Overview and methods of pretreatment

This page is under review through August, 2016

The Manual user will notice that many of the stormwater practices discussed in this Manual recommend pretreatment as an integral part of the best management practice (BMP) application. In fact, in many applications (e.g. infiltration, stormwater ponds), the BMP would not be properly used if pretreatment is ignored. Pretreatment techniques keep a BMP from being overloaded, primarily by sediment. Pretreatment is also required for post-construction practices covered under the Construction Stormwater General Permit.

Contents

Importance of pretreatment

Sediment, trash, debris, and organic materials found in stormwater runoff can clog and significantly affect the functionality of structural stormwater best management practices (BMPs). Reducing these burdens prior to entering structural stormwater BMP(s) will preserve their long-term functionality, particularly for filtration and infiltration BMPs. Pretreatment reduces maintenance and prolongs the lifespan of structural stormwater BMPs by removing trash, debris, organic materials, coarse sediments, and associated pollutants prior to entering structural stormwater BMPs. Implementing pretreatment devices also improves aesthetics by capturing debris in focused or hidden areas more amenable for removal.

Pretreatment practices serve an important role in the stormwater treatment network. They are installed immediately preceding one or more structural stormwater BMPs and are designed with consideration of the flow network and the downstream structural stormwater BMP characteristics. Pretreatment is highly recommended as an integral part of all post-construction structural stormwater BMPs and is required as part of Minnesota’s NPDES/SDS Construction Stormwater (CSW) General Permit for filtration/infiltration water quality BMPs (section III.D.1.d). Pretreatment practices are NOT stand-alone treatment practices and should only be installed in conjunction with a treatment practice immediately downstream.

Pretreatment practices include settling devices, screens, and pretreatment vegetated filter strips. Selecting the appropriate pretreatment device is critical and is primarily based on the downstream structural BMP, and the contributing drainage area (size, land use, underlying soils, trees/vegetation, etc.). The variety of pretreatment methods and flexibility of design allows for site-specific utilization of the most applicable pretreatment practice. It is recommended that pretreatment practices be designed to be easily maintained and capture a minimum of 25% of the sediment from runoff. Pollutants are captured primarily by physical screening or sedimentation/settling. The figure to the right shows the spectrum of particles sizes and classes and typical ranges of treatment for pretreatment, conventional structural stormwater BMPs, and structural stormwater BMPs that incorporate advanced treatment processes.

Pretreatment practices capture solids that are quickly settled or screened, including gross solids and most sand particles (roughly 100 microns (μm) and larger), although some pretreatment practices also capture floatables. In many watersheds, this material accounts for a large portion of the total pollutant load. Installing multiple pretreatment practices of the same type in series rarely increases performance because the pollutants will be captured by the first practice (if properly designed and maintained) and subsequent pretreatment practices will not be effective. Structural stormwater BMPs such as wet ponds and filtration practices generally capture large silts in addition to sands and gross solids, approximately down to 10 μm-sized particles. To capture fine silts, clays, and dissolved or colloidal pollutants, structural stormwater BMPs with advanced treatment such as infiltration, chemical reactions, or biodegradation must be used.

Methods of pretreatment

There are several recommended pretreatment practices that are compatible with structural stormwater BMPs. Differences in each pretreatment practice should be understood to ensure the selected practice is appropriate to the site, the downstream structural stormwater BMP, and maintenance capabilities of the individual or organization responsible for maintenance. The pretreatment descriptions presented below and in the following tables provide assistance in the selection of the proper pretreatment practice for the site-specific loading condition and proposed structural stormwater BMP. The descriptions highlight the types of pretreatment practices, their mechanism of pollutant removal, and their differences are described below.

