Erosion prevention practices - erosion control blankets and anchoring devices

Erosion control blankets (ECBs) are typically biodegradable, open-weave blankets that provide temporary cover and support for establishing vegetation on bare soil areas.

Contents

Purpose and function

ECBs provide cover for bare soil and support for emergent vegetation (i.e., typically grass) from the time of seeding until root density and top growth are capable of long-term erosion protection. ECBs function by shielding bare soil and newly seeded areas against raindrop and wind erosion, providing a dense matrix of biodegradable material (e.g., straw, coconut) that stabilizes and supports emergent vegetation and later decomposes to further aid in plant growth. They also help to increase precipitation infiltration and decrease soil crusting and compaction. ECBs are designed and fabricated in a variety of types that last from a few months to approximately three years. Temporary ECBs can be grouped into categories based on functional longevity (Erosion Control Technology Council; see Table 1, page 5)

- Category 1: Ultra short-term – typically 3 months

- Category 2: Short-term – typically 12 months

- Category 3: Extended term – typically 24 months

- Category 4: Long-term – typically 36 months

Applicability

Degradable ECBs are appropriate for any bare soil area where temporary protection from raindrop and wind erosion is needed, or where newly seeded grass requires short-term cover and support prior to germination, early growth, and full establishment.

Site applicability

ECBs are typically used where vegetation requires only temporary support for establishment, such as flat upland areas and slopes less than 4H:1V. They are also effective in establishing vegetation on relatively flat shoreline areas, swales, ditches, and athletic fields, or grassy areas that will be mowed closely such as places where longer term plastic netting may cause a tripping hazard or be pulled up later by equipment. ECBs can also be used as temporary cover for small bare areas that are idle for a few weeks (i.e., time periods too long to remain unprotected, but too short to seed). In these cases, blankets can be unrolled on bare portions of the site for a short period, removed when work commences, and reused.

ECBs can be especially useful for establishing permanent vegetation on slopes 2H:1V or greater. They are generally effective for slopes up to 1.5H:1V, but may be used for slopes as steep as 1H:1V. Manufacturer specifications should be consulted to verify that the selected ECB is appropriate for the site’s slope conditions.

Permit applicability

The MPCA Construction General Permit has several requirements regarding temporary stabilization. See Section 8.

- Permittees must stabilize all exposed soil areas, including stockpiles. Stabilization must be initiated immediately to limit soil erosion when construction activity has permanently or temporarily ceased on any portion of the site and will not resume for a period exceeding 14 calendar days. Stabilization must be completed no later than 14 calendar days after the construction activity has ceased. Stabilization is not required on constructed base components of roads, parking lots and similar surfaces. Stabilization is not required on temporary stockpiles without significant silt, clay or organic components (e.g., clean aggregate stockpiles, demolition concrete stockpiles, sand stockpiles) but must provide sediment controls at the base of the stockpile.

- For Public Waters that the Minnesota DNR has promulgated "work in water restrictions" during specified fish spawning time frames, permittees must complete stabilization of all exposed soil areas within 200 feet of the water's edge, and that drain to these waters, within 24 hours during the restriction period.

- Other permit requirements exist during the construction of post-construction/permanent stormwater and temperature control BMPs discharging to special waters and impaired waters. In those cases, Permittees must immediately initiate stabilization of exposed soil areas, as described in item 8.4, and complete the stabilization within seven (7) calendar days after the construction activity in that portion of the site temporarily or permanently ceases.

- Finally, it shall be noted that stabilization requires more than seed alone. Section 25 of the 2018 MPCA Construction Stormwater General Permit states: "Stabilize", "Stabilized", "Stabilization" means the exposed ground surface has been covered by appropriate materials such as mulch, staked sod, riprap, erosion control blanket, mats or other material that prevents erosion from occurring. Grass seeding, agricultural crop seeding or other seeding alone is not stabilization. Mulch materials must achieve approximately 90 percent ground coverage (typically 2 ton/acre). [Minn. R. 7090].

ECBs provide a quick, effective, and economical approach for stabilizing areas that need very short-term protection – for a few weeks or months, where temporary seeding may not be warranted.

Effectiveness

ECBs are effective in reducing rill, sheet, and wind erosion of bare soil on a range of situations, including slopes, swales, ditches, channels, and shore areas. Although their erosion reduction performance is generally 90 percent or more, their ultimate effectiveness is dependent upon the quality of surface preparation, installation methods (i.e., soil contact, staking pattern), and site conditions (e.g., slopes, soils, rainfall, etc.). The following table summarizes expected performance for an array of typical water quantity and quality target constituents for erosion control blankets.

