Construction stormwater practices - diversion and working in the dry

Working “in the dry” refers to the dewatering of areas where piers, abutments, bulkheads, retaining walls, or other structures must be built in areas with flowing or standing water (e.g., creeks, rivers, lakes, wetlands, etc.). Working in the dry typically involves the use of a diversion or cofferdam. Diversions are used to isolate a segment of stream via a pump-around, to facilitate work in the dry channel. A cofferdam is a temporary, watertight structure erected around a construction site to keep water from inundating the site during construction. Cofferdams can vary in design from simple earthen dikes to elaborate sheet piling structures. The construction area within the dam is pumped out or otherwise dewatered after the dam is built, and kept relatively dry until construction work is completed.

Temporary diversion methods can be divided into two groups of practices based on primary function: those which divert the entire stream or those which divert only part of the stream. Typical diversion practices in the former category include diversion channels/ditches, diversion pipes/culverts, and pumping (“pump-arounds”). The latter category (partial stream diversion) typically includes methods such as cofferdams and diversion dikes/ berms. These methods are not discussed extensively in this BMP chapter; please refer to Diversion barrier controls (cofferdams/temporary dikes) for a discussion on the use of cofferdams and diversion dikes/berms.

Contents

Purpose and function

Temporary stream diversion allows for “working in the dry” when construction projects are adjacent, below, or within surface waters. They collect and redirect the flow of a stream using a new channel, pipe, or similar practice to allow a relatively dry working space for construction activities that require these conditions. In addition to restricting flows from entering the construction zone, diversion methods prevent sediment and other construction-related contaminants from entering the stream during construction activities by routing upstream flows around the active construction zone.

Applicability

Temporary diversion methods apply when relatively dry conditions are required for construction activities adjacent, below, or within surface waters and it is necessary to divert flow around the work zone to maintain “dry” conditions. Temporary diversion methods vary based on the size of the waterway being diverted, as discussed below.

Site applicability

Stream diversions are typically used for constructing, removing, or performing maintenance of large structures or other projects located within the stream channel. Examples of these situations include the construction of dams, detention ponds, instream grade control, installation of pipelines and other utilities, stream bank restoration and protection, and maintenance of existing structures.

For large streams, temporary diversion methods typically consist of the use of structures such as berms or cofferdams to divert flow to one side of the stream (“partial diversion”) and allow dry conditions on the other side. For smaller streams, temporary diversions such as lined ditches, pipes, and pumping may be used to divert the entire waterway.

Selection of the appropriate diversion type is highly site specific. The best temporary diversion method for a site is that which meets the needs of the project while minimizing site disturbance. The table below summarizes several common temporary diversion practices, the conditions in which they typically apply, and limitations of use.

Typical diversion methods for working in the dry and their applicability.

Link to this table

| Diversion practice | Applicability | Limitations |

|---|---|---|

| Partial stream diversion |

|

|

| Diversion channels/ditches |

|

|

| Piped diversions/ culverts (bypass pipe) |

|

|

| Pumped diversions (“pump-arounds”) |

|

|

Permit applicability

The MPCA Construction Stormwater General Permit does not include provisions that specifically reference “diversion”; however, there are several sections that are applicable to Diversion and Working in the Dry, including the following:

- Regarding connection of drainage channels to surface waters, Section 8.6 states: “Permittees must stabilize the normal wetted perimeter of the last 200 linear feet of temporary or permanent drainage ditches or swales that drain water from the site within 24 hours after connecting to a surface water or property edge. Permittees must complete stabilization of remaining portions of temporary or permanent ditches or swales within 14 calendar days after connecting to a surface water or property edge and construction in that portion of the ditch temporarily or permanently ceases.”

- Regarding dewatering of diversions, Section 10.2 states: “Permittees must discharge turbid or sediment-laden waters related to dewatering or basin draining (e.g., pumped discharges, trench/ditch cuts for drainage) to a temporary or permanent sediment basin on the project site unless infeasible. Permittees may dewater to surface waters if they visually check to ensure adequate treatment has been obtained and nuisance conditions (see Minn. R. 7050.0210, subp. 2) will not result from the discharge. If permittees cannot discharge the water to a sedimentation basin prior to entering a surface water, permittees must treat it with appropriate BMPs such that the discharge does not adversely affect the surface water or downstream properties.”

- Further, Section 10.4 adds: “Permittees must discharge all water from dewatering or basin-draining activities in a manner that does not cause erosion or scour in the immediate vicinity of discharge points or inundation of wetlands in the immediate vicinity of discharge points that causes significant adverse impact to the wetland.”

