Cost-benefit considerations for stormwater and rainwater harvest and use/reuse

This page is under construction

What are the total costs and cost per element of a harvesting and use system? Costs can be highly dependent on the situation and context. The total cost of a harvest and use system can be divided into the four major components of a harvesting and use system:

- Collection

- Storage

- Treatment

- Distribution

The individual components required to construct each of the four systems usually depends on the site and/or use of the water. For the collection component, storm sewer pipes and roof drains may already be part of the design, thus reducing cost. The storage component is typically the largest cost item. If storage already exists at a site, such as existing wet ponds, providing storage for a harvest and use system can be done at minimal cost. Treatment costs can vary dramatically, depending on the source water and the end use, from virtually no treatment to meeting drinking water standards. Costs for distribution are usually associated with connection to an irrigation system. The location and elevation of the irrigation site in proximity to the source and storage areas affect the amount of pipes and pumps needed. If a site already has an irrigation system in place drawing from a potable water source, the distribution portion of the system costs may be minimal.

The site setting affects the cost of harvest and use systems. For example, in highly urban areas the choices for stormwater treatment may be limited and components such as storage (which is often an underground cistern) may be quite expensive on a cost/unit treatment basis. However, harvest and use may still more cost-effective than other stormwater management techniques such as green roofs or underground infiltration facilities. It is difficult to compare unit costs of harvest and use systems across different settings.

Contents

Total system costs

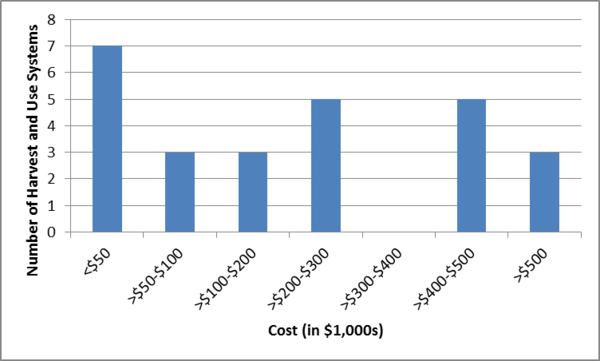

The total cost of a stormwater harvest and use system varies due to the large range in the size and scale of these systems. In a Minnesota Pollution Control Agency (MPCA) survey for stormwater harvest and use systems in the Twin Cities Metropolitan Area, 26 respondents provided total system cost information, summarized in the MPCA survey responses of total stormwater harvest and use system costs graph below. Total costs ranged from 💲1,500 to 💲1,500,000, with eight systems over 💲400,000. Of the 26 systems with cost information, 22 were irrigation systems (💲1,500 - 💲1.5M), 1 was a toilet flushing system (💲300,000), 1 was a toilet flushing and vehicle washing system (💲57,500), and 2 were irrigation and vehicle washing systems (💲10,000 - 💲425,000).

Individual component costs

Major individual component costs of stormwater harvest and use systems include land acquisition, excavation and material removal, and the storage/treatment systems. Very little detailed component cost information is currently available because costs for many of the storage and treatment systems are packaged together. Examples of harvest and use system itemized costs are discussed below.

The 2011 Met Council Stormwater Reuse Guide developed a list of stormwater harvest and use system construction activity components and cost units for developing system cost estimates, reproduced in the Stormwater Harvesting and Use Component Checklist and Cost Units table. A cost analysis of different cistern materials was summarized by CONTECH Inc. in their 2011 Cistern Design Considerations for Large Rainwater Harvesting Systems Professional Development Advertising article, reproduced in the Comparison of materials used for rainwater harvesting systems table below. Some itemized component cost information was also compiled in the Texas Manual on Rainwater Harvesting, summarized in the Itemized stormwater harvest and use system component costs table below. These itemized costs include cistern and gutter costs on a per volume/length basis, and treatment system consumables (such as filters and cartridges) that must be replaced regularly as part of normal system operation and maintenance.

Comparison of materials used for rainwater harvesting systems

Link to this table

| Material | Cost low - high | Installation hard - easy | Longevity short - long | Durability low - high | Maintenance Access hard - easy | Best Use Capacity (gallons) | |

|---|---|---|---|---|---|---|---|

| Underground | FiberglassX | 💲💲💲💲💲 | ●●●○○ | ●●●●○ | ●●○○○ | ●●●●○ | 5,000 to 30,000 |

| Polyethylene | 💲 | ●●●●● | ●●●○○ | ●●●○○ | ●●○○○ | > 5,000 | |

| Steel Reinforced Polyethylene (SRFE) | 💲💲💲 | ●●●●○ | ●●●●● | ●●●●● | ●●●●○ | 10,000 to 100,000+ | |

