Difference between revisions of "Sediment control practices - Stabilized earth/soil berm"

| Line 156: | Line 156: | ||

**[[Erosion prevention practices - erosion control blankets and anchoring devices]] | **[[Erosion prevention practices - erosion control blankets and anchoring devices]] | ||

**[[Erosion prevention practices - turf reinforcement mats]] | **[[Erosion prevention practices - turf reinforcement mats]] | ||

| + | **[[Erosion prevention practices - Riprap]] | ||

*Sediment control practices | *Sediment control practices | ||

Revision as of 20:10, 8 February 2019

This section of the manual is being developed

Berms are compacted or vegetated structures that are designed to 1) slow, pond, or filter runoff, and 2) divert runoff on a construction site to a sediment trap/basin, or ensure clean upland runoff does not move into disturbed areas. They may also be called filter berms, diversion berms, or earth berm barriers, depending on their composition and use. Berms can be constructed from soil, rock, wood chips, and compost, depending on the construction site characteristics (discussed below). They are typically used as a temporary perimeter control BMP to divert clean runoff away or around disturbed areas on a construction site as well as to collect sediment-laden flows from disturbed areas and direct them toward sediment traps or basins. Berms are often used where the installation of silt fence is not feasible or may be used in combination with a silt fence to minimize under-draining of the fence and increase sheet flow runoff filtering.

Contents

Purpose and function

Berms prevent off-site sedimentation by diverting runoff to a sediment trapping device and can also be used to divert clean water from entering a disturbed area. They can also trap sediment by ponding and settling out sheet flow runoff, or by filtering sediment as runoff passes through permeable berms. Stabilized earth/soil berms are constructed from compacted soil, compost, mulch/wood chips, aggregate, or other filtering materials.

Applicability

The size, soil condition, and topography of the site must be considered before selecting, sizing, and installing a stabilized berm. They should be installed before upslope construction activities begin, particularly any activities causing soil disturbance. They should be maintained until the contributing area is fully stabilized and vegetation is established. Berms should be stabilized immediately with vegetation, erosion control blankets, or similar measures to prevent the berm from eroding and becoming a source of sediment in runoff. image

Site applicability

Berms are effective for treating smaller, flatter drainage areas. Berms can be used on larger sites by installing multiple berms to partition the drainage area so that individual structures are not overwhelmed by incoming flow. Berm effectiveness is reduced when slopes exceed 10%. Berms constructed of wood chips, compost, or mulch are recommended for flatter areas while berms constructed of earthen materials are more suitable for steeper slopes. Berms are well suited for redirecting sheet flow to treatment areas such as temporary sediment traps and can be installed along a slope to intercept sheet flow. Earth/soil berms are generally not recommended for areas receiving concentrated flow; however, they can be appropriate for locations downgradient from areas of disturbed earth and across or at the bottom of a slope, provided that sufficient space is provided to disperse and handle the accumulated runoff and resultant flow. They can also be installed along roadways and other areas to facilitate diversion of runoff and at the tops of slopes as an erosion prevention measure.

Permit applicability

Stabilized earth and soil berms are cited for use for several construction activities in the MPCA Construction Stormwater General Permit (2018), specifically for practices that are susceptible to clogging from excess sediment:

- Section 16.4 states: “Permittees must not excavate infiltration systems to final grade, or within three (3) feet of final grade, until the contributing drainage area has been constructed and fully stabilized unless they provide rigorous erosion prevention and sediment controls (e.g., diversion berms) to keep sediment and runoff completely away from the infiltration area.”

- Similarly, Section 17.3 states: “Permittees must not install filter media until they construct and fully stabilize the contributing drainage area unless they provide rigorous erosion prevention and sediment controls (e.g., diversion berms) to keep sediment and runoff completely away from the filtration area.”