- Regarding impacts to receiving water quality, Section 15.2 states: “Permittees must design the project so all stormwater discharged from the project during and after construction activities does not cause a violation of state water quality standards (see here), including nuisance conditions, erosion in receiving channels or on downslope properties, or a significant adverse impact to wetlands caused by inundation or decrease of flow.”

The U.S. Army Corps of Engineers (USACE) requires a permit for any work performed in navigable waters. Refer to 33 CFR Parts 321 and 322 for additional information and applicability.

A Public Waters Work Permit may also be required from the MN DNR, depending on the project scope. Link here for additional information.

Effectiveness

Properly designed and installed diversions are effective at keeping sediment out of the adjacent waterbody. Where temporary drainage ditches/channels are used to dewater or divert a waterbody, special attention is required to ensure that bare soil along the bypass ditch or channel is stabilized. Careful installation and removal of the diversion structure and restoration of the work area are required to ensure effectiveness.

Expected performance benefits for diversion and working in the dry.

Link to this table

| Water quantity | |

|---|---|

| Flow attenuation | Little or no design benefit |

| Runoff volume reduction | Little or no design benefit |

| Water quality | |

| Soil erosion | Primary design benefit |

| Sediment control | Little or no design benefit |

| Nutrient loading | Little or no design benefit |

| Pollutant removal | |

| Total suspended solids | Little or no design benefit |

| Total phosphorus | Little or no design benefit |

| Heavy metals | Little or no design benefit |

| Floatables | Little or no design benefit |

| Oil and grease | Little or no design benefit |

Planning considerations

Considerations for diversion method selection and approach

The selection of appropriate methods for temporary diversion should be approached on a project and site-specific basis. Prior to designing a stream diversion, determine if the construction of a temporary diversion might cause a greater environmental impact than if the project were constructed without the diversion. For short-term projects constructed during dry periods, construction of the diversion may cause more site disturbance than all other earth disturbing activities of the project and could result in a large percentage of the overall project costs. Planning for temporary diversion methods should include the following considerations.

- Verify that applicable permits have been obtained before the diversion is installed

- Plan the timing of construction to minimize the time that a temporary diversion is needed

- Consider stream size and anticipated flow rates during construction

- Determine type of surface water (e.g., special water, impaired water, trout stream, trout lake, etc.)

- Determine weather patterns and seasonal variations in stream flow

- Identify potential impacts of failure, including impacts to

- public safety

- the environment

- project schedule and budget

- Legal considerations including right-of-way and private property lines

Whenever planning for working in the dry, project designers, construction engineers, project managers and/or contractors should contact their local DNR office for help in selecting the appropriate diversion method(s) for their construction activity and location. Additional considerations for special or impaired waters are discussed below

Considerations for special or impaired waters

MPCA requires increased water quality protection measures on projects located within one mile of waters designated special and/or impaired waters. Check the interactive map called “Special Waters and Impaired Waters Search” to determine if your project is located near a special or impaired water. NPDES/SPS permits from MPCA for construction sites near specially-protected and impaired waters require additional controls, conditions, or an individual permit, including:

- Sites that discharge near waters with qualities that warrant extra protection (special waters) must use additional best management practices and enhanced runoff controls.

- Sites that discharge near an “impaired water,” impaired for phosphorus, turbidity, dissolved oxygen, and biotic impairment, must meet special conditions during project design and/or when preparing a Stormwater Pollution Prevention Plan (SWPPP), or a Construction Stormwater permit application.

Failure to incorporate increased protection measures on special and/or impaired waters could be a violation of MPCA standards (Minnesota DNR Best Practices Manual, 2014).

Design

Care should be taken during the design phase to ensure that construction and operation of the temporary diversion will avoid or minimize any damage to the waterway, aquatic and terrestrial habitat, and aquatic life. At all times during construction, operation, maintenance, and removal, sufficient water flow/volume must be diverted to sustain downstream aquatic life. The diversion structure should not constrict stream flow such that backups or washouts occur due to fluctuations in water depth or flow volume. Temporary berms or dams should be installed upstream and downstream of the work site to block stream flow from entering the construction site.

The timing and duration of construction activities are key factors for determining the appropriate design flow for stream diversion design. Improperly sized diversion methods can result in increased project costs, loss of water quality benefits, and increased erosion.

The design capacity of the temporary stream diversion should take into account the length of time the diversion will be in use. If high flows or flood hazards are anticipated during the operation of the diversion, capacity should be increased to prevent failure and erosion of the diversion practice.

Piped diversions

For piped diversions, the pipe should be sized to safely convey, at a minimum, the 2-year, 24-hour design storm, or anticipated high-flow conditions if applicable. The temporary pipe should be constructed from durable material, such as High-density polyethylene (HDPE), that can withstand the anticipated site conditions. Provide energy dissipation at the downstream end of the diversion pipe.

