TCMA Chloride Management Plan - Prioritizing and Implementing Restoration and Protection

Reducing chloride at the source is needed throughout the entire TCMA, not only to restore already impacted waters but also to protect all water resources. There are multiple sources to consider, a variety of options to reduce chloride, and a large geographical area to address. This section is intended to provide guidance, resources, and information to assist in making the important decisions of the what, how and when for managing chloride. The available data indicates that surface waters and groundwater that exceed the state’s chloride standards, as well as many lakes and streams that are considered to be at high risk for chloride impairment. Many lakes, streams, and wetlands have minimal or no data available, especially during critical times of the year, which makes it difficult to determine the current chloride status. Reductions in chloride loads not only benefit surface and groundwater quality, but may also reduce damage to infrastructure and vehicles due to corrosion, and reduce impacts to vegetation along roadways. Finally, improved winter maintenance practices that reduce salt usage also result in direct cost-savings to winter maintenance organizations and private applicators. Without making efforts to reduce chloride loads, the trend of increasing chloride concentrations in lakes, wetlands, streams, and groundwater is expected to continue and the cost-savings related to improved winter maintenance practices will be lost. Treating waters already contaminated by chloride through RO or distillation is impractical and cost-prohibitive.

Contents

- 1 Performance-based approach for reducing chloride

- 2 Prioritization and critical areas

- 3 Implementation strategies

- 3.1 Winter maintenance leadership (state, county, city, schools and private)

- 3.2 Winter maintenance professionals (state, county, city, schools, parks, private)

- 3.3 Watershed management organizations and districts and Soil and Water Conservation Districts

- 3.4 Municipalities

- 3.5 Wastewater treatment facilities and industrial dischargers

- 3.6 Water softeners

- 3.7 Water treatment facilities (water supply)

- 3.8 Citizens

- 3.9 Minnesota Pollution Control Agency

- 3.10 Policy makers

- 3.11 Secondary audiences

- 3.11.1 Those awarding maintenance contracts

- 3.11.2 Some example language to consider

- 3.11.3 Grant-giving organizations

- 3.11.4 Driver education programs and Department of Driver and Vehicle Services

- 3.11.5 Pavement designers, researchers, engineers

- 3.11.6 Water experts in most any field including limnologists, hydrologists, biologists, chemists

- 3.11.7 Agriculture

- 3.11.8 Other state organizations

- 3.12 Chloride reduction strategy

- 3.12.1 Implementation strategies: traditional framework

- 3.12.2 A few salt saving BMPs for winter maintenance programs

- 3.12.3 Implementation strategies: non-traditional framework

- 3.12.4 Alternative pavement types and urban design

- 3.12.5 Driver behavior changes

- 3.12.6 Non-chloride deicers

- 3.12.7 Snow melting equipment

- 3.12.8 Training and professional development opportunities

- 3.12.9 MS4 permit implications/strategies/reporting

- 3.12.10 Private (commercial, industrial, residential)

- 3.12.11 Homeowners and small business owners

- 3.13 Citizen attitudes and practices

- 3.14 Success stories

- 3.14.1 Maintenance Decision Support System and Automatic Vehicle Location -- MNDOT

- 3.14.2 Dakota County

- 3.14.3 Scott County

- 3.14.4 St. Louis County Public Works Department

- 3.14.5 City of Cottage Grove

- 3.14.6 City of Eagan

- 3.14.7 City of Minnetonka

- 3.14.8 Norwood Young America

- 3.14.9 City of Plymouth

- 3.14.10 City of Prior Lake

- 3.14.11 Rice Creek Watershed Cities

- 3.14.12 City of Richfield

- 3.14.13 City of Shoreview

- 3.14.14 City of St. Paul

- 3.14.15 City of Waconia

- 3.14.16 University of Minnesota, Twin Cities

- 3.14.17 Joe’s Lawn & Snow

- 3.15 Cost considerations and funding opportunities

- 3.16 Related pages

Performance-based approach for reducing chloride

Deicing salt is currently the most common and preferred method for meeting the public’s winter travel expectations. There is currently not an environmentally safe and cost-effective alternative that is effective at melting ice. Therefore, the continued use of salt as the predominant deicing agent for public safety in the TCMA is expected. Setting a specific chloride load reduction target for each individual winter maintenance chloride source is challenging, as is measuring actual chloride loads entering our surface and groundwater from deicing salt and other nonpoint sources in the TCMA. Therefore, priority should be put on improving winter maintenance practices to use only a minimal amount of salt, also referred to as Smart Salting, across the entire TCMA. With these considerations in mind, the implementation approach for achieving the TMDLs and protecting all waters in the TCMA is to focus on performance of improved winter maintenance practices as well as continuing to monitor trends in local waterbodies.

A standard approach to TMDL implementation is to translate the wasteload allocation (WLA) component of the TMDL directly to a numeric permit limit, which is typical for permitted facilities with monitoring requirements. In the case of urban stormwater regulated through a Municipal Separate Storm Sewer System (MS4) Permit, the WLA may be presented in the form of a percent reduction from a baseline condition. The specified percent reduction is then included in the MS4 Permit. With a performance-based approach, the numeric WLA is translated to a performance criterion. This can include the development and implementation of winter maintenance plan which identifies a desired level of the BMP implementation and a schedule for achieving specific implementation activities. Progress made towards those goals are documented and reported, along with annual estimates of salt usage and reductions achieved through BMPs implemented.

In cases where it is not feasible to calculate a numeric effluent limit, federal regulations allow for the use of the BMPs as effluent limits (40 CFR § 122.44(k)). Such a performance-based or BMP approach to compliance with WLAs is being taken by states to address the Chesapeake Bay TMDL for nutrients. The TMDL is being implemented through state Implementation Plans. Some states are taking a performance-based approach to addressing urban stormwater sources, requiring minimum levels of the BMP implementation rather than requiring specific levels of pollutant load reductions.

A performance-based approach will be tracked through documentation of existing winter maintenance practices, goals for implementing improved practices including schedules, and reporting on progress made. Entities may choose to use the Winter Maintenance Assessment tool (WMAt), which is a winter maintenance BMP tracking tool, to assess and document practices and set goals, or another approach of their choice. Entities should track progress and document efforts, including, to the extent possible, estimates of reduced salt usage as a result of improved practices. Entities that have achieved their goals for winter maintenance will have documented their practices in a winter maintenance plan. Entities that have already made significant progress in winter maintenance activities will be able to demonstrate this through their documentation of existing practices. This plan should be reviewed annually and evaluated against the latest knowledge and technologies available for winter maintenance.

The performance-based approach doesn’t focus on specific numbers to meet, but rather on making progress through the use of BMPs. Progress is measured by degree of implementation and trends in ambient monitoring. In a traditional approach with numeric targets, progress would be measured by accounting for salt applied and comparing to the targets. The performance-based approach is intended to allow for flexibility in implementation and recognize the complexities involved with winter maintenance. Because the performance-based approach does not provide a specific numeric target, a limitation of the approach is that it is not definitive on when enough progress has been made. This can only be determined by continued ambient monitoring that demonstrates compliance with water quality standards.

Prioritization and critical areas

To see this section as a separate page link here.

This plan has been developed for many different audiences. Organizations interested in reducing the amount of salt in waters should start with an effort to fully understand the problem and determine what role the organization plays in contributing, preventing, or remediating the growing trend of increased chloride in surface and groundwater.

Prioritization of efforts to reduce chloride may be based on current water quality conditions. Waters found to exceed the state standard and their contributing watersheds should be given top priority for chloride reduction efforts. Many waters are considered to be high risk, but do not exceed the standard at this time. These areas may be given second priority unless there are no known chloride impairments in the watershed, and then the high risk waters could be given highest priority.