Effectiveness

Diversion berms are highly effective for moving sediment-laden flows to traps, basins, or other structures/areas where sediment can be removed via settling or filtration. When used as a sheet flow barrier, berms can be effective in sediment removal, but may need frequent maintenance as they are prone to clogging from mud and soil. They are somewhat effective for flow attenuation by slowing down flow, and for removing nutrients and metals associated with sediment. Berms are typically ineffective for managing floating pollutants.

Expected performance for stabilized earth/soil berms.

Link to this table

| Water quantity | |

|---|---|

| Flow attenuation | Secondary design benefit |

| Runoff volume reduction | Little or no design benefit |

| Water quality | |

| Soil erosion | Primary design benefit |

| Sediment control | Primary design benefit |

| Nutrient loading | Secondary design benefit |

| Pollutant removal | |

| Total suspended solids | Primary design benefit |

| Total phosphorus | Secondary design benefit |

| Heavy metals | Secondary design benefit |

| Floatables | Little or no design benefit |

| Oil and grease | Little or no design benefit |

Planning considerations

Berms should be integrated into an erosion prevention and sediment control system that takes the entire site into consideration. Prior to any earth disturbing activities, berms should be installed where appropriate on downgradient limits-of-disturbance, and upgradient of buffer or disturbed zones (i.e., where used to divert clean upland runoff around areas to be graded). They should be integrated with other BMPs, such as minimization of disturbed areas, minimization of the length of exposure time, or adequate seeding and mulching. If downgradient berms become overloaded with sediment and runoff volumes, additional upgradient controls may be necessary. Like other perimeter control BMPs, stabilized earth/soil berms must remain in place until the construction site is fully stabilized.

As noted above, perimeter controls including stabilized earth/soil berms typically need a high degree of maintenance. For best results, plan and schedule project activities to minimize maintenance needs, ideally through timely grading operations and stabilization of disturbed areas with seeding, mulching, or other ground covers. Timing of berm installation may be adjusted to accommodate short term activities, such as clearing and grubbing, and passage of vehicles. Such activities must be completed as quickly as possible and the stabilized berms reinstalled immediately after the activity is finished, or before the next precipitation event, whichever comes first.

Design

Berm design is dependent on their intended use, i.e., as a flow diversion device or as a flow interceptor and small sediment barrier/trap. Berms can be constructed from material stockpiles on site. For example, shredded wood mulch or wood chips can be derived from the clearing and grubbing phase of the project. Topsoil is often stockpiled at the construction site until needed for final grading; this can be a valuable resource for constructing a stabilized berm until it is needed elsewhere. The following design recommendations apply to berms:

- Do not use soil berms in areas of concentrated flow. Properly spaced stone and/or fiber log check dams may be used to prevent ditch downcutting prior to stabilization.

- Berms should be designed to carry peak flows from a 2-year, 24-hour storm event.

- It is recommended that drainage areas for individual berm structures be small enough to ensure effectiveness as a sediment removal or flow diversion device.

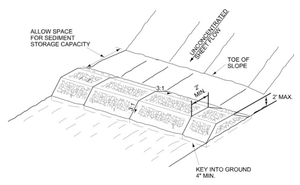

- The maximum drainage area slope should be 10%. On steep or long slopes, multiple berms installed perpendicular to the flow path may be placed at regular intervals down the slope.

- To the extent possible, berms should be placed away from the toe of a slope and on the flattest area available to allow sheet flow energy to dissipate and provide a greater storage area for sediment.

- Install berms on the contour perpendicular to sheet flow with the ends turned upslope to prevent runoff from bypassing the berm.

- Berms constructed from soil should be stabilized immediately using methods such as vegetation, erosion control blankets, or similar measures.

- Install energy dissipation such as riprap where flows diverted by berms may cause scour or erosion.

Recommended berm shape, base width, height, and side slopes depend on the berm material and are summarized in the table below.

