.

Storage

Snow Piles:

- Store in an area where the solids can be recovered after the snow melts.

- Locate snow piles down-slope from salt and sand storage to prevent snow melt from flowing through salt or sand storage areas.

- Avoid pushing snow into lakes, ponds, wetlands, rivers, or other natural areas.

Improper storage of salts can lead to groundwater cantamination

Salt and Salt/Sand Piles:

- Storage areas often cause groundwater or surface water contamination. These problems can be easily tracked back to the source. Do not skimp on proper storage. When locating new storage for liquid or granular products investigate local visual screening ordinances.

- Indoor storage is recommended.

- Store on an impervious (water proof) surface.

- Floor should be sloped away from the door.

- Sweep loading areas back into the pile.

- Store away from lakes, rivers, ditches, storm drains, and wetland edges.

Salt storage areas are often a source of groundwater contamination. To reduce risk, have a covered storage area on an impervious pad. Take measures to keep salt or salt brine from leaving storage area.

A common mistake is storing a salt pile downhill from a snow pile

Salt Bags

- Protect from rain or snow.

- Dispose of bags properly.

- Seal all open bags.

Liquids

- Know the freezing point of the liquid. This will determine if it can be stored outdoors. Salt brine (NaCl) will freeze at -6o F.

- Tanks should be double-walled or have secondary containment. Secondary containment is like creating a bath tub around the tank so if the tank leaks, the “tub” captures the spill.

- Label the tank documenting its contents.

- Click here for more information on storage tanks see

Sand piles:

- Winter sand is typically mixed with some deicer to prevent freeze-up of the pile; therefore, sand pile storage should be the same as salt pile storage.

- Store leftover winter sand for next year. Do not use it for other purposes.

Prevent groundwater contamination. Do not locate storage areas near wells. Limestone regions with fissures and sinkholes are very prone to groundwater contamination, as are those with sandy soils.

Weather

Know existing and potential weather conditions for a successful snow and ice control operation. Monitor the weather closely to prepare to act early in storm situations. Check the National Weather Service http://www.noaa.gov, local TV stations, or website weather. A Road Weather Information System (RWIS) is available for [http://www.rwis.dot.state.mn.us/ free on-line} at. The RWIS provides real time pavement temperatures and other information from locations around the state.

Pavement Temperature

Pavement and air temperature are different. Know the pavement temperature to determine the proper amount and type of material to apply. Weather stations report air temperature which is measured at least 6 ft. in the air. The air temperature is not helpful when trying to determine what to apply to surfaces on the ground.

Air temperature measurements are generally the same in a given area, but pavement temperatures in the same general location can vary greatly. Pavement temperatures are influenced by exposure to sun, pavement type, and subsurface materials.

The same air temperature in November and January will often accompany very different pavement temperatures.

The hand-held temperature sensors can be purchased from auto part stores for less than $100. Some temperature sensors only accurately monitor in the warm temperature range, confirm the one purchased measures in the cold temperature range. Mirror-mounted temperature sensors are also available; they are less likely to be lost or stolen, but do cost more and are generally not available at an auto parts store. RoadWatch by Commercial Vehicle Group, Inc. is one example of this type of sensor. A small investment in equipment will improve performance.

Knowing the pavement temperature allows the application of the proper amount of material for each situation.

Getting prepared for winter

- Calculate the area of the parking lots, service roads, and sidewalks.

- Understand the environmental problems caused by snow, salt, and sand storage. Determine where and how to best store each item.

- Understand the properties of various deicers, and then select the type(s) to use.

- Train the crew on proper application rates.

- Mark islands, fire hydrants, and other landmarks that could be obscured by snow.

- Note existing conditions of curbs and other items that might be damaged by winter maintenance activities.

- Note or mark all catch basins, manholes, sidewalk segments that may cause a hazard to the plow and the operator.

Drainage

Inspect storm drains in the fall. Remove obstructions such as leaves, sticks, and trash to prepare for the spring melt. Because storm drains lead to lakes, rivers, ponds, and wetlands, never use salt to open frozen storm drains. Salt used to thaw frozen drains harms aquatic life. Use non-chemical methods such as heat to open drains.

Poor drainage on the maintenance surfaces will result in icy surfaces and will increase the risk of safety problems. These areas cause the application of salt on non-snow event days in the winter. To remedy this, inventory the site and note drainage problems. Make a checklist so the professional or client can fix these drainage problems in the summer.

Examples of drainage problems:

- Roof that drips on the steps

- Downspout discharging on sidewalk

- Sidewalk segments sloped into a V

- Potholes or low spots in parking lots

Storm drains lead to the nearest lake, river, pond, or wetland. They do not go to a treatment plant.

Equipment

The trend in winter maintenance is to use less material to accomplish the same results. Following this trend will reduce environmental impacts and save money. Below are listed a few tips, but there are many other innovations in the equipment area that can help to reduce application rates.

- Purchase a pavement sensor (Figure 8)

- Buy equipment that can deliver very low rates of granular products.

- Outfit larger trucks with ground speed controls so that the application rate changes automatically as the speed changes.

- Modify existing equipment so that it can discharge the application rates described in the “Application Rates” section. Older equipment often applies more salt than recommended.

- Outfit sidewalk spreaders with shields to better direct the spread pattern.

- Invest in equipment that can deliver liquid deicers.

- Obtain a tank for liquid storage or find a near-by source of liquids to fill up trucks.

Calibration

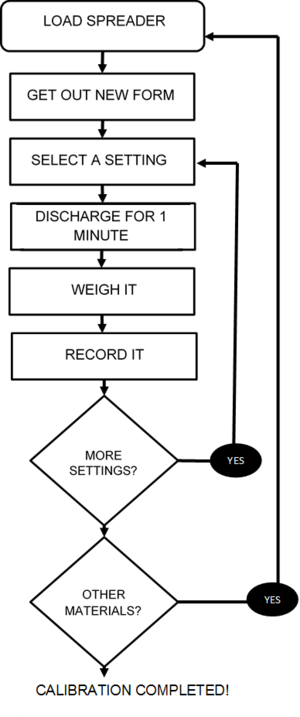

Calibration is an essential procedure to understand how much material will be discharged at a given setting. No matter how sophisticated or simple the operation, calibrate each piece of equipment in the fall of the year.

Calibration tells how much material will be applied at each setting.

Simple Calibration for Salt Spreaders=

If the equipment has different settings, it must be calibrated for each setting and for each product, as they all flow differently. It generally takes a team of two or three people to calibrate equipment efficiently.

Ground Speed Controlled Spreaders

Ground speed controlled spreaders are run by a computer in the cab and are tied to the speedometer and an auger or conveyor sensor in the rear of the truck. The application rate is set and the computer regulates the amount of salt discharged (regardless of the speed traveled) consistently. Most equipment used for winter maintenance of roads have ground speed controls. These are more effective and efficient systems than the manually controlled systems.