Pumped diversions

For pumped diversions, size the pump based on the anticipated flow. At a minimum, the pump should be able to pump a 2-year, 24-hour event. A second pump of the same size is recommended to provide redundancy in the event of pump failure, or in case of increased pumping requirements.

When operating a pumped diversion, pump water from upstream of the construction area to the existing downstream channel. The intake must be screened to prevent fish and other aquatic species from becoming entrained. Stabilize the pump outlet location to prevent erosion.

Channel diversions

Temporary stream diversion channels should have trapezoidal cross-sections with side slopes no steeper than 2:1 (horizontal to vertical). Size the channel based on the anticipated flow. Excavated material can be stored along the banks of the temporary ditch for short-term applications; longer term use or use where soil berms may create drainage or environmental hazards may require stockpiling away from the site. As noted in “Effectiveness”, if a diversion ditch or channel is used, bare soil along the channel should be stabilized using a material appropriate for the expected velocity to prevent erosion of the channel and sedimentation of the stream. This is critical when ditched diversions are installed in highly erodible soils, such as silts. Inspect soils along the upslope areas to determine stability, and seed, mulch, or otherwise stabilize areas that may erode into the temporary ditch. The table below provides guidelines for stream diversion channel lining material based on expected velocity, drainage area, and design storm. Note that the use of other materials may be also be appropriate but should be evaluated on a site by site basis.

Recommendations for temporary stream diversion channel lining.

Link to this table

| Lining material | Acceptable velocity range | Upstream drainage area | Design storm capacity |

|---|---|---|---|

| Erosion control blanket1 | Up to 1.5 ft/sec | Up to 1 sq. mi. | 2-year, 24-hour |

| Turf reinforcement mat (non-vegetated)2 | Up to 8.0 ft/sec | Up to 1 sq. mi. | 2-year, 24-hour |

| Geotextile (Type 1) | Up to 11 ft/sec | Up to 1 sq. mi. | 2-year, 24-hour |

| Riprap with geotextile | |||

| Average 4” (3” – 6”) | Up to 4 ft/sec | Up to 5 sq. mi. | 10-year, 24-hour |

| Average 8” (4” – 12”) | Up to 6 ft/sec | ||

| Average 14” (5” – 18”) | Up to 13 ft/sec | ||

| Plastic sheeting3 | > 13 ft/sec | Up to 2 sq. mi. | 2-year, 24-hour |

1 Only for use with intermittent, low flows. Vegetation should be established when using as a channel lining.

2 TRM with temporary seeding may be used when sufficient time is available for the diversion channel to vegetate. The acceptable velocity for vegetated TRMs should not exceed 16 ft/sec.

3 Do not use where woody and other heavy debris moves with flow. Use thicker sheeting for longer runs, or when used for more than six months.

Construction recommendations and specifications

Whenever a temporary diversion is used, construction should be scheduled during drier times of the year (e.g., November to March), during periods of low or no stream flow, to the extent practicable. Construction in the waterway should progress as quickly as practical to reduce the risk of exceeding the temporary diversion capacity.

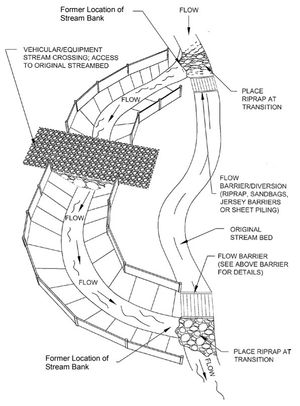

Prior to starting construction, install erosion and sediment control devices to prevent sediment from entering the diversion or the stream. This should include stabilization of the inlet and outlet of the temporary stream diversion using approved techniques such as riprap over geotextile. The temporary stream diversion should be properly stabilized prior to accepting flows. Install instream diversion dams/berms at the upstream and downstream ends of the work area.

When constructing a diversion channel or ditch, contain the stream with appropriate methods such as sandbags on the opposing bank while cutting the diversion channel into the natural stream channel. Excavate and stabilize the diversion channel as a continuous operation. Remove large debris (e.g., rocks, sticks, etc.) and smooth the channel surface so that the channel lining material rests flush with the channel.

During construction, minimize disturbance and removal of adjacent (riparian) vegetation. Ensure that any construction vehicles and equipment are free of petroleum residues and sealed to prevent leakage of fuels and oils into the water body. The main body of the construction equipment may not enter the water body except if necessary to cross the stream to access the work site; only the bucket of an excavator/backhoe may operate in the water body.

