Difference between revisions of "Alleviating compaction from construction activities"

m |

m |

||

| Line 1: | Line 1: | ||

| + | {{alert|This page is under review through January, 2016|alert-under-review}} | ||

| + | |||

| + | There is an increasing reliance on infiltration best management practices (BMPs) to meet water quality goals, meet regulatory requirements, and promote green infrastructure. Infiltration BMPs must be properly designed, constructed, and maintained to perform as intended. Some BMPs, such as permeable pavement, require compaction to provide strength and stability. However, soils are often unintentionally compacted during the construction process. This page addresses unintentional compaction issues at construction sites and presents [http://stormwater.pca.state.mn.us/index.php/Dummy_page_3#Recommended_procedures_for_alleviating_compaction methods for alleviating compaction]. | ||

| + | |||

| + | ==Causes and effects of compaction at construction sites== | ||

| + | Soils at construction sites are generally compacted as a result of excavation, mixing, stockpiling, equipment storage, and equipment traffic. In addition, exposed subsoil is susceptible to compaction. Clay soils and wet soils are more susceptible to compaction. Even at sites where selective grading is employed, compaction occurs as a result of construction equipment, stockpiling and vehicle traffic (Randrup, 1998; Lichter and Lindsay, 1994). | ||

| + | |||

| + | When soil is compacted, porosity decreases and bulk density increases. Typical increases in bulk density are shown below, with other compacting activities included for comparison. As a result, permeability of air and water in soil decreases, soil water-holding capacity is reduced, and root growth is impeded. On a watershed scale, soil compaction leads to increased runoff and erosion. | ||

| + | |||

| + | {{:Increase in bulk density by land use or activity}} | ||

| + | |||

| + | The effects of compaction are difficult to overcome and may persist for decades. Natural processes such as freeze-thaw cycles, animal burrowing, and root growth only slowly diminish compaction. These natural processes are typically limited to the upper foot or two of soil. Even when bulk densities decrease, the original soil structure may not be achieved (Randrup, 1997; Schueler and Holland, 2000). | ||

| + | |||

| + | ==Determining the extent of compaction at a construction site== | ||

| + | [[File:Ponding in infiltration practice 1.jpg|300px|left|thumb|alt=ponded water in infiltration practice|<font size=3>Ponded water in an infiltration practice may be an indicator of compacted soils.</font size>]] | ||

| + | [[File:Sparse vegetation and erosed surface in infiltration basin.jpg|300px|thumb|alt=image of erosion and sparse vegetation in infiltration practice|<font size=3>Sparse vegetation and erosion within an infiltration basin may be an indicator of compacted soils.</font size>]] | ||

| + | [[file:Compaction tester.jpg|300 px|thumb|alt=image of compaction tester|<font size=3>Compaction tester (penetrometer)</font size>]] | ||

| + | |||

| + | Soil compaction can be evident through field observations, including presence of ponded water, discolored or poor plant growth, and eroded soil. Compaction can be determined through field measurements, including taking bulk density samples, using commercially available cone penetrometers, and using surface nuclear gauges. Other measurements, such as [http://stormwater.pca.state.mn.us/index.php/Determining_soil_infiltration_rates soil infiltration], may be used as indicators of compaction. | ||

| + | |||

| + | It is beyond the scope of this document to present a comprehensive discussion of the various methods for determining soil compaction. A short summary of advantages and disadvantages of common methods is presented below, with links to documents that provide more detailed information. | ||

| + | *Use of bulk density measurements are described by Blake and Hartge (1986), Randrup (1993), and Lichter and Costello (1994). Although taking bulk density measurements is relatively simple and fast, the technique is not suitable for rocky, sandy, dry, or wet soils. | ||

| + | *Use of penetrometers is described by Randrup and Lichter (2001), Gregory et al (2006), NRCS (2012), and Indiana Department of Transportation (2003). Advantages include fast and continuous profiling, reliable and economic equipment free of operator effects, generation of reliable results for soft-earth materials, and well-documented use. Disadvantages include high initial capital cost, need for skilled operators, limitations in gravels or cemented materials, and questionable data in unsaturated soils, particularly clays. | ||

| + | *Use of nuclear gauges is described by Randrup and Lichter (2001), Alberty (1984), and New York Department of Transportation (2015). Nuclear gauges are suitable for measuring compaction in soils with less than 5 percent organic matter at depths up to 6 inches. They are easy to use and provide instant data. Drawbacks include expense, need for licensed personnel, and potential safety concerns. | ||

| + | |||

| + | ==Methods for alleviating compaction== | ||

| + | Alleviation of compaction of disturbed soil is crucial to the installation of successful stormwater infiltration practices, particularly vegetated practices. While natural processes can alleviate soil compaction, additional techniques to alleviate soil compaction are often desirable because | ||

| + | *it can take many years for natural processes to loosen up soil; | ||

| + | *natural processes operate primarily within the first foot or so of soil, and compaction from development can extend to two or more feet; and | ||

| + | *once soil compaction becomes so severe that plants and soil microbes can no longer thrive, natural processes are no longer able to reduce soil compaction. | ||

| + | |||

| + | The two most common methods for alleviating compaction are soil ripping (also called subsoiling or tilling) and addition of organic matter. These two are typically combined. | ||

| + | |||

| + | ===Soil ripping=== | ||

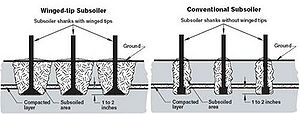

| + | [[File:wing tip and conventional tip subsoiler.png|300px|thumb|alt=photos of wing tip and conventional tip subsoilers|<font size=3>Photos of wing tip and conventional tip subsoilers ([[Construction specifications for bioretention#References|Kees]], 2008).</font size>]] | ||

| + | |||

| + | [[File:schematic of winged tip and conventional tip subsoiler.jpg|300px|thumb|alt=schematic of wing tip and conventional tip subsoilers|<font size=3>Comparison of soil disturbance from a winged tip versus a conventional tip: winged tips can typically be spaced farther apart because they fracture more of the soil than conventional tips ([[Construction specifications for bioretention#References|Kees]], 2008).</font size>]] | ||

| + | |||

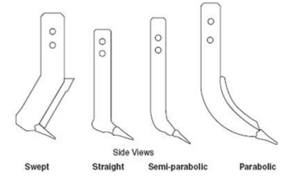

| + | [[File:agricultural shank designs.png|300px|thumb|alt=schematic showing different shank designs|<font size=3>Example of different shank designs commonly used for agricultural tillage ([[Construction specifications for bioretention#References|Kees]], 2008).</font size>]] | ||

| + | |||

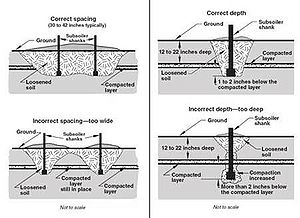

| + | [[File:spacing and depth of subsoilers.jpg|300px|thumb|alt=schematic illustrating proper depth and spacing of subsoilers|<font size=3>Impacts of having subsoiler shanks spaced correctly (top left) versus spaced too widely apart (bottom left) and having shanks at correct depth (top right) versus too deep (bottom right) (Image from [[Construction specifications for bioretention#References|Kees]], 2008). Note: compaction on a construction site can be much more severe than just the plow layer shown in the above agricultural or forestry images.</font size>]] | ||

| + | |||

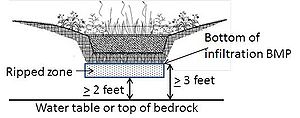

| + | [[File:Illustration of depth to bedrock or wt.jpg|300px|thumb|alt=schematic illustrating separation distance from bottom of infiltration BMP and soil ripped zones to water table or top of bedrock|<font size=3>Schematic illustrating separation distance from bottom of infiltration BMP and soil ripped zones to water table or top of bedrock</font size>]] | ||

| + | |||

| + | The goal of soil ripping or subsoiling is to fracture compacted soil without adversely disturbing plant life, topsoil, and surface residue. Soil compaction occurs most frequently with soils having a high clay content. Fracturing compacted soil promotes root penetration by reducing soil density and strength, improving moisture infiltration and retention, and increasing air spaces in the soil. Compacted layers typically develop 12 to 22 inches below the surface when heavy equipment is used. Conventional cultivators cannot reach deep enough to break up this compaction. Subsoilers (rippers) can break up the compacted layer without destroying soil aggregate structure, surface vegetation, or mixing soil layers (Kees, 2008). | ||

| + | |||

| + | How effectively compacted layers are fractured depends on the soil's moisture, structure, texture, type, composition, porosity, density, and clay content. Success depends on the type of equipment selected, its configuration, and the speed with which it is pulled through the ground. No one piece of equipment or configuration works best for all situations and soil conditions, making it difficult to define exact specifications for subsoiling equipment and operation. | ||

