Keeping surfaces clear for winter parking lot and sidewalk maintenance

We are in the process of migrating the Winter Parking Lot and Sidewalk Maintenance manual to the Minnesota Stormwater Manual. This page is undergoing review. You can access a pdf version of the maintenance manual here. Other changes and updates to information on salt management will be posted in the What's new page in the manual. Information on road salt and water quality can be found on MPCA's website

This section provides information on keeping surfaces clear during winter.

Contents

- 1 Winter Maintenance Basics

- 2 Loading/hauling

- 3 Deicing/Anti-Icing Information

- 3.1 Anti-icing

- 3.2 Get started in anti-icing

- 3.3 Anti-icing Tips

- 3.4 Equipment

- 3.5 Deicing

- 3.6 Pre-wetting and Pretreating Salt and Sand

- 3.7 Guidelines for Pretreating Stockpiles

- 3.8 Treating the salt stockpile

- 3.9 Treated Stockpile Application

- 3.10 Guidelines for Pre-wetting

- 3.11 Traction

- 3.12 Advantages of sand (abrasives)

- 3.13 Disadvantages of sand

- 3.14 Sweeping

- 4 Application Rates for Reduced Environmental Impacts

- 5 Deicing Application Rate Guidelines for Parking Lots and Sidewalks

Winter Maintenance Basics

- Anti-ice before the storm.

- Remove snow from surfaces as quickly as possible to reduce compaction.

- Plow before applying deicers to avoid dilution of the salt.

- Minimize deicer use during the storm.

- Never plow or blow snow into bodies of water, wetlands, traffic or into streets.

- Minimize back-up maneuvers to reduce chance of accidents.

- Limit use of salt and sand during the storm; use only to reduce bonding.

- Do not use salt to burn off snow.

- Use application rate chart to determine how much salt to use.

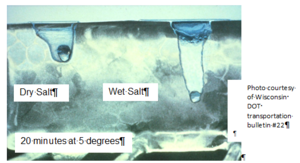

- Don’t apply dry salt (sodium chloride) below 15º F pavement temperature. It will not melt fast enough to help.

- Below 15° F, use a wetted salt.

- For extreme cold, skip melting and use sand.

- Clean up spills.

- Accurately record the material used at each site.

- Pay attention to its effectiveness and record observations.

- Use only what is needed based on proper application rates for the conditions.

- Put extra back in salt pile or return extra bags.

Loading/hauling

- Don’t overfill the truck or spreader: material will spill out as it is driven or pushed. This is a common practice and wastes salt.

- Large snow piles may need to be hauled to another site.

- Schedule this work when the mall or facility is closed to minimize conflicts with vehicles and pedestrians.

- Clean up loading area, sweep extra back into the pile.

Deicing/Anti-Icing Information

Anti-icing is the prevention of ice accumulation and build-up on surfaces. Deicing is the removal of ice that has accumulated on surfaces.

Anti-icing

Anti-icing is a proactive approach. It should be first in a series of strategies for each winter storm. Applying a small and strategic amount of liquid on the pavement before a storm will prevent snow and ice from bonding to the pavement. This buys time for the clean-up efforts.

Anti-icing is like frying eggs: grease the pan and the eggs come out easily with no mess to clean up. Like greasing the frying pan, the purpose of anti-icing is to keep snow from sticking to the pavement. Anti-icing provides safer pavement during the event and faster clean up after the event.

Anti-icing requires about ¼ the material and 1/10 the overall cost of deicing. It can increase safety at the lowest cost, and is effective and cost-efficient when correctly used and approached with realistic expectations.

Anti-icing prevents formation of frost. It can be effective for up to several days depending on the weather conditions.

Get started in anti-icing

The basic equipment needed includes: pavement temperature sensor, storage tank, spray truck system, transfer pump, hoses, and fittings.

What to do

- Calibrate

- Use application rates suggested in the Rate section of this manual

- Apply with stream nozzles to maintain dry areas between sprayed areas to reduce slipperiness. Stream nozzles work the best for anti-icing.