The equipment vendor will have specific calibration instructions for the operation based the type and brand of equipment. Contact them; it is in their best interest to provide instructions to calibrate and correct product use. This is the basic principle behind calibrating a ground speed controlled spreader:

- The speedometer input (sensor) lets the controller know how fast or slow the truck is traveling.

- The auger or conveyor input (sensor) tells the controller how fast or slow the auger is turning.

- To calibrate a ground oriented controller, input the pounds discharged per revolution.

- Once the computer knows the pounds/ revolution, it will calculate the necessary auger speed needed to hit the target application rates at the speed the truck is traveling.

Best bet: Contact manufacturer for calibration instructions.

Calibration allows accurate deicer use

Manual Controlled Spreaders

Manual controlled spreaders fall into two categories. Those that have an auger or conveyor and those that are gravity fed. They operate by selecting a setting that changes the size of the discharge opening and/or the auger or conveyor speed. More or less salt may be discharged depending on the speed of application. Most parking lot and sidewalk spreaders fit into one of these two categories.

All good programs are based on calibration of equipment.

The basic principle behind calibrating an auger/conveyor spreader is to choose a setting, run the spreader for a timed interval, and weigh the discharge. Record the discharge and repeat for all settings. In the end, there will be data that tells the operator how much material will be delivered at each setting. With this information, the operator can choose the proper setting. Without this information, they have no guidance on which setting to use. Calibration is different for gravity fed spreaders. There is more detail on this in a few pages.

Apply wisely. The chemicals applied cannot be recovered.

Surfaces such as pervious asphalt, pervious concrete, and pervious pavers do not experience refreeze. All melted snow and ice travel to the storage layer below the surface. Salt is generally not needed on these surfaces and sand should be avoided.

Example: Step #1, blank calibration form

See the References and Resources section for a full size form to copy for calibration. This is how the empty form looks.(Keep a stack of these on a clipboard when ready to begin the calibration.)

Example: Step #2, calibration form filled out during calibration

Fill in the header information and column 2, the discharge weight per setting.

Example: Step #3, calibration form ready to put in truck for road application'

Back in the shop, do the calculations to fill in the rest of the blanks. Multiply the weight in column 2 with the multiplier in the top row. This provides the pounds per mile that needed to fill in the table.

Some fish species are affected by concentrations of less than 1000 ppm NaCl, about 1 to 1.5 tablespoons of salt in 5 gallons of water.

Example: Step #4, calibration form ready to zip tie to hand spreader or put in truck for parking lot application.

Divide by 63 to convert pounds per lane mile to pounds per 1,000 square feet. This is very useful for parking lot and sidewalk applications.

Gravity Flow Equipment

This is applicable for equipment that does not have a motorized delivery system such as an auger. This type of equipment might be a pickup mounted spreader, gator mounted spreader or a hand push spreader. Gravity flow equipment is typically controlled by gate opening and speed of application.

Step 1: Calculate discharge rate

- Mark out a 10-foot stretch of pavement. (By increasing the size of the test area i.e., the longer the test area, the more accurate the results will be).

- Sweep it clean of sand or any other material.

- Using a constant speed, apply one pass of material to the test area.

- Measure the width the material is spread or bounces, in feet.

- Sweep up and weigh the material that is within the marked 10-foot stretch.

- Record the lever position/setting for the gate/chute. If there are no numbers for the positions, make permanent marks on the equipment to identify the positions.

- To improve accuracy, repeat this two more times and calculate the average weight of material applied.

- Record results in columns A, B, C, and D (Figure 14).

Step 2: Repeat step #1 for various settings.

Step 3: Fill out chart.

- Fill out columns E, F, and G (Figure 14).

- If using more than one type of material, repeat the test for each material.

- Place the completed calibration chart with the equipment.

Shortcuts:

- Put down a tarp over the application area; this makes it quicker to recover and weigh material.

- After the first pass, put a bag around spreader to catch discharge material. The first pass is needed to determine the spread width.

Calculate application rate:

What if calibration is not a practice?

Even without calibrating the equipment, the amount of material to use can be determined but will take more time to calculate. Know the material, the size of the area to be treated, and the pavement temperature, then consult the application rate chart (application rate section) and do the math. Without calibration, the way to evenly distribute the recommended amount across the maintenance area must be determined by the professional. This approach may work well for treating sidewalks using the “chicken feed” method. For example:

- 20oF degrees pavement temperature and rising

- Using dry salt

- Sidewalk is 2,000 square feet

- Table recommends 2.25 lbs. per 1,000 square feet (for this situation)

- Measure about 4.5 lbs. of salt

- Figure out a way to spread it evenly over the 2,000 sq. ft. surface

Sand fills in lake bottoms, accelerating the aging process of lakes. Lakes get shallower as they age, some eventually becoming wetlands.

Materials

All products have pros and cons. No one material is suitable for every condition. It is best to have a variety to choose from to select the one that works the best, with the least amount applied, in a specific situation. Understand the melting properties of the deicers; do not use the product without understanding how it works.

The best way to reduce impacts, save money and maintain customer satisfaction is to:

- Know what is in the product.

- Know the product’s practical melting range.

- Use it only when it will be effective.

- Use the minimum amount needed to get the job done.

- Seek out products that allow for smaller application rates.

Abrasives:

- Sand is an abrasive; it does not melt snow and ice.

- Abrasives provide traction on top of packed snow or ice.

- Abrasives and deicers typically work better alone, rather than together.

- A small amount of salt must be mixed in the sand to keep it from freezing in the pile (less than 10%).

Salts

- Sodium Chloride, Magnesium Chloride, Potassium Chloride and Calcium Chloride are all considered “salts.”

- Salt is a deicer; it will melt snow and ice.

- Salt lowers the freezing point of water from 32° F to a colder temperature.

- Salt must be dissolved to work; therefore, liquids act faster than solids.

- Salts have different melting characteristics, depending on the selection.

- Road salt (NaCl) is a granular product and is mined from the earth.

- Magnesium Chloride (MgCl2) and Calcium Chloride (CaCl2) can naturally occur as liquids.

- MgCl2 and CaCl2 are hygroscopic, drawing moisture from the air to the pavement.

- Salt brine (NaCl) is commonly used at a 23.3% concentration as this has the lowest freezing point and can be stored and handled down to -6°F.

Acetates:

- Acetates are chemically manufactured, not mined from the earth.

- Acetates are more expensive than chloride salts.

- Acetates are less corrosive than salts.

- They have a wide melting range, depending on the selection.

- They are not better or worse than chloride salts, they are different.

Plant-based additives

Corn, beet, molasses, or other organic additives are added to salt or salt brine to change its performance, though how they function as an ice melting agent is not well understood. Clear Roads (2015), a national resource consortium of state agencies, is studying this issue.

- Often have very low ice melt capacity.

- May be used to reduce corrosion.

- Are sticky and may help dry material stay on the surface longer.

Speed of Melting

Will the road salt used have time to work or is it better to switch to a different deicer? This chart will aid in making that decision.

Do not use dry road salt below 15º F. This wastes money and time.