Prioritization of reduction efforts may also be based on the relative size and impact of the source of chloride, such as prioritizing winter maintenance activities in areas with a high density of impervious surfaces, or putting emphasis on residential water softeners for those watersheds where wastewater treatment facilities are identified as a major contributor of chloride. There may also be other ways that are more appropriate for each organization to determine where to prioritize reduction efforts.

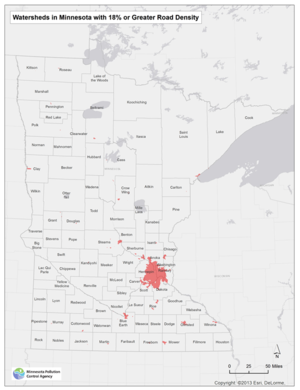

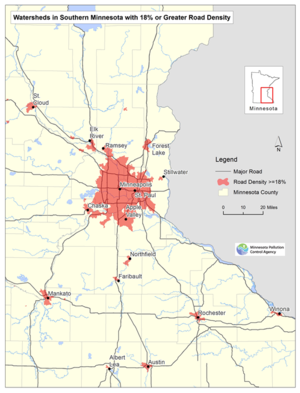

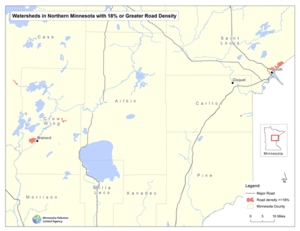

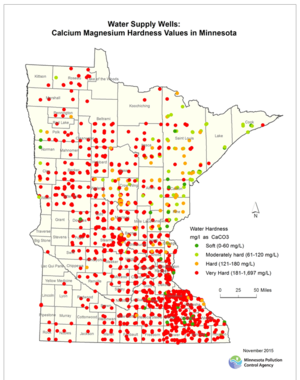

Critical areas have been identified where chloride reduction efforts are necessary to achieve water quality goals. Two strategies have been used based on the source of chloride to identify critical watershed. The first strategy identifies watersheds with road densities of 18% or greater to identify watershed where chloride concentrations are typically above water quality standards. The maps illustrate critical watersheds statewide, in southern Minnesota, and in the norther part of Minnesota. An interactive map showing these critical areas is available on the MPCA Road Salt & Water Quality website. The second strategy used to identify critical areas for chloride reduction focuses on areas with drinking water supply wells with hard and very hard water. Through these two strategies critical areas have been identified across the state where chloride loadings are to be expected high and therefore implementation efforts to reduce chloride should be focused. For the protection of surface and ground waters implementation is encouraged statewide.

Implementation strategies

To see this section as an individual page, link here.

This section provides the overall framework for the implementation strategies that are necessary to protect and restore our water resources. These high-level strategies are intended for both protection and restoration and are described by audience. The next section will provide more detailed implementation activities for the various sources of chloride. The over-arching implementation strategy is a performance-based approach. This approach allows stakeholders and regulators flexibility in the type of BMPs and the timing of implementation, and allows individuals an opportunity to develop chloride management strategies that are practical for their individual situation. Success under the performance-based approach will be measured in terms of the BMPs implemented.

A tool called the WMAt has been developed by the MPCA and is available for use by winter maintenance professionals across the state. The WMAt can be used voluntarily to understand current practices, identify areas of improvement, and track progress. While optional, everyone involved in winter maintenance is highly encouraged to use the WMAt. The tool is intended to streamline and simplify implementation goals and strategies. The tool can also be used to compare practices with other entities and learn from each other in order to achieve the greatest chloride reductions while providing a high level of service. Utilization of this planning tool will allow the user to track their progress over time and show the results of their efforts. The tool can serve as both a reporting mechanism to understand the current practices and as a planning tool to understand future practices. The planning side of the tool will help understand the challenges and costs associated with improved practices.

The overall performance-based implementation strategy for the primary audiences and a suggested timeframe is presented in the Performance-Based Chloride Reduction Strategies table with descriptive text following the figure. Secondary audiences are described at the end of this section and are not presented in a table.

Performance-Based Chloride Reduction Strategies

Link to this table

| Audience | years 1-2 | years 1-2 years 3-5 | years 6-10 | Beyond year 10 |

|---|---|---|---|---|

| Winter Maintenance Leadership (state, county, city, schools, private): those not involved in day to day operations of maintenance crew. |

|

|

|

|

| Winter Maintenance Professionals (state, county, city, schools, private): plow drivers, mechanics, supervisors of crew. |

|

|

|

|

| WMOs/WDs, Environmental Organizations and Institutions, and Educators |

|

|

|

|

| Municipalities |

|

|

|

|

| Wastewater Treatment Plants and Industrial Dischargers |

|

|

|

|

| Water Treatment Facilities (water supply) |

|

|

|

|

| Citizens |

|

|

|

|

| MPCA |

|

|

|

|

| Policy Makers (city, county, state, other) |

|

|

|

|

Winter maintenance leadership (state, county, city, schools and private)

To view this section as an individual page link here.

Winter maintenance leadership is the group responsible for hands-on efforts and operation management. This group includes the individuals in charge of the shop facilities, selling winter maintenance services, determining the type of pavement overlays, or organizing the “getting ready for winter” refresher training. This group does not include the plow drivers or their direct supervisors.

Winter maintenance leadership is a very diverse group that plays a variety of roles across many organizations. Their influence is significant and they have great potential to positively impact reductions in salt use. This group can advocate for change by understanding the economic benefits of salt reduction, including the direct cost savings as a result of using less salt.

The following table presents example activities and timelines for winter maintenance leadership to consider. Throughout implementation, goals and practices should be reviewed, assessed, and adaptively updated to reduce the use of chloride. Examples presented in this section include specific possible actions. However, these actions are intended to be examples and are not meant to put emphasis on the specific actions. Each entity will need to assess the most relevant and cost-effective actions to take in their situation to reduce salt loadings.

Examples of Implementation Strategies for Winter Maintenance Leadership

Link to this table

| Assessment Items | Goals | Actions |

|---|---|---|

| Does salt leave storage sites in ways not intended? | No salty runoff water from salt sheds. | Storage sheds 1, 2, 4 are ok. Re-grade floor of storage shed 3 so water that enters the shed stays in shed. |

| Do customers know that salt harms the environment and that improved practices are being implemented to reduce salt use yet provide great service? | Give all customers the opportunity to learn about efforts to reduce salt. | Meet or talk to all customers when bidding on work explaining approaches to winter maintenance and environmental protection (private contractors) or run cable TV infomercials about salt reduction reasons and strategies during November (municipal). |

| Do trucks contribute salt to the truck wash water? | Re-use 50% of winter truck wash water for brine making or have less salt on truck prior to entering the wash. | Install filter system to remove wash water oils and solids, install tank to capture wash water, integrate filtered wash water in brine making system or Install a truck cleaning station before the truck wash to encourage thorough truck emptying in an area where granular salt can be easily reclaimed. |

| Which organizations have been most successful in reducing salt and what are the lessons learned? | Identify outstanding success in areas of interest (i.e. storage buildings, contracts that don’t bill by the ton, using non-traditional plow drivers to get 24 hour coverage). | Look at Clear Roads research, Snow and Ice Management Association (SIMA) research, APWA research, AASHTO research, attend the Freshwater Society’s annual Road Salt Symposium and other winter maintenance conferences to identify the leaders. Talk to them directly. |

| Are lower salt use pavements being installed (permeable, heated, narrower)? | Find some sort of pavement surface that requires 20% less salt on it. | Install permeable asphalt in parking lot near "Smith" lake. |

| Is payment based on amount of salt applied? | Have a profitable contract without billing by the ton which encourages overuse of salt. | Look at SIMA website for example contracts that do not charge by volume. |

| Is concern over liability resulting in over applying salt? | See if other states have a law to reduce liability for private companies doing winter maintenance. | Encourage legislators to look at New Hampshire’s law that limits liability of private contractors in winter maintenance. |

Example: Years 1-2

- Better understand the impacts of salt on the environment and how organization may contribute.