| Plastic Crates | 💲💲💲 | ●●●○○ | ●●○○○ | ●○○○○ | ●○○○○ | 5,000 to 50,000 | |

| Concrete | 💲💲💲💲💲 | ●●○○○ | ●●●●○ | ●●○○○ | ●●●●○ | 30,000+ (with high loading) | |

| Fabricated Steel | 💲💲💲💲 | ●●●●○ | ●●●○○ | ●●●●○ | ●●●●○ | not recommended | |

| Waterproof Corrugated Metal | 💲💲 | ●●●●○ | ●●●○○ | ●●●●● | ●●●●○ | 5,000 to 30,000 | |

| Above-Ground | Monolithic | 💲💲💲 | ●●●●○ | ●●●●● | ●●●●○ | ●●●●● | Up to 20,000 |

| Plate Assembled On-Site | 💲💲💲 | ●●○○○ | ●●●●● | ●●●●○ | ●●●●● | 15,000+ |

Itemized stormwater harvest and use system component costs

Link to this table

| System | System Component | Cost | Cost Recurrence |

|---|---|---|---|

| Materials | Tanks | 💲0.50/gallon for fiberglass to 💲4/gallon for wielded steel tank | |

| Gutters | 💲0.30/foot for vinyl/plastic to 💲6 - 12/foot for aluminum/galvalume | ||

| Annual maintenance (costs will be dependent on system size) | Cartridge Filter | 💲20-60 | Filter must be changed regularly |

| Reverse Osmosis Filter | 💲400-1,500 | Change filter when clogged (depends on turbidity) | |

| UV Light Disinfection | 💲350-1,000; 💲80 to replace UV bulb | Change UV bulb every 10,000 hours or 14 months | |

| Ozone Disinfection | 💲700-2,600; 💲1,200+ for in-line monitor to test effectiveness | ||

| Chlorine Disinfection | 💲1/month manual dose or a 💲600-3,000 automatic self-dosing system |

Stormwater Harvesting and Use Component Checklist and Cost Units

Link to this table

| Phase | Component | Unit | Check if required for system: |

|---|---|---|---|

| Collection | Cleaning of roof (if retrofit project) | Square foot | |

| Roof washing system | Each | ||

| Gutters | Linear foot | ||

| Gutter screens | Linear foot | ||

| Downspouts | Linear foot | ||

| Scuppers | Each | ||

| Catch basins | Each | ||

| Catch basin filters | Each | ||

| Manholes | Each | ||

| Oil/water separators | Each | ||

| Storm sewers | Linear foot | ||

| Bypass valves | Each | ||

| First flush diverter | Each | ||

| Storage – Ponds/ basins | Site demolition | Varies | |

| Excavation | Cubic foot | ||

| Disposal of excess soil | Cubic foot | ||

| Vegetation restoration | Square foot | ||

| Baffles at outlet | Linear foot | ||

| Filters at outlet | Each | ||

| Outlet structure | Each | ||

| Pumping system including pump, motor, valves, and pressure tank (for non-gravity and pressurized systems) | Varies | ||

| Aeration | Varies | ||

| Electrical supply (for pumps or aeration) | Varies | ||

| Below-ground storage | Site demolition | Varies | |

| Excavation and backfill | Cubic foot | ||

| Imported aggregate bedding material | Cubic foot | ||

| Disposal of excess soil | Cubic foot | ||

| Vegetation or pavement restoration | Square foot | ||

| Pre-fabricated tanks | Each | ||

| Baffles, calming inlet, and/or filters, if not supplied with pre-fabricated tank | Each | ||

| Cast-in-place concrete tank | Varies | ||

| Pumping system including pump, motor, valves, and pressure tank (for non-gravity and pressurized systems) | Varies | ||

| Maintenance access manhole | Each | ||

| Electrical supply (for pumps) | Varies | ||

| Treatment systems | Piping | Linear foot | |

| Valves | Each | ||

| Flow meter (when needed to regulate chemical feed) | Each | ||

| Electrical supply | Varies | ||

| Maintenance access manhole (if located underground) | Each | ||

| Backflow prevention valves (if connected to potable water for supplemental supply and/or for filter backwash) | Each | ||

Suspended & Colloidal Solids Removal Systems

|

Varies | ||

Residual Suspended Solids Removal Systems

|

Varies | ||

Residual Colloidal Solids Removal Systems

|

Varies | ||

Dissolved Solids Removal Systems

|

Varies | ||

Disinfection

|

Varies | ||

| Distribution | Pumping system including pump, motor, valves and pressure tank | Varies | |

| Piping for distribution | Linear foot | ||

| Valves for pressure control, and regulating flow | Each | ||

| Valve boxes | Each | ||

| Sprinkler nozzles – impulse, spray, rotating, bubbler, or drip | Each | ||

| Irrigation controllers with wiring to each sprinkler (for automated control systems) | Varies | ||

| Drain plug (for winterization) | Each |

Harvest and use system construction bid estimate examples

Due to the large variability in harvest and use system costs, construction bid estimates are provided as examples of itemized costs.