Practical Melting Temperature

Use care when reading the melting temperature on bags of deicers. The package often lists the eutectic temperature, which is the lowest possible melting temperature. At this temperature, it would take a very long time to melt ice. Instead, use the lowest practical melting temperatures in the chart below or ask the supplier for the practical melting temperature and the time it takes to melt ice at that temperature. It should be noted that there is not a standard measure for determining the lowest practical melting temperature. Across the literature there are a range of values. In the References and Resources section there are lists of several websites to learn more about the lowest practical melting temperature.

Testing

When ordering a liquid product in bulk, test it. If it is NaCl brine it should be 23.3%. If it is another liquid, use the vendor recommended density and test to confirm. Hydrometers are the tools for testing the density of liquids. They are inexpensive and look similar to a thermometer. Research the product, understand the practical melting temperature, and know the list of ingredients. Take time to test the materials to ensure that they perform as expected. Product labeling can be confusing; some list the eutectic temperature while others list the lowest practical melting temperature.

The list of ingredients may or may not be included. Often, the percentage of each ingredient is not included. Do not rely solely on the bag or on the manufacturer’s literature. There are no labeling requirements; manufacturers can choose to label products in their own way.

Cost and Availability

Of the deicers, NaCl is typically the cheapest and easiest to find. Because of this, it is widely used and overused. Sodium chloride is only effective at pavement temperatures above 15oF. Because it doesn’t work well at colder temperatures, it is often over-applied in attempts to increase its effectiveness. At temperatures lower than 15oF degrees, switch to a different deicer.

Non-chloride deicers are more difficult to find and often cost more. Take the time to source and try non-chloride products if there are concerns from the professionals or customers about the long-term effects of chlorides on the lakes and rivers. All deicers have environmental impacts but the impacts of chlorides are very long-term.

Salt and sand mixes are commonly used to stretch the salt budget. This is an ineffective practice. Salt and sand work against each other. To save money, use deicers when melting is needed and sand for temporary traction to buy time at temperatures too low for deicers to be effective. Pre-wetted sand has shown to be effective in keeping sand in place longer on icy surfaces.

Using 50/50 salt/sand mix is generally half right or half wrong. Using a salt/sand mix leads to over application of both materials.

Sidewalk Tips

Always remove snow prior to applying deicers. Plow, blow, or sweep first; the chances of refreeze diminish and slush build-up is minimized.

- Sidewalks are the most over-salted areas in winter maintenance.

- Use drop spreaders, not rotary spreaders. If using a rotary spreader, install shields to restrict the spread pattern. This minimizes the application rate and protects the vegetation.

- Many slip and fall incidents occur within 10 ft. of the curb lines. Adjust practices to include proactive measures like anti-icing.

- If the professional is not responsible for sidewalk maintenance, consider providing this information to the responsible party.

- Focus on aggressive mechanical removal of snow. The less snow, the less deicer required. This will lend itself to a safer surface.

- Deicers can harm heated sidewalks.

- Abrasives can harm permeable pavers or permeable concrete.

Salt only needs to melt 1/16 inch to prevent the bond between the pavement and the ice. Save money by applying salt before the ice bonds to the surface it doesn’t need to melt through the ice.

Building Entrances

Steps are often the most over-salted area in all of winter maintenance. This overabundance of deicer causes damage to floors inside the building as salt and/or sand is tracked in. It causes problems outside of the building with deterioration of concrete and metal structures. Over applying deicer costs more money than necessary, pollutes the water, and does not provide any additional safety. The right amount of deicer and proper mechanical removal of snow and ice will yield better results.

A free short video for small site winter maintenance is available. It is designed for those that do winter maintenance of small sites such as stairs, curb cuts, and handicap ramps. The video is a visual instruction tool useful for those who apply granular deicer to small areas outside building entrances. It recommends:

- Do site assessments, document drainage problems, and fix them in the summer (e.g., roof that drips on steps, downspout that drains to sidewalk).

- Always remove snow prior to applying deicers. The less snow, the less deicer required for a safer walking surface.

- Use the proper tool for snow and ice removal:

- Push shovel (no sides) for pushing snow.

- Scoop shovel (sides) for lifting snow.

- Broom or blower for light fluffy snow.

- Ice scraper for use under ice and compaction.

- Ice chisel for breaking open compaction, or under ice and compaction.

- Use hand-held spreaders to disperse deicers. Spreaders:

- Provide more even distribution.

- Reduce amount needed.

- Reduce tracking into buildings.

- Save money with reduced salt application.

- Save infrastructure: less salt, less corrosion.

- Look for opportunities to close extra building entrances during the winter. High maintenance, non-essential entrances are perfect candidates.

To determine the amount of deicer needed for steps, stairs, and small sites:

- Refer to the application rate chart.

- For those who do maintenance as a small part of their job, it is unlikely they will ever use an application rate chart. Here are some guidelines to get them closer to the proper rates. The goal should be:

- Even spread pattern with granules no farther than 3 in. apart

- Even spread pattern with no granules touching each other

- No piles of deicer

- No deicer on dry pavement

- No deicer in vegetation

Handheld spreaders and shakers, not scoops, should be used to apply deicer to steps and building entrances. This will save at least 50% of the salt normally used per winter without reducing the level of safety.

Parking Lot Tips

- It is hard to walk and push shopping carts through salt and sand accumulations in parking lots. Sand is ineffective once it is on the pavement. Sweep it up to prevent a slippery situation.

- Handicap parking spots are often over-salted and over-sanded. They should get the same amount of salt or sand as other areas.

- Sand/salt mix generally isn’t advised; however, it may help in freezing rain situations.

- Always plow before applying materials.

- It may be possible to use a lower rate in high traffic areas. Traffic tends to help mix and melt.

- Store snow downhill from any salt storage areas. Avoid water running through salt storage.

Calculating Parking Lot or Sidewalk Area

The amount of deicer needed is based on the size of the parking lot. Here are simple ways to calculate the area of the parking lot.

Ask the property owner for a scaled map of the facility to calculate areas.

Ask the property owner for the size of the area to be treated.

Measure the parking lot.

Use an internet mapping tool to calculate areas.

The area, or square feet, of a square or rectangle is:

Length (L) X Width (W)

The area, or square feet, of a circle is:

π r2 or 3.14 x (r x r) where r is half of the distance across the circle.

The area, or square feet, of a right triangle is:

Length (L) X Width (W) divided by 2

Measuring the area, along with knowing the pavement temperature, will allow the use of the application rate charts. This will help to reduce the amount of chemicals applied.

Take Action to Keep Surfaces Clear

Winter Maintenance Basics

- Anti-ice before the storm.

- Remove snow from surfaces as quickly as possible to reduce compaction.

- Plow before applying deicers to avoid dilution of the salt.

- Minimize deicer use during the storm.

- Never plow or blow snow into bodies of water, wetlands, traffic or into streets.

- Minimize back-up maneuvers to reduce chance of accidents.

- Limit use of salt and sand during the storm; use only to reduce bonding.

- Do not use salt to burn off snow.