| + | |||

| + | Subsoilers are available with a wide variety of shank designs. Shank design affects subsoiler performance, shank strength, surface and residue disturbance, effectiveness in fracturing soil, and the horsepower required to pull the subsoiler. According to Kees (2008), “Parabolic shanks require the least amount of horsepower to pull. In some forest applications, parabolic shanks may lift too many stumps and rocks, disturb surface materials, or expose excess subsoil. Swept shanks tend to push materials into the soil and sever them. They may help keep the subsoiler from plugging up, especially in brush, stumps, and slash. Straight or "L" shaped shanks have characteristics that fall somewhere between those of the parabolic and swept shanks.” | ||

| + | |||

| + | Researchers have found that there is a “critical depth”, and according to Spoor and Godwin (1978) this “critical depth is dependent upon the width, inclination and lift height of the tine foot and on the moisture and density status of the soil.” Spoor and Godwin (1978) explain that tine depth is crucial because “At shallow working depths the soil is displaced forwards, side-ways and upwards (crescent failure), failing along well defined rupture planes which radiate from just above the tine tip to the surface at angles of approximately 45<sup>o</sup> to the horizontal. Crescent failure continues with increasing working depth until, at a certain depth, the critical depth, the soil at the tine base begins to flow forwards and sideways only (lateral failure) creating compaction at depth.” They found that below the critical depth “compaction occurs rather than effective soil loosening.” They also found that “The wetter and more plastic a soil is, the shallower is the critical depth.” An approach developed by Silsoe College, Cranfield University, in collaboration with Transco UK, for use on pipeline sites, was to work progressively deeper with repeated passes, up to 5 or 6 under extreme conditions, with the tractor operating on the same tramline/traffic lane on each pass (Spoor & Foot, 1998).” | ||

| + | |||

| + | Shanks are available with winged tips and conventional tips. Winged tips cost more than conventional tips and require more horsepower, but can often be spaced farther apart. Increasing wing width also increases critical depth – the depth below which little soil loosening occurs (Owen 1987, Spoor 1978). Using shallow leading tines ahead of deeper tines also increases required shank spacing (Spoor 1978). According to Kees (2008), the shank’s tip should run to a depth of 1 to 2 inches below the compacted layer. Kees (2008) also recommends making sure that the shanks on the subsoiler are spaced so that they run in the tracks of the tow vehicle, because the equipment used to pull subsoilers is heavy enough to create compaction itself. Ideal shank spacing will depend on soil moisture, soil type,degree of compaction, and the depth of the compacted layer. Spacing should be adjustable so the worked area can be fractured most efficiently. Because ideal shank configuration will vary with varying soil textures and moisture, shank spacing and height should be adjustable in the field (Kees 2008). | ||

| + | |||

| + | Kees (2008) recommends following ground contours whenever possible when subsoiling to “increase water capture, protect water quality, and reduce soil erosion.” He also states that “in some cases, two passes at an angle to each other may be required to completely fracture compacted soil.” Spoor and Godwin (1978) also found that “Relatively closely spaced tines, staggered to prevent blockage, are more efficient at producing complete loosening than repeated passes with tines at wider spacings.” | ||

| + | |||

| + | Travel speed of the subsoiler also affects subsoiling disturbance. “Travel speed that is too high can cause excessive surface disturbance, bring subsoil materials to the surface, create furrows, and bury surface residues. Travel speed that is too slow may not lift and fracture the soil adequately” (Kees2008). | ||

| + | |||

| + | Soils should be mostly dry and friable. Urban (2008) describes ideal conditions for compaction reduction as follows: “soil moisture must be between field capacity and wilt point during compaction reduction for maximum effectiveness." | ||

| + | |||

| + | Always know where utilities are buried prior to subsoiling. Avoid subsoiling in area that have buried utilities, wires, pipes, culverts, or diversion channels (Kees 2008, Urban 2008). | ||

| + | |||

| + | According to Spoor and Godwin (1978) “The number of variables involved and soil variation make the accurate prediction of the critical depth for field conditions impractical. Simple field modifications are available, however, such as increasing tine foot width and lift height or loosening the surface layers, to allow rapid implement adjustment to satisfy a range of field conditions.” | ||

| + | |||

| + | If subsoiling was effective, “The ground should be lifted slightly and remain relatively even behind the subsoiler, without major disruption of surface residues and plants. No more than a little subsoil and a few rocks should be pulled to the surface. If large furrows form behind the subsoiler, the shanks may not be deep enough, the angle on winged tips may be too aggressive, or the travel speed may be too high” (Kees 2008). | ||

| + | |||

| + | Cost for subsoiling varies by project. The Pennsylvania Stormwater Best Management Practices Manual estimates the cost of tilling soils ranges from $800 to $1000 per acre, while the cost of compost amending soil is about the same. | ||

| + | |||

| + | An extensive literature review of the effects of soil ripping can be found in [[File:Bioretention task 6 soil ripping.docx]]. | ||

| + | |||

| + | ===Compost=== | ||

| + | [[Turf#Compost|Compost]] is the product resulting from the controlled biological decomposition of organic materials that has been sanitized through the generation of heat and stabilized to the point that it is beneficial to plant growth. It is an organic matter resource that has the unique ability to improve the chemical, physical, and biological characteristics of soil. It can be derived from composted yard waste, food waste, manure, leaves, grass clippings, straw, or biosolids. | ||

| + | |||

| + | Compost aggregates soil particles (sand, silt, and clay) into larger particles (Cogger, 2005). Aggregation of soil particles creates additional porosity, which reduces the bulk density of the soil (Cogger, 2005). Compost can also reduce the bulk density of a soil by dilution of the mineral matter in the soil (Cogger, 2005). When the porosity of the soil increases and the particle surface area increases, water holding capacity is also increased (Cogger, 2005). Increases in macropore continuity have been found as well (Harrison et al., 1998). Studies have cited numerous beneficial abilities of compost: increased water drainage, increased water holding capacity, increased plant production, increased root penetrability, reduction of soil diseases, reduction of heavy metals, and the ability to treat many chemical pollutants (EPA, 1997; Harrison et al., 1998; WDOE Stormwater Management Manual, 2007; Olson 2010). | ||

| + | |||

| + | Research studies illustrate the importance of compost on maintaining or improving soil infiltration rates. [http://stormwater.safl.umn.edu/updates-may-2010 Olson] showed that bulk densities in residential areas decreased from an average of 1.4 grams per cubic centimeter to 0.93 to 1.15 grams per cubic centimeter following amendment with compost. Saturated conductivities were 3.4 to 6.1 times greater following compost amendment. [http://www.ncbi.nlm.nih.gov/pubmed/23353881 Olson et al.] (2013) studied effects of tilling with and without compost on soil infiltration in compacted urban soils. The geometric mean of saturated hydraulic conductivity on the compost plots was 2.7 to 5.7 times that of the control plot. On soils with just tilling, the geometric mean of saturated hydraulic conductivity was 0.5 to 2.3 times that of the control plot, indicating little overall improvement. Compost addition was more effective than tilling by reducing the soil strength and compaction and increasing soil infiltration. | ||

| + | |||

| + | Information on compost is provided in the following table. | ||

| + | |||

| + | {{:When purchasing compost to be used for turf establishment}} | ||

| + | |||

| + | ===Composting and ripping combined=== | ||

| + | Studies show that tilling in sand, compost, or both is an effective technique to alleviate soil compaction. Two of these studies are summarized below. | ||

| + | *Olson (2010) found that plots where soil was ripped and amended with compost showed reduced soil strength, bulk densities were 18 to 37 percent lower on compost plots compared to controls, and the geometric mean of K<sub>sat</sub> on the compost plots was 2.7 to 5.7 times that of the control plot. | ||

| + | *A study at [http://urbanforestry.frec.vt.edu/documents/articles/CityTrees.pdf Virginia Tech] shows soils with compost incorporated into the soil to a depth of 2 feet has decreased bulk density in the subsoil and is accelerating the process of soil formation and long-term carbon storage compared to other treatments in the study. The result is that trees growing in the compost-amended soil have increased height, canopy diameter, and trunk diameter compred to trees in other treatments. | ||

| + | |||

| + | Tilling in compost amendment may not be desirable on sites with steep slopes, a high water table, wet saturated soils, or downhill slope toward a house foundation (Schueler Technical Note #108); where there are tree roots or utilities; or where nutrients leaching from compost would pose a problem. Since soil restoration techniques will need to be tailored to site conditions, a prescriptive soil restoration specification is not recommended. However, Pennsylvania, Virginia, and Washington State have specifications for soil amendment and restoration and these may be used as guidance in determining how to amend a compacted soil. | ||