- Installation of 3 – 29,000 gallon underground storage tanks: The Contractor bid averages for installation of three 29,000 gallon underground storage tanks table below summarizes the average of four contractor bids for the installation of three 29,000 gallon underground storage tanks (120” diameter x 50’ length) for an irrigation harvest and use system designed for an approximate 8 acre drainage area and an approximate 3 acre irrigation area. This estimate is for storage (3 tanks) components only. The average capital cost for one gallon of storage is 💲1.46 per gallon. The underground storage tank components were 71 percent of the total installation bid.

- Installation of 1 – 1,500 gallon aboveground tank harvest and use system: The Engineers estimate for installation of one 1,500 gallon aboveground corrugated steel storage tank table below summarizes the engineer’s estimate for the installation of one 15,000 gallon aboveground corrugated steel storage tank that captures rainwater from a 2,100 square foot roof connected to a hose for on-site exterior water use. This estimate is for collection (gutters), storage (tank), and distribution (hose) components. The total capital cost for one gallon of storage is approximately 💲20 per gallon. The aboveground storage tank components were 46 percent of the total construction estimate.

Contractor bid averages for installation of three 29,000 gallon underground storage tanks

Link to this table

| BASE BID ITEM | ESTIMATED QUANTITY | UNIT | UNIT PRICE AVERAGE | TOTAL AVERAGE BID |

|---|---|---|---|---|

| Part 1 - General and Erosion Control | ||||

| MOBILIZATION | 1 | LS | 💲23,340 | 💲23,340 |

| SEDIMENT CONTROL LOG -- INSTALL, MAINTENANCE AND REMOVAL | 267 | LF | 💲5 | 💲1,335 |

| TEMPORARY FENCE -- INSTALL AND REMOVAL | 160 | LF | 💲8 | 💲1,280 |

| STABILIZED CONSTRUCTION EXIT -- INSTALL, MAINTENANCE AND REMOVAL | 1 | LS | 💲2,410 | 💲2,410 |

| EROSION CONTROL BLANKET | 424 | SY | $4 | $1,696 |

| STORM DRAIN INLET PROTECTION -- INSTALL, MAINTENANCE AND REMOVAL | 2 | EA | 💲387 | 💲774 |

| DUST CONTROL | 10 | HRS | 💲121 | 💲1,210 |

| Total Part 1 | 💲32,045 | |||

| Part 2 - Removals | ||||

| REMOVE EXISTING SEDIMENT CONTROL LOG OR SILT FENCE Total Part 2 | 268 | LF | 💲4 | 💲1,072 |

| Total Part 2 | 💲1,072 | |||

| Part 3 - Grading | ||||

| COMMON EXCAVATION -- INCLUDES TANK TRENCH EXCAVATION AND FILL TO PROPOSED GRADE | 1955 | CY | $9 | $9 |

| REMOVAL OF EXCAVATED MATERIAL | 1389 | CY | $10 | $13,890 |

| AGGREGATE BACKFILL | 1009 | CY | $41 | $41,369 |

| Total Part 3 | 💲72,854 | |||

| Part 4 – Underground Storage Tank Components | ||||

| RAINWATER HARVESTING TANK (120" DIA. X 50-FEET) | 3 | EA | 💲77,639 | 💲232,917 |

| CONSTRUCT DRAINAGE STRUCTURE | 6 | EA | 💲1,153 | 💲6,918 |

| CONCRETE, REINFORCED COLLAR (RISER MANHOLE CAP) | 6 | EA | 💲1,085 | 💲6,510 |

| CONCRETE, REINFORCED COLLAR (AT RISER CONNECTION TO TANK) | 6 | EA | 💲1,248 | 💲7,488 |

| INSTALL CASTING | 6 | EA | 💲1,221 | 💲7,326 |

| 18" HDPE PIPE | 115 | LF | 💲73 | 💲8,395 |

| SOIL DENSITY COMPACTION TESTING | 12 | EA | 💲430 | 💲5,160 |

| Total Part 4 | 💲274,714 | |||

| Part 5 – Site Restoration | ||||

| RAPID STABILIZATION | 0.42 | AC | 💲3,173 | 💲1,333 |

| PERMANENT SEEDING | 0.42 | AC | 💲6,336 | 💲2,661 |

| TURF ESTABLISHMENT | 1 | EA | 💲2,500 | 💲2,500 |

| Total Part 5 | 💲6,494 | |||

| Total Bid | 💲386,590 | |||

| PRICE PER TANK (3 – 29,000 gallon tanks) | 💲129,060 | |||

| PRICE PER TANK PER YEAR OVER 25 YEAR | 💲5,162 | |||

| PRICE PER GALLON (87,000 gallons) | 💲4.44 | |||

| PRICE PER GALLON PER YEAR OVER 25 YEARS | 💲0.06 | |||

Engineers estimate for installation of one 1,500 gallon aboveground corrugated steel storage tank