- Use application rate chart to determine how much salt to use.

- Don’t apply dry salt (sodium chloride) below 15º F pavement temperature. It will not melt fast enough to help.

- Below 15° F, use a wetted salt.

- For extreme cold, skip melting and use sand.

- Clean up spills.

- Accurately record the material used at each site.

- Pay attention to its effectiveness and record observations.

- Use only what is needed based on proper application rates for the conditions.

- Put extra back in salt pile or return extra bags.

Because it uses less materials, mechanical snow and ice removal is the best strategy for protecting the water.

Loading/hauling

- Don’t overfill the truck or spreader: material will spill out as it is driven or pushed. This is a common practice and wastes salt.

- Large snow piles may need to be hauled to another site.

- Schedule this work when the mall or facility is closed to minimize conflicts with vehicles and pedestrians.

- Clean up loading area, sweep extra back into the pile.

Deicing/Anti-Icing Information

Anti-icing

Anti-icing is the most cost-effective and environmentally safe practice in winter maintenance. This is the direction to pursue. Anti-icing is a proactive approach. It should be first in a series of strategies for each winter storm. Applying a small and strategic amount of liquid on the pavement before a storm will prevent snow and ice from bonding to the pavement. This buys time for the clean-up efforts.

Anti-icing is like frying eggs: grease the pan and the eggs come out easily with no mess to clean up. Like greasing the frying pan, the purpose of anti-icing is to keep snow from sticking to the pavement. Anti-icing provides safer pavement during the event and faster clean up after the event.

Anti-icing requires about ¼ the material and 1/10 the overall cost of deicing. It can increase safety at the lowest cost, and is effective and cost-efficient when correctly used and approached with realistic expectations.

Anti-icing prevents formation of frost. It can be effective for up to several days depending on the weather conditions.

Anti-icing is quick. It is possible to treat a parking lot in a matter of minutes. It is an excellent strategy for saving time. Charging by the hour is not a desired practice when changing to anti-icing.

Get started in anti-icing

The basic equipment needed includes: pavement temperature sensor, storage tank, spray truck system, transfer pump, hoses, and fittings.

What to do

- Calibrate.

- Use application rates suggested in the Rate section of this manual.

- Apply with stream nozzles to maintain dry areas between sprayed areas to reduce slipperiness. Stream nozzles work the best for anti-icing.

- If using fan nozzles apply extra light. This makes a dry surface wet and users will have less friction until it dries.

- Try anti-icing in a low traffic area to build confidence about its properties.

- Read some of anti-icing guidelines in the reference section of this manual.

- Stream nozzles prevent slippery conditions better than fan spray.

- Too little CaCl2 or MgCl2 is safer than too much.

Test the application rates and spray pattern to become confident in preventing the bonding of ice without creating a slimy or slippery situation.

What not to do

- Do not re-apply if there is still residue. It can remain many days after application.

- Do not apply MgCl2 or CaCl2 to a warm surface (above 35º F pavement temperature). It can become “greasy” as it pulls moisture to the pavement. These liquids do not always become greasy, but there is a higher potential in warmer temperatures and higher humidity.

- Do not over apply MgCl2 or CaCl2.

- Do not apply liquids before a rain storm. They will wash away.

Anti-icing Tips

- Liquids are more efficient than solids and may be applied days in advance of an event.

- It is better to use less than more. Over-application can cause slippery conditions because it makes a dry surface wet.

- Anti-icing is often effective for heavy frosts.

- Liquids are dispersed by the traffic. Spray the traffic lanes and the liquid will migrate with the tires to the parking areas.

- Some users advise against spraying the service road in front of buildings and instead spray traffic lanes and back service roads to allow the traffic to spread the liquids near the building where foot traffic is higher. This can reduce tracking into the building and over-application in a high-traffic area.

- For service roads on hills, some users recommend applying to only the top half of the hill, relying on traffic to carry it down the hill, to avoid a slippery situation at the bottom of the hill.

- Anti-ice when weather forecasts indicate a need. Do not anti-ice on a regular schedule, e.g., every Friday.

- Early application is particularly important for frost or light freezing drizzle.

- Pretreated or pre-wet materials are not as efficient as liquids for anti-icing. These require more material overall than with liquids. The pre-wet granular materials don’t stay in place as well as the liquids. Pre-wet granular solids can work if applied at very low application rates immediately before the snow event.

Anti-icing requires less material, and less material means less water pollution.

Using less salt doesn’t have to reduce safety, but it does protect the lakes, streams and groundwater.

Equipment

- Anti-icing unit, e.g., transport vehicle with tank.

- For larger trucks: Stream nozzles (minimum eight holes), 8-inch spacing, bar height 12 to 14 inches from surface, 30 to 35 psi at the bar. These can be purchased or constructed.

- Solid stream – fan spray is more apt to make slippery conditions.

- A hand held pump sprayer or backpack sprayer can be used for sidewalks. Remember to leave a pattern of wet and dry to reduce the chance of creating slippery conditions.

- There are many ways to retrofit a pick-up truck or ATV with a tank and one of the following boom, spray bar, or hose reel with sprayer.

- A shutoff switch in the cab is recommended.

Deicing

Deicing is a reactive operation where a deicer is applied to the top of an accumulation of snow, ice, or frost that has already bonded to the pavement surface and can no longer be physically removed. Deicing costs more than anti-icing in materials, time, equipment, and environmental damage. Deicing is the “traditional” approach to winter maintenance.

Removing ice that has already bonded to the pavement is difficult. Removing it mechanically can damage equipment and surfaces. Generally, enough ice must be melted chemically to break the bond between the ice and the pavement. This requires larger amounts of chemical, making deicing much less efficient than anti-icing.

Use the application rate table (Figure 24) to help with deicing. Using recommended rates will help with these common problems:

- Over-salting. Most over-salting can be prevented by using calibrated spreaders and good judgment in selecting application rates based on pavement temperatures.

- Trying to melt everything. Don’t try to melt all the snow on the surface with salt. This is an overuse of materials. Apply just enough to loosen the bond between the pavement surface and the snowpack so it can be plowed off.

The goal is not to melt everything. The goal is to penetrate through the ice and snow and break the bond so the pavement can be plowed.

Pre-wetting and Pretreating Salt and Sand

Pre-wetting and pretreating both mean getting dry material wet. Salt only melts snow and ice when it is in solution (dissolved). Dry salt does nothing until it is dissolved. Liquids applied to dry salt jump-start the melting process and penetrate ice and snow pack faster. Wet materials stick to the pavement and are less likely to end up in the nearby vegetation.

When integrating the liquids, decrease the application rate of the granular product. This is a common mistake made by new users of liquids.

- There are many types of liquid deicers.

- Salt brine is a common liquid deicer made from water and rock salt (NaCl).

- Brines can contain other ingredients besides water and rock salt.

- Pre-wetting (truck treatment) is the process of adding liquid to solids as they are applied to the pavement.

- Pretreating is the process of adding liquid to solids in the stockpile.