| + | |||

| + | ==Recommended procedures for alleviating compaction== | ||

| + | Soil restoration techniques will need to be tailored to site conditions. A prescriptive soil restoration specification is therefore not recommended. The following procedure borrows from methods described in Olson et al (2013), Pennsylvania Department of Environmental Protection (2006), and Virginia Tech (2012). | ||

| + | |||

| + | ===Applicability=== | ||

| + | The following procedure is applicable to sites with subsoils that are compacted during construction. Apply the procedure if compaction is above ideal bulk density indicated in the table below. | ||

| + | |||

| + | {{:General relationship of soil bulk density to root growth based on soil texture}} | ||

| + | The procedure should not be applied in areas where tree roots are to be protected. The procedure is not intended to improve soil chemical properties. | ||

| + | |||

| + | ===Procedure=== | ||

| + | [[file:Soil ripping.png|300 px|thumb|alt=image of soil ripping|<font size=3>Example of subsoiling and incorporation of compost and sand. Note the equipment is kept out of the practice.</font size>]] | ||

| + | |||

| + | [[file:Ponding in infiltration practice 2.jpg|300 px|thumb|alt=image of failed infiltration BMP|<font size=3>Example of a site where vehicle traffic occurred within the infiltration practice, resulting in soil compaction and ponding of water.</font size>]] | ||

| + | |||

| + | General recommendations include the following. | ||

| + | *Prepare a site map, including areas where traffic and storage is to be avoided | ||

| + | *Fence off areas where traffic and material storage should be avoided | ||

| + | *If appropriate, submit compost and soil analysis to the landscape architect or owner | ||

| + | *Soil should be neither wet nor dry | ||

| + | *Keep equipment out of treatment practice (if possible) and work backwards away from excavated soils so that treated soil is not trafficked by the equipment | ||

| + | |||

| + | Although exact procedures will vary with site conditions, the following procedures are recommended. | ||

| + | [[File:Illustration of depth to bedrock or wt.jpg|300px|thumb|alt=schematic illustrating separation distance from bottom of infiltration BMP and soil ripped zones to water table or top of bedrock|<font size=3>Schematic illustrating separation distance from bottom of infiltration BMP and soil ripped zones to water table or top of bedrock</font size>]] | ||

| + | *If deep tillage is employed, utilize a spacing of 12 inches. See the [http://stormwater.pca.state.mn.us/index.php/Dummy_page_3#Soil_ripping above section on soil ripping] for additional guidance, including appropriate equipment to use. | ||

| + | *Comingle soil and compost using a tree spading machine, tined bucket, or similar equipment. Prior to spading add an average of 2.5 to 3 inches of compost to the soil surface. Comingle the soil to a depth of 15 to 18 inches. For guidance on compost see the previous section on [http://stormwater.pca.state.mn.us/index.php/Dummy_page_3#Compost compost]. | ||

| + | *Insert the spading machine or bucket through the compost layer and into the subsoil and raise a bucket of soil at least 24 inches above the soil surface. Tip the bucket and allow soil to fall. Repeat this procedure until no clumps of compacted soil larger than 12 inches in diameter remain. The tines of the bucket can be used to break apart larger clumps if necessary. Fifty percent of the soil shall be in clumps 6 inches or smaller. No clumps shall be greater than 18 inches in diameter. Maintain a 3 foot minimum separation distance between the bottom of the practice and the seasonally high water table or bedrock and a 1 foot minimum between the bottom of the subsoiled zone and the water table or top of bedrock. | ||

| + | *Use existing topsoil or replace topsoil and rototill to 4 inches or up to 8 inches if severely disturbed. | ||

| + | *For vegetated practices, follow these guidelines. | ||

| + | **Select vegetation based on a specified zone of hydric tolerance. [http://www.pca.state.mn.us/index.php/water/water-types-and-programs/stormwater/stormwater-management/plants-for-stormwater-design.html ''Plants for Stormwater Design - Species selection for the Upper Midwest''] is a good resource. | ||

| + | **Specify native [[Minnesota plant lists|plant species]] over non-native species. This includes wild flowers, grasses, shrubs, and if appropriate, trees. Hardy native species that thrive in our ecosystem without chemical fertilizers and pesticides are the best choices. | ||

| + | **[[Minnesota plant lists#Salt tolerance|Salt resistant vegetation]] should be used in locations with probable adjacent salt application, i.e. roadside, parking lot, etc. | ||

| + | **Plugs, bare root plants or potted plants are RECOMMENDED over seed for herbaceous plants, shrubs, and trees. Erosion control mats pre-vegetated with herbaceous plants are also acceptable. For turf, sod is recommended over seed. (NOTE: Fluctuating water levels following seeding (prior to germination) can cause seed to float and be transported, resulting in bare areas that are more prone to erosion and weed invasion than vegetated areas. Seed is also difficult to establish through mulch, a common surface component of bioretention. It may take more than two growing seasons to establish the function and desired aesthetic of mature vegetation via seeding.) | ||

| + | **Bioretention systems should be operated off-line for 1 year or, within the first year, until vegetation is established. | ||

| + | **Example target plant coverage includes | ||

| + | ***at least 50 percent of specified vegetation cover at end of the first growing season; | ||

| + | ***at least 90 percent of specified vegetation cover at end of the third growing season; | ||

| + | ***supplement plantings to meet project specifications if cover targets are not met; and | ||

| + | ***tailoring percent coverage targets to project goals and vegetation. For example, percent cover required for turf after 1 growing season would likely be 100 percent, whereas it would likely be lower for other vegetation types. | ||

| + | **If trees are incorporated into the practice, follow the [http://stormwater.pca.state.mn.us/index.php/Design_guidelines_for_tree_quality_and_planting_-_tree_trenches_and_tree_boxes tree planting guidelines] described in this manual. | ||

| + | |||

| + | {{alert|Maintain a 3 foot minimum separation distance between the bottom of the practice and the seasonally high water table or bedrock and a 1 foot minimum between the bottom of the subsoiled zone and the water table or top of bedrock.|alert-danger}} | ||

| + | |||

| + | ==Precedents for soil restoration specifications== | ||

| + | The above procedure is not prescriptive and provides general guidelines developed from other literature sources. Specific information from those other sources is provided below as a means of comparison or to provide alternate approaches. | ||

| + | |||

| + | *The Virginia Tech Rehabilitation study website provides a [http://urbanforestry.frec.vt.edu/SRES/background.html Soil Profile Rebuilding Specification] based on their research. The basic steps in their specification are described below. | ||

| + | **Spread mature, stable compost to a 4 inch depth over compacted subsoil. | ||

| + | **Subsoil to a depth of 24 inches. | ||

| + | **Replace topsoil to 4 inches (6 to 8 inches if severely disturbed). | ||

| + | **Rototill topsoil to a depth of 6 to 8 inches. | ||

| + | **Plant with woody plants. | ||

| + | *Washington State’s Department of Ecology’s [http://www.ecy.wa.gov/programs/wq/stormwater/manual.html Stormwater Management for Western Washington] (Volume V: Runoff Treatment BMPs, Chapter 5, pages 5-7 to 5-10) includes a very detailed soil restoration specification that includes the following. | ||

| + | **The topsoil layer has a minimum organic matter content of 10 percent dry weight in planting beds, 5 percent organic matter content in turf areas, and a pH from 6.0 to 8.0 or matching the pH of the undisturbed soil. The topsoil layer shall have a minimum depth of 8 inches except where tree roots limit the depth of incorporation of amendments needed to meet the criteria. Subsoils below the topsoil layer should be scarified at least 4 inches with some incorporation of the upper material to avoid stratified layers, where feasible. | ||

| + | **Mulch planting beds with 2 inches of organic material. | ||

| + | **Use compost and other materials that meet these organic content requirements. | ||

| + | ***The organic content for pre-approved amendment rates can be met only using compost that meets the definition of composted materials in [http://apps.leg.wa.gov/wac/default.aspx?cite=173-350 WAC 173-350-100]. The compost must also have an organic matter content of 40 to 65 percent and a carbon to nitrogen ratio below 25:1. The carbon to nitrogen ratio may be as high as 35:1 for plantings composed entirely of plants native to the Puget Sound Lowlands region. | ||

| + | ***Calculated amendment rates may be met through use of composted materials meeting above conditions, or other organic materials amended to meet the carbon to nitrogen ratio requirements and meeting the contaminant standards of Grade A Compost. The resulting soil should be conducive to the type of vegetation to be established. | ||

| + | **The soil quality design guidelines listed above can be met by using one of the methods listed below. | ||

