Difference between revisions of "MS4 fact sheet - Vehicle Washing"

m (→Typical cost) |

m (→Typical cost) |

||

| Line 74: | Line 74: | ||

<noinclude> | <noinclude> | ||

| − | [[Category:MS4 | + | [[Category:Level 3 - Regulatory/Municipal (MS4)/Fact sheet]] |

</noinclude> | </noinclude> | ||

Latest revision as of 18:36, 22 November 2022

Municipal Separate Storm Sewer System (MS4) vehicle washing involves the removal of dust and dirt from the exterior of trucks, boats and other vehicles, as well as the cleaning of cargo areas and engines and other mechanical parts. Washing of vehicles and equipment generates oil, grease, sediment and metals in the wash water as well as degreasing solvents, cleaning solutions and detergents used in the cleaning operations.

The impacts of these constituents discharging to downstream water bodies include increased biochemical oxygen demand (BOD), increased temperature and acidity, and reduced oxygen levels. These environmental effects cause potentially fatal physiological disorders and reduced immune status in aquatic fish and other organisms.

The EPA considers wash water to be a non-stormwater discharge (i.e. illicit discharge); therefore, wash water from a facility must be directed to a sanitary sewer or treated on-site prior to discharge. MS4s often own and maintain their own fleet of vehicles that may include cars, tractors, trucks, parks equipment, and other types of vehicles.

This fact sheet provides guidance on techniques to reduce water pollution from the washing of MS4 vehicle fleets applicable to MS4 Stormwater Pollution Prevention Plans (SWPPPs).

Contents

Benefits and pollution reduction

Appropriate vehicle wash water treatment and disposal helps to maintain the clarity, temperature and oxygen levels of downstream water bodies by keeping associated pollutants out of storm drains.

Program development and implementation

Programs designed to manage vehicle wash water include a combination of the elements identified below. The program elements implemented are dependent on the MS4’s access and authority to discharge to sanitary sewer, available resources, and size of staff and vehicle fleet.

Contracting vehicle washing services

Properly maintained commercial washing and steam cleaning businesses are usually better equipped to handle wash waters and are permitted to discharge wash water to the sanitary sewer system. Negotiate with commercial car washes and steam cleaning businesses to handle fleet vehicle washing whenever possible. This option eliminates the cost of building the proper facility and the liability of operating it. However, this option may not be feasible for fleets of higher quantity or vehicles of larger size.

Wash racks

MS4s with a large fleet of vehicles might consider building MS4-operated wash racks. Wash racks are designed to collect wash water and ultimately discharge to the sanitary sewer rather than the storm sewer. Wash racks consist of designated, paved wash areas that are bermed or sloped to contain and direct wash water to a collection point. Wash water is collected in a sump connected to the sanitary sewer, an on-site process treatment system, or an enclosed recycling system. Connections to the sanitary sewer need approval from the sewer authority and may require pretreatment.

On-site treatment

Another suitable option is to contain and treat all wash water on the premises by using a detention pond or bermed area that will retain the wash water on site to evaporate and infiltrate. An individual National Pollutant Discharge Elimination System/State Disposal System (NPDES/SDS) permit is needed for such a treatment system. Separate containment is required for salt brine.

MS4-operated vehicle washing facility BMPs

Designated area - Wash all vehicles in designated areas only. Wash vehicles inside or under cover wherever possible. When washing outdoors, provide an impervious concrete wash pad with a collection system. Alternatively, consider a pervious wash area where infiltration precludes runoff to storm drains. Depth to ground water table and local geology must be considered in this case; avoid this practice in areas with shallow ground water tables and karst topography.

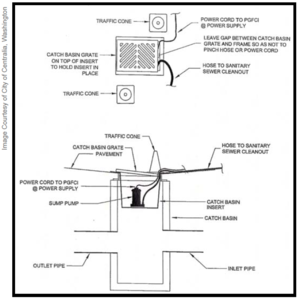

Collect wash water - Wash all vehicles in designated areas designed to collect and hold wash water before discharge to the sanitary sewer system (e.g. berming). Pretreatment may be required prior to discharge to the treatment plant. Contact your sewer authority early in the design process. In areas not served by a sanitary sewer, haul contents of the holding tank to a treatment plant. If the parking lot has a catch basin connected to a storm sewer, this can be used as a collection point. The storm sewer could be temporarily blocked or plugged so that a temporary pump or vacuum could collect the wash water which can then be disposed of in a sanitary sewer or holding tank.

Minimize run-on - Minimize the run-on of rain water or snowmelt to the designated wash area through berming or diking the area.

Avoid detergents Avoid detergents whenever possible by considering power washing and steam cleaning. If detergents are necessary, a phosphate-free, non-toxic, biodegradable soap is recommended. However, even detergents labeled biodegradable or phosphate-free are not safe to discharge to the storm drain; both require treatment provided by the sanitary sewer system in order to reap the environmental benefits. In fact, phosphate replacement chemicals may be more toxic than phosphate. No water that contains any detergent should discharge to the stormwater system. Detergents should also be avoided if an oil/water separator is used for pretreatment prior to discharge to the sanitary sewer.