Recommended dimensions for stabilized berms. Source: MnDOT Standard Specifications for Construction

Link to this table

| Berm Type/Material | Recommended shape | Recommended base width | Recommended height | Recommended side slopes |

|---|---|---|---|---|

| Type 1 - compost | Trapezoidal | 5 feet | 2 feet (minimum) | 2:1 |

| Type 2 - slash mulch | Trapezoidal | 5 feet | 2 feet (minimum) | 2:1 |

| Type 3 - rock weeper system | Trapezoidal | 8 feet | 2 feet (maximum) | 2:1 |

| Type 4 - topsoil | Trapezoidal | 7 feet | 2 feet (minimum) | 2:1 |

| Type 5 - rock | Trapezoidal | 5 feet | 2 feet (maximum) | 2:1 |

Permissible velocities for prevention of erosion of the berm are based on soil type and are summarized in the table below. These values reflect the maximum velocity of runoff that should be intercepted by a berm before erosion is likely to occur.

Maximum runoff velocity (feet per second) for a berm based on soil type. These values reflect the maximum velocity of runoff that should be intercepted by a berm before erosion is likely to occur.

Link to this table

| Soil Type | Permissible Velocity (fps) | |||

|---|---|---|---|---|

| Channel Vegetation | ||||

| Bare | Poor | Fair | Good | |

| Sand, silt, sandy loam, and silty, loam | 1.5 | 1.5 | 2.0 | 3.0 |

| Sandy clay, lam, and sandy clay, loam | 2.0 | 2.5 | 3.0 | 4.0 |

| Clay | 2.5 | 3.0 | 4.0 | 5.0 |

Construction recommendations and specifications

Berm material selection, design, siting, and installation is dependent on its use, i.e., as a flow diversion device or as a flow interceptor (e.g., flow attenuator, sediment removal BMP). General construction recommendations include:

- Ensure berm fabrication, construction, or installation is appropriate for the intended use in terms of location, slope, spacing, and endpoints.

- Berm shape is usually trapezoidal, and shape must be consistent through its length.

- Berms must be substantial enough to maintain their structural integrity while handling incoming flows.

- Fiber rolls and other lighter weight products used as berms must have full soil contact and be properly staked down or otherwise secured.

- Some materials used for berming (e.g., mulch, bark) may require netting to prevent washouts.

- Soil berms handling erosive flows require stabilization (e.g., erosion control blanket over seed).

- Flow diversion berms should discharge to a sediment control BMP (for muddy flows) or a scour-resistant dispersal area (for clean upland diversion flows).

The MnDOT Standard Specifications for Construction (2018 Edition) includes several specifications relevant to stabilized earth/soil berms. MnDOT Specification 2573.3 Part E discusses installation of filter berms used as a perimeter control, with specific guidance provided based on construction material, as follows:

- Part E.1 covers Type 1 and Type 2 filter berms, which are constructed from compost or slash mulch. The specification states: “For slope breaks and perimeter control, install filter berms along the contour of the slope and perpendicular to sheet flow. Install the filter berms so the beginning and end of the installation points slightly up the slope to create a “J” shape at each end to contain runoff from above and prevent it from flowing around the ends of the berm. For slopes that receive runoff from above, place a filter berm at the top of the slope to control the velocity of the flow running onto the slope, and to spread the runoff into sheet flow… Upon formation, immediately seed compost filter berms.”

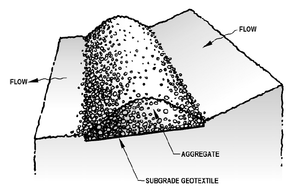

- Part E.2 pertains to Type 3 filter berms constructed from aggregate, stating: “Line the bottom of the rock weeper with a Type IV geotextile per 3733, “Geotextiles.” Provide a rock weeper that forms a trapezoidal-shaped berm. Install coarse filter aggregate per 3149, “Granular Material,” on the front half of the berm. Install Class I riprap per 3601, “Riprap Material,” on the back half of the berm.”

- Part E.3 covers Type 4 filter berms, which are constructed from soil. The specification states: “For perimeter control, construct a topsoil berm using topsoil salvaged from the project. Immediately following formation, stabilize the berm with seed and mulch or an equivalent approved by the Engineer.”