- If using fan nozzles apply extra light. This makes a dry surface wet and users will have less friction until it dries.

- Try anti-icing in a low traffic area to build confidence about its properties

- Read some of anti-icing guidelines in the reference section of this manual

Test the application rates and spray pattern to become confident in preventing the bonding of ice without creating a slimy or slippery situation.

Tip: Stream nozzles prevent slippery conditions better than fan spray.

Tip: Too little CaCl2 or MgCl2 is safer than too much.

What not to do

- Do not re-apply if there is still residue. It can remain many days after application.

- Do not apply CaCl2 or MgCl2 to a warm surface (above 35º F pavement temperature). It can become “greasy” as it pulls moisture to the pavement. These liquids do not always become greasy, but there is a higher potential in warmer temperatures and higher humidity.

- Do not over apply CaCl2 or MgCl2.

- Do not apply liquids before a rain storm. They will wash away.

Anti-icing Tips

- Liquids are more efficient than solids and may be applied days in advance of an event.

- It is better to use less than more. Over-application can cause slippery conditions because it makes a dry surface wet.

- Anti-icing is often effective for heavy frosts.

- Liquids are dispersed by the traffic. Spray the traffic lanes and the liquid will migrate with the tires to the parking areas.

- Some users advise against spraying the service road in front of buildings and instead spray traffic lanes and back service roads to allow the traffic to spread the liquids near the building where foot traffic is higher. This can reduce tracking into the building and over-application in a high-traffic area.

- For service roads on hills, some users recommend applying to only the top half of the hill, relying on traffic to carry it down the hill, to avoid a slippery situation at the bottom of the hill.

- Anti-ice when weather forecasts indicate a need. Do not anti-ice on a regular schedule, e.g., every Friday.

- Early application is particularly important for frost or light freezing drizzle.

- Pretreated or pre-wet materials are not as efficient as liquids for anti-icing. These require more material overall than with liquids. The pre-wet granular materials don’t stay in place as well as the liquids. Pre-wet granular solids can work if applied at very low application rates immediately before the snow event.

Equipment

- Anti-icing unit, e.g., transport vehicle with tank.

- For larger trucks: Stream nozzles (minimum eight holes), 8-inch spacing, bar height 12 to 14 inches from surface, 30 to 35 psi at the bar. These can be purchased or constructed.

- Solid stream – fan spray is more apt to make slippery conditions.

- A hand held pump sprayer or backpack sprayer can be used for sidewalks. Remember to leave a pattern of wet and dry to reduce the chance of creating slippery conditions.

- There are many ways to retrofit a pick-up truck or ATV with a tank and one of the following boom, spray bar, or hose reel with sprayer.

- A shutoff switch in the cab is recommended.

Deicing

Deicing is a reactive operation where a deicer is applied to the top of an accumulation of snow, ice, or frost that has already bonded to the pavement surface and can no longer be physically removed. Deicing costs more than anti-icing in materials, time, equipment, and environmental damage. Deicing is the “traditional” approach to winter maintenance.

Removing ice that has already bonded to the pavement is difficult. Removing it mechanically can damage equipment and surfaces. Generally, enough ice must be melted chemically to break the bond between the ice and the pavement. This requires larger amounts of chemical, making deicing much less efficient than anti-icing.

Use the application rate table to help with deicing. Using recommended rates will help with these common problems:

- Over-salting. Most over-salting can be prevented by using calibrated spreaders and good judgment in selecting application rates based on pavement temperatures.

- Trying to melt everything. Don’t try to melt all the snow on the surface with salt. This is an overuse of materials. Apply just enough to loosen the bond between the pavement surface and the snowpack so it can be plowed off.

Tip: The goal is not to melt everything. The goal is to penetrate through the ice and snow and break the bond so the pavement can be plowed.