Pretreatment settling devices

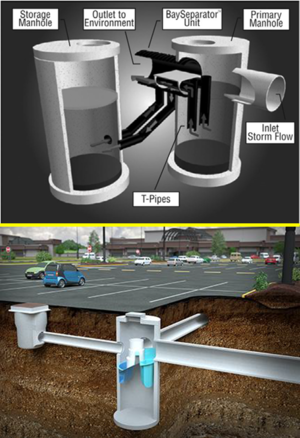

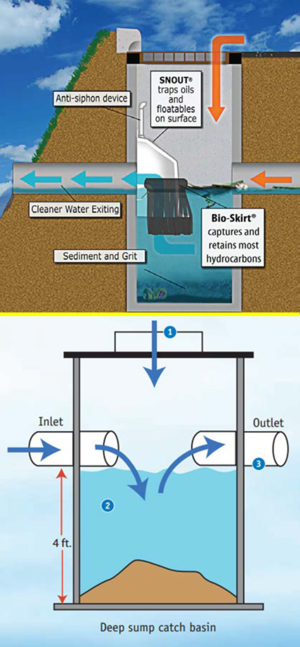

Pretreatment settling devices are flow-through structures or devices, proprietary or non-proprietary, above or below ground, where settling is the primary mechanism of pollutant removal. Some of these devices also provide treatment in addition to settling by utilizing a variety of mechanisms to separate and capture pollutant-laden material. Aliases for these devices include water quality inlets, flow-through devices, hydrodynamic separators, grit chambers, forebays, sump manholes, and other descriptors.

- Settling devices are typically designed to dissipate flow energy and detain runoff to allow coarse sediments to settle out of the water column.

- Some settling devices use multiple chambers equipped with baffles, weirs, sumps or orifices to manage flow and capture pollutants; hoods or inverted elbows to retain floating organic material, oil, and debris.

Pretreatment screens

Pretreatment screens are small catch basins or conveyance trenches in which screening is the primary mechanism of pollutant removal. These pretreatment devices use a perforated plate or mesh screen to separate and collect sediment, trash, debris and organic material as runoff passes over or through them. Screens often comprise thin sheets of metal, plastic, or fabric (e.g., geotextile) with holes or slots that allow water to pass through but limit particulate pollutant passage by deflection or sieving.

Pretreatment vegetated filter strips

Pretreatment vegetated filter strips, also sometimes called buffer strips or buffers, are sloped surfaces that rely on shallow (i.e., water level less than the height of the vegetation), distributed flow through dense vegetation to reduce flow velocity, allow particles to settle, allow particle interception by the vegetation as their primary mechanism of pollutant removal. Pretreatment vegetated filter strips are not to be confused with treatment vegetated filter strips, which are designed and used as standalone structural stormwater BMPs. Concentrated or channelized flow is common to structural stormwater BMP treatment swales, but is not appropriate for pretreatment vegetated filter strips.

Pretreatment characteristics

Pretreatment as defined above relies upon two primary treatment mechanisms (1) settling and/or (2) physical screening. Settling refers to the method of slowing flow velocities and temporarily detaining flow to allow solids denser than water to settle out of the flow. Screening refers to the method of removing solids by a porous material with a minimal thickness, such as a single sheet of metal with holes in it, as water flows through it, or forcing water to flow through submerged outlets to capture floatables.

The table below provides a general summary of the characteristics for the three types of pretreatment practice.

- Relative pollutant removal is classified as either low, medium or high. These descriptions are relative across pretreatment practices and account for the ability of a specific pretreatment practice to remove coarse sediments, trash and debris, and organic material. The ratings do not imply that removal exceeds any numeric threshold, but rather that the practice removes more pollutants than pretreatment practices rated lower. Stormwater pollutants such as nutrients, non-coarse sediments, pathogens, hydrocarbons, metals, and pesticides that are associated with coarse sediments, trash, debris and organic material captured by pretreatment practices will also be captured.

- Relative capital cost is classified as low, medium or high. This refers to the anticipated cost required for purchasing the practice and/or the installation costs that are required to implement the pretreatment practice so that it operates as designed. It does not include the land use costs or lifecycle maintenance costs. This is a relative comparison among all pretreatment practices and it is important to note that the costs vary from site to site.