- Adding brine to dry salt, the combination will work faster than dry salt.

- Use magnesium chloride (MgCl2) or calcium chloride (CaCl2) liquid with dry salt, it will work faster and at lower temperatures.

- Wet material bounces less.

Generally it is possible to use 1/3 less material when using a pre-wet or pretreat, and it works faster than dry salt!

Guidelines for Pretreating Stockpiles

Pretreating is mixing a liquid deicer into the stockpile of salt or sand. It can be purchased as a product already mixed and ready to use or can be created. To create a pre-treated stockpile, add liquids conservatively. The dry material can only hold so much liquid before leaching occurs. Watch the storage area to make sure it can contain the wet salt pile. Test mixing skills and observe the amount of leaching on a small stockpile before doing this on a large scale.

Treating the salt stockpile:

- Spray and mix the salt stockpile with a liquid deicing chemical (not brine).

- When treating the stockpile, apply at 6 to 8 gallons/ton, less is better.

- Because leach risk at a stockpile is increased, proper storage is critical.

- To minimize problems, mix up pre-wet materials per storm event not per season.

Treated Stockpile Application:

- Pretreated salt can be applied with a pickup truck, a dump truck, a drop, or rotary spreader or almost any type of equipment used for dry salt.

- No equipment changes are required.

- Remember to turn down the application rate; it requires 1/3 less material than dry salt.

Cover salt and salt/sand piles and place on an impervious pad to limit runoff and infiltration of chlorides.

Covering the stockpile protects the salt from wind, rain and snow and reduces waste.

Guidelines for Pre-wetting

Pre-wetting is combining liquid from a tank to dry material from the hopper at the point of discharge. The most common set up is on a truck but it can be configured for smaller equipment. The liquid and granular usually come together at the spinner or auger. While pre-wetting requires some equipment changes, it provides flexibility to switch the amount and type of liquid.

Tips:

- Turn down the application rate; 1/3 less material than dry salt is needed.

- Add tanks and hoses on the truck.

- Turn on/off the liquid from inside the cab.

- Synchronize the flow of liquids with the flow of solids to achieve the proper mix.

- A common application rate is 8 -14 gallons/ton for salt brine, 6-8 gallons/ton for MgCl2.

- The higher the liquid to granular ratio, the faster it works. Some go up to 60 gallons per ton.

- Pre-wetting with a chemical other than salt brine can improve cold weather performance.

- Pre-wetting is most practical with a dump truck. Use of a pickup truck may be limited due to the weight of the material.

- Think twice before mixing chemicals to form “hotter” brine. This is where problems often occur.

Use cautiously. Many deicers contain trace metals including cyanide, arsenic, lead, and mercury.

Two common overuses of salt 1) applying to already wet surfaces, and 2) not giving the material enough time to work and adding more salt on top of the first application of salt.

Traction

Use winter sand and other abrasives when temperatures are too cold for deicing chemicals to be effective. But be aware that sand does not melt anything. It provides temporary traction and only when it is on top of snow and ice. When sand is in contact with the pavement, sweep it up. It is no longer useful and can only harm the environment. Sand on dry pavement can cause skidding.

Advantages of sand (abrasives):

- Short-term traction: Abrasives can be helpful in areas of slow moving traffic, such as intersections.

- Useful in very cold temperatures when chemicals will not work.

Disadvantages of sand:

- Sand is not cheap when considering handling, clean-up, and disposal costs.

- Sand will be tracked into lots or buildings. Sweep this up as often as possible and dispose of it properly.

- Used sand is contaminated with various pollutants such as oil, grease, metal, and rubber and should not be used for clean fill unless screened. It should not be used for sandboxes or beaches, and should not be dumped in wetlands, fields, or any natural area.

- Once sand is driven over many times, the particles are much finer and can cause air quality concerns.

- Cannot be used over pervious asphalt, pervious concrete, or pervious pavers.

Sweeping

Sweep the sand from the parking lot areas midwinter as well as in the spring. Trailer-type power sweepers are available that can be hauled behind a pickup truck. Smaller power brooms or sweepers may be used on sidewalks. Workers should wear a dust mask to avoid inhalation of the fine dust particles.

- Used sand is contaminated with pollutants such as oil, grease, metal, and rubber.

- Sweepings often can be brought to a landfill. Inform landfill operator in advance.

- Keep children from playing on the sweeping piles.

- Sweepings may be reused by some industries.

- Before reusing sweepings the trash, leaves and other debris should be removed. This is often accomplished by screening. When screening sweepings for reuse, use a small mesh for the final screening to ensure that all of the larger debris has been removed. (A 3/4-inch mesh will screen out much of the debris.) Dispose of trash and debris removed from the sweepings by recycling it (e.g., aluminum cans), composting it (e.g., leaves), or sending it to a sanitary landfill.

Evaluate the effectiveness of actions

After the Storm

When snow and ice control operations have ended after the storm, evaluate what was done, what worked, and what could be changed to improve operations.

- Have an after-the-storm discussion with the maintenance crew.

- Have an after-the-storm discussion with the property manager.

- Consider the environmental impacts caused by deicer/abrasive use.

- Based on all aspects of the storm fighting experience, look for ways to improve practices.

- Clean and check all equipment.

- At the end of the season, clean and maintain the truck, tanks, brine-making systems, and pumps according to manufacturer specifications.

- Do not use deicers at the end of the season just to use them up. Save them for next year. Place all piles on an impervious pad and cover them. This includes salt and salt/sand mixes.

- If there is no place for year round storage, contact the city, they may be willing to purchase it, take it, or store it. Everyone benefits from good storage and less salt in our water.

Save extra salt at the end of the season. Do not apply just to get rid of it.

Documenting and charting

Good documentation leads to reduced use of materials, more effective snow and ice control, reduced environmental impacts, and cost savings.

- Without documention and charts, there is no measurement of performance.

- Track the material use. Learn to record what and how much is applied at each site, from each visit. Be prepared to analyze and make adjustments to the process based on what is learned.

- Use forms like those shown (Figure 21 and Figure 22) to record and track the work and observations.

There is no management of what is not measured.

Following Best Practices and documenting actions will help prove the professional is doing the best job possible and may reduce liability. Documentation Form for Anti-Icing

Application Rates for Reduced Environmental Impacts

Effective application rates are based on many factors, including type and rate of precipitation, air and pavement temperature, forecast and temperature trend, humidity, dew point, type of surface and subsurface material, and sun exposure. The application rate tables used in this book have been taken from the Minnesota Snow and Ice Control Field Handbook for Snowplow Operators, Second Revision (LRRB 2012). They were converted from gallons or pounds per lane mile to gallons or pounds per 1000 square feet.

These application rates are not perfect but are to be used as goal to work toward. Develop specific application rate tables to standardize performance. Track application rates measure and improve performance. Modify the practices incrementally over time to fit the needs. Make it a goal to reduce application rates and keep surfaces safe.