- Create a chart of items to investigate that may reduce salt use/waste. Consider creating a list of items to be assessed, including goals, actions, and priorities.

- Visit the Snow and Ice Management Association website for example contracts that do not charge by volume.

- Encourage legislators to look at New Hampshire’s law that limits liability of private contractors in winter maintenance.

Watch a video: This video, produced by the MWMO and the UMN, is used to train seasonal and full-time property employees as well as business owners, front desk staff and anyone else who needs to control snow and ice in or near entrances and on sidewalks-

Example: Years 3-5

- Install truck cleaning station before truck wash and provide training for proper use.

- Provide training for crew on how to monitor pavement temperatures, calibrate equipment, chose deicer’s that will work best based on pavement temperatures.

- Revise contracts to avoid billing by the ton and stay profitable, meet with them for ideas.

- Educate customers about winter maintenance strategies.

Example: Years 6-10

- Re-grade floor of storage shed #3.

- Install permeable asphalt in parking lot near “Smith” Lake

Winter maintenance professionals (state, county, city, schools, parks, private)

Winter maintenance professionals are responsible for performing outdoor, hands-on winter maintenance and those who supervise them. The primary duties include snow and ice removal from roads, sidewalks, parking lots, and trails, and applying a variety of deicers and abrasives. Some are part of emergency services and have exemption for laws that may cover weight restrictions on trucks or hours of consecutive work.

Winter maintenance professionals are employed by the public and private sectors, working for very small organizations to large organizations. Unusual hours and working in a variety of difficult winter weather conditions are typical in this industry. All of these professionals are under public scrutiny and receive comments about their work, because it directly and visibly impacts the public. There is a lot of pride within this sector as they are called on repeatedly, in the most difficult weather, to get the traveling public to their destinations safely.

The state, county, and city winter maintenance operations in the TCMA are under the extreme pressure of moving people safely on high volume, high speed roads, during all times of the day and night. Although their job is difficult, they often have the advantages of more sophisticated equipment, bigger support staff, less staff turn-over, and access to better and more frequent training than their private counterparts.

Private winter maintenance companies are very diverse and have a unique set of challenges. They often assume legal liability for “slip and falls” at their customer sites. They cannot bill clients when they attend training and have fewer incentives for training their crews. It can be difficult to locate this segment to invite them to Smart Salting trainings. The equipment used for small sites is less sophisticated and prone to over application of material. Their customers are spread out geographically, creating problems for proper and efficient storage and the transport of materials. Part-time seasonal workers fill many of the positions in these companies, which makes proper training an additional challenge for the employer.

The areas of maintenance vary greatly from seldom used sidewalks to the interstate. It ranges from concrete bridge decks to the marble steps of the capitol building. Each maintenance area has unique challenges that must be understood and mastered. The public generally does not understand or appreciate the difficulty of winter maintenance, and certainly does not understand the increasing challenges and changes coming to this industry as it moves towards conservative use of salt.

Maintenance professionals should become educated on the environmental impacts of salt and how their practices contribute to it. Maintenance professionals could attend training on lower salt use strategies, keep an open mind towards change, and look for ways to make salt use more efficient.

Operators could attend training and learn about changes that can be made on an individual basis. Many salt saving strategies do not need the cooperation of an entire agency; they can be incorporated into daily work. Other salt savings actions can be led by supervisors that will involve teamwork within the department, such as moving from manual controlled spreaders to computer controlled spreaders.

Supervisors may assess their current maintenance program using the WMAt, or other assessment techniques, to assess advanced, standard, and remedial practices. The remedial practices could be prioritized then followed by working towards improving good practices to make excellent practices.

Training opportunities, tools, and other resources for winter maintenance professionals can be found in Appendix D.

Example: Years 1-2

- Clean out salt from truck thoroughly before washing truck.

- Reduce speed when applying salt.

- Avoid plowing off other’s salt, communicate with other drivers.

- Bring extra salt back to the pile, do not use it up on the route if not needed.

- Add tanks to 5 trucks a year starting in 2017.

- Work out agreement to buy brine from neighboring agency.

- All supervisors will attend training.

- Speed up physical removal of snow by changing our call out policy to 2 inches of snow.

- Reduce speed of application on high speed roads to 30mph.

- Calibrate most equipment yearly.

Example: Years 3-5

- Speed up physical removal of snow by changing call out policy to 1 inch of snow.

- Work out salt building agreement for salt storage with neighboring agency.

- Calibrate all equipment yearly.

Example: Years 6-10

- Push snow across bridges and/or truck it away.

- Adjust to selecting the appropriate material for the pavement temperature all of the time.

- All personnel will attend training.

Watershed management organizations and districts and Soil and Water Conservation Districts

To view this section as an individual page link here

The WMOs, WDs, and SWCDs play a significant role in the management of the TCMA waters and provide an opportunity to combine the goals and recommendations of the CMP into watershed plans. This important group, together with environmental organizations, agencies and educators are the key organizations to help increase awareness of the problem and encourage reduced salt use across the TCMA. Much of the changes in attitudes and environmental awareness has stemmed from this group of organizations. There are a wide range of possibilities for incorporating key elements of this CMP into watershed plans, as well as important roles that the WMO/WDs can take to help reduce salt use.

The WMOs/WDs/SWCDs play an important role in developing funding programs specifically for private entities, who may have limited funding options.

Example: Years 1-2

- Partner with the MPCA to offer the Smart Salting winter maintenance training for local private and public winter maintenance professionals each winter.

- Educate 50% of constituents on the benefits of smart salt use.

- Create awareness about the environmental impacts of chloride through education, outreach, and other activities to local residents, applicators, elected officials and businesses.

- Monitor local surface waters for chloride concentrations to track trends, track progress and understand the movement of chloride through the watershed.

- Develop incentive based program for chloride reduction strategies.

- Host yearly workshops for local winter maintenance professionals to encourage the use of the WMAt and track progress of BMPs implemented.

- Provide a measuring cup type salt scooper to homeowners and small businesses at the point of sale of salt in order to raise awareness of the amount of salt they are using.

Example: Years 3-5

- Educate 75% of constituents on the benefits of smart salt use.

- Offer grants to private and public winter maintenance organizations for upgrading equipment or implementing innovating practices.

- Implement a rebate program to residents to install on-demand water softeners and remove old, inefficient water softeners.

- Provide “free” advertising to private applicators who meet “smart salting” criteria.

- Encourage local businesses and public buildings to reduce salt use through improved insurance benefits and liability protection.

- Partner with local stakeholder on innovative projects to reduce chloride at the source and alternatives for de-icing and water softening.

Example: Years 6-10

- Educate 100% of constituents on the benefits of smart salt use.

- Create model ordinances, educational materials, or incentives for the organization or others to use and/or adopt. For example:

- Restrict the application of salt within a city to trained winter maintenance professionals.

- Citizens are asked to prove their knowledge of salt impacts on the environment and sign a pledge to use less salt, in return for a stormwater fee credit.

