Filtration devices

Contents

Filtration Devices

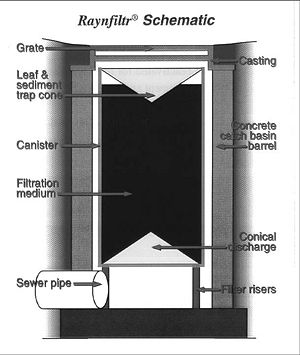

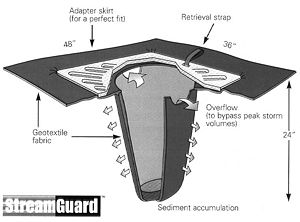

Filtration devices (inserts) allow stormwater to pass through filter media which are designed to reduce specific stormwater pollutants, but primarily solids and oils. Pollutants are captured physically or through sorption onto the filter media. Filters may either be inserts that are retrofitted into existing catch basins or manholes, or stand alone units supplied by a manufacturer.

Design Criteria

- Pollutants of interest for reduction

- Desired removal efficiency

- Design flow or volume, site constraints on size, desired location of treatment unit

- Pre-treatment requirements

- Installation and maintenance costs, life of unit

Benefits

- Units are typically underground or within existing structures and do not consume much site space

- Filtration devices can be customized to reduce a specific pollutant of concern

- Can often be easily incorporated into fully developed sites

- Can be used for pre-treatment prior to infiltration practices

- Relevant for use on industrial sites because filters can remove pollutants such as metals and oils

Limitations

- Efficiency has not been widely tested

- Each type of unit has specific design constraints

and limitations for use

- Can be more costly that other treatment methods

- Treatment may be greatly reduced if frequent maintenance is not conducted

- Subject to freezing in cold climates

Description

Filtration devices, depending on the design, can treat stormwater to reduce nutrients, sediment, floatables, metals, oil, and/or organic compounds. Different filtration media are used depending on the type of pollutant to be removed. Filter media may be a screen, fabric, activated carbon, perlite, zeolite, or other materials. Often a combination of filter media can be used to target the specific pollutants of interest.

These devices differ from the structural stormwater filters described in Chapter 12 in two aspects. First, these devices are proprietary and are designed to fit as an insert into the hydraulic infrastructure (eg. a catch basin). Second, the media material may have unique characteristics which are different from the soil/sand media recommended for general stormwater filtration.

Filtration devices have been developed for use in locations such as underground chambers, catch basins, trench drains, and roof drains. The manufacturer specifications should indicate key design parameters such as size, allowable flow rate, allowable pollutant concentrations, and removal efficiency. A bypass should be part of the system to allow high flows to circumvent the filtration device.

Performance data are often provided by the manufacturer. Users should review this information to ensure it was provided by an independent source

The MPCA Construction General Permit allows limited use of proprietary devices or “alternative methods.” Use of the alternative device as a stand alone BMP must be approved by the MPCA prior to installation. Approval is limited to those devices that achieve approximately 80% removal of total suspended solids. Additionally, the MPCA requires a two-year monitoring plan to measure the actual effectiveness of the method. If a device does not meet this 80% total suspended solids removal requirement, then these devices could be used as pretreatment or supplemental to another stormwater practice.

Selection

When selecting or specifying a filtration device, designers should research the following:

- What are the minimum or maximum drainage areas recommended for the device or method?

- What flow rates or volumes can the device accommodate? Will accessory structures be necessary to divert high flow around the filtration device?

- What are the characteristics of the pollutants in the water used for testing? What particle size distribution was tested? Research protocols used for testing.

- Are pollutant removal tests verified by independent organizations such as USEPA, University of New Hampshire, University of Minnesota, Wisconsin Department of Natural Resources, or others?

- Does the device contain a by-pass for high flows? If so, then what is the percentage of flow is prior to by-pass.

- What are the construction costs? Does the cost include all materials, installation, and delivery?

- What are the maintenance requirements? What are the costs of the required maintenance? Is there a standard operation and maintenance plan? What is the typical life of the filtration unit?

- Does the local regulatory authority approve the use of filtration devices?

- Will the manufacturer provide design computations and CADD details?

MANAGEMENT SUITABILITY

- Water Quality (Vwq) - Applicable

- Channel Protection (Vcp) - Not Applicable

- Overbank Flood Protection (Vp10) - Not Applicable

- Extreme Flood Protection (Vp100) - Not Applicable

- Recharge Volume (VRE) - Not Applicable

Mechanisms

- Infiltration - Not Applicable

- Screening/ Filtration - Applicable

- Temperature Control - Not Applicable

- Settling - Not Applicable

- Evaporation - Not Applicable

- Transpiration - Not Applicable

- Soil Adsorption - Applicable

- Biological/ Micro. Uptake - Not Applicable

Pollutant removal

- Total Suspended Solids - Applicable a

- Nutrients - Total Phosphorus/Total Nitrogen - Not Applicable

- Metals - Cadmium, Copper, Lead, and Zinc - Applicable A

- Pathogens - Coliform, Streptococci, E. Coli - Not Applicable

- Toxins - Hydrocarbon, Pesticide - Not Applicable

a Target pollutants - actual percentage of pollutant removal varies with each device and installation