Expected performance for erosion control blankets

Link to this table

| Flow attenuation | Little or no design benefit |

| Runoff volume reduction | Little or no design benefit |

| Pollution prevention | |

| Soil erosion | Primary design benefit |

| Sediment control | Little or no design benefit |

| Nutrient loading | Primary design benefit |

| Pollutant removal | |

| Total suspended solids | Primary design benefit |

| Total phosphorus | Primary design benefit |

| Heavy metals | Secondary design benefit |

| Floatables | Little or no design benefit |

| Oil and grease | Little or no design benefit |

Planning considerations

Most ECB manufacturers readily provide information regarding their product’s performance, design specifications, slope/channel limits, longevity in the field (i.e., 3 months to 3 years), and other supporting data. ECBs should be selected based on site conditions. For example, products designed for flatter slopes will not perform adequately on steeper slopes, and using a blanket intended to last for three months on a slope where a full growing season is needed to establish dense vegetative cover will likely result in failure. Some higher longevity products may interfere with wildlife movement or habitat. The Minnesota DNR provides additional information on wildlife-friendly erosion control. The current list of MnDOT approved/qualified products for ECBs can be found on MnDOT's website.

ECBs should be installed as soon as possible after seeding is completed. Make sure all labor, tools, materials, and equipment (workers, blankets, stakes or staples, trencher, mallets, knives or shears, etc.) are on hand and ready when installation commences. Check site square footage vs. blanket coverage area to ensure sufficient blanket quantities. For long slopes, ensure equipment access to the top of the slope so that blankets can be unrolled from top to bottom. Try to complete installation over all seeded areas in one operation if possible. Divert upland runoff away from the seeded/blanketed area if possible.

Design

ECBs are constructed of various degradable organic and/or synthetic materials (e.g., straw, wood excelsior, coconut, polypropylene) that are woven, glued or structurally bound with nettings or meshes. Components are stitched or glued together, or into/between biaxially oriented process nettings or woven natural fiber nettings. Alternations in the fiber, netting and bonding components can instill various degrees of blanket effectiveness, durability, and functional longevity. Blankets should be of uniform thickness, with the material fibers evenly distributed over the area of the blanket. The blankets should be porous enough to promote plant growth yet shield the underlying soil surface from erosion. All material should have been properly cured to achieve curled and barbed fibers, and blankets should be smolder resistant.

The net backing on each blanket should consist of cotton string or polypropylene mesh. For Category 1 blankets, the net backing should start to decompose after one month with 80 percent breakdown occurring within three months. For Category 2 and 3 blankets, the netting should contain sufficient UV stabilization for breakdown to occur within a normal growing season. For Category 4, the netting should be UV stabilized to provide a service life of two to three years. For blankets designated as “netting on two sides,” the fiber material should be sandwiched between a top and a bottom layer of net backing. The fiber material in each blanket should be securely attached to the net backing to prevent movement of the fiber.

The staples used to anchor Category 1 and 2 blankets should be U shaped, 11 gauge or heavier steel wire, having a span width of 1 inch and a length of 6 inches or more from top to bottom after bending. Staples used to anchor Category 3 and 4 blankets should have a minimum length of 8 inches. Wooden and other biodegradable stakes are recommended for areas where stray metal may cause problems. Spacing and patterns for staking vary according to each specific site – for example, closer staking patterns are required for steep slopes, ditches, channels, and shorelines. Regardless, all installations must meet or exceed minimum manufacturer’s requirements regarding slope/channel applications, staking patterns, and other factors to achieve their specified effectiveness.

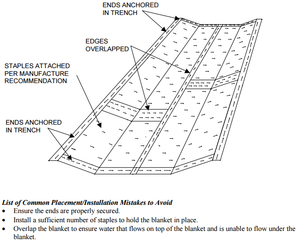

Considerations for effective installation of ECBs includes the following.

- Grade, clean, and seed the area first; install ECBs within 24 hours of seeding for best results.

- Anchor blanket at the top of the slope in a 6-inch slot on the contour, backfill, and compact.

- Install with netting on top, with majority of thread stitching on the bottom.

- Unroll from upslope to downslope, overlapping ends of the upslope roll at least 7 inches over the downslope roll. Overlap adjacent sides by at least 4 inches.

- Ensure blankets lie flat with good contact on the soil, with no bulges; do not stretch blankets.

- For channels, anchor blankets in a 6-inch backfilled slot at the top of the banks.