Pre-wetting and Pretreating Salt and Sand

Pre-wetting and pretreating both mean getting dry material wet. Salt only melts snow and ice when it is in solution (dissolved). Dry salt does nothing until it is dissolved. Liquids applied to dry salt jump-start the melting process and penetrate ice and snow pack faster. Wet materials stick to the pavement and are less likely to end up in the nearby vegetation.

When integrating the liquids, decrease the application rate of the granular product. This is a common mistake made by new users of liquids.

- There are many types of liquid deicers.

- Salt brine is a common liquid deicer made from water and rock salt (NaCl).

- Brines can contain other ingredients besides water and rock salt.

- Pre-wetting (truck treatment) is the process of adding liquid to solids as they are applied to the pavement.

- Pretreating is the process of adding liquid to solids in the stockpile.

- Adding brine to dry salt, the combination will work faster than dry salt.

- Use magnesium chloride (MgCl2) or calcium chloride (CaCl2) liquid with dry salt, it will work faster and at lower temperatures.

- Wet material bounces less.

Guidelines for Pretreating Stockpiles

Pretreating is mixing a liquid deicer into the stockpile of salt or sand. It can be purchased as a product already mixed and ready to use or can be created. To create a pre-treated stockpile, add liquids conservatively. The dry material can only hold so much liquid before leaching occurs. Watch the storage area to make sure it can contain the wet salt pile. Test mixing skills and observe the amount of leaching on a small stockpile before doing this on a large scale.

Treating the salt stockpile

- Spray and mix the salt stockpile with a liquid deicing chemical (not brine).

- When treating the stockpile, apply at 6 to 8 gallons/ton, less is better.

- Because leach risk at a stockpile is increased, proper storage is critical.

- To minimize problems, mix up pre-wet materials per storm event not per season.

Treated Stockpile Application

- Pretreated salt can be applied with a pickup truck, a dump truck, a drop, or rotary spreader or almost any type of equipment used for dry salt.

- No equipment changes are required.

- Remember to turn down the application rate; it requires 1/3 less material than dry salt.

Guidelines for Pre-wetting

Pre-wetting is combining liquid from a tank to dry material from the hopper at the point of discharge. The most common set up is on a truck but it can be configured for smaller equipment. The liquid and granular usually come together at the spinner or auger.

While pre-wetting requires some equipment changes, it provides flexibility to switch the amount and type of liquid.

Tips:

- Turn down the application rate; 1/3 less material than dry salt is needed.

- Add tanks and hoses on the truck.

- Turn on/off the liquid from inside the cab.

- Synchronize the flow of liquids with the flow of solids to achieve the proper mix.

- A common application rate is 8 -14 gallons/ton for salt brine, 6-8 gallons/ton for MgCl2.

- The higher the liquid to granular ratio, the faster it works. Some go up to 60 gallons per ton.

- Pre-wetting with a chemical other than salt brine can improve cold weather performance.

- Pre-wetting is most practical with a dump truck. Use of a pickup truck may be limited due to the weight of the material.

- Think twice before mixing chemicals to form “hotter” brine. This is where problems often occur.

Traction

Use winter sand and other abrasives when temperatures are too cold for deicing chemicals to be effective. But be aware that sand does not melt anything. It provides temporary traction and only when it is on top of snow and ice. When sand is in contact with the pavement, sweep it up. It is no longer useful and can only harm the environment. Sand on dry pavement can cause skidding.

Advantages of sand (abrasives)

- Short-term traction: Abrasives can be helpful in areas of slow moving traffic, such as intersections.

- Useful in very cold temperatures when chemicals will not work.

Disadvantages of sand

- Sand is not cheap when considering handling, clean-up, and disposal costs.

- Sand will be tracked into lots or buildings. Sweep this up as often as possible and dispose of it properly.

- Used sand is contaminated with various pollutants such as oil, grease, metal, and rubber and should not be used for clean fill unless screened. It should not be used for sandboxes or beaches, and should not be dumped in wetlands, fields, or any natural area.

- Once sand is driven over many times, the particles are much finer and can cause air quality concerns.