Dry pre-wash Initially clean vehicles without using water (e.g., sweep loose material in cargo areas), collect the loosened material, and dispose of properly as solid waste.

Wash vehicles on paved surfaces. If not on a wash rack, collect water with a catch basin insert like the one shown below.

Conserve water -Conserve water when rinsing and washing vehicles.

Concrete washouts Use water tight above-or below-grade concrete washouts for concrete trucks. Remove materials by vacuuming once the washout is at or near 75 percent capacity. Dispose of materials in an approved manner by checking with the local sanitary sewer authority to determine if there are special disposal requirements for concrete wash water. Educate users (MS4 staff and/or subcontractors) on concrete washout use and maintenance. See the MPCA Concrete Washout Guidance in the Additional Resources section for more information.

Storm drain stenciling Stenciling storm drains will help remind employees to wash vehicles only in designated areas and away from storm drains (see the fact sheet on Storm Drain Stenciling).

Easy-access cleanup supplies - Provide cleanup supplies near designated wash areas to facilitate immediate cleanup. Use dry cleanup methods (e.g. absorbents) rather than hosing down the area to prevent discharge to storm drains.

Avoid cleaning chemicals Cleaning chemicals can contain ingredients that pose threats to human health if they enter ground water and drinking water supplies and can be highly toxic to fish and other aquatic life. Consider these questions:

- What are the goals in using chemical cleaners?

- Are these goals aesthetic only?

- Have you tried pressure cleaning with plain water then steam cleaning without chemicals to see whether these goals can still be achieved?

- Can you eliminate the use of some or all cleaning chemicals?

Also consider the ingredients of the chemical products used. Demand that vendors provide the complete ingredient list for each cleaner, so you can evaluate the potential risks of using the product since any materials end up in the environment, even if discharged indirectly through the sanitary sewer. Avoid the following ingredients, specifically: dispersants and emulsifiers, alkylphenol ethoxylate (APE) non-ionic surfactant, petroleum distillates (e.g., kerosene, white spirits, mineral spirits, Stoddard solvent, petroleum naphtha), hexane, methyl ethyl ketone (MEK), toluene, xylenes and naphthalene, alkyl benzene sulfonates (ABS) and linear alkyl sulfonates (LAS), molybdenum, caustic soda (sodium hydroxide) and potassium hydroxide that can contain significant levels of mercury, phosphates, glycols, and acids.

An existing building could be used or a concrete or asphalt pad constructed that is large enough for at least one truck to be washed. The pad should have a collection sump and the wash water would flow by gravity or be pumped from the collection point to an existing sanitary sewer line. It is preferable to have a roof over the washing area to keep clean stormwater out.

Recycle wash water

Utilize recycle units to reuse wash water prior to disposal. Since recycle units clean wash water only enough so that the water is suitable for washing, rinsing will still have to be done with fresh water. Normally, recycle units do not remove detergents, dissolved solids or heavy metals. This will enable reduced detergent usage. However, hazardous waste limits should be known to determine how many cycles of reuse can be conducted while remaining under the limit.

Employee training

Train employees and subcontractors in the MS4's vehicle washing procedures to avoid illicit discharges.

Example Program

The City of Centralia, WA, operates a Fish Friendly (Charity) Car Wash Program that has special kits available for parking lot charity car washes that pump wash water into the sanitary sewer system, keeping contaminants out of storm drains and local surface waters. All City charities and groups can borrow the kits at no charge from the Surface and Stormwater Management Department. The car wash kit includes event signs indicating that it is a Fish Friendly Car Wash. The Fish Friendly (Charity) Car Wash Program also includes disseminating public education materials in the form of letters, flyers and press releases targeted at local charities and special interest groups, as well as local businesses.

Maintenance considerations

Plumbing, recycling, and pretreatment systems require periodic inspection and maintenance. Containment berms should be inspected for failures; holding tanks and concrete washout volumes should be inspected for remaining capacity and emptied when at 75 percent capacity. A wash rack's paved surfaces and sump should be inspected and cleaned periodically to remove buildup of particulate matter or other pollutants. The area surrounding the wash rack should be visually inspected for leaks, overspray, or other signs of ineffective containment due to faulty design or physical damage to berms.

Typical cost

Building a new wash rack and recycling unit can be expensive ($2,000 to $5,000 for berm construction; $10,000 to $30,000 for plumbing modifications; $60,000 to $200,000 for onsite treatment and recycling). Costs associated with discharge to the sanitary sewer (e.g. required pretreatment) could be reduced or eliminated with a recycling system. However, for facilities that cannot recycle their wash water, the cost of pretreating wash water prior to discharge to the sanitary sewer can represent a cost limitation. Collection and hauling of contaminated water to sewage treatment plants is an additional cost. The purchase of wash water containment equipment is often a one-time expense and this equipment is often used for a number of years.

Costs for contracting with commercial car washes can vary depending on the size of the fleet. Rates are subject to negotiation, but they would constitute an annual operating cost that could be included as part of the MS4 budget. If the appropriate facilities are available, vehicle washing BMPs are relatively inexpensive housekeeping measures (e.g. berms, wet/dry vacuums, cleanup supplies).

This page was last edited on 22 November 2022, at 18:36.