Link to this table

| ITEM | ESTIMATED QUANTITY | UNIT | UNIT PRICE | TOTAL COST |

|---|---|---|---|---|

| RAINWATER HARVESTING PACKAGE: 1,500 GALLON ABOVE GROUND CORRUGATED STEEL TANK AND ASSOCIATED FITTINGS & ACCESSORIES, INCLUDING PUMP AND FILTER SYSTEM. (72" DIA. X 9') | 1 | EA | 💲15,000 | 💲15,000 |

| REINFORCED CONCRETE FOUNDATION ON IMPROVED SUBGRADE | 1 | EA | 💲2,500 | 💲2,500 |

| REMOVE EXISTING GUTTER | 60 | LF | 💲9 | 💲540 |

| 5" BOX GUTTER | 222 | LF | 💲10 | 💲2,220 |

| GUTTER DOWNSPOUTS | 45 | LF | 💲15 | 💲675 |

| 6" HDPE PIPE | 110 | LF | 💲30 | 💲3,300 |

| RODENT GUARD | 1 | EA | 💲350 | 💲350 |

| SCOUR STOP MAT | 32 | SF | 💲30 | 💲960 |

| EROSION CONTROL BLANKET | 14 | SY | 💲20 | 💲284 |

| ENGINEER'S REPORT | 1 | EA | 💲2,500 | 💲2,500 |

| O&M GUIDELINES | 1 | EA | 💲1,500 | 💲1,500 |

| Total | 💲29,829 | |||

Funding sources

There are many sources of funding that can be used to finance stormwater harvest and use systems (Stormwater Harvest and Use Funding Sources table). Due to the high cost of these systems, more than one source of funding is often needed. Of the 26 respondents to the 2016 MPCA stormwater harvest and use system survey that provided cost and funding source information, 16 respondents utilized two or more sources of funding to finance their harvest and use system.

Stormwater harvest and use funding sources

Link to this table

| Funding Source | Funding Type |

|---|---|

| Watershed Organization Implementation and Cost-Share Programs |

|

| State Agency Grants and Loans | |

| County Funds |

|

| Municipal Funds and Utility Fees |

|

| Other Public Financing |

|

| Private Financing |

|

Financial incentives and benefits

There are many financial incentives and benefits that should be factored in to the global net cost of a stormwater harvest and use system. These include:

- Points toward U.S. Green Building Council LEED or Institute of Sustainable Infrastructure Envision ratings which demonstrate how well public entities are sustainably managing energy, material, and water resources (LEED) and planning for climate change and long-term resiliency in public infrastructure investments (Envision)

- Reduced potable water utility costs

- Reduced downstream stormwater infrastructure costs

- Increased resiliency in stormwater management and potable water systems due to reductions in stormwater volume and potable water demand

- Ecosystem services

Additional cost resources

Cost-Benefit case studies

- Bill Hicks, P.E. 2008. A Cost-Benefit Analysis of Rainwater Harvesting at Commercial Facilities in Arlington County, Virginia.

- Sarah Lawson, Ph.D. (Rainwater Management Solutions). Sample Rainwater Harvesting Case Study Costco Store in Northern Virginia.

System costs

- Contech Construction Products, Inc. September 2011. Cistern Design Considerations for Large Rainwater Harvesting Systems.

- USEPA. January 2013. Rainwater Harvesting Conservation, Credit, Codes, and Cost Literature Review and Case Studies.

Related pages

- Overview for stormwater and rainwater harvest and use/reuse

- Design criteria for stormwater and rainwater harvest and use/reuse

- Construction specifications for stormwater and rainwater harvest and use/reuse

- Operation and maintenance for stormwater and rainwater harvest and use/reuse

- Water quality considerations for stormwater and rainwater harvest and use/reuse

- Environmental concerns for stormwater and rainwater harvest and use/reuse

- Cost-benefit considerations for stormwater and rainwater harvest and use/reuse

- Case studies for stormwater and rainwater harvest and use/reuse

- Calculating credits for stormwater and rainwater harvest and use/reuse

- Definitions for stormwater and rainwater harvest and use/reuse

- Links for stormwater and rainwater harvest and use/reuse

- References for stormwater and rainwater harvest and use/reuse

- Technical support for stormwater and rainwater harvest and use/reuse