- Create consumer awareness materials available at participating stores (promoting the sales of shovels and snow blowers instead of ice melt).

- Encourage hazardous household waste centers to accept ice-melt products.

Municipalities

To view this section as an individual page link here.

Expectations for all municipalities will begin with an assessment of the existing winter maintenance practices and designing a plan to improve practices. The MS4s will have an additional requirement to report progress on the use of improved winter maintenance practices to the MPCA.

The purpose of this assessment is to determine where opportunities exist to make reductions in salt use. The information in the CMP may be used by municipalities to assess existing practices, specifically the assessment criteria in Appendix B. For a quicker and more thorough assessment, the online WMAt, currently under development, could be used. The WMAt designed to be an easy-to-use web-based tool. This tool will allow municipalities to evaluate their current winter maintenance program at a very detailed level and create a customized plan for implementing salt savings. The tool will allow an individual to assess their current practices and speculate on potential future practices to understand how to reduce the use of chlorides while still providing an acceptable level of service.

This tool is developed for winter maintenance professionals with a broad and detailed understanding of the winter maintenance operations. These professionals should conduct the assessment, then set and share the goals so that the organization can work to meet the goals.

Municipalities can choose to assess existing practices using any means. Municipalities should identify practices to improve winter maintenance activities, with priority on eliminating remedial or unacceptable practices. The implementation goal for each MS4 will be specific to the MS4.

Each municipality will have a unique implementation goal. Some municipalities have already made substantial improvements in practices and require minor effort to improve practices. For leading edge operations it is worthwhile to note the technology and tools for further reductions of salt use are constantly evolving and changing. Organizations currently demonstrating the best practices will still have to dedicate time and resources to stay current with the industry. Leading edge operations could consider sharing their experiences with other organizations that are attempting to lower salt use. For organizations that are just beginning reductions, it may be worthwhile to observe the operations and equipment of those who have already made progress on reducing salt. Networking with other operators could be part of the organization’s plan. Organizations outside of Minnesota may also have valuable insights. Many municipalities in the Midwest and Canada have developed expertise in different areas of winter maintenance and are recognized by their peers across the nations.

Example: Years 1-2

- Educate civic leaders on the benefits to reducing chloride and its importance.

- Partner with the MPCA to offer the Smart Salting winter maintenance training for local private winter maintenance professionals in the area each winter.

- Educate 50% of constituents on the benefits of smart salt use.

- Create awareness about the environmental impacts of chloride through education, outreach, and other activities to local residents, applicators, elected officials, and businesses.

- Attend trainings, workshops, and events to learn about new technology and strategies for reduced salt use.

Example: Years 3-5

- Educate 75% of constituents on the benefits of smart salt use.

- Recognize private winter maintenance organizations for upgrading equipment or implementing innovating practices.

- Implement a rebate program to residents to install on-demand water softeners and remove old, inefficient water softeners.

- Provide “free” advertising to private applicators who meet Smart Salting criteria.

- Encourage local businesses and public buildings to reduce salt use through improved insurance benefits and liability protection.

- Partner with state and local stakeholders on innovative projects to reduce chloride at the source.

Example: Years 6-10

- Educate 100% of constituents on the benefits of smart salt use.

- Create model ordinances, educational materials, or incentives for the organization or others to use and/or adopt. For example:

- Restrict the application of salt within a city to trained winter maintenance professionals.

- Citizens are asked to prove their knowledge of salt problems in the water and sign a pledge to use less salt, in return for a stormwater fee credit.

- Create consumer awareness materials available at participating stores (promoting the sales of shovels and snow blowers instead of ice melt).

- Encourage hazardous household waste centers to accept ice-melt products.

Wastewater treatment facilities and industrial dischargers

To view this section as an individual page link here.

This section addresses municipal and industrial WWTPs that either create saline water in their operations or receive saline water and discharge it. The concentration of chloride present in the waste stream will vary for every facility and is dependent on the source of chloride. The major source of chloride to municipal WWTP is from residential water softeners (>90% in some municipalities).

If WWTPs effluent chloride concentrations demonstrate a reasonable potential to exceed 230 mg/L, the MPCA will work with the permitted entity to include appropriate permit conditions, including monitoring requirements, compliance schedules, and possible effluent limits. If a permitted facility receives a chloride limit they will be required to identify sources of chloride.

For municipal wastewater facilities, technologies capable of removing chloride from wastewater are either cost-prohibitive, technologically infeasible, or a mix of the two. The RO and evaporation of the resulting brine is the most viable option for removal of chloride at the WWTP. The MPCA analyzed the cost and implementation concerns of using RO treatment and evaporation to remove chloride for WWTPs in 2012 (Henningsgaard 2012), which is also summarized in the section addressing costs. Based on the assessment, RO treatment and evaporation are cost prohibitive and pose significant implementation concerns.

The most feasible option for reducing chloride loading to the WWTPs is upstream source reduction. The two primary sources of chloride to WWTPs are industrial users and residential water softeners. If a facility has a chloride limit or would like to voluntarily reduce chloride, WWTPs should work through their Industrial Pretreatment Program (IPP) to identify significant users who may be contributing chloride. The WWTPs can review existing data from industrial users or can require industrial users to collect chloride data. If industrial users are identified as a significant source of chloride, the WWTP can work with the industrial user through the IPP to develop and implement a plan to reduce chloride loads

Water softeners

To view this section as an individual page link here.

One option for municipalities includes the potential of providing lime or membrane water softening at the water treatment plant (WTP) in an attempt to eliminate water softening at individual residences. This option assumes that all WTP users would be connected to city drinking water and would have taken their water softener offline. Water softening at the WTP has the potential to be more cost efficient than individual residential water softening for many users.

The MPCA supports any effort to reduce chloride loading to the WWTPs, including encouraging residential users to switch to high efficiency ion exchange softeners. However, the MPCA does not believe that switching residents to high efficiency softeners will automatically allow a WWTP to come into compliance with chloride permit limits. The MPCA is developing a guidance document that will provide WWTPs chloride source reduction methods, treatment alternatives, and permitting strategies that will help WWTPs to come into compliance with the chloride water quality standard. The following steps will help to reduce the amount of salt being discharged to a WWTP:

- Know the hardness level of local water supply.

- Consider whether a water softener is needed and avoid the ongoing expenses if it isn’t. Test water for hardness. Typically water hardness greater than 120 mg/L CaCO3 needs to be softened. See the University of Kentucky’s Guidance: Hard Water- To Soften or Not to Soften for more information.

- Do not over soften. Program the water softener to obtain an optimal level of hardness.

- Uninstall an old timed softener and replace it with a new demand softener. A new demand softener could be optimized to minimize backwashing and the newer model would have a more efficient ion exchange resin.

- If using a timer-based softener, set to recharge at the lowest effective rate and turn it off when on vacation.

- Install a bypass so landscape irrigation water is not softened.

- Consider alternatives to salt-based water softeners.

- Move to centralized water softening using lime rather than salt

Homeowners with water softeners with an on-site septic system, salt reduction strategies should also be taken. Chlorides in on-site septic systems will infiltrate to groundwater and may result in elevated levels of chloride in groundwater which can impact water supplies as well as groundwater recharge of lakes, streams, and wetlands.

Example: Years 1-2

- Monitor chloride in effluent and review past monitoring reports for chloride concentrations.

- Evaluate chloride data and determine if reasonable potential to exceed 230 mg/L exist.

- If potential to exceed 230 mg/L work with MPCA permit staff and create a plan to reduce upstream chloride sources.

Example: Years 3-5

- Identify goals for chloride reductions.