- Cannot be used over pervious asphalt, pervious concrete, or pervious pavers.

Sweeping

Sweep the sand from the parking lot areas midwinter as well as in the spring. Trailer-type power sweepers are available that can be hauled behind a pickup truck. Smaller power brooms or sweepers may be used on sidewalks. Workers should wear a dust mask to avoid inhalation of the fine dust particles.

- Used sand is contaminated with pollutants such as oil, grease, metal, and rubber.

- Sweepings often can be brought to a landfill. Inform landfill operator in advance.

- Keep children from playing on the sweeping piles.

- Sweepings may be reused by some industries.

- Before reusing sweepings the trash, leaves and other debris should be removed. This is often accomplished by screening. When screening sweepings for reuse, use a small mesh for the final screening to ensure that all of the larger debris has been removed. (A 3/4-inch mesh will screen out much of the debris.) Dispose of trash and debris removed from the sweepings by recycling it (e.g., aluminum cans), composting it (e.g., leaves), or sending it to a sanitary landfill.

Application Rates for Reduced Environmental Impacts

Effective application rates are based on many factors, including type and rate of precipitation, air and pavement temperature, forecast and temperature trend, humidity, dew point, type of surface and subsurface material, and sun exposure. The application rate tables used in this book have been taken from the Minnesota Snow and Ice Control Field Handbook for Snowplow Operators, Second Revision (LRRB 2012). They were converted from gallons or pounds per lane mile to gallons or pounds per 1000 square feet.

These application rates are not perfect but are to be used as goal to work toward. Develop specific application rate tables to standardize performance. Track application rates measure and improve performance. Modify the practices incrementally over time to fit the needs. Make it a goal to reduce application rates and keep surfaces safe.

One application rate will not fit all situations; how long an application lasts depends on:

- Pavement temperature

- Application rate

- Precipitation

- Type of material applied

- Salt lost to plowing or traffic blowing it off of the surface

Anti-icing application rates. These are a starting point only. Adjust based on experience.

Link to this table

| Condition | Gallons/1000 sq. ft. | Other Products | |

|---|---|---|---|

| CaCl2 or MgCl2 | Salt Brine(NaCl) | ||

| 1. Regularly scheduled applications | 0.2 - 0.4 | 0.3 – 0.6 | Follow manufacturers’ recommendations |

| 2. Prior to frost or black ice event | 0.2 - 0.4 | 0.3 – 0.6 | |

| 3. Prior to light or moderate snow | 0.2 - 0.4 | 0.3– 0.8 | |

| CAUTION: Too high an application rate may result in slippery conditions or tracking. | |||

How to use the anti-icing rate table above:

- Determine the parking lot or sidewalk area in square feet.

- Divide the area by 1,000 (chart is based on a 1,000 square foot area).

- Find the application rate: Choose the condition in the first column of the table and follow sideways, stopping at the anti-icing chemical being used.

- Determine how many gallons needed: Multiply the application rate by the answer in #2.

Example: The parking lot is 20,000 square feet. The chart tells how much to apply for 1,000 square feet. The plan is to apply brine prior to light or moderate snow. Do a calculation to see how much brine is needed:

- Divide the parking lot size by the chart size (20,000/1,000 = 20).

- Application rate from chart is between 0.3 to 0.8 gallons.

- Then multiply 20 x 0.5 = about 10 gallons are needed.

Tip: To convert from gallons to ounces: multiply the result by 128.

Deicing Application Rate Guidelines for Parking Lots and Sidewalks

These rates are based on road application guidelines (LRRB 2012).

Develop specific application rates by adjusting the current rates incrementally downward toward the guidelines. Where temperature categories overlap, select the rate most applicable to the present situation.

