Construction stormwater best management practice – Stormwater Inlet Protection

The goal of stormwater inlet protection is to trap sediment from a construction site before it enters a storm sewer. This will keep sediment from being transported to lakes or streams and can also prevent clogging of the storm sewer caused by heavy sediment loads. A stormwater inlet refers to manholes, catch basins, curb inlets and other drop-type structures constructed to direct stormwater into storm sewers or other underground drainage systems. Inlet protection best management practices (BMPs) are fairly inexpensive, easy to construct, and if maintained properly can successfully reduce sediments from entering our waterways

Contents

What is required by the NPDES/SDS construction stormwater permit?

The NPDES/SDS construction stormwater permit requires that sediment control practices be utilized to minimize sediment from entering surface waters, curb and gutter systems and storm sewer inlets. The permit states that all storm drain inlets must be protected by appropriate BMPs throughout construction and until all sources with potential for discharging to the inlet have been stabilized.

The permit also requires that the inlet protection BMPs be inspected at least once every seven days and within 24 hours after a rainfall event greater than 0.5 inches in 24 hours. All nonfunctioning inlet protection BMPs must be replaced or repaired within 24 hours of discovery. For full details of the permit requirements, a copy of the NPDES/SDS construction stormwater permit is available online.

Planning considerations

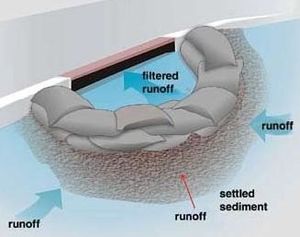

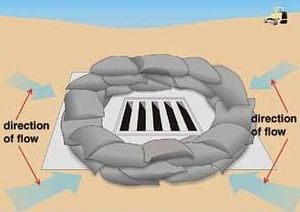

Inlet protection BMPs should be installed prior to any soil disturbance on a construction site where stormsewer systems are in place or BMPs should be installed as stormsewer systems are constructed and inlets begin collecting stormwater. The basic approach to inlet protection BMPs is to install a barrier around the inlet that ponds or filters the flow of stormwater resulting in the settling or filtration of sediment. It is important to note that ponding will occur behind the inlet protection BMPs and that regular maintenance is needed to remove sediment and prevent a safety hazard. Many different types of inlet protection BMPs exist and can be utilized depending on the field conditions and type of inlet.

Commonly used inlet protection BMPs include:

- Rock logs

- Compost logs

- Sediment control inlet hats

- Silt fence rings and rock filter combinations

- Pop-up head risers

- Filter bag inserts

- Sand or gravel bags

Additional commercial products are available. See Resources at the end of this factsheet for a link to the Minnesota Department of Transportation’s list of approved products.

Maintenance considerations

The effectiveness of inlet protection BMPs is greatly diminished if not maintained properly. After each rainfall, inlet protection should be inspected. Sediment collected around the inlet protection BMP should be regularly removed. Care should be taken to dispose of sediment in a location that is not susceptible to additional erosion.

If excess sediment clogs or blocks the inlet protection BMP, flooding may occur and cause a safety hazard or property damage. If significant ponding does occur around the inlet, inspect for any clogging that may be preventing proper drawdown. As soon as the contributing drainage area is stabilized, the inlet protection BMP should be removed.

Cold climate considerations

It is important to consider winter conditions when planning construction and designing inlet protection BMPs. Construction sites must comply with the NPDES/SDS permit throughout winter even if the site is idle and regular inspection of the inlet protection must continue throughout the winter months.

The most common problem with inlet protection BMPs in the winter is clogging due to ice build-up. Snow should be removed around the inlets when possible to prevent the snow from melting and freezing creating ice build-up. If ice build-up does occur, it is necessary to manually break-up the ice for removal or use steam to instigate melting. Under no circumstance should salt be used to remove the ice. Using salt adds unnecessary salt loads to the drainage system.

Drainage system inlet inserts and filters can become a potential source of freeze-up, especially if water does not drain immediately through the BMP. All BMPs used at inlets should have overflow assurance so that flow will by-pass a frozen fabric or natural material filter. Inspection and maintenance will often result in easy ice break-up when problems are quickly discovered.

Prior to the spring, site managers should inspect each of the inlets and undertake actions as necessary to assure unimpeded flow through the inlet protection BMPs.

Resources

Minnesota Department of Transportation (Mn/DOT) Approved Products List

MPCA Protecting Water Quality in Urban Areas – Manual

MPCA Stormwater Construction Inspection Guide

Small Business Environmental Assistance Program Compliance Calendar for Construction Stormwater