- Part E.4 pertains to Type 5 filter berms constructed from riprap, stating: “Install Class II riprap on top of a Type IV geotextile liner per 3733, “Geotextiles.” Configure riprap in a trapezoidal-shaped berm.”

Specification 2573.3 Part P.1 covers maintenance of filter berms, stating: “Expand, enlarge, or augment the filter berm with additional erosion and sediment control practices if concentrated flows bypass or breach the berm or to maintain the dimensions of the berm.” Inspection and maintenance of stabilized earth/soil berms is discussed below.

Specification 2573.5 Part A discusses basis of payment for filter berms. The specification states: “The contract pay item for Topsoil filter berm includes seed and mulch. The contract pay item for rock or rock weeper filter berm when converted from temporary to permanent conditions includes the cost to modify the berm dimensions.”

Specification 2573.5 Part B.1 covers temporary seeding as a stabilization measure for soil berms, stating: “Perform temporary seeding in addition to temporary mulching on graded areas with topsoil and unable to receive permanent seeding or slopes and topsoil berms left idle for longer than 21 days. Use cover crop and mid-term stabilization seed mixtures as shown in 3876, “Seed”, Table 3876-1 for temporary seeding. Prepare the soil in accordance with 2574.3.A and 2574.3.B, except for stockpile and berms where no soil preparation is needed.”

Specification 3874 is specifically dedicated to filter berms and outlines specific design requirements. The specification includes the following guidance:

- Specification 3874.1 (Scope) states: “Provide filter berms to slow, filter, and divert storm water runoff and other pollutant water.”

- Specification 3874.2 (Requirements) states: “Provide the following types of filter berms. Dimensions may vary by the contract:”

- Part A (Type 1 – Compost): “Provide compost berms meeting the following requirements and characteristics:

- (1) Grade 2 Compost per 3890,

- (2) Trapezoidal shape with 5 ft. base width,

- (3) Min. height 2 ft. in loose volume, and

- (4) 2:1 (V:H) side slopes.

- Part B (Type 2 – Slash Mulch): “Provide slash mulch berms meeting the following requirements and characteristics:

- (1) Type 5 Mulch per 3882,

- (2) Trapezoidal shape with 5 ft. base width,

- (3) Min. height 2 ft. in loose volume, and

- (4) 2:1 (V:H) side slopes.

- Part C (Type 3 – Rock Weeper System): “Provide rock weeper systems meeting the following requirements and characteristics:

- (1) Type IV Geotextile Fabric per 3733,

- (2) Trapezoid shape with 8.0 ft. base width,

- (3) Max height 2.0 ft.,

- (4) 2:1 (V:H) side slopes

- (5) Front half composed of Coarse Filter Aggregate per 3149.2.H, and

- (6) Back half composed of Class I Riprap per 3601.

- Part D (Type 4 – Topsoil): “Provide topsoil filter berm meeting the following requirements and characteristics:

- (1) Topsoil Excavation material per 2105,

- (2) Trapezoid shape with 7 ft. base width,

- (3) Min. height 2 ft., and

- (4) 2:1 (V:H) side slopes.

- Part E (Type 5 – Rock): “Provide rock filter berm meeting the following requirements and characteristics:

- (1) Type IV Geotextile fabric per 3733 as a liner,

- (2) Class II Riprap per 3601,

- (3) Trapezoid shape with 5 ft. base width,

- (4) Max. Height 2.0 ft., and

- (5) 2:1 (V:H) side slopes.

- Part A (Type 1 – Compost): “Provide compost berms meeting the following requirements and characteristics:

Inspection and maintenance

The control of runoff is a key element of sediment control on a construction site, and berms can be an effective measure for managing sediment from construction runoff if they are properly installed and maintained. Frequent inspection and maintenance are essential to the proper performance of this BMP. As noted above, Specification 2573.3 Part P.2 discusses maintenance requirements for berms, stating: “Expand, enlarge, or augment the filter berm with additional erosion and sediment control practices if concentrated flows bypass or breach the berm or to maintain the dimensions of the berm.” Inspect berms weekly, before rain events, and after rain events, particularly events of 0.5 inch or greater, to ensure they are functioning. If not, complete the following tasks as needed:

- Look for runoff bypassing ends of berms or undercutting berms and repair.