| + | ***Leave undisturbed native vegetation and soil, and protect from compaction during construction. | ||

| + | ***Amend existing site topsoil or subsoil either at default pre-approved rates, or at custom calculated rates based on tests of the soil and amendment. | ||

| + | ***Stockpile existing topsoil during grading, and replace it prior to planting. Stockpiled topsoil must also be amended if needed to meet the organic matter or depth requirements, either at a default pre-approved rate or at a custom calculated rate. | ||

| + | ***Import topsoil mix of sufficient organic content and depth to meet the requirements. More than one method may be used on different portions of the same site. Soil that already meets the depth and organic matter quality standards, and is not compacted, does not need to be amended. | ||

| + | *The 2006 [http://www.elibrary.dep.state.pa.us/dsweb/View/Collection-8305 Pennsylvania Stormwater Best Management Practices Manual’s] chapter on [http://www.elibrary.dep.state.pa.us/dsweb/Get/Document-68010/6.7.3%20BMP%20Soil%20Amendment%20and%20Restoration.pdf soil amendment and restoration] provides a sample specification for soil restoration. Their specification is not prescriptive, but does provide guiding principles, compost material specifications, and performance requirements. They require sub-soiling to loosen soil to less than 1400 kPa (200 psi) to a depth of 20 inches below final topsoil grade to reduce soil compaction in all areas where plant establishment is planned in areas where subsoil has become compacted by equipment operation, or has become dried out andcrusted, or where necessary to obliterate erosion hills. | ||

| + | |||

| + | ==Additional references and fact sheets== | ||

| + | *[http://your.kingcounty.gov/solidwaste/greenbuilding/documents/Post-Construction-Soil-Standard.pdf Achieving the Post-construction Soil Standard] - provides guidance for preserving and restoring healthy soils on developments. | ||

| + | *[http://edis.ifas.ufl.edu/ss529 Soil Compaction in the Urban Landscape] | ||

| + | *[http://ag.udel.edu/udbg/sl/soils/combating_soil_compaction.pdf Combating Soil Compaction] | ||

| + | *[http://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/nrcs142p2_053278.pdf Urban Soil Compaction] | ||

| + | |||

| + | ==References== | ||

| + | * Alberty, C.A., H.M. Pellett, and D.H. Taylor. 1984. [http://hriresearch.org/docs/publications/JEH/JEH_1984/JEH_1984_2_2/JEH%202-2-48-53.pdf Characterization of soil compaction at construction sites and woody plant response]. J. Environ. Hortic. 2(2):48-53. | ||

| + | *Blake, G.R., and K.H. Hartge. 1986. ''Bulk density, radiation methods''. In Klute, A. (Ed.). Methods of Soil Analysis, Part 1. Physical and Mineralogical Methods. Agronomy Monographs, No. 9 (2nd ed.). American Society of Agronomy, Madison, WI. | ||

| + | *Brown, R.A. and Hunt, W.F. (2010). “Impacts of construction activity on bioretention performance.” Journal of Hydrologic Engineering. 15(6), 386-394. | ||

| + | *Chaplin, Jonathan, Min Min, and Reid Pulley. 2008. [http://conservancy.umn.edu/bitstream/handle/11299/5607/200801.pdf?sequence=1&isAllowed=y Compaction Remediation for Construction Sites.] Final Report. Department of Bioproducts and Biosystems Engineering, University of Minnesota, St. Paul, Minnesota. | ||

| + | *Cogger, C. ''Potential Compost Benefits for Restoration of Soils Disturbed by Urban Developmen''t. Compost Science & Utilization 13.4 (2005): 243-251. | ||

| + | *Gregory, J.H., Dukes, M.D., Jones, P.H., Miller, G.L., 2006. [http://abe.ufl.edu/mdukes/pdf/stormwater/Gregor-et-%20al-JSWC-compaction-article.pdf Effect of urban soil compaction on infiltration rate]. Journal of Soil and Water Conservation 61, 117-124. | ||

| + | *Hamilton, G.W., Waddington, D.V., 1999. ''Infiltration rates on residential lawns in central Pennsylvania''. Journal of Soil and Water Conservation 54, 564-568. | ||

| + | *Hanks, D. and A. Lewandowski, 2003. [http://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/nrcs143_019258.pdf Protecting Urban Soil Quality: Examples for Landscape Codes and Specifications]. USDA Natural Resources Conservation Services. | ||

| + | *Indiana Department of Transportation. 2003. [http://docs.lib.purdue.edu/cgi/viewcontent.cgi?article=1544&context=jtrp Dynamic Cone Penetration Test (DCPT) for Subgrade Assessment]. Publication No. FHWA/IN/JTRP-2002/30, SPR-2362. | ||

| + | *Kees, Gary. 2008. [http://www.fs.fed.us/t-d/pubs/pdfpubs/pdf08342828/pdf08342828dpi72.pdf Using Subsoiling To Reduce Soil Compaction]. U.S. Forest Service Technology & Development Publication 3400 Forest Health Protection 0834-2828-MTDC. Downloaded from http://www.fs.fed.us/t-d/pubs/htmlpubs/htm08342828/index.htm July 15, 2013 | ||

| + | *Lichter, J.M., and L.R. Costello. 1994. ''An evaluation of volume excavation and core sampling techniques for measuring soil bulk density''. J. Arboric. 20(3): 160-164. | ||

| + | *Natural Resource Conservation Service. 2012. National Engineering Handbook. [http://directives.sc.egov.usda.gov/OpenNonWebContent.aspx?content=31850.wba Chapter 11, Cone Penetrometer]. Part 631. | ||

| + | *Natural Resource Conservation Service. 1998. [http://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/stelprdb1044790.pdf Soil Quality Test Kit Guide]. | ||

| + | *New York Department of Transportation. 2015. [https://www.dot.ny.gov/divisions/engineering/technical-services/technical-services-repository/GTM-10b.pdf Geotechnical Test Method: Test Method For Earthwork Compaction Control By Nuclear Gauge]. Geotechnical Engineering Bureau. GTM-10, Revision#5. | ||

| + | *Ocean County Soil Conservation District (OCSCD), Schnabel Engineering Associates, Inc., USDA Natural Resources Conservation Service. 2001. [http://www.soildistrict.org/wp-content/uploads/2012/07/impacts-of-soil-disturbance-on-bulk-density-and-infiltration-in-ocean-county-nj.pdf Impact of soil disturbance during construction on bulk density and infiltration in ocean county]. New Jersey. | ||

| + | *Olsen, H.J. 1990. ''Construction of an electronic penetrometer for use in the field''. Computers and Electronics in Agriculture. 5:1:65-75. | ||

| + | *Olson, N.C. J.S. Gulliver, J.L. Nieber, and M. Kayhanian. 2013. ''Remediation to improve infiltration into compact soils''. Journal of Environmental Management. 117:85-95. | ||

| + | *Olson, Nicholas Charles. 2010. [http://www.cura.umn.edu/sites/cura.advantagelabs.com/files/publications/E2010-1.pdf Quantifying the Effectiveness of Soil Remediation Techniques in Compact Urban Soils]. University Of Minnesota Master Of Science Thesis. | ||

| + | *Owen, Gordon T. 1987. ''Soil disturbance associated with deep subsoiling in compact soils''. Canadian Agricultural Engineering: 33-37. | ||

| + | *Pennsylvania Department of Environmental Protection. 2007. [http://www.elibrary.dep.state.pa.us/dsweb/Get/Document-48472/00_Cover_TOC.pdf Pennsylvania Stormwater Best Management Practices Manual]. Section 5.6.2. [http://www.elibrary.dep.state.pa.us/dsweb/Get/Document-67972/5.6.2%20BMP%20Minimize%20Soil%20Compaction%20in%20Disturbed%20Areas.pdf Minimize Soil Compaction in Disturbed Areas]. | ||

| + | *Pennsylvania Department of Environmental Protection. 2006. [http://www.elibrary.dep.state.pa.us/dsweb/Get/Version-69220/ Pennsylvania Stormwater Best Management Practices Manual. BMP 6.7.3: Soil Amendment & Restoration]. | ||

| + | *Pitt, R., Chen, S., Clark, S.E., Swenson, J., and Ong, C.K. 2008. “Compaction’s impact on urban storm-water infiltration.” Journal of Irrigation and Drainage Engineering. 134(5), 652-658. | ||

| + | *Randrup, T.B. 1993. ''Soil Compaction and Plant Growth'' (Jordkomprimering og Plantevaskst). The Royal Veterinary and Agricultural University. Danish Forest and Landscape Research Institute. Copenhagen, Denmark. 78 pp. | ||