- Relative maintenance frequency and effort are classified as low, medium or high. Maintenance frequency reflects how often maintenance will typically be required for these practices. Maintenance effort reflects the anticipated time, skill of labor, and equipment necessary to complete maintenance. These vary depending on pretreatment device placement (ease of access), size and the pollutants/soil types in the watershed. These values are relative to the other pretreatment practices.

- Relative space requirements are classified as low, medium or high. Space requirements are the anticipated footprint used by the specific pretreatment practice after installation. This varies for a specific pretreatment practice, but provides a relative comparison of the footprint required for the various pretreatment practices. If the practice is large, but located below ground it is considered to have a small footprint and is classified as low.

Pretreatment practice summary of characteristics

Link to this table

| Pretreatment practice | Mechanism of pollutant removal | Relative pollutant removal | Capital cost | Relative maintenance frequency | Relative maintenance effort | Relative space requirements |

|---|---|---|---|---|---|---|

| Pretreatment settling devices | Screening & settling | Medium | Medium to High | Medium1 | Low to Medium | Low to Medium |

| Pretreatment screens | Screening | Low | Low | High | Medium | Low |

| Pretreatment vegetated filter strips | Screening & Settling | Medium | Low | Low | High | High |

1 Pretreatment settling devices are prone to plugging, which will drive maintenance costs up.

Cost considerations

Although cost is variable depending on the specific site properties and the size of the pretreatment practice, the above table provides general guidance for selecting a pretreatment practice based on capital cost. In addition to capital costs, land value cost and lifecycle maintenance costs should be considered when selecting a pretreatment practice. The capital cost is the cost of purchasing the practice and/or the costs to implement the practice which will vary based on site conditions, type of practice, and size of the practice. Land value costs will be highly variable and largely dependent upon the potential of the site to generate revenue or other benefits within the pretreatment practice footprint. Maintenance costs are a long-term cost representing the combined frequency of maintenance and the effort required to carry out the maintenance, including acquisition of maintenance equipment, personnel training, labor, and disposal of accumulated sediment and debris. Maintenance costs should also consider how the pretreatment practice reduces maintenance costs in the structural stormwater BMP. To more fully understand the entire cost of installing one pretreatment practice from another, all three costs (capital, land value, and maintenance) should be considered on a site by site basis.

Some factors that may influence cost include the following.

- Some underground settling devices have expensive capital costs, but these may be offset by placement underground, thereby reducing land acquisition expense.

- A pretreatment practice (e.g. underground settling device) with expensive capital costs may be offset by savings of maintenance costs if the party in charge has other similar practices and an established, streamlined maintenance program/equipment for that specific type of practice (e.g. a vac truck).

Pretreatment applicability

Specific pretreatment practices may be more or less applicable under certain conditions. The table below provides a general summary of the applicability for the three types of pretreatment practice.

- Cold climate suitability is classified as low, medium or high. This refers to the anticipated capability of a particular pretreatment practice to function and provide pretreatment for elevated sediment concentrations in spring and with snowmelt-related runoff relative to the other pretreatment practices. Winter variability factors that affect pretreatment mechanisms include reduced biological activity, reduced settling velocities, frost heave, reduced drainage basin infiltration and variable thawing and freezing cycles. Variations of weather-driven events such as rainfall-upon-snow events, peak spring runoff and snow storage/management are also cold climate factors affecting pretreatment. If the functionality of a pretreatment practice is greatly affected by cold climate factors, the practice is classified as low. If the pretreatment’s functionality remains consistent year-round, it is classified as high.

