Overview for permeable pavement

The anticipated construction period for this page is January through March, 2013

The anticipated review period for this page is January through March, 2013

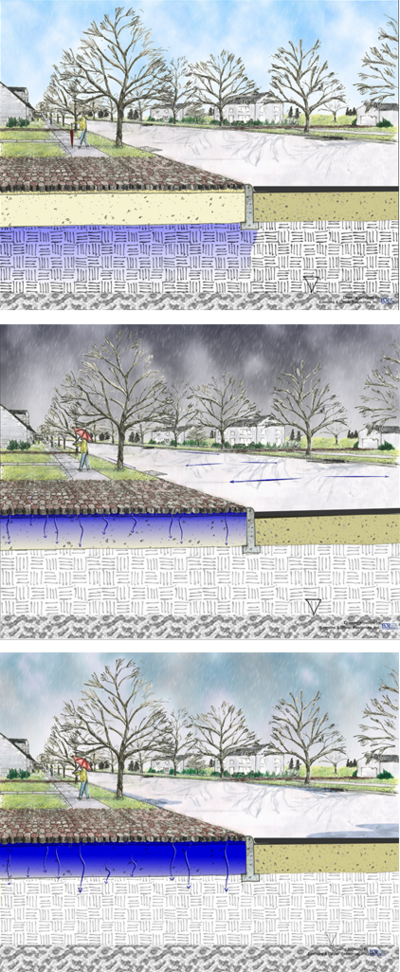

Permeable pavements allow stormwater runoff to filter through surface voids into an underlying stone reservoir where it is temporarily stored and/or infiltrated. The most commonly used permeable pavement surfaces are pervious concrete, porous asphalt, and permeable interlocking concrete pavers (PICP). Permeable pavements have been used for areas with light traffic at commercial and residential sites to replace traditionally impervious surfaces such as low-speed roads, parking lots, driveways, sidewalks, plazas, and patios. Permeable pavement is not ideal for high traffic/high speed areas because it has lower load-bearing capacity than conventional pavement.

While the designs vary, all permeable pavements have a similar structure, consisting of a surface pavement layer, an underlying stone aggregate reservoir layer, optional underdrains, and geotextile over uncompacted soil subgrade.

From a hydrologic perspective, permeable pavement is typically designed to manage rainfall landing directly on the permeable pavement surface area. Permeable pavement surface areas may accept runoff contributed by adjacent impervious areas such as driving lanes or rooftops. Runoff from adjacent vegetated areas is often discouraged because sediment in runoff from adjacent areas increases clogging of the permeable pavement, especially at the edges. Additionally, the capacity of the underlying reservoir layer limits the contributing area.

Contents

Benefits and limitations

- Benefits: Permeable pavements allow for conversion and/or design of typical Permeable pavements allow conversion and/or design of typical impervious areas (i.e. parking lots) to pervious areas that infiltrate stormwater runoff. When compared to typical impervious areas, properly designed and maintained permeable pavements can reduce the runoff quantity, reduce total suspended solids (TSS) and total phosphorus (TP) loads into receiving water bodies, and reduce runoff temperatures. In addition, permeable pavements can reduce nitrogen, metals and process oils. Permeable pavements are well suited for high density urban areas with limited space for other BMPs such as ponds, swales or bioretention systems.

- Limitations: As with all BMP’s, permeable pavement has limitations that need to be considered before design and construction. Limitations are discussed in detail in the permeable pavement design section.

Pretreatment Considerations

Pretreatment that removes sediment from runoff draining onto permeable pavement from impervious surfaces is desirable since sediment can clog permeable pavements. For that reason, pretreatment areas should emit practically no sediment onto the permeable pavement surface. Locating such areas next to impervious surfaces upslope from the permeable pavement may not be possible on some sites. Permeable pavement itself can be considered a pre-treatment device and included in a stormwater treatment train if underdrains are utilized within the storage reservoir. The underdrains will typically be routed to a bioretention area.

Permit Applicability

Permeable pavements can be utilized to assist in meeting stormwater requirements for volume, total suspended solids, and total phosphorus. The section on credits provides guidance on the implementation of permeable pavements that may be utilized to meet various runoff volume and pollutant runoff reduction goals.

Retrofit Suitability

In most cases, existing impervious surfaces can easily be replaced with permeable pavements to achieve improved runoff conditions. Retrofit requires the removal of the old pavement and subgrade and the installation of the underlying reservoir layer and the permeable pavement. When possible, compacted subgrade soils should be removed or loosened to achieve the maximum infiltration rate possible.

Cold Climate Suitability

The effective use of permeable pavement has been documented in a variety of climates. However, special consideration is necessary for cold climates, arid regions, or areas with high wind erosion (California 2003). Dramatic reductions in life span of the infiltration properties of the pavement may occur in these areas due to particulate clogging. In cold climates like Minnesota, the most notably special consideration is regarding the application of sand in the winter for added traction. This is not recommended. Fortunately, permeable pavements require significantly less use of de-icing sand and chemicals to maintain a safe walking or driving surface.

Special Receiving Waters Suitability

Many of the same design considerations and limitations apply to permeable pavement as to other infiltration practices. Infiltration of runoff from hotspots (e.g., gas stations, chemical storage areas, etc.) should be carefully considered and in many cases avoided. Special consideration also needs to be taken near wellhead areas and basement foundations. Some designs may require consideration of storms in excess of the infiltration capabilities of the pavement. For these situations the design should ensure the excess runoff does not negatively impact special surface waters (e.g.,trout streams) through the implementation of additional BMPs.

Water Quality

In general, permeable pavement provides removal of TSS and other pollutants through processes similar to other filtration and infiltration BMPs. However, permeable pavements are not suggested for areas that may receive high loading rates of TSS due to their propensity for surface clogging. The expected annual volume and pollutant reductions for designs without an underdrain are a function of the underlying reservoir storage volume. The greater the storage volume, the greater the annual volume and pollutant reductions. If a system is designed to infiltrate the MIDS performance standard of 1.1 inches of runoff from the tributary impervious surfaces, it would result in a 91% annual runoff volume reduction from a site with hydrologic soil group (HSG) C soils (infiltration rate of 0.2 inches/hr). Annual pollutant load reductions for this example are approximately equal to the volume reduction. A site with HSG A soils (infiltration rate of 1.6 inches/hr) would result in higher annual reductions.

For designs with underdrains, the reductions are less because a portion of the water is captured by the underdrains before it can be infiltrated. Of the water intercepted and draining through the underdrain, 45% (with upper and lower 90% confidence bounds of 65% and 24%, respectively) of the total phosphorus and 74% (with upper and lower 90% confidence bounds of 93% and 33%, respectively) of total suspended solids removal can be expected.

Water Quantity

The primary advantage of permeable pavements is their ability to provide volume reduction by reducing runoff from a site and/or providing attenuation during runoff events. The volume of water that will be reduced during a given rainfall event will be equivalent to the volume available for storage below the pavement or underdrain (if an underdrain is present). More discussion on this item is available in the section on credits.