- Develop a compliance schedule if chloride limits are established through NPDES permit.

- Educate industrial dischargers on the importance of reducing chloride in waste streams.

- Educate residents in cities that pre-soften water that they do not need water softeners.

Example: Years 6-10

- Work with water softening companies to offer a trade-in program to upgrade to high efficiency residential water softeners.

- Offer a credit to a city or industrial discharger for reducing chloride concentrations in wastewater.

- Work with municipality to install municipal lime softening at the WTP.

Water treatment facilities (water supply)

To view this section as an individual page link here.

This sector draws water from groundwater or surface water sources and tests and treats it before distributing it to residents. Municipalities that soften the water before it is distributed to households or municipalities that are considering this, care should be taken to minimize salt use and salt waste. Assess the need for soft water in the area and look for non-salt approaches such as lime softening. Consider the mass balance of how much salt is used by individual water softeners versus centralized water softening. However, users may be unaware the water from the municipality is softened or may be accustomed to having a residential softener leading to double softening. Municipalities can also evaluate how high saline water is disposed of in the cleaning and flushing process.

Example: Years 1-2

- Assess hardness level of water and need for softening.

- Determine if non-chloride source softening is a viable option.

- Survey homeowners on the use of residential water softening.

- Educate customers on water conservation and the benefits related to chloride reduction.

Example: Years 3-5

- Encourage residents to install high efficiency water softeners.

- Encourage home by-pass of soft water for irrigation and drinking water. Create cost share program to encourage plumbing changes needed to accommodate this.

- For those with RO systems, explore ways to capture RO waste water which is saline and route to water softener.

Example: Years 6-10

- Reuse salt from cleaning municipal water softening equipment.

- Use non-chloride techniques for softening source water.

Citizens

To view this section as an individual page link here.

This group includes everyone living or working in the TCMA. Each person contributes to the attitudes and practices that have created a high and steadily growing volume of salt to be used each year. In order to reverse this situation each person must contribute to changing attitudes and practices that are more sustainable and require less salt. The list of actions that this group can take is extensive. Citizens form public policy, set the expectations that our maintenance crews must live up to, and use salt on their own property such as water softening and salting their sidewalks in the winter. Engaging the citizenry in the TCMA offers the best chance to get salt use under control.

There are many ways to reduce salt use while maintaining high safety standards. Below are a few simple steps that residents can take to help reduce the amount of chloride entering waters. More ideas are listed on the MPCA’s website.

Citizens can look for ways to reduce salt use. Every teaspoon of salt reduction prevents five gallons of water from being polluted. Small changes can have big results. Typically the biggest salt uses are sidewalk/driveway/steps (winter maintenance) salt and water softeners, with the outdoor use for winter maintenance being the largest use.

Winter safety

- Support local and state winter maintenance crews in their efforts to reduce their salt use.

- Work together with local government, businesses, schools, churches, and non-profits to find ways to reduce salt use in the community.

- Inform and educate local and state policy makers on the importance of this issue.

- Shovel. The more snow and ice removed manually, the less salt is needed and the more effective it can be. Whether through shoveling, blowing, plowing or scraping, getting out early and keep up with the storm. Salt may not be needed.

- Do not apply salt to areas that have not been shoveled.

- Generally speaking, sidewalk salts work better when it is warmer. Below 15°F is too cold for salt as most salts stop working at this pavement temperature. Use sand instead for traction, but remember that sand does not melt ice. If melting snow or ice look for opportunities when the sun is shining or the temperatures are warming, which will be more effective with less salt.

- Slow down. Drive for the conditions and make sure to give plow drivers plenty of space to do their work. Consider purchasing winter (snow) tires.

- Be patient. If the salt is not visible on the road doesn't mean it hasn't been applied. These products take time to work. Allow more time for trips to account for driving at a slower speed.

- More salt does not mean more melting. Use less than 4 pounds of salt per 1,000 square feet (an average parking space is about 150 square feet). One pound of salt is approximately a heaping 12-ounce coffee mug. Consider purchasing a hand-held spreader to apply a consistent amount.

- Sweep up extra salt and sand. If salt or sand is visible on dry pavement it is no longer doing any work and will be washed away. Reuse this salt or sand somewhere else.

- Research the products. Choose the right one for the conditions. Salts are used because they are able to decrease the freezing point of water. Whatever product selected, know the temperature it stops working.

- There are no labeling laws for bags of deicers. Therefore the information on the bag may be accurate or misleading; it may contain a list of all ingredients, a partial list, or no ingredient list. See the MPCA salt & water quality website for information on common deicers and the practical melting ranges.

- Watch a video. This video, produced by the MWMO, provides tips to homeowners about more environmentally friendly snow and ice removal: Improved Winter Maintenance: Good Choices for Clean Water.

- Read and pass along Nine Mile Creek Watershed District's (NMCWD) brochure about residential snow and ice care: Residential snow and ice care (NMCWD)

Water softening

- Use a high efficiency water softener.

- Avoid using softened water for irrigation or drinking water.

- Do not use a water softener if source water is already softened by the WWTP.

Minnesota Pollution Control Agency

To view this section as an individual page link here.

The MPCA will continue to provide support to stakeholders to address chloride impacts on surface water and groundwater resources, as resources allow. The MPCA will continue to monitor lakes, streams, and groundwater for chloride, in cooperation with the TCMA partners, to track progress and better understand water quality trends. The MPCA recognizes the importance of the MPCA Smart Salting (S2) training program and will continue to support and improve the training as new technologies and resources are available. The MPCA will also continue providing necessary technical assistance, resources, tools including supporting and hosting the WMAt, to its permitees, stakeholders and local partners, and to facilitate forums discussing progress of implementation of the CMP and adaptive management strategies in the TCMA as resources are available.

Example: Years 1-2

- Explore ways to support a sustainable MPCA Smart Salting Program.

- Host, support and update the WMAt on the MPCA website.

- Continue to monitor lakes, rivers, and groundwater for chloride.

- Solicit assistance in statewide chloride monitoring through partnerships and grant programs.

- Participate in the Freshwater Society’s annual Road Salt Symposium.

- Update website with educational information on lower salt use for citizens.

- Support and provide access to the “Salt Dilemma” display at various events and venues.

- Provide technical assistance to permitee for reducing chloride

Example: Years 3-5

- Continue to monitor lakes, rivers, and groundwater for chloride.

- Continue to update impaired waters list with waterbodies exceeding the state’s chloride standard.

- Participate in the Freshwater Society’s annual Road Salt Symposium.

- Support and provide access to the “Salt Dilemma” display at various events and venues.

- Continue to provide technical assistance to permittees for reducing chloride and fulfilling permit requirements for Chloride TMDLs.

- Integrate chloride reduction opportunities into other MPCA programs.

- Include chloride reduction as a priority at the MPCA where possible.

Example: Years 6-10

- Continue to monitor lakes, rivers, and groundwater for chloride.

- Continue to update impaired waters list with waterbodies exceeding the state’s chloride standard.

- Continue to support the implementation of the TCMA CMP.

- Support and provide access to the “Salt Dilemma” display at various events and venues.

- Continue to provide technical assistance to permittees for reducing chloride

Policy makers

To view this section as an individual page link here.

State, county, city policy makers, and those that make policy to govern other entities have an important role to play in chloride management. Policy is the tool that helps speed up behavior change in areas where behavior change is not progressing or progressing fast enough. One of the challenges facing policy makers is that they may not fully understand the environmental impacts of salt. In order to enable policy makers to be more active in this area, information about the environmental impacts of salt and awareness of the existing voluntarily efforts to improve salt reductions is necessary. There are many policies and actions that can be considered to assist with reducing salt use.