| + | *Randrup, T.B. 1997. ''Soil Compaction on Construction Sites''. Journal of Arboriculture, 23:5:207-210. | ||

| + | *Schueler, T.R., and H.K. Holland. 2000. ''The Practice of Watershed Protection; Techniques for Protecting our Nation's Streams, Lakes, Rivers, and Estuaries''. Mahler Books, Austin ,TX. Published by the Center for Watershed Protection. 742 pp. | ||

| + | *Schueler, T. 2000. ''The Compaction of Urban Soil: The Practice of Watershed Protection''. Center for Watershed Protection, Ellicott City, MD. Pages 210-214 downloaded from http://www.cwp.org/online-watershed-library/cat_view/63-research/75-monitoring | ||

| + | *Schueler, T. R. ''Can Urban Soil Compaction Be Reversed?'' Technical Note #108 from Watershed Protection Techniques. 1(4): 666-669. | ||

| + | *Selbig, W.R., and N. Balster. 2010. [http://pubs.usgs.gov/sir/2010/5077/pdf/sir20105077.pdf Evaluation of turf-grass and prairie-vegetated rain gardens in a clay and sand soil: Madison, Wisconsin, water years 2004–08]. U.S. Geological Survey, Scientific Investigations Report 2010–5077, 75 p. | ||

| + | *Spoor, G. & Godwin, R.J. 1978. ''An experimental investigation into the deep loosening of soil by rigid tines''. Journal of Agricultural Engineering Research, 23, 243–258. | ||

| + | *Spoor, G., Tijink, F.G.J. & Weisskopf, P. 2003. ''Subsoil compaction: risk, avoidance, identification and alleviation''. Soil and Tillage Research, 73, 175–182. | ||

| + | *Spoor, G. "Alleviation of Soil Compaction: Requirements, Equipment and Techniques." Soil Use and Management 22 (2006):113-122. | ||

| + | *Tyner, J.S., Wright, W.C., and Dobbs, P.A. (2009). ''Increasing exfiltration from pervious concrete and temperature monitoring''. Journal of Environmental Management. 90, 2636-2641. | ||

| + | *Urban, James. 2008. ''Up by Roots''. International Society of Arboriculture: Champaign, IL. | ||

| + | *Virginia Tech. 2012. [http://urbanforestry.frec.vt.edu/SRES/specification.html Soil Profile Rebuilding Specification]. Departments of Forest Resources and Environmental Conservation, Horticulture, and Crop and Soil Environmental Sciences. | ||

| + | |||

| + | |||

| + | <!-- | ||

Information on alleviating compaction from construction activities is scattered in different places within this manual. This page brings that information together. It is not intended to be a comprehensive review and set of recommendations for alleviating compaction resulting from construction activities. Until such a review occurs however, this page provides basic information and recommendations for alleviating compaction. | Information on alleviating compaction from construction activities is scattered in different places within this manual. This page brings that information together. It is not intended to be a comprehensive review and set of recommendations for alleviating compaction resulting from construction activities. Until such a review occurs however, this page provides basic information and recommendations for alleviating compaction. | ||

| Line 21: | Line 217: | ||

*[http://ag.udel.edu/udbg/sl/soils/combating_soil_compaction.pdf Combating Soil Compaction] | *[http://ag.udel.edu/udbg/sl/soils/combating_soil_compaction.pdf Combating Soil Compaction] | ||

*[http://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/nrcs142p2_053278.pdf Urban Soil Compaction] | *[http://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/nrcs142p2_053278.pdf Urban Soil Compaction] | ||

| + | --> | ||

Revision as of 21:29, 4 January 2016

This page is under review through January, 2016

There is an increasing reliance on infiltration best management practices (BMPs) to meet water quality goals, meet regulatory requirements, and promote green infrastructure. Infiltration BMPs must be properly designed, constructed, and maintained to perform as intended. Some BMPs, such as permeable pavement, require compaction to provide strength and stability. However, soils are often unintentionally compacted during the construction process. This page addresses unintentional compaction issues at construction sites and presents methods for alleviating compaction.

Contents

- 1 Causes and effects of compaction at construction sites

- 2 Determining the extent of compaction at a construction site

- 3 Methods for alleviating compaction

- 4 Recommended procedures for alleviating compaction

- 5 Precedents for soil restoration specifications

- 6 Additional references and fact sheets

- 7 References

Causes and effects of compaction at construction sites

Soils at construction sites are generally compacted as a result of excavation, mixing, stockpiling, equipment storage, and equipment traffic. In addition, exposed subsoil is susceptible to compaction. Clay soils and wet soils are more susceptible to compaction. Even at sites where selective grading is employed, compaction occurs as a result of construction equipment, stockpiling and vehicle traffic (Randrup, 1998; Lichter and Lindsay, 1994).

When soil is compacted, porosity decreases and bulk density increases. Typical increases in bulk density are shown below, with other compacting activities included for comparison. As a result, permeability of air and water in soil decreases, soil water-holding capacity is reduced, and root growth is impeded. On a watershed scale, soil compaction leads to increased runoff and erosion.

Increase in soil bulk density as a result of different land uses or activities.

Link to this table

| Land use or activity | Increase in bulk density (grams / cubic centimeter | Source (link to Reference list) |

|---|---|---|

| Grazing | 0.12 to 0.20 | Smith, 1999 |

| Crops | 0.25 to 0.35 | Smith, 1999 |

| Construction, mass grading | 0.34 to 0.35 | Randrup, 1998; Lichter and Lindsey, 1994 |

| Construction, no grading | 0.20 | Lichter and Lindsey, 1994 |

| Construction traffic | 0.17 to 0.40 | Lichter and Lindsey, 1994; Smith, 1999; Friedman, 1998 |

| Athletic fields | 0.38 to 0.54 | Smith, 1999 |

| Urban lawn and turf | 0.30 to 0.40 | Various sources |

The effects of compaction are difficult to overcome and may persist for decades. Natural processes such as freeze-thaw cycles, animal burrowing, and root growth only slowly diminish compaction. These natural processes are typically limited to the upper foot or two of soil. Even when bulk densities decrease, the original soil structure may not be achieved (Randrup, 1997; Schueler and Holland, 2000).

Determining the extent of compaction at a construction site

Soil compaction can be evident through field observations, including presence of ponded water, discolored or poor plant growth, and eroded soil. Compaction can be determined through field measurements, including taking bulk density samples, using commercially available cone penetrometers, and using surface nuclear gauges. Other measurements, such as soil infiltration, may be used as indicators of compaction.

It is beyond the scope of this document to present a comprehensive discussion of the various methods for determining soil compaction. A short summary of advantages and disadvantages of common methods is presented below, with links to documents that provide more detailed information.

- Use of bulk density measurements are described by Blake and Hartge (1986), Randrup (1993), and Lichter and Costello (1994). Although taking bulk density measurements is relatively simple and fast, the technique is not suitable for rocky, sandy, dry, or wet soils.

- Use of penetrometers is described by Randrup and Lichter (2001), Gregory et al (2006), NRCS (2012), and Indiana Department of Transportation (2003). Advantages include fast and continuous profiling, reliable and economic equipment free of operator effects, generation of reliable results for soft-earth materials, and well-documented use. Disadvantages include high initial capital cost, need for skilled operators, limitations in gravels or cemented materials, and questionable data in unsaturated soils, particularly clays.

- Use of nuclear gauges is described by Randrup and Lichter (2001), Alberty (1984), and New York Department of Transportation (2015). Nuclear gauges are suitable for measuring compaction in soils with less than 5 percent organic matter at depths up to 6 inches. They are easy to use and provide instant data. Drawbacks include expense, need for licensed personnel, and potential safety concerns.

Methods for alleviating compaction

Alleviation of compaction of disturbed soil is crucial to the installation of successful stormwater infiltration practices, particularly vegetated practices. While natural processes can alleviate soil compaction, additional techniques to alleviate soil compaction are often desirable because

- it can take many years for natural processes to loosen up soil;

- natural processes operate primarily within the first foot or so of soil, and compaction from development can extend to two or more feet; and

- once soil compaction becomes so severe that plants and soil microbes can no longer thrive, natural processes are no longer able to reduce soil compaction.

The two most common methods for alleviating compaction are soil ripping (also called subsoiling or tilling) and addition of organic matter. These two are typically combined.

Soil ripping

The goal of soil ripping or subsoiling is to fracture compacted soil without adversely disturbing plant life, topsoil, and surface residue. Soil compaction occurs most frequently with soils having a high clay content. Fracturing compacted soil promotes root penetration by reducing soil density and strength, improving moisture infiltration and retention, and increasing air spaces in the soil. Compacted layers typically develop 12 to 22 inches below the surface when heavy equipment is used. Conventional cultivators cannot reach deep enough to break up this compaction. Subsoilers (rippers) can break up the compacted layer without destroying soil aggregate structure, surface vegetation, or mixing soil layers (Kees, 2008).