One application rate will not fit all situations; how long an application lasts depends on:

- Pavement temperature

- Application rate

- Precipitation

- Type of material applied

- Salt lost to plowing or traffic blowing it off of the surface

How to use the anti-icing rate table above:

- Determine the parking lot or sidewalk area in square feet.

- Divide the area by 1,000 (chart is based on a 1,000 square foot area).

- Find the application rate: Choose the condition in the first column of the table and follow sideways, stopping at the anti-icing chemical being used.

- Determine how many gallons needed: Multiply the application rate by the answer in #2.

Example: The parking lot is 20,000 square feet. The chart tells how much to apply for 1,000 square feet. The plan is to apply brine prior to light or moderate snow. Do a calculation to see how much brine is needed:

- Divide the parking lot size by the chart size (20,000/1,000 = 20).

- Application rate from chart is between 0.3 to 0.8 gallons.

- Then multiply 20 x 0.5 = about 10 gallons are needed.

Tip: To convert from gallons to ounces: multiply the result by 128.

One 50 lb. bag of salt can contaminate over 10,000 gallons of water.

Deicing Application Rate Guidelines for Parking Lots and Sidewalks

These rates are based on road application guidelines (LRRB 2012).

Develop specific application rates by adjusting the current rates incrementally downward toward the guidelines. Where temperature categories overlap, select the rate most applicable to the present situation.

Application Rates for Reduced Environmental Impacts

Effective application rates are based on many factors, including type and rate of precipitation, air and pavement temperature, forecast and temperature trend, humidity, dew point, type of surface and subsurface material, and sun exposure. The application rate tables used in this book have been taken from the Minnesota Snow and Ice Control Field Handbook for Snowplow Operators, Second Revision (LRRB 2012). They were converted from gallons or pounds per lane mile to gallons or pounds per 1000 square feet.

These application rates are not perfect but are to be used as goal to work toward. Develop specific application rate tables to standardize performance. Track application rates measure and improve performance. Modify the practices incrementally over time to fit the needs. Make it a goal to reduce application rates and keep surfaces safe.

One application rate will not fit all situations; how long an application lasts depends on:

- Pavement temperature

- Application rate

- Precipitation

- Type of material applied

- Salt lost to plowing or traffic blowing it off of the surface

Anti-Icing Application Rate Guidelines

=How to use the anti-icing rate table above:

- Determine the parking lot or sidewalk area in square feet.

- Divide the area by 1,000 (chart is based on a 1,000 square foot area).

- Find the application rate: Choose the condition in the first column of the table and follow sideways, stopping at the anti-icing chemical being used.

- Determine how many gallons needed: Multiply the application rate by the answer in #2.

Example: The parking lot is 20,000 square feet. The chart tells how much to apply for 1,000 square feet. The plan is to apply brine prior to light or moderate snow. Do a calculation to see how much brine is needed:

- Divide the parking lot size by the chart size (20,000/1,000 = 20).

- Application rate from chart is between 0.3 to 0.8 gallons.

- Then multiply 20 x 0.5 = about 10 gallons are needed.

Tip: To convert from gallons to ounces: multiply the result by 128.

One 50 lb. bag of salt can contaminate over 10,000 gallons of water.

Deicing Application Rate Guidelines for Parking Lots and Sidewalks

These rates are based on road application guidelines (LRRB 2012).

Develop specific application rates by adjusting the current rates incrementally downward toward the guidelines. Where temperature categories overlap, select the rate most applicable to the present situation.

Deicing Application Rate Guidelines for Parking Lots and Sidewalks

Instructions for using application rate table for calibrated spreaders

- Using Deicing Application Rate Guidelines for Parking Lots and Sidewalks. Select the row (↑) with the appropriate pavement temperature, temperature trend, and weather conditions.

- Select the column (↓) that has the type of material used.

- Find the box where the row (↑) and columns (↓) intersect to find the application rate.

- Compare those values to the calibration chart for the spreader.*

- Select the correct spreader setting for the rate calculated.

Example:

- Parking lot is 54,000 sq. ft.

- Temperature: 22ºF and falling. It has finished snowing. (↑)

- Using salt pretreated with salt brine. (↓)

- Find the 20 – 25º ↓ box. Follow it to the right to the column labeled “Salt Pre-wetted/pretreated with salt brine.” Read the rate in the box. The box where the column and row intersect shows a rate of 2.0 /1000 square feet. (↑↓)

- Refer to the calibration chart in the vehicle and set the spreader to the setting that most closely matches the 2.0 lbs. /1000 square feet.

- The mixture is ready to apply.

Instructions for using application rate table for spreaders that are NOT calibrated

Using the example above:

- Calculate size factor: Divide the parking lot size (54,000 sq. ft.) by 1,000 sq. ft.

54,000/1,000 = 54. The size factor is 54.

- Find application rate (2.0).

- Multiply application rate by size factor 2 x 54 = 108.

- The amount needed for the entire lot is 108 lbs. pre-wetted/pretreated salt brine.

- Because the spreader is not calibrated, the setting is unknown.

- Although the calibration setting is not known, this establishes the amount of salt to use and increases efficiency.

- Determine the best method to spread the 108 pounds evenly across the parking lot.

Once chlorides enter the ground or surface water, they never go away.

Results

The first winter maintenance training and certification workshops were held in 2005. After holding several classes, it was determined that a training manual was needed.

The Winter Parking Lot and Sidewalk Maintenance Manual was written in 2006 and the training classes using the manual started in the winter of 2006-2007. In order to evaluate the effectiveness of the training, three class exercises were created. These exercises show potential rate reductions, potential change in practices, and evaluate the training program. The results from the in class exercises were compiled at the end of the 2007-2008 winter season and are shown below.

Potential Changes

In 2007-2008, 345 people attended 14 Winter Parking Lot and Sidewalk Maintenance Workshops and filled out the forms used to evaluate the course. The summary of all the exercises is given below.

Rate Reduction:

- 95% of attendees discovered the need to either reduce the amount of material that used, or to not use that material at all.

- 96% of attendees who used rock salt found that a need to reduce the application rates.

- 24% of all attendees used sand or salt/sand mix. It was discovered to be using the wrong material.

- 62% Average potential reduction in salt application rates.

- 20% - 89% Range of potential reduction

Best Management Practices (BMP)

Attendees were given a survey about the use of BMPs. Out of the recommended BMPs:

- Before training: 31% of BMPs were already being used.

- After training: 76% BMPs will be used in the future (as stated by participants).

Evaluation:

- Recommend class to colleagues? 93% yes

- Was this class useful to you? 87% yes

- Do you think you will be able to reduce the environmental impacts of the winter maintenance activities as a result of attending this class? 79% yes

Comments from those attending class:

“It’s about time people got concerned about our water. Thanks for your work”

“Real world examples by people using these methods brings integrity to the presentation”

“Awesome job! I can see the wheels turning in people’s heads”

“Spread the word fast. This information is too important!”

“I am very surprised to learn so much about a subject that I thought I knew.”