Example: Years 1-2

- Better understand environmental impacts of salt use and ways the constituents contribute.

- Understand options for reducing chloride use.

- Support the implementation of the CMP.

- Develop a limited liability law to protect private contractors from being sued if they are following BMPs under the Smart Salting (S2) training, similar to New Hampshire. Fear of law-suits often drives over application of salt.

- Create an ordinance for city that all salt and salt/sand piles must be stored indoors and on an impermeable surface.

Example: Years 3-5

- Require statewide certification of salt applicators similar to the Department of Agriculture’s pesticide applicator certification program.

- Require all new construction to have irrigation water and drinking water plumbed so as to not pass through the water softening.

- Require water softeners that recharge by the time of day and not by the salinity of water be banned from sale.

- Provide funding to various state agencies to support local implementation of salt reduction practices.

- Discuss lower levels of service with constituents.

Example: Years 6-10

- Develop labeling laws for deicers sold in MN so ingredients are listed along with practical. melting range. Also should include warning about the environmental impacts of using the material.

- Policies should be reviewed to determine effectiveness in chloride reductions.

- Work with other policy makers to understand the most effective policies.

Secondary audiences

To view this section as an individual page link here.

This group includes those that have a smaller, but important, role in reducing the amount of salt entering surface and ground water.

Those awarding maintenance contracts

The property manager or contracts department for any organization hiring winter maintenance services should consider requiring those bidding on work to have successfully completed the MPCA Smart Salting training. When crews are on-site conducting maintenance work a high percentage (to be determined by contracts department) should have successfully completed the training within the past five years. Here are things to consider when negotiating a contract for winter maintenance services:

- Have all contracted and landlord winter maintenance workers applying salt attend the MPCA Smart Salting training.

- Charge for level of service (i.e., hourly, event-based or seasonally), not per pound of product.

- Develop a Snow and Ice Policy and set clear expectations (see Smart Salting training website for example policies).

- Clean up accidentally spilled piles of salt.

- Use mechanical methods of snow and ice removal (plow, shovel, brush, blow) prior to using any chemical control – capabilities needed.

- If using sand, conduct year-around sweeping to remove any excess product applied in winter.

- Record what and how much product is applied for each event.

- Calibrate all equipment at least annually and document the results.

- Use salt (NaCl) only if pavement temperature is above 15 degrees Fahrenheit.

- Find ways to wet salt – 30% less material can be used, it works faster and stays in place Show progress towards lower application rates based on the

MPCA’s training program.

Some example language to consider

Snow plowing and deicing of parking lots will be done in a manner similar to guidelines provided under both the Minnesota Pollution Control Agency and the Minnesota Department of Transportation Winter Parking Lot and Sidewalk Maintenance manual provided to LESSOR.

LESSOR shall request LESSOR’S vendor to attend Smart Salting training offered by the Minnesota Pollution Control Agency. The following link provides information about the Minnesota Pollution Control Agency’s Road Salt Education Program.

Grant-giving organizations

Ensure that grant opportunities are available for protection and restoration of surface and ground waters for chloride. Consider ways to ensure a simple application process and equal access to funds for non-traditional source reduction (pollution prevention) projects addressing chloride. Possible areas include:

- Research or implementation of reduced-salt strategies to winter maintenance.

- Research or implementation of lower or no salt pavement strategies.

- Citizen involvement on environmental impacts and solutions.

- Research or implementation of changing winter driver behavior and expectations.

- Research high efficiency residential water softening and non-chloride options.

- Re-using waste stream products for deicing.

- Research or implementation of urban design solutions that reduce salt use. (Examples: parking ramps/covered parking as an alternative to vast parking lots. Skyways or covered walkways. Transit-oriented development so people have alternatives to driving.)

Driver education programs and Department of Driver and Vehicle Services

For all new drivers, those getting additional licenses such as commercial or motorcycle licenses, and those moving into Minnesota, consider educating about winter tires, appropriate winter driving, and the environmental impacts of salt. Include training on winter driving, the temperature range at which salt does not work, how bridge decks and ramps freeze before the roads, and other tips for safe winter driving. Teach drivers to respect the plowing operations and take pressure off of public works departments for instantly cleared surfaces. Send information with driver license renewals to current drivers on tips for winter driving.

Pavement designers, researchers, engineers

Become educated on the issues with high-salt-use surfaces and the impacts to water resources. Look for opportunities to invent, test, and implement lower-salt-use pavement surfaces. This includes sidewalks, parking lots, roads, bridges, ramps, trails, parking ramps, steps or other highly salted surfaces in the winter months. Possible areas include, but are not limited to:

- Permeable surfaces

- Flexible surfaces

- Heated surfaces

- Different color or texture of surfaces

- Smaller surfaces

- Pavement overlays

Water experts in most any field including limnologists, hydrologists, biologists, chemists

Understand the impacts of chloride to water resources and the pathways it takes to get there. Look for opportunities to invent, test, and implement techniques to prevent salt from entering water resources after application or for strategies to mitigate for it. Problem areas to consider include:

- Recovering salt after application to paved surfaces

- Options for treating chloride in stormwater ponds

- Research the impacts of infiltration into ground water versus surface flow to surface waters

- Options for mitigating chloride already present in surface waters

- Capturing and reusing salt water (truck wash, runoff, waste water discharge)

Agriculture

The primary source of chloride from agricultural lands in the TCMA is from fertilizers and land application of food processing waste and biosolids from municipal sewage treatment. Excessive chloride concentrations on agricultural lands can be harmful to crop growth in addition to contributing to elevated levels of chloride in surface runoff and groundwater infiltration. Conservation practices and nutrient management not only protect water resources, but can save farmers money. Development and implementation of nutrient management plans could potentially be conducted for agricultural lands. Conservation practices and nutrient management planning information and guidance can be found at the Minnesota Department of Agriculture website.

Other state organizations

The Minnesota Department of Health (MDH) should continue to monitor chloride in drinking water, as resources allow. The Metropolitan Council may continue to monitor chloride in lakes, wetlands, streams, and groundwater, as well as chloride in wastewater discharges in the TCMA. The Minnesota Department of Natural Resources (DNR) could continue to monitor chloride impacts on aquatic life, plants, and animals. The Board of Water and Soil Resources (BWSR) will continue to administer grant programs to protect, enhance, and restore water quality in lakes, rivers, and streams in addition to protecting groundwater and drinking water sources from degradation, as resources allow.

The MnDOT should continue to provide in-house training and leadership throughout the state in an effort to enable the implementation of effective chloride reducing BMPs. This includes research on innovative technology and passing the knowledge on to others. The Minnesota Department of Agriculture could potentially work with farmers to develop nutrient management plans, which include methods to reduce chloride-based fertilizers.

Chloride reduction strategy

To view this section as an individual page link here.

Implementation strategies: traditional framework

Chloride management is a challenging issue in Minnesota and requires a balance between public safety and the environment. In addition to the balance, chloride management is complex since every winter event is different. The different events can be a result of the type of precipitation, temperature, longevity of the event, timing of the event, etc. In addition to variations in each event, winter seasons can be highly variable from year to year.

Snow and ice maintenance practices vary between road authorities and private applicators. Training, equipment, available resources, client expectations, and political pressure all factor into the amount of deicer being applied.

There is no single BMP that can cost-effectively remove snow and ice and maintain an appropriate level of service for all of the various situations. Chloride management can only be achieved through implementation of an array of different BMPs. The BMPs vary by effectiveness in reducing chloride application and cost of implementing the BMP.