- Retrofit suitability is classified as low, medium or high and reflects the relative effort required to insert a specific pretreatment practice with an existing structural stormwater BMP. This does not include the effectiveness of the pretreatment practice, but rather a measure of anticipated total effort (planning, design, installation, and related expenses) and space required to insert the pretreatment practice within existing infrastructure. A high retrofit suitability indicates the pretreatment practice requires relatively minimal effort, space or both to retrofit the practice into existing infrastructure. A low retrofit suitability suggests that the pretreatment practice will require significant effort, space, or both to install the practice into existing infrastructure.

- Suitability for ultra-urban settings is classified as low, medium or high. Factors include size of the pretreatment footprint, linked infrastructure requirements and constraints, limitations associated with highly impervious contributing areas, and application within traditional curb and gutter and stormsewer systems. Ultra-urban settings typically have high land values, complex infrastructure, and substantial impervious area. Pretreatment practices that require minimal space or are underground, have simple infrastructure requirements and are relatively simple to retrofit into existing infrastructure are often most suitable to ultra-urban settings and are classified as high. A low classification indicates a practice either requires substantial space or requires significant effort to install in ultra-urban areas.

Pretreatment practice applicability

Link to this table

| Pretreatment Practice | Cold Climate Suitability | Retrofit suitability | Suitability for ultra-urban settings |

|---|---|---|---|

| Pretreatment settling devices | Medium to High | Medium | Low to High |

| Pretreatment screens | Low | High | High |

| Pretreatment vegetated filter strips | Medium | Low to Medium | Low |

Pretreatment practice compatibility with downstream structural stormwater BMPs

Pretreatment compatibility with structural stormwater BMPs is wide ranging and summarized in the following table. Site specific characteristics will help guide which practice is best suited in a given application. Factors such as size, topography, site use, pollutant type, and flow (overland/concentrated) will often distinguish which pretreatment practice is best suited for that BMP or site. Taking into consideration the most common type of pollutant (large debris, small debris, hydrocarbons, etc.), space limitations, topography, and receiving flow type will lead to the best-suited pretreatment practice at a given site. Assuming no other limitations, some examples include the following.

- Pretreatment vegetated filter strips are recommended for the following conditions.

- Above-ground BMPs, such as a small residential raingarden

- If the pretreatment device is receiving sheet flow;

- In areas and structural stormwater BMPs with more natural vegetation where the filter strip will visually match the site

- For smaller particle sizes in the runoff because a vegetative filter strip will perform better

- Above ground settling devices such as a forebay are recommended for the following conditions.

- Channelized flow, because it captures and provides pretreatment for channelized or pipe flow

- Underground settling devices are recommended for the following conditions.

- In highly urban areas with little space available, due to high land values

- On a steep site because it would be difficult to grade an above ground settling device

- If the receiving BMP is an underground infiltration or filtration system, particularly if construction is in tandem

- Pretreatment screens are recommended for the following conditions.

- For areas with leaf debris or other large debris

Pretreatment practice compatibility with downstream structural stormwater BMPs

Link to this table

| Structural treatment practices | Pretreatment settling devices | Pretreatment screens | Pretreatment vegetated filter strips |

|---|---|---|---|

| Bioinfilitration/bioretention with no underdrain (rain garden) | X | X | X |

| Infiltration Basin | X | X | X |

| Infiltration Trench | X | X | X |

| Permeable Pavement with no underdrain | (As elevations allow) | X | |

| Tree Trench/Tree Box with no underdrain | X | X | X |

| Stormwater Re-use and rainwater harvesting | X | X | X |

| Biofiltration/Bioretention with an underdrain | X | X | X |

| Permeable Pavement with an underdrain | (As elevations allow) | X | |

| Tree Trench/Tree Box with an underdrain | X | X | X |

| Swales | X | X | X |

| Sand Filters | X | X | X |

| Iron Enhanced Sand Filter | X | X | X |

| Green Roofs | |||

| Stormwater Re-use and rainwater harvesting | X | X | X |

| Stormwater Ponds | X | X | X |

| Stormwater Wetlands | X | X | X |