- Shingle and overlap edges parallel to the water flow by at least 4 inches.

- Overlap edges perpendicular to the water flow by at least 7 inches.

- For high velocity ditches and channels, space stakes at 1.5 feet below the waterline.

- Staple every 3 feet on flatter slopes, and every 2 feet below flow lines in ditches and channels.

- Use longer anchors in loose soil; use degradable stakes instead of metal staples near runways.

- For slopes steeper than 2H:1V and longer than 100 feet, and for ditches with slopes greater than 10H:1V, use 6 inch check slots every 100 feet on the contour / across the channel.

Standards and specifications

MnDOT Specification 2575.3 part G.2 (page 506) provides guidance for placement of erosion control blankets, including the following.

- Table 2575-2 summarizes requirements for stapling of blankets.

- Part K.2 (page 507, 508) covers maintenance of rolled erosion control products.

- Specification 2575.4.I (page 511) prescribes requirements for measurement of rolled erosion control products.

- ECBs should meet Specification 3885 (“Rolled Erosion Control Products”; page 679).

- Table 3885-1 summarizes acceptable types of rolled erosion control products.

- Tables 3885-2, 3885-3, and 3885-4 summarize physical requirements for rolled erosion control products by category.

- Table 3885-5 summarizes specifications for blanket anchors.

The Erosion Control Technology Council developed standard specifications for erosion control blankets and mulch control nets. Their work is summarized in the following table.

Erosion Control Technology Council standard specifications for erosion control blankets and mulch control nets

Link to this table

| Type | Product Description | Material Composition | Slope Applications* | Channel Applications* | Minimum Tensile Strength 1 | |

|---|---|---|---|---|---|---|

| Maximum Gradient | C Factor 2, 5 | Permissible Shear Stresss 3, 4, 6 | ||||

| ULTRA SHORT-TERM - Typical 3 month functional longevity | ||||||

| 1.A | Mulch Control Nets | A photodegradable synthetic mesh or woven biodegradable natural fiber netting. | 5:1 (H:V) | < 0.10 @ 5:1 | = 0.25 lbs/ft2 (12 Pa) | 5 lbs/ft (0.073 kN/m) |

| 1.B | Netless Rolled Erosion Control Blankets | Natural and/or polymer fibers mechanically interlocked and/or chemically adhered together to form a RECP. | 4:1 (H:V) | < 0.10 @ 4:1 | = 0.5 lbs/ft2 (24 Pa) | 5 lbs/ft (0.073 kN/m) |

| 1.C | Single-net Erosion Control Blankets & Open Weave Textiles | Processed degradable natural and/or polymer fibers mechanically bound together by a single rapidly degrading, synthetic or natural fiber netting or an open weave textile of processed rapidly degrading natural or polymer yarns or twines woven into a continuous matrix. | 3:1 (H:V) | < 0.15 @ 3:1 | = 1.5 lbs/ft2 (72 Pa) | 50 lbs/ft (0.73 kN/m) |

| 1.D | Double-net Erosion Control Blankets | Processed degradable natural and/or polymer fibers mechanically bound together between two rapidly degrading, synthetic or natural fiber nettings. | 2:1 (H:V) | < 0.20 @ 2:1 | = 1.75 lbs/ft2 (84 Pa) | 75 lbs/ft (1.09 kN/m) |

| SHORT-TERM - Typical 12 month functional longevity | ||||||

| 2.A | Mulch Control Nets | A photodegradable synthetic mesh or woven biodegradable natural fiber netting. | 5:1 (H:V) | < 0.10 @ 5:1 | = 0.25 lbs/ft2 (12 Pa) | 5 lbs/ft (0.073 kN/m) |

| 2.B | Netless Rolled Erosion Control Blankets | Natural and/or polymer fibers mechanically interlocked and/or chemically adhered together to form a RECP. | 4:1 (H:V) | < 0.10 @ 4:1 | = 0.5 lbs/ft2 (24 Pa) | 5 lbs/ft (0.073 kN/m) |

| 2.C | Single-net Erosion Control Blankets & Open Weave Textiles | An erosion control blanket composed of processed degradable natural or polymer fibers mechanically bound together by a single degradable synthetic or natural fiber netting to form a continuous matrix or an open weave textile composed of processed degradable natural or polymer yarns or twines woven into a continuous matrix. | 3:1 (H:V) | < 0.15 @ 3:1 | = 1.5 lbs/ft2 (72 Pa) | 50 lbs/ft (0.73 kN/m) |