The CMP includes an arsenal of BMPs, which give chloride applicators multiple ways to reduce chloride. This provides BMPs that can be used by high-use/high-experience entities all the way down to low-use/low-experience entities. A wide range of BMPs also allows greater flexibility in the timing and extent of implementation of BMPs.

Traditional BMP strategies can be implemented by chloride applicators. The primary recommended strategies include, but are not limited to:

- Shift from granular products to liquid products

- Improved physical snow and ice removal

- Snow and ice pavement bond prevention

- Training for maintenance professionals

- Education for the public and elected officials

These strategies are centered on the continued use of chloride containing products in the most efficient and effective manner possible. This approach assumes maintaining the same level of service. There are several industry shifts that are needed to reduce salt waste. These changes are applicable to all winter maintenance areas in which a high level of service is expected: roads, parking lots, and sidewalks. Implementing the strategies above will lower salt use, but it may not be reduced enough to protect or restore all water resources.

As part of the stakeholder process to develop the CMP, a TechEx was developed and consists of hands-on salt applicators and suppliers. The TechEx was engaged to better understand the state of the practice and the BMPs available to the winter maintenance industry. The TechEx provided valuable information on specific BMPs that are currently being used by various entities and the benefits of implementing these salt reducing BMPs. This team has been instrumental in the development of the WMAt that will assist winter maintenance organizations in developing their own customized salt reduction plan. Their knowledge, experience, and dedication to using smart salting techniques has been utilized to create this first ever comprehensive evaluation of all available chloride BMPs. Utilization of this planning tool will allow the user to track progress over time and show the results of the efforts.

The tool can serve as both a reporting mechanism to understand the current practices and as a planning tool to understand future practices. The planning part of the tool will help the user understand the challenges and costs associated with improved practices. The WMAt provides a more detailed and comprehensive list of the BMPs available to winter maintenance professionals.

A few salt saving BMPs for winter maintenance programs

While the preferred and most effective approach for developing a chloride reduction plan for individual winter maintenance programs is to utilize the WMAt, here are a few BMPs that have been proven to reduce salt use.

- Calibrate all equipment regularly (both liquid and granular systems).

- Integrate liquids (avoid applying dry material).

- Develop a Winter Maintenance Policy/Plan and share it with supervisors, crew, and customers.

- Provide state-of-the-art Smart Salting training, education, and professional development for all who work in the industry.

- Store salt indoors and on an impermeable pad.

- Anti-icing before events to reduce bonding of snow to pavement.

- Use ground speed controllers.

- Upgrade to equipment that can deliver low application rates.

- Select products that will work well given the pavement temperatures and conditions.

- Select application rates based on road temperatures and trends, the product used cycle time and other factors.

- Start mechanical removal as soon as possible and keep at it throughout the storm.

- Use a variety of methods to reduce bounce and scatter of salt

- Reduce speed

- Higher liquid to granular ratio

- Lower spinner elevation

- Chutes or skirts

- Reduced spinner speed

- Target center of road.

- Refine application rates charts and continually test lower rates.

These BMPs may not be practical for all winter maintenance programs and should not be considered the best or only options for salt reducing activities, but rather a list of BMPs that many programs have already begun implementing and are seeing reduced salt use as a result. To determine the activities appropriate for each organization please visit the MPCA’s Stormwater Manual to utilize the WMAt.

The MnDOT is a leader in winter maintenance related research in the state. Research reports and technical summaries on the latest research can be found on the MnDOT Research Services website.

Implementation strategies: non-traditional framework

The continued use of chloride containing deicing materials to provide safe winter conditions may not be a sustainable long-term solution. Therefore, considering practices that fall outside the current and common methods for winter maintenance are worth evaluating. When evaluating non-traditional methods, it is important to consider the environmental impacts of the methods.

Non-traditional approaches require public acceptance in terms of costs, expectations, and changes in behavior. Implementation of these practices will require a combination of messaging to the public which includes discussion of the potentially significant costs to individuals and government. Five of the main areas where change may be considered include:

- Adopt a lower level of service for roadways, parking lots, and/or sidewalks during snow and ice conditions.

In this scenario, the public would be given a lower level of service on the roadways, parking lots, and/or sidewalks. Physical removal of snow would likely remain the same but the salting would diminish. There are many ways in which winter maintenance professionals could change their level of service. For example, roads could be salted less frequently or perhaps less of the road could be salted. Instead of roads free of ice and snow from shoulder to shoulder, the melted zone could be reduced, perhaps to the middle of the drive lane. Salting could be restricted to critical areas such as intersections, ramps, hills, and high speed roads. Road salt would still be used, but to a lesser extent.

Winter speed limits – alter the speed limits to match the driving conditions during winter storm events or super cold weather times when black ice is present. The MnDOT currently uses a managed traffic lane approach for dealing with high traffic volumes and congestion on the interstate system within the TCMA. It provides a way for the MnDOT to suggest a speed that will reduce braking and further congestion. This same approach could be utilized to manage the expectations of drivers in terms of speed during snow and ice conditions. The temporary winter speed limit approach has been taken in several states including Illinois, Pennsylvania, Colorado, Maine, and Oregon.

- Primary challenges: Changing the public’s behavior and would require acceptance from the public. The cost of longer commute times and less safe travel conditions in winter months are unknown with this approach however. This would affect non-motorized commuters as well (i.e. pedestrians and bicyclists).

- Benefits: Potential to immediately reduce the amount of chloride entering our waters and would save money in salt purchases. This strategy would be easy to implement from a technical perspective but challenging to implement without political and public support.

Alternative pavement types and urban design

In this scenario, government transportation agencies and private industry would adopt different forms of pavement that can be kept clear with less or without the use of salt. This could include various forms of heated roadways, new types of improved traction surfaces, surfaces constructed with internal anti-icing features, solar roadways which could generate heat as well as electricity, permeable pavements, and flexible pavements. Narrower roadways may also allow for less application of deicing material.

Urban design methods such as parking ramps and covered parking, skyways or covered walkways, porous paving, public transit, transit-oriented development, and higher density development may also help to reduce impervious surfaces, reduce impervious surfaces requiring deicing, and reduce the overall chloride use.

- Primary challenges: would require large-scale public funding, and substantial rework of existing roadways. May result in much higher direct costs making its adoption less desirable and practical. This would be difficult to implement on a large scale due to funds, but may be feasible at a smaller, watershed scale. This approach may take a significant amount of time to convert traditional roads to high performance roads. It will be important to educate entities on permeable pavements and the importance in reducing chloride application since the runoff from permeable pavement surfaces will enter the groundwater.

- Benefits: No drastic change in the public expectations for winter travel conditions. Could implement as infrastructure is redeveloped. Would allow for treatment of other pollutants as well.

Driver behavior changes

Use of winter tires or other types of tires with improved traction could be required. This might possibly reduce the expectations for a high level of service, and any salt savings would need to be linked to this secondary step of diminished road melting. There remain concerns that driver behavior would not change enough to allow less salt use. Some types of tires have been associated with increased road wear and subsequent pollution, and Minn. Stat. 169.72, prohibits studded tires. The challenge with this approach lies again with public acceptance and driver education on how to safely use winter tires. There would also be a direct cost to consumers and the enforcement of such a requirement. Increased maintenance to roads would likely be an indirect cost associated with this approach, which the resulting salt savings would be modest at best.

Work with large employers to establish a work from home policy during snow events for employees who have suitable jobs. Possibly this will reduce traffic enough during critical times to allow maintenance to be more effective with less salt.