Application rates for deicing

Link to this table

| Pavement Temp. (ºF) and Trend (↑↓) | Weather Condition | Maintenance Actions | Application Rate in lbs./per 1000 square foot area | |||

|---|---|---|---|---|---|---|

| Salt Pre-wetted/Pretreated With Salt Brine | Salt Pre-wetted/ Pretreated With Other Blends | Dry Salt | Winter Sand (abrasives) | |||

| >30º↑ | Snow | Plow, treat intersections only | 0.75 | 0.5 | 0.75 | not recommended |

| >30º↑ | Frz. Rain | Apply chemical | 1.25 | 1.0 | 1.5 | not recommended |

| 30º↓ | Snow | Plow & apply chemical | 1.25 | 1.0 | 1.5 | not recommended |

| 30º↓ | Frz. Rain | Apply chemical | 1.5 | 1.25 | 1.75. | not recommended |

| 25 - 30º ↑ | Snow | Plow & apply chemical | 1.25 | 1.0 | 1.5 | not recommended |

| 25 - 30º ↑ | Frz. Rain | Apply chemical | 1.5 | 1.25 | 1.75 | not recommended |

| 25 - 30º ↓ | Snow | Plow & apply chemical | 1.25 | 1.0 | 1.5 | not recommended |

| 25 - 30º ↓ | Frz. Rain | Apply chemical | 1.75 | 1.5 | 2.25 | 3.25 |

| 20 - 25º ↑ | Snow or Frz. Rain | Plow & apply chemical | 1.75 | 1.5 | 2.25 | 3.25 for frz. rain |

| 20 - 25º ↓ | Snow | Plow & apply chemical | 2.0 | 2.0 | 2.75 | not recommended |

| 20 - 25º ↓ | Frz. Rain | Apply chemical | 2.5 | 2.0 | 3.0 | 3.25 |

| 15º to 20º↑ | Snow | Plow & apply chemical | 2.0 | 2.0 | 2.75 | not recommended |

| 15º to 20º↑ | Frz. Rain | Apply chemical | 2.5 | 2.0 | 3.0 | 3.25 |

| 15º to 20º↓ | Snow or frz. rain | Plow & apply chemical | 2.5 | 2.0 | 3.0 | 3.25 for frz. rain |

| 0 to 15º ↑ ↓ | Snow | Plow, treat with blends, sand hazardous areas | not recommended | 3.0 | not recommended | 5.0 spot treat as needed |

| < 0º | Snow | Plow, treat with blends, sand hazardous areas | not recommended | 4.5 | not recommended | 5.0 spot treat as needed |

All application rates are based on thoroughly cleared surfaces

Instructions for using application rate table for calibrated spreaders

- Using Deicing Application Rate Guidelines for Parking Lots and Sidewalks. Select the row with the appropriate pavement temperature, temperature trend, and weather conditions.

- Select the column that has the type of material used.

- Find the box where the row and columns intersect to find the application rate.

- Compare those values to the calibration chart for the spreader.

- Select the correct spreader setting for the rate calculated.

- Example

- Parking lot is 54,000 sq. ft.

- Temperature: 22ºF and falling. It has finished snowing.

- Using salt pretreated with salt brine.

- Find the 20 – 25º ↓ box. Follow it to the right to the column labeled “Salt Pre-wetted/pretreated with salt brine.” Read the rate in the box. The box where the column and row intersect shows a rate of 2.0 /1000 square feet.

- Refer to the calibration chart in the vehicle and set the spreader to the setting that most closely matches the 2.0 lbs. /1000 square feet.

- The mixture is ready to apply.

- Instructions for using application rate table for spreaders that are NOT calibrated

Using the example above:

- Calculate size factor: Divide the parking lot size (54,000 sq. ft.) by 1,000 sq. ft. 54,000/1,000 = 54. The size factor is 54.

- Find application rate (2.0).

- Multiply application rate by size factor 2 x 54 = 108.

- The amount needed for the entire lot is 108 lbs. pre-wetted/pretreated salt brine.

- Because the spreader is not calibrated, the setting is unknown.

- Although the calibration setting is not known, this establishes the amount of salt to use and increases efficiency.

- Determine the best method to spread the 108 pounds evenly across the parking lot.