| 2.D | Double net Erosion Control Blankets | Processed degradable natural and/or polymer fibers mechanically bound together between two degradable, synthetic or natural fiber nettings. | 2:1 (H:V) | < 0.20 @ 2:1 | = 1.75 lbs/ft2 (84 Pa) | 75 lbs/ft (1.09 kN/m) |

| EXTENDED-TERM - Typical 24 month functional longevity | ||||||

| 3.A | Mulch Control Nets | A slow degrading synthetic mesh or woven natural fiber netting. | 5:1 (H:V) | < 0.10 @ 5:1 | = 0.25 lbs/ft2 (12 Pa) | 25 lbs/ft (0.36 kN/m) |

| 3.B | Erosion Control Blankets & Open Weave Textiles | An erosion control blanket composed of processed slow degrading natural or polymer fibers mechanically bound together between two slow degrading synthetic or natural fiber nettings to form a continuous matrix or an open weave textile composed of processed slow degrading natural or polymer yarns or twines woven into a continuous matrix. | 1.5:1 (H:V) | < 0.25 @ 1.5:1 | = 2.00 lbs/ft2 (96 Pa) | 100 lbs/ft (1.45 kN/m) |

| LONG-TERM - Typical 36 month functional longevity | ||||||

| 4 | Erosion Control Blankets & Open Weave Textiles | An erosion control blanket composed of processed slow degrading natural or polymer fibers mechanically bound together between two slow degrading synthetic or natural fiber nettings to form a continuous matrix or an open weave textile composed of processed slow degrading natural or polymer yarns or twines woven into a continuous matrix. | 1:1 (H:V) | < 0.25 @ 1:1 | = 2.25 lbs/ft2 (108 Pa) | 125 lbs/ft (1.82 kN/m) |

* C factor and shear stress for Types 1.A., 2.A. and 3.A mulch control nettings must be obtained with netting used in conjunction with pre-applied mulch material.

1 Minimum Average Roll Values when tested in the machine direction using ECTC Modified ASTM D 5035.

2 C Factor calculated as ratio of soil loss from RECP (rolled erosion control product) protected slope (tested at specified or greater gradient, h:v) to ratio of soil loss from unprotected (control) plot in large-scale testing. These performance test values should be *supported by periodic bench scale testing under similar test conditions using ECTC Test Method # 2.

3 Minimum shear stress RECP (unvegetated) can sustain without physical damage or excess erosion > 12.7 mm(0.5 in) soil loss] during a 30-minute flow event in large-scale testing. These performance test values should be *supported by periodic bench scale testing under similar test conditions and failure criteria using ECTC Test Method #3.

4 The permissible shear stress levels established for each performance category are based on historical experience with products characterized by Manning's roughness coefficients in the range of 0.01 - 0.05.

5 Acceptable large-scale test methods may include ASTM D6459 or other independent testing deemed acceptable by the engineer.

6Acceptable large-scale testing protocol may include ASTM D6460 or other independent testing deemed acceptable by the engineer.

Inspection and maintenance

Inspect the erosion control blanket (ECB) installation site immediately after seeding to verify seed coverage. The site must be relatively smooth and free of rocks larger than 2 inches, sticks, protruding roots, clumps of vegetation, trash, and debris. Inspect the ECB after installation, checking staking patterns, anchor slot backfill, soil contact, overlaps, and proper shingling (i.e., upslope ECB edges lap over the downslope blanket edge). Pay particular attention to installations on long steep slopes and below the waterline in ditches and channels.

Flag off the area after installation to keep equipment, vehicles, and foot traffic off ECBs. Inspect ECBs weekly after installation, and within 24 hours after each rainfall of ½ inch or more. Look for “pulls” or sags on steep slopes, where the weight of precipitation clinging to the ECB is pulling the blanket downhill, away from its anchor slot(s) and staples. Check for areas where overlaps are pulled apart, or become flipped up by runoff or animals. If protected species of animals are present, look for areas where burrowing or crawling animals may be trapped by higher longevity blankets. The figure to the left illustrates the proper installation technique for ECBs. The photo to the right shows an example of blanket failure.

ECBs should be maintained until vegetation is established. It may be necessary to irrigate blankets and underlying seed during long dry periods to ensure seed germination and growth. Use at least 3,000 gallons per acre, and apply irrigation water during cloudy periods or in the evening, if possible, to avoid excessive evaporation.

If bulges appear due to emerging seedlings pushing the blanket off the ground, the problem is likely a result of improper staking or stapling. Install additional stakes 1.5 feet apart in the bulge areas as soon as possible so that the grass can find its way through the blanket.