How effectively compacted layers are fractured depends on the soil's moisture, structure, texture, type, composition, porosity, density, and clay content. Success depends on the type of equipment selected, its configuration, and the speed with which it is pulled through the ground. No one piece of equipment or configuration works best for all situations and soil conditions, making it difficult to define exact specifications for subsoiling equipment and operation.

Subsoilers are available with a wide variety of shank designs. Shank design affects subsoiler performance, shank strength, surface and residue disturbance, effectiveness in fracturing soil, and the horsepower required to pull the subsoiler. According to Kees (2008), “Parabolic shanks require the least amount of horsepower to pull. In some forest applications, parabolic shanks may lift too many stumps and rocks, disturb surface materials, or expose excess subsoil. Swept shanks tend to push materials into the soil and sever them. They may help keep the subsoiler from plugging up, especially in brush, stumps, and slash. Straight or "L" shaped shanks have characteristics that fall somewhere between those of the parabolic and swept shanks.”

Researchers have found that there is a “critical depth”, and according to Spoor and Godwin (1978) this “critical depth is dependent upon the width, inclination and lift height of the tine foot and on the moisture and density status of the soil.” Spoor and Godwin (1978) explain that tine depth is crucial because “At shallow working depths the soil is displaced forwards, side-ways and upwards (crescent failure), failing along well defined rupture planes which radiate from just above the tine tip to the surface at angles of approximately 45o to the horizontal. Crescent failure continues with increasing working depth until, at a certain depth, the critical depth, the soil at the tine base begins to flow forwards and sideways only (lateral failure) creating compaction at depth.” They found that below the critical depth “compaction occurs rather than effective soil loosening.” They also found that “The wetter and more plastic a soil is, the shallower is the critical depth.” An approach developed by Silsoe College, Cranfield University, in collaboration with Transco UK, for use on pipeline sites, was to work progressively deeper with repeated passes, up to 5 or 6 under extreme conditions, with the tractor operating on the same tramline/traffic lane on each pass (Spoor & Foot, 1998).”

Shanks are available with winged tips and conventional tips. Winged tips cost more than conventional tips and require more horsepower, but can often be spaced farther apart. Increasing wing width also increases critical depth – the depth below which little soil loosening occurs (Owen 1987, Spoor 1978). Using shallow leading tines ahead of deeper tines also increases required shank spacing (Spoor 1978). According to Kees (2008), the shank’s tip should run to a depth of 1 to 2 inches below the compacted layer. Kees (2008) also recommends making sure that the shanks on the subsoiler are spaced so that they run in the tracks of the tow vehicle, because the equipment used to pull subsoilers is heavy enough to create compaction itself. Ideal shank spacing will depend on soil moisture, soil type,degree of compaction, and the depth of the compacted layer. Spacing should be adjustable so the worked area can be fractured most efficiently. Because ideal shank configuration will vary with varying soil textures and moisture, shank spacing and height should be adjustable in the field (Kees 2008).

Kees (2008) recommends following ground contours whenever possible when subsoiling to “increase water capture, protect water quality, and reduce soil erosion.” He also states that “in some cases, two passes at an angle to each other may be required to completely fracture compacted soil.” Spoor and Godwin (1978) also found that “Relatively closely spaced tines, staggered to prevent blockage, are more efficient at producing complete loosening than repeated passes with tines at wider spacings.”

Travel speed of the subsoiler also affects subsoiling disturbance. “Travel speed that is too high can cause excessive surface disturbance, bring subsoil materials to the surface, create furrows, and bury surface residues. Travel speed that is too slow may not lift and fracture the soil adequately” (Kees2008).

Soils should be mostly dry and friable. Urban (2008) describes ideal conditions for compaction reduction as follows: “soil moisture must be between field capacity and wilt point during compaction reduction for maximum effectiveness."

Always know where utilities are buried prior to subsoiling. Avoid subsoiling in area that have buried utilities, wires, pipes, culverts, or diversion channels (Kees 2008, Urban 2008).

According to Spoor and Godwin (1978) “The number of variables involved and soil variation make the accurate prediction of the critical depth for field conditions impractical. Simple field modifications are available, however, such as increasing tine foot width and lift height or loosening the surface layers, to allow rapid implement adjustment to satisfy a range of field conditions.”

If subsoiling was effective, “The ground should be lifted slightly and remain relatively even behind the subsoiler, without major disruption of surface residues and plants. No more than a little subsoil and a few rocks should be pulled to the surface. If large furrows form behind the subsoiler, the shanks may not be deep enough, the angle on winged tips may be too aggressive, or the travel speed may be too high” (Kees 2008).

Cost for subsoiling varies by project. The Pennsylvania Stormwater Best Management Practices Manual estimates the cost of tilling soils ranges from $800 to $1000 per acre, while the cost of compost amending soil is about the same.

An extensive literature review of the effects of soil ripping can be found in File:Bioretention task 6 soil ripping.docx.

Compost

Compost is the product resulting from the controlled biological decomposition of organic materials that has been sanitized through the generation of heat and stabilized to the point that it is beneficial to plant growth. It is an organic matter resource that has the unique ability to improve the chemical, physical, and biological characteristics of soil. It can be derived from composted yard waste, food waste, manure, leaves, grass clippings, straw, or biosolids.

Compost aggregates soil particles (sand, silt, and clay) into larger particles (Cogger, 2005). Aggregation of soil particles creates additional porosity, which reduces the bulk density of the soil (Cogger, 2005). Compost can also reduce the bulk density of a soil by dilution of the mineral matter in the soil (Cogger, 2005). When the porosity of the soil increases and the particle surface area increases, water holding capacity is also increased (Cogger, 2005). Increases in macropore continuity have been found as well (Harrison et al., 1998). Studies have cited numerous beneficial abilities of compost: increased water drainage, increased water holding capacity, increased plant production, increased root penetrability, reduction of soil diseases, reduction of heavy metals, and the ability to treat many chemical pollutants (EPA, 1997; Harrison et al., 1998; WDOE Stormwater Management Manual, 2007; Olson 2010).

Research studies illustrate the importance of compost on maintaining or improving soil infiltration rates. Olson showed that bulk densities in residential areas decreased from an average of 1.4 grams per cubic centimeter to 0.93 to 1.15 grams per cubic centimeter following amendment with compost. Saturated conductivities were 3.4 to 6.1 times greater following compost amendment. Olson et al. (2013) studied effects of tilling with and without compost on soil infiltration in compacted urban soils. The geometric mean of saturated hydraulic conductivity on the compost plots was 2.7 to 5.7 times that of the control plot. On soils with just tilling, the geometric mean of saturated hydraulic conductivity was 0.5 to 2.3 times that of the control plot, indicating little overall improvement. Compost addition was more effective than tilling by reducing the soil strength and compaction and increasing soil infiltration.

Information on compost is provided in the following table.

When purchasing compost to be used for turf establishment or incorporation into soil as a postconstruction soil amendment, look for these specifications.

Link to this table

| Parameter | Parameter Definition | Range (Provided by G. Black, MPCA, 2007) |

|---|---|---|

| Source Material/Nutrient Content | Compost typically comes from biosolids/animal manure or yard wastes. Compost made from biosolids and animal manure typically contains more nutrients.1 |

|

| Maturity | Maturity refers to the level of completeness of the composting process. Composts that have not progressed far enough along the decomposition process may contain phytotoxic compounds that inhibit plant growth.2 | Seed emergence and seed vigor = minimum 80% relative to positive control |

| Stability | Compost stability refers to the biological activity in the composted material. Unstable composts may use available nitrogen in the soil and stunt plant growth. | CO2 Evolution rate: < 8 mg CO2-C/g-OM/day |

| pH | pH is a measure of acidity/alkalinity. Amending soil with compost can alter soil pH, which in turn can improve plant growth. | 5.5 – 8.5 |

| Soluble salts | The term “soluble salts” refers to the amount of soluble ions in a solution of compost and water. Because most plant nutrients are supplied in soluble form, excess non-nutrient soluble salts can inhibit plant growth. | Varies widely according to source materials for compost, but should be < 10 dS/m (mmhos/cm) |

| Organic matter | Organic matter is a measure of the amount of carbon-based materials in compost. There is no ideal range of organic matter for compost, but knowing the amount of organic matter in compost may help determine application rates for specific applications. | 30-65% dry weight basis |

| Particle size | It is helpful to know the size of particles in a compost product. There is no ideal range, but particle size does influence the usability of a compost product for a specific application. | Pass through 1-inch screen or less; 3/4 inch is preferable per MnDOR Specification 3890 |

| Biological contaminants (weed seeds and pathogens) | Biological contaminants consist of pathogens (disease causing organisms) and weed seeds. High temperatures will inactivate both types of biological contaminants. Minnesota State composting rules require commercial composting operations to hold temperatures over 55 degrees C over an extended period of time to destroy pathogens. In addition, compost operations must monitor the process to prove that these conditions have been met. | Meet or exceed US EPA Class A standards, 40 CFR §503.32(a) levels |

| Physical contaminants (inerts)* | Inerts are man-made materials (like pieces of plastic or glass) that do not decompose. There is no ideal range but they may be aesthetically unpleasing and add no value to the compost. | < 1% dry weight basis3 |

| Trace metals | Trace metals are elements that can be toxic to humans, animals, or plants at elevated concentrations | Meet or exceed US EPA Class A standards, 40 CFR §503.32(a) levels |

| * Inert material should not be present in adequately screened, vegetated waste compost. Caution should be used when the compost originates as mixed municipal or unscreened compost. | ||