- Repair damaged areas of the berm (washed out, eroded, and flattened areas).

- Recompact soil around berm as necessary to prevent breakouts and/or piping.

- Perform repairs using a piece of equipment or hand tool capable of excavating, contouring, and compacting back to the berm’s original design.

- Remove accumulated sediment and debris once sediment depth reaches one-half of berm height and repair any damage to vegetative cover.

- Prevent damage to the berm by ensuring that equipment operators do not drive over the berm.

- Remove berm once the site reaches final stabilization. Fill, compact, and vegetate areas of ground disturbance to blend with adjacent ground.

Costs

The following table summarizes estimated BMP costs based on MnDOT data summarizing average bid prices for awarded projects in 2017.

Unit costs related to stabilized earth/soil berms

Link to this table

| Bid Item | Item Description | Units | Average Price |

|---|---|---|---|

| 2573515/00011 | Filter berm type 1 (compost) | linear feet | $28.00 |

| 2573515/00013 | Filter berm type 3 (rock weeper system) | linear feet | $26.97 |

| 2573515/00014 | Filter berm type 4 (topsoil) | linear feet | $2.30 |

| 2573515/00015 | Filter berm type 5 (rock) | linear feet | $48.02 |

| 2105604/00003 | Grade protection | square yard | $23.50 |

| 2574550/00012 | Compost grade 2 | cubic yard | $50.22 |

| 2575513/00050 | Mulch material type 5 (slash mulch) | cubic yard | $45.00 |

| 2105604/00034 | Geotextile fabric type IV | square yard | $2.31 |

| 2451511/00030 | Coarse filter aggregate (CV) | cubic yard | $52.78 |

| 2511501/00011 | Random riprap class I | cubic yard | $64.10 |

| 2511501/00012 | Random riprap class II | cubic yard | $74.82 |

Reference materials

Except where more stringent requirements are presented in this guidance, BMPs shall comply with MnDOT and other state requirements. Primary design references include:

- 2018 Minnesota NPDES/SDS Construction Stormwater General Permit

- 2018 MnDOT Standard Specifications for Construction

- MnDOT Erosion Control Handbook II

The following is a list of additional resources that are not specific to Minnesota:

- Contractor’s Handbook for Erosion, Sediment, and Stormwater Management on Capital Project Construction Sites (Lexington-Fayette Urban County Government) (2018)

- Idaho Transportation Department Best Management Practices Manual (2014) (Chapter 2, SC-1)

- Iowa Statewide Urban Design and Specification (SUDAS) Design Manual (2013) (Chapters 7E-3 and 7E-8)

- Kentucky Erosion Prevention and Sediment Control Manual (Revised 2009) (Chapter 4.3.3)

- Montana Department of Transportation: Erosion and Sediment Control Best Management Practices Manual (2015)

- New York State Standards and Specifications for Erosion and Sediment Control (2016)

Related Materials

- Stabilization practices

- Erosion prevention practices - temporary seeding and stabilization

- Erosion prevention practices - natural and synthetic mulches

- Erosion prevention practices - tackifiers and soil stabilizers

- Erosion prevention practices - erosion control blankets and anchoring devices

- Erosion prevention practices - turf reinforcement mats

- Erosion prevention practices - Riprap

- Sediment control practices

- Sediment control practices - Vehicle tracking BMPs

- Sediment control practices - Perimeter controls for disturbed areas

- Sediment control practices - Check dams (ditch checks, ditch dikes)

- Sediment control practices - Diversion barrier controls (cofferdams/temporary dikes)

- Sediment control practices - Storm drain inlet protection

- Sediment control practices - Outlet energy dissipation

- Sediment control practices - Sediment traps and basins

- Sediment control practices - Stabilized earth/soil berm