If sagging occurs, install longer anchors on a closer pattern as soon as possible. Use scissors or shears to cut out bulges or large sags, then stake the area securely. If necessary, use hand scattered straw and mulch control netting for spot repairs.

Where animal species are being trapped or hindered by higher longevity blankets, consider using a shorter-term blanket and replacing it after a few months, if necessary. Otherwise, replace the ECB in the problem area(s) with sod, straw, or hydromulch.

MnDOT’s workmanship and rework schedule (2016; version under development at the time of manual update) identifies common deficiencies for various types of stabilization BMPs – including ECBs – and corrective actions for these deficiencies. Once complete, the full, final version of this table will replace Table 2575-4 in MnDOT Standard Specifications for Construction (2016 edition).

Excerpt from Table 2575-4 Required Corrective Action

Link to this table

| Item | Corrective Action Required if: | Corrective action |

|---|---|---|

| Erosion control blankets and mats |

|

|

Costs

The following table summarizes estimated BMP costs based on MnDOT data summarizing average bid prices for awarded projects in 2014.

Average erosion control blanket bid prices for Specification Year 2014

Link to this table

| Bid Item | Item Description | Units1 | Average Price |

|---|---|---|---|

| 2575.523/00009 | Erosion Control Blankets Category 0 | SY2 | $2.39 |

| 2575.523/00011 | Erosion Control Blankets Category 1 | SY | $1.31 |

| 2575.523/00012 | Erosion Control Blankets Category 2 | SY | $1.02 |

| 2575.523/00013 | Erosion Control Blankets Category 3 | SY | $1.50 |

| 2575.523/00014 | Erosion Control Blankets Category 4 | SY | $1.75 |

| 2575.523/00015 | Erosion Control Blankets Category 5 | SY | $1.65 |

| 2575.523/00016 | Erosion Control Blankets Category 6 | SY | $2.90 |

| 2575.519/00010 | Disk Anchoring | SY | $0.02 |

1 To convert to a per acre cost, multiple by 4840

2 SY = square yard

Reference materials

Except where more stringent requirements are presented in this guidance, BMPs shall comply with MnDOT and other state requirements. Primary design references include the following.

- MnDOT Erosion Control Handbook II

- Minnesota Urban Small Sites Best Management Practice Manual (Mulches, Blankets and Mats)

- 2018 Minnesota NPDES/SDS Construction Stormwater General Permit

- MnDOT Standard Specifications for Construction (2016 Edition)

The following is a list of additional resources that are not specific to Minnesota.

- Clark County Washington Stormwater Manual (BMP C122: Nets and Blankets)

- Clean Water Services Erosion Prevention and Sediment Control Manual (4.1.3 Ground Cover, 4.1.5 Matting)

- Kentucky Division of Water Best Management Practices (BMPs) for Controlling Erosion, Sediment, and Pollutant Runoff from Construction Sites – Planning and Technical Specifications Manual

- North Carolina Erosion and Sediment Control Planning and Design Manual (6.17 Rolled Erosion Control Products, 6.18 Compost Blankets)

- Tennessee Department of Environment and Conservation (TDEC) Erosion and Sediment Control Handbook (7.11 Rolled Erosion Control Products)

- Virginia Erosion and Sediment Control Handbook (3.36 Soil Stabilization Blankets and Matting)

- United States Department of Agriculture – Forest Service. Erosion Control Treatment Selection Guide

Related pages

- Erosion prevention practices

- Erosion prevention practices - temporary seeding and stabilization

- Erosion prevention practices - natural and synthetic mulches

- Erosion prevention practices - tackifiers and soil stabilizers

- Erosion prevention practices - erosion control blankets and anchoring devices

- Erosion prevention practices - turf reinforcement mats

- Erosion prevention practices - Riprap

- Sediment control practices

- Sediment control practices - Vehicle tracking BMPs

- Sediment control practices - Perimeter controls for disturbed areas

- Sediment control practices - Check dams (ditch checks, ditch dikes)

- Sediment control practices - Diversion barrier controls (cofferdams/temporary dikes)

- Sediment control practices - Storm drain inlet protection

- Sediment control practices - Outlet energy dissipation

- Sediment control practices - Sediment traps and basins

- Sediment control practices - Stabilized earth/soil berm

- Construction stormwater treatment - dewatering, including chemical treatment and sediment filtration

- Construction stormwater best management practice – buffer zones

- Other practices