1 MnDOT Grade 1 compost is derived from animal material; Grade 2 compost is derived from leaves and yard wastes. See MnDOT Specification 3890

2MnDOT Specification 3890 states: "Considered mature and useable when 60 percent decomposition has been achieved as determined by an ignition-loss analysis test method and any one additional test method including the Solvita test value of equal to or greater than 5. This means that the compost product has no offensive smell, no identifiable organic materials, and will not reheat to more than 20 °F [11 °C] above the ambient temperature."

3 MnDOT Specification 3890 states: "< 3% at 0.15 in [4 mm]"

Composting and ripping combined

Studies show that tilling in sand, compost, or both is an effective technique to alleviate soil compaction. Two of these studies are summarized below.

- Olson (2010) found that plots where soil was ripped and amended with compost showed reduced soil strength, bulk densities were 18 to 37 percent lower on compost plots compared to controls, and the geometric mean of Ksat on the compost plots was 2.7 to 5.7 times that of the control plot.

- A study at Virginia Tech shows soils with compost incorporated into the soil to a depth of 2 feet has decreased bulk density in the subsoil and is accelerating the process of soil formation and long-term carbon storage compared to other treatments in the study. The result is that trees growing in the compost-amended soil have increased height, canopy diameter, and trunk diameter compred to trees in other treatments.

Tilling in compost amendment may not be desirable on sites with steep slopes, a high water table, wet saturated soils, or downhill slope toward a house foundation (Schueler Technical Note #108); where there are tree roots or utilities; or where nutrients leaching from compost would pose a problem. Since soil restoration techniques will need to be tailored to site conditions, a prescriptive soil restoration specification is not recommended. However, Pennsylvania, Virginia, and Washington State have specifications for soil amendment and restoration and these may be used as guidance in determining how to amend a compacted soil.

Recommended procedures for alleviating compaction

Soil restoration techniques will need to be tailored to site conditions. A prescriptive soil restoration specification is therefore not recommended. The following procedure borrows from methods described in Olson et al (2013), Pennsylvania Department of Environmental Protection (2006), and Virginia Tech (2012).

Applicability

The following procedure is applicable to sites with subsoils that are compacted during construction. Apply the procedure if compaction is above ideal bulk density indicated in the table below.

General relationship of soil bulk density to root growth based on soil texture

Link to this table

| Soil texture | Ideal bulk densities (g/cm3) | Bulk densities that may affect plantgrowth (g/cm3) | Bulk densities that restrict root growth (g/cm3) |

|---|---|---|---|

| sands, loamy sands | <1.60 | 1.69 | >1.80 |

| sandy loams, loams | <1.40 | 1.63 | >1.80 |

| sandy clay loams, loams, clay loams | <1.40 | 1.60 | >1.75 |

| silts, silt loams | <1.30 | 1.60 | >1.75 |

| silt loams, silty clay loams | <1.40 | 1.55 | >1.65 |

| sandy clays, silty clays, clay loams with 35-45% clay | <1.10 | 1.49 | >1.58 |

| clays (>45% clay) | <1.10 | 1.39 | >1.47 |

The procedure should not be applied in areas where tree roots are to be protected. The procedure is not intended to improve soil chemical properties.

Procedure

General recommendations include the following.

- Prepare a site map, including areas where traffic and storage is to be avoided

- Fence off areas where traffic and material storage should be avoided

- If appropriate, submit compost and soil analysis to the landscape architect or owner

- Soil should be neither wet nor dry

- Keep equipment out of treatment practice (if possible) and work backwards away from excavated soils so that treated soil is not trafficked by the equipment

Although exact procedures will vary with site conditions, the following procedures are recommended.

- If deep tillage is employed, utilize a spacing of 12 inches. See the above section on soil ripping for additional guidance, including appropriate equipment to use.

- Comingle soil and compost using a tree spading machine, tined bucket, or similar equipment. Prior to spading add an average of 2.5 to 3 inches of compost to the soil surface. Comingle the soil to a depth of 15 to 18 inches. For guidance on compost see the previous section on compost.

- Insert the spading machine or bucket through the compost layer and into the subsoil and raise a bucket of soil at least 24 inches above the soil surface. Tip the bucket and allow soil to fall. Repeat this procedure until no clumps of compacted soil larger than 12 inches in diameter remain. The tines of the bucket can be used to break apart larger clumps if necessary. Fifty percent of the soil shall be in clumps 6 inches or smaller. No clumps shall be greater than 18 inches in diameter. Maintain a 3 foot minimum separation distance between the bottom of the practice and the seasonally high water table or bedrock and a 1 foot minimum between the bottom of the subsoiled zone and the water table or top of bedrock.

- Use existing topsoil or replace topsoil and rototill to 4 inches or up to 8 inches if severely disturbed.

- For vegetated practices, follow these guidelines.

- Select vegetation based on a specified zone of hydric tolerance. Plants for Stormwater Design - Species selection for the Upper Midwest is a good resource.

- Specify native plant species over non-native species. This includes wild flowers, grasses, shrubs, and if appropriate, trees. Hardy native species that thrive in our ecosystem without chemical fertilizers and pesticides are the best choices.

- Salt resistant vegetation should be used in locations with probable adjacent salt application, i.e. roadside, parking lot, etc.

- Plugs, bare root plants or potted plants are RECOMMENDED over seed for herbaceous plants, shrubs, and trees. Erosion control mats pre-vegetated with herbaceous plants are also acceptable. For turf, sod is recommended over seed. (NOTE: Fluctuating water levels following seeding (prior to germination) can cause seed to float and be transported, resulting in bare areas that are more prone to erosion and weed invasion than vegetated areas. Seed is also difficult to establish through mulch, a common surface component of bioretention. It may take more than two growing seasons to establish the function and desired aesthetic of mature vegetation via seeding.)

- Bioretention systems should be operated off-line for 1 year or, within the first year, until vegetation is established.

- Example target plant coverage includes

- at least 50 percent of specified vegetation cover at end of the first growing season;

- at least 90 percent of specified vegetation cover at end of the third growing season;

- supplement plantings to meet project specifications if cover targets are not met; and

- tailoring percent coverage targets to project goals and vegetation. For example, percent cover required for turf after 1 growing season would likely be 100 percent, whereas it would likely be lower for other vegetation types.

- If trees are incorporated into the practice, follow the tree planting guidelines described in this manual.

Precedents for soil restoration specifications

The above procedure is not prescriptive and provides general guidelines developed from other literature sources. Specific information from those other sources is provided below as a means of comparison or to provide alternate approaches.

- The Virginia Tech Rehabilitation study website provides a Soil Profile Rebuilding Specification based on their research. The basic steps in their specification are described below.

- Spread mature, stable compost to a 4 inch depth over compacted subsoil.

- Subsoil to a depth of 24 inches.

- Replace topsoil to 4 inches (6 to 8 inches if severely disturbed).

- Rototill topsoil to a depth of 6 to 8 inches.

- Plant with woody plants.

- Washington State’s Department of Ecology’s Stormwater Management for Western Washington (Volume V: Runoff Treatment BMPs, Chapter 5, pages 5-7 to 5-10) includes a very detailed soil restoration specification that includes the following.

- The topsoil layer has a minimum organic matter content of 10 percent dry weight in planting beds, 5 percent organic matter content in turf areas, and a pH from 6.0 to 8.0 or matching the pH of the undisturbed soil. The topsoil layer shall have a minimum depth of 8 inches except where tree roots limit the depth of incorporation of amendments needed to meet the criteria. Subsoils below the topsoil layer should be scarified at least 4 inches with some incorporation of the upper material to avoid stratified layers, where feasible.