Actual Changes

Following the winter season, follow up interviews were conducted to learn more about the winter maintenance changes made since training. The individuals interviewed had attended the training and volunteered to be part of our follow up research on the effectiveness of the training class. Several examples of these interviews are included below.

School District of Superior Wisconsin

Michael Soderlund - Maintenance Worker

Michael Soderlund attended the Parking Lot Training in October, 2007. After the training, many new successful changes were implemented. Overall, the District of Superior reduced their total use of deicers. One of the biggest steps forward was the production of their own brine. Michael said that everything is currently working well and there is no marked reduction in quality. Many District of Superior workers were initially hesitant about the new practices, but after a few tries they realized that the new methods work just as well or even better. The material application rates were greatly reduced, especially in the middle school and high school. The actual reduction rates are given below.

Rates:

2006-2007

The district used 294 bags of ice melt (50 lb. bags) The total was $2,320.48 .

2007-2008

The district used 196 bags of ice melt. The total was $1,552.32

Reduction in ice melt use: 33.3% Reduction in cost: 33.1%

University of Minnesota (UMN) - Twin Cities campus

Jim Weber - U of M Facilities Management

Over the past few years, the UMN recognized the need to become much more environmentally conscious with winter maintenance and storm water management. They made many changes in their snow removal program; two key areas were employee training and calibration of equipment. By increasing awareness of proper application rates, they were able to significantly decrease the amount of deicing chemical used. They started an aggressive anti-icing program with liquid magnesium chloride for their sidewalks and salt brine for the streets and loading docks. Pre-storm applications were extremely successful in reducing the bond of snow and ice to walks as well as giving them more response time on the front end of snow events. They focused on mechanical removal of snow as their first line of defense and they have changed the main deicer for walks from a blended material to straight magnesium chloride. They dramatically reduced the sand in their sidewalk and street program which has saved them time and money in spring clean-up and long term savings are expected in storm sewer maintenance. Small amounts of sand are still used as pattern indicators for their sidewalk trucks and for use during extreme cold weather. The numbers speak for themselves:

Material # 1 – Rock Salt

1997 - 2005 average: 775 tons of salt

2006 - 2008 average: 462 tons of salt

Net Average Reduction: 313 tons

Percent Reduction: 41%

Material Cost: $48.53/ton

Amount Saved: $15,193 average per year (2006 – 2008)

Material #2 – Ice Melt (Magnesium Chloride - MgCl2)

1997 - 2005 average: 131 tons

2006 - 2008 average: 64 tons

Net Average Reduction: 67 tons

Percent Reduction: 51%

Material Cost: $410/ton

Amount Saved: $27,470 average per year (2006 – 2008)

Material #3 – Sand

1997 - 2005 average: 1965 tons

2006 - 2008 average: 18 tons

Net Average Reduction: 1,947 tons

Percent Reduction: 99%

Material Cost: $8.30/ton

Amount Saved: $16,160 average per year (2006 – 2008)

Net-Work Services Company (NSC)

Bob Rush – Director of Operations

NSC is a national facility management company that services commercial properties in 22 states. NSC’s responsibility is to manage all building services which include hiring and managing winter maintenance contractors. While working in his prior role as Regional Manager for Minnesota and North Dakota, Bob Rush required all of his Minnesota winter maintenance contractors to be trained and certified on the best practices. As Director of Operations he has implemented a regional training program based on the Minnesota program. This allowed NSC to expand the best practices training to all winter maintenance contractors in cold weather states. Bob has taken many steps to reduce the impacts of winter maintenance and to improve the safety of his operations

Bob required all suppliers in the seven county metro area to switch to a standardized treated salt for parking areas. He helped calibrate all truck mounted spreading equipment to ensure they were not over-applying the deicer. Bob required all Twin City Metro and Duluth area suppliers to switch to a mag/hex for sidewalks. This standardized the deicer which helped the suppliers determine the correct application rates per sq. ft. based on temperature and location of the sidewalk.

He requested that all Twin City Metro suppliers attend the MPCA snow training program. He rewarded the suppliers that were able to show their certifications. NSC held regional training sessions with all contractors, reviewed best practice for snow removal, and discussed the proper techniques and timing for deicer application. Bob requires preseason re-training of large suppliers to refresh them on the best practices. He expanded the material that was developed by the MPCA and trained his 14 Regional Managers on best practices, impact on the environment, and the need for continual training. They, in turn, introduced the training material into the larger markets such Salt Lake City, Denver, Omaha, and Boise.

They eliminated sand use in Minneapolis and Denver and continue to educate the maintenance contractors on the impact that sand has on the environment. In the first year of the program, NCS reduced deicer use by 15-20% in parking lots and by 20-25% on sidewalks. They hope to see additional reductions in the amount of wasted material by continuing to help the teams understand the use of technology and best practices. Bob developed a working group to continue to research better practices and material with the goal of reducing deicer use and our impact on the environment.

Joe’s Lawn and Snow

Joe Mather - Owner

Joe’s Lawn and Snow is a small company located in the Twin Cities area. Joe attended the certification class in the winter of 2013-2014 and sent four employees. The changes were implemented for the last half of the season. They normally would have expected to use 20 tons of salt and only used 9 tons.

Prior to attending the class, they relied on application rates listed on the deicers and their best judgment to determine how much material to apply and did not calibrate their equipment. They learned a lot in the class and implemented many practices in their first year. Practices implemented included:

- Purchased new spreader

- Calibrated equipment

- Made a “bowl” to catch any excess salt at spinner and reuse this

- Made modifications to spreader to get more even spread and prevent salt piles

- Reduced application rates

- Tested application rates and results and kept refining

- Purchased hand-held and truck mounted temperature sensors

- Use temperature to help determine rates and materials

- Identify drainage patterns and appropriate snow storage areas prior to winter

- Use sediment traps to contain solids in runoff and they clean out manholes

- Experimented with anti-icing using liquids and will continue to experiment

They were not able to reliably calibrate and adjust their old spreader so they purchased a new one. He plans to add mud flaps with pockets to prevent salt from going all over the truck and catch extra salt which they will reuse. They tested areas in parking lots to determine the best application rates. Before winter, they mark the edges of their parking lots with blue poles and used a different color to indicate where snow should be stacked. They have a covered salt storage area on one of their properties. It is a 20 x 30’ concrete walls and “tarp-type” top. It has a subfloor and a capture drain. It was a $20,000 investment. They had this prior to training. They do spring and fall sweeping.

They reduced their application rates by about ½ and then adjusted them up based on results as needed. With the changes made, they were able to reduce their salt usage by about 50% without reducing their results.

Cadwell Lawn and Landscaping

Charles Cadwell – Owner

After attending the Parking Lot Training in 2005, Charles Cadwell’s company examined their procedures for applying salt and deicing chemicals at Ridgedale Center and found areas that were candidates for improvement. Practices in previous years included using salt rather carelessly and applying it to attempt to keep snow from accumulating during a storm. As such, it was quite common to apply 12 to 14 tons of salt during a given storm. Since training, they examined their practices and have taken measures to reduce usage of salt products.