When dewatering construction areas adjacent to stream diversions, dewatering discharge must not negatively impact water quality or cause erosion or temporary sedimentation in the stream or the temporary diversion. Do not discharge dewatering from the construction site directly to the stream. For appropriate methods, see Dewatering.

Detailed guidance on planning and executing projects within and adjacent to waterbodies can be found in the Minnesota DNR’s Best Practices Manual (Best Practices for Meeting DNR General Public Waters Work Permit GP 2004-0001), Chapter 3: Methods of In-Water Construction.

Inspection and maintenance

Temporary diversions are critical for work in waterways and must therefore be inspected and maintained frequently to ensure they function as designed. The following general inspection and maintenance recommendations apply to all temporary diversion methods.

- Ensure that bypass pump(s) can handle incoming flows, especially after precipitation or periods of rapid snowmelt.

- Inspect flow barriers (dams, berms, etc.) at the start and end of each work day and if excess water is observed in work areas that are supposed to be dry. Inspect for leakage and repair.

- Inspect diversion structures at least weekly and after significant rain events to check for buildup of sediment and debris and remove as needed.

- Inspect diversion channels for signs of erosion, and repair or replace lining as necessary.

- Inspect pumped and piped diversions to ensure flow is adequately diverted. Inspect for leakage and repair as necessary.

- Inspect the diversion path for erosion and repair any damages with rock, gravel, or other appropriate methods.

- Inspect the diversion discharge point for erosion and repair as necessary.

- Inspect dewatering device(s) and ensure that discharge is not sediment laden.

Temporary diversion removal

The temporary stream diversion should be removed as soon as practicable and only after construction is complete and the work site and existing stream channel have been stabilized. Do not remove the downstream diversion until all sediment-laden water from the upstream diversion has been filtered through an approved sediment filtering device such as a dewatering basin or filter bag. If using a temporary diversion channel, remove the lining material and then fill and stabilize the channel using appropriate erosion control practices. Stabilize the points of tie-in to the existing stream channel using riprap or other appropriate methods. After removing the diversion, revegetate any area disturbed by the removal.

Costs

Temporary diversion method selection and approach should occur on a project and site-specific basis. Therefore, costs for construction of temporary stream diversions may vary widely depending on the type of structure, the intended purpose, and the size and nature of the stream being diverted. The following table summarizes some example estimated BMP costs based on MnDOT data summarizing average bid prices for awarded projects in 2017.

Unit costs related to diversion and working in the dry

Link to this table

| Bid Item | Item Description | Units | Average Price |

|---|---|---|---|

| 2105601/00045 | Temporary stream diversion system | lump sum | $27,523.34 |

| 2452601/00011 | Steel sheet piling (temporary) | lump sum | $31,747.97 |

| 2452618/00011 | Steel sheet piling (temporary) | square foot | $37.64 |

Reference materials

Except where more stringent requirements are presented in this guidance, BMPs shall comply with MnDOT and other state requirements. Primary design references include:

- 2018 Minnesota NPDES/SDS Construction Stormwater General Permit

- 2018 MnDOT Standard Specifications for Construction

- Best Practices for Meeting DNR General Public Waters Work Permit GP 2004-0001, version 4 (October 2014) (Chapter 3)

- MnDOT Erosion Control Handbook II

The following is a list of additional resources that are not specific to Minnesota:

- District of Columbia Erosion and Sediment Control Manual (Chapter 8)

- Illinois Urban Manual (2011) (Practice Standard 976: Temporary Stream Diversion)

- UDFCD Urban Storm Drainage Criteria Manual (USDCM), Volume 3 Stormwater Quality (2010) (SM-8)

Related pages

- Erosion prevention practices

- Erosion prevention practices - temporary seeding and stabilization

- Erosion prevention practices - natural and synthetic mulches

- Erosion prevention practices - tackifiers and soil stabilizers

- Erosion prevention practices - erosion control blankets and anchoring devices

- Erosion prevention practices - turf reinforcement mats

- Erosion prevention practices - Riprap

- Sediment control practices

- Sediment control practices - Vehicle tracking BMPs

- Sediment control practices - Perimeter controls for disturbed areas

- Sediment control practices - Check dams (ditch checks, ditch dikes)

- Sediment control practices - Diversion barrier controls (cofferdams/temporary dikes)

- Sediment control practices - Storm drain inlet protection

- Sediment control practices - Outlet energy dissipation

- Sediment control practices - Sediment traps and basins

- Sediment control practices - Stabilized earth/soil berm

- Construction stormwater treatment - dewatering, including chemical treatment and sediment filtration

- Construction stormwater best management practice – buffer zones

- Other practices

This page was last edited on 2 February 2023, at 12:59.