- Mulch planting beds with 2 inches of organic material.

- Use compost and other materials that meet these organic content requirements.

- The organic content for pre-approved amendment rates can be met only using compost that meets the definition of composted materials in WAC 173-350-100. The compost must also have an organic matter content of 40 to 65 percent and a carbon to nitrogen ratio below 25:1. The carbon to nitrogen ratio may be as high as 35:1 for plantings composed entirely of plants native to the Puget Sound Lowlands region.

- Calculated amendment rates may be met through use of composted materials meeting above conditions, or other organic materials amended to meet the carbon to nitrogen ratio requirements and meeting the contaminant standards of Grade A Compost. The resulting soil should be conducive to the type of vegetation to be established.

- The soil quality design guidelines listed above can be met by using one of the methods listed below.

- Leave undisturbed native vegetation and soil, and protect from compaction during construction.

- Amend existing site topsoil or subsoil either at default pre-approved rates, or at custom calculated rates based on tests of the soil and amendment.

- Stockpile existing topsoil during grading, and replace it prior to planting. Stockpiled topsoil must also be amended if needed to meet the organic matter or depth requirements, either at a default pre-approved rate or at a custom calculated rate.

- Import topsoil mix of sufficient organic content and depth to meet the requirements. More than one method may be used on different portions of the same site. Soil that already meets the depth and organic matter quality standards, and is not compacted, does not need to be amended.

- The 2006 Pennsylvania Stormwater Best Management Practices Manual’s chapter on soil amendment and restoration provides a sample specification for soil restoration. Their specification is not prescriptive, but does provide guiding principles, compost material specifications, and performance requirements. They require sub-soiling to loosen soil to less than 1400 kPa (200 psi) to a depth of 20 inches below final topsoil grade to reduce soil compaction in all areas where plant establishment is planned in areas where subsoil has become compacted by equipment operation, or has become dried out andcrusted, or where necessary to obliterate erosion hills.

Additional references and fact sheets

- Achieving the Post-construction Soil Standard - provides guidance for preserving and restoring healthy soils on developments.

- Soil Compaction in the Urban Landscape

- Combating Soil Compaction

- Urban Soil Compaction

References

- Alberty, C.A., H.M. Pellett, and D.H. Taylor. 1984. Characterization of soil compaction at construction sites and woody plant response. J. Environ. Hortic. 2(2):48-53.

- Blake, G.R., and K.H. Hartge. 1986. Bulk density, radiation methods. In Klute, A. (Ed.). Methods of Soil Analysis, Part 1. Physical and Mineralogical Methods. Agronomy Monographs, No. 9 (2nd ed.). American Society of Agronomy, Madison, WI.

- Brown, R.A. and Hunt, W.F. (2010). “Impacts of construction activity on bioretention performance.” Journal of Hydrologic Engineering. 15(6), 386-394.

- Chaplin, Jonathan, Min Min, and Reid Pulley. 2008. Compaction Remediation for Construction Sites. Final Report. Department of Bioproducts and Biosystems Engineering, University of Minnesota, St. Paul, Minnesota.

- Cogger, C. Potential Compost Benefits for Restoration of Soils Disturbed by Urban Development. Compost Science & Utilization 13.4 (2005): 243-251.

- Gregory, J.H., Dukes, M.D., Jones, P.H., Miller, G.L., 2006. Effect of urban soil compaction on infiltration rate. Journal of Soil and Water Conservation 61, 117-124.

- Hamilton, G.W., Waddington, D.V., 1999. Infiltration rates on residential lawns in central Pennsylvania. Journal of Soil and Water Conservation 54, 564-568.

- Hanks, D. and A. Lewandowski, 2003. Protecting Urban Soil Quality: Examples for Landscape Codes and Specifications. USDA Natural Resources Conservation Services.

- Indiana Department of Transportation. 2003. Dynamic Cone Penetration Test (DCPT) for Subgrade Assessment. Publication No. FHWA/IN/JTRP-2002/30, SPR-2362.

- Kees, Gary. 2008. Using Subsoiling To Reduce Soil Compaction. U.S. Forest Service Technology & Development Publication 3400 Forest Health Protection 0834-2828-MTDC. Downloaded from http://www.fs.fed.us/t-d/pubs/htmlpubs/htm08342828/index.htm July 15, 2013

- Lichter, J.M., and L.R. Costello. 1994. An evaluation of volume excavation and core sampling techniques for measuring soil bulk density. J. Arboric. 20(3): 160-164.

- Natural Resource Conservation Service. 2012. National Engineering Handbook. Chapter 11, Cone Penetrometer. Part 631.

- Natural Resource Conservation Service. 1998. Soil Quality Test Kit Guide.

- New York Department of Transportation. 2015. Geotechnical Test Method: Test Method For Earthwork Compaction Control By Nuclear Gauge. Geotechnical Engineering Bureau. GTM-10, Revision#5.

- Ocean County Soil Conservation District (OCSCD), Schnabel Engineering Associates, Inc., USDA Natural Resources Conservation Service. 2001. Impact of soil disturbance during construction on bulk density and infiltration in ocean county. New Jersey.

- Olsen, H.J. 1990. Construction of an electronic penetrometer for use in the field. Computers and Electronics in Agriculture. 5:1:65-75.

- Olson, N.C. J.S. Gulliver, J.L. Nieber, and M. Kayhanian. 2013. Remediation to improve infiltration into compact soils. Journal of Environmental Management. 117:85-95.

- Olson, Nicholas Charles. 2010. Quantifying the Effectiveness of Soil Remediation Techniques in Compact Urban Soils. University Of Minnesota Master Of Science Thesis.

- Owen, Gordon T. 1987. Soil disturbance associated with deep subsoiling in compact soils. Canadian Agricultural Engineering: 33-37.

- Pennsylvania Department of Environmental Protection. 2007. Pennsylvania Stormwater Best Management Practices Manual. Section 5.6.2. Minimize Soil Compaction in Disturbed Areas.

- Pennsylvania Department of Environmental Protection. 2006. Pennsylvania Stormwater Best Management Practices Manual. BMP 6.7.3: Soil Amendment & Restoration.

- Pitt, R., Chen, S., Clark, S.E., Swenson, J., and Ong, C.K. 2008. “Compaction’s impact on urban storm-water infiltration.” Journal of Irrigation and Drainage Engineering. 134(5), 652-658.

- Randrup, T.B. 1993. Soil Compaction and Plant Growth (Jordkomprimering og Plantevaskst). The Royal Veterinary and Agricultural University. Danish Forest and Landscape Research Institute. Copenhagen, Denmark. 78 pp.

- Randrup, T.B. 1997. Soil Compaction on Construction Sites. Journal of Arboriculture, 23:5:207-210.

- Schueler, T.R., and H.K. Holland. 2000. The Practice of Watershed Protection; Techniques for Protecting our Nation's Streams, Lakes, Rivers, and Estuaries. Mahler Books, Austin ,TX. Published by the Center for Watershed Protection. 742 pp.

- Schueler, T. 2000. The Compaction of Urban Soil: The Practice of Watershed Protection. Center for Watershed Protection, Ellicott City, MD. Pages 210-214 downloaded from http://www.cwp.org/online-watershed-library/cat_view/63-research/75-monitoring

- Schueler, T. R. Can Urban Soil Compaction Be Reversed? Technical Note #108 from Watershed Protection Techniques. 1(4): 666-669.

- Selbig, W.R., and N. Balster. 2010. Evaluation of turf-grass and prairie-vegetated rain gardens in a clay and sand soil: Madison, Wisconsin, water years 2004–08. U.S. Geological Survey, Scientific Investigations Report 2010–5077, 75 p.

- Spoor, G. & Godwin, R.J. 1978. An experimental investigation into the deep loosening of soil by rigid tines. Journal of Agricultural Engineering Research, 23, 243–258.

- Spoor, G., Tijink, F.G.J. & Weisskopf, P. 2003. Subsoil compaction: risk, avoidance, identification and alleviation. Soil and Tillage Research, 73, 175–182.

- Spoor, G. "Alleviation of Soil Compaction: Requirements, Equipment and Techniques." Soil Use and Management 22 (2006):113-122.

- Tyner, J.S., Wright, W.C., and Dobbs, P.A. (2009). Increasing exfiltration from pervious concrete and temperature monitoring. Journal of Environmental Management. 90, 2636-2641.

- Urban, James. 2008. Up by Roots. International Society of Arboriculture: Champaign, IL.

- Virginia Tech. 2012. Soil Profile Rebuilding Specification. Departments of Forest Resources and Environmental Conservation, Horticulture, and Crop and Soil Environmental Sciences.