- Primary challenge: need for widespread changes from the public. Likely indirect cost passed onto consumers. Safety concerns. Increase damage to roads.

- Benefits: would allow for easier continued reduction in salt use.

Non-chloride deicers

There is a fairly wide variety of other chemicals that can be used for anti-icing and/or deicing, chemicals which do not contain chloride. However, there are significant environmental concerns with most of the existing alterative products. In general the toxicity of non-chloride based deicers is often more severe to surface water organisms in the short term as the chemicals breakdown. There are fewer long-term concerns with non-chloride deicers, which should be evaluated against the long-term permanency with chloride. Of the four strategies, this may be the easiest to implement, but the environmental impacts of these alternatives are the highest of the options listed and needs to be better understood.

- Primary challenge: in general, the costs of alternative products that work as well at melting ice are more expensive than chloride containing products. The environmental consequences of alternative products are relatively unknown.

- Benefits: no requirement for public acceptance or changes in behavior. Easy to begin implementing and only requires minor adaptations from maintenance professionals to understand how to effectively and appropriately use these new chemicals.

See MnDOT’s Transportation Research Synthesis Report: Chloride Free Snow and Ice Control Material for further information on non-chloride deicers and other non-traditional strategies such as permeable pavement, reducing road widths, solar, and others.

Snow melting equipment

Snow melting equipment may be a viable solution in some cases. However, the costs, practicalities, and other environmental consequences of snow melting equipment should be explored further before implementing this method.

Training and professional development opportunities

- MPCA Level I Smart Salting Training – Snow and Ice Control Best Practices

- This training program is aimed at high level BMPs for private applicators and for city, county and state winter maintenance professionals. There are two classes offered:

- Winter Parking Lot and Sidewalk Maintenance with reduced environmental impacts. The parking lot and sidewalk training manual is given to each participant.

- Winter Road maintenance with reduced environmental impacts. The Field Handbook for snowplow operators is given to each participant.

- The training schedule for the MPCA Smart Salting trainings can be found at http://stormwater.pca.state.mn.us/index.php/Smart_Salting_(S2)_training_information

- This training program is aimed at high level BMPs for private applicators and for city, county and state winter maintenance professionals. There are two classes offered:

- MPCA Level II Smart Salting Training

- This program is currently being developed and is intended to provide a higher level of training for more experienced winter maintenance professionals.

- The training will provide winter maintenance professionals an opportunity to learn how to utilize the WMAt.

- Minnesota Local Technical Assistance Program (LTAP)

- Snow and Ice Control Material Application

- This training is aimed at determining proper application rates during various conditions in order to use salt and sand effectively and efficiently.

- Snowplow Salt and Sander Controller Calibration Hands-on Workshop

- This workshop is aimed at calibrating salt and sander controllers. Attendees receive hands-on calibration instruction.

- Snow and Ice Control Material Application

- Freshwater Society’s Annual Road Salt Symposium

- The symposium brings together environmental and transportation professionals to learn about the latest research on the environmental impacts of road salt and innovations that are helping overcome the problems. Environmental leadership awards are presented to local organizations that are making progress in reducing salt.

- American Public Works Association (APWA)

- Offer training at APWA meetings and conferences: http://www.apwa.net/topics/education-and-training

- List of those certified by the MPCA Smart Salting trainings can be found at:

- Offer training at APWA meetings and conferences: http://www.apwa.net/topics/education-and-training

http://stormwater.pca.state.mn.us/index.php/Smart_Salting_(S2)_training_certificate_holders

- Small site Smart Salting training video and homeowner Smart Salting training video can be found at https://www.pca.state.mn.us/water/educational-resources .

More training and professional development opportunities can be found in Appendix D. MS4 Permit Implications/Strategies/Reporting

MS4 permit implications/strategies/reporting

One of the challenges for public road authorities is the variability in road types, conditions, and meeting driver expectations. Each municipality is faced with unique challenges and circumstances that will play a role in determining the specific BMPs implemented. Development of winter maintenance policies/plans that are proactive and aim to minimize salt use is a critical first step for all winter maintenance programs to begin implementing the BMPs in an effective and strategic way. Training and regular professional development for all applicators is another key strategy to allow winter maintenance programs to reduce overall chloride use while providing an appropriate level of service.

Municipalities in the TCMA make up the most significant portion of salt applicators and would be expected to take on the majority of the BMP activities for reducing chloride. Those municipalities with a National Pollutant Discharge Elimination System (NPDES) Permit with the MPCA in a chloride impaired watershed will be required to report progress on the implementation of the salt reducing BMPs beginning after issuance of the next Phase 2 MS4 permit, which is expected to occur in 2019. The Phase 1 MS4s, (St. Paul and Minneapolis) will be asked to report their progress in 2016.

The WMAt is a valuable resource to MS4s in terms of prioritizing and implementing the BMPs. Use of the WMAt is not a requirement but will allow each MS4 to determine their own priorities that may be based on cost, location, ease of acceptance, or other important factors unique to the MS4’s particular situation. The WMAt provides the specific BMPs related to all areas of winter maintenance to aid in the development in a detailed plan that meets the unique conditions of each individual program and can be prioritized and implemented according specific needs and constraints.

Another valuable resource for public road authorities is their peer group. Several public road authorities have improved practices, significantly reduced chloride use, and have recognized cost savings by implementing BMPs. These success stories, when shared between entities can be a great way to demonstrate specifically how chloride reductions have been successfully achieved. Case studies describing some of these local success stories and specific areas of improvement are discussed below in Section 3.5.

The MS4 reporting will consist of discussion of the BMPs that have already been implemented and the BMPs that are planned, including a timeline for implementation. Further information on reporting requirements can be found on the MPCA MS4 program website.

Private (commercial, industrial, residential)

A major challenge in the overall reduction of chloride use in the TCMA is getting private applicators to reduce chloride usage. There are five primary hurdles related to this effort:

- Liability concerns for applicators and property owners

- Education and training for applicators, including cost

- Contracting practices and incentives for applicators

- Diversity in personnel experience

- Private companies often are excluded from grant opportunities

Two potential approaches to educating/training private applicators include a required training approach and a voluntary training approach, both discussed further below. A required training assumes that an ordinance or other regulatory mechanism is adopted by a governing body that requires training. A voluntary approach assumes that there is no ordinance or regulatory mechanism in place.

Potential Required Training Approach: for watersheds with chloride impairments (or suggested reductions)

- Implement a state-wide Smart Salting certification program.

- Watersheds to require the MPCA Smart Salting training for anyone performing professional level winter maintenance in the watershed.

- Cities within those watersheds create an ordinance requiring Smart Salting training certification to work in their cities.

- Cities ask commercial property owners in their city to become trained. They award contracts only to certified applicators.

- All government organizations (state/counties/parks/schools/cities) to hire only Smart Salting certified contractors to maintain government properties.

- The MPCA, watersheds, and cities all help advertise the training.

Voluntary Training Approach:

- The MPCA to continue offering Smart Salting training.

- Increase the number of classes

- Expand locations of classes

- Incorporate alternative methods for certification (e.g., Webinars)

- Increase advertising about the availability and importance of being “certified” winter maintenance professionals

- Watershed organizations and cities host and advertise classes in their area.

- Ask cities/watersheds to host and advertise Smart Salting training classes in their area.

- Improve communications with contractors by advertising training and following the research recommendations:

- Websites (the MPCA, watersheds, cities)

- In-person at trainings, seminars, and conferences (both winter and summer maintenance)

- Via other professional organizations (MNLA was commonly referenced)

- Posting in newsletters of other professional organizations

- Telephone