They reduced the speed setting on our auger to slow the feed rate of salt to the wheel. At the same time, they maintained the speed of the wheel and that made for better dispersion of the salt (more even dispersion of salt and greater coverage in a given load).

They inspected the truck tailgate because in previous years, they had a problem with spillage that resulted in "piles" of salt being dropped at random during turns or when hitting potholes or speed bumps. They found gaps between the tailgate sander and the truck bed that they filled with weather stripping. That forced all salt to be fed through the auger and baffle so that spillage was eliminated. That further increased the coverage per given load that was achieved.

Based on the information provided in training, they no longer apply salt or other chemicals during a storm. Salt is applied after the snow has been mechanically removed. The one exception to this is where some material might be needed to provide traction and permit traffic safety at stop signs or on slopes. In these situations, the materials are applied only sparingly after plowing is done.

Average salt usage for a given snow event is now five to six tons. That is based on the number of loader buckets put in the truck where one bucket is considered to be one ton (Ridgedale does not have a scale). That form of measurement is standard for what they did in previous years and from one contractor to another.

They were able to further reduce salt applications the winter of 2007 -2008 by educating the customer on the mechanical removal being the major step and only when that is complete is it reasonable to apply salt to the pavement. The mall was very receptive to only using salt when absolutely necessary. Supporting this approach, they were also able to maintain good performance in terms of the number of slip-and-fall incidents that occurred due to ice or snow. That supported the approach of using mechanical removal and then salt application as a standard process.

References and Resources

References

Axler, R. (n.d.) How Much Salt is a Problem? Lake Superior Duluth Streams.

Clear Roads Research Study: Field Evaluation of Organic Materials for Winter Snow and Ice Control. (2015). TRB Annual Meeting Paper 15-4555. http://docs.trb.org/prp/15-4555.pdf

Hosseini, Hossain, Fu, San Gabriel and Seters Field Evaluation of Organic Materials for Winter Snow and Ice Control

Freshwater Crisis. (n.d.) National Geographic.

Healthy Rivers: a Water Course. (2004). [Multimedia CD]. St. Paul MN: Minnesota Department of Natural Resources.

LRRB. (2012). Minnesota snow and ice control: Field handbook for snowplow operators. Minnesota Local Road Research Board, St. Paul, MN.

MPCA. 2013. The condition of Minnesota’s groundwater, 2007-2011. Minnesota Pollution Control Agency, St. Paul, MN.

MPCA. 2015. Twin Cities Metropolitan Area Chloride Management Plan. Minnesota Pollution Control Agency,St. Paul, MN.

MPCA. 2015. Twin Cities Metropolitan Area Chloride Total Maximum Daily Load. Minnesota Pollution Control Agency, St. Paul, MN.

Parking Lot and Sidewalk Maintenance for Reduced Environmental Impacts (2005-2006). Fortin Consulting, Inc. Funded by a Minnesota Pollution Control P2 grant.

Sander, A., E. Novotny, O. Mohseni, H.G. Stefan, (2007) Inventory of Road Salt Uses in the Minneapolis/St. Paul Metropolitan Area. University of Minnesota St. Anthony Falls Laboratory Engineering, Environmental and Geophysical Fluid Dynamics. Report No. 503. Prepared for Minnesota Department of Transportation.

Stefan, H., Novotny, E., Sander, A., and Mohseni, O. 2008. Study of Environmental Effects of Deicing Salt on Water Quality in the Twin Cities Metropolitan Area, Minnesota. Minnesota Department of Transportation. Report No. MN/RC 2008-42. http://www.lrrb.org/media/reports/200842.pdf

Sohanghpurwala, A. A. (2008, February 5). Cost of Winter Maintenance on Infrastructure. [Power Point Presentation]. Brooklyn Center, MN: Seventh Annual Road Salt Symposium.

Additional Resources

=Training and technical assistance

Anti-icing Equipment: Recommendations and Modifications. Iowa Department of Transportation. Includes drawings for shop-made equipment. http://www.iowadot.gov/maintenance/pdf/manualantiicingequipment.pdf

AASHTO Snow and Ice Pooled Fund Cooperative. Snow and Ice List Serve: http://sicop.transportation.org/Pages/SnowandIceList-Serve.aspx.

Amsler Sr., D. E. (2004). “Are You Using the Right Amount of Ice Control Chemical?” Salt & Highway Deicing, Vol. 40, No. 2.

Approved product list. (2014-2015). Minnesota Department of Transportation, St. Paul, MN. http://www.dot.state.mn.us/maintenance/pdf/approved-products-winter-chemicals.pdf

Axler, R. (n.d.) How Much Salt is a Problem? Lake Superior Duluth Streams. http://www.lakesuperiorstreams.org/understanding/impact_salt_2.html

Blackburn, R.; Amsler, D; & Bauer, K. (2003, July). Guidelines for Snow and Ice Control. [Power Point]. Presented at 10th AASHTO/TRB Maintenance Management Conference, Duluth MN.

Blackburn, R., Bauer, K., Amsler, D. E., Boselly, S. E., McElroy, A. D. (2004). Snow and ice control: Guidelines for materials and methods. National Cooperative Highway Research Program Report 526. Transportation Board: Washington, D.C. http://onlinepubs.trb.org/onlinepubs/nchrp/nchrp_rpt_526.pdf.

Calibration Procedures Manual. (2000-2001) Circuit Training and Assistance Program (CTAP).

The Circuit Training and Assistance Program (CTAP), a joint program of MN/DOT and the Minnesota Local Technical Assistance Program (LTAP). Brings training to cities, counties and townships. www.mnltap.umn.edu/ctap.

Correlating Lab Testing and Field Performance for De-icing and Anti-icing Chemicals. [Final report]. (2010, August 31). Western Transportation Institute for Wisconsin Department of Transportation and Clear Roads.

Determining the toxicity of de-icing materials. (2013). Clear Roads Fact Sheet. http://clearroads.org/wp-content/uploads/dlm_uploads/11-02_12-30-13-Final-Fact-Sheet.pdf

Guide to Field-Testing Deicing and Anti-Icing Chemicals. Minnesota Department of Transportation. http://www.dot.state.mn.us/products/snow_ice/index.html

Highway Deicing: Comparing Salt and Calcium Magnesium Acetate. (1991). Special Report 235, p. 11. Washington, D.C.: Transportation Research Board, National Research Council.

Johnson, G.R. & Sucoff, E. (2015).Minimizing De-icing Salt Damage to Trees. University of Minnesota Extension. http://www.extension.umn.edu/garden/yard-garden/trees-shrubs/minimizing-de-icing-salt-injury-to-trees/

Katz, D.B. (2015). Road maps to liquids. [Snow and Ice Maintenance Association website publication]. http://www.sima.org/news2/2015/04/16/road-map-to-liquids.

Managing Street Sweepings. (1997, September). Minnesota Pollution Control Fact Sheet w-sw4-54. http://www.pca.state.mn.us/index.php/view-document.html?gid=13934.