Difference between revisions of "Design criteria for permeable pavement"

| Line 195: | Line 195: | ||

===Reservoir Layer=== | ===Reservoir Layer=== | ||

| − | The reservoir below the permeable pavement surface should be composed of clean, washed crushed stone aggregate and thickness sized for both the storm event to be stored and the structural requirements of the expected traffic loading. The recommended minimum void ratio should be 40% per ASTM C29. Reservoir base layers for pervious concrete are typically washed | + | The reservoir below the permeable pavement surface should be composed of clean, washed crushed stone aggregate and thickness sized for both the storm event to be stored and the structural requirements of the expected traffic loading. The recommended minimum void ratio should be 40% per ASTM C29. Reservoir base layers for pervious concrete are typically washed AASHTO No. 57 stone and those for porous asphalt are AASHTO No. 2, 3, or 5. PICP uses AASHTO No. 2, 3, or 4 stone. |

| − | + | ||

| + | |||

| + | If exposed to vehicular loads, all crushed stone should be Minnesota Department of Transportation (MnDOT) Class A or B coarse aggregate, minimum 80% crushed, typically granite, basalt, gneiss, trap rock, diabase, gabbro, or similar material. The maximum Los Angeles Rattler Loss should be 35% per AASHTO T-96 and no greater loss than 10% per AASHTO T-104 Magnesium Sulfate Soundness Test on the non-igneous portions and as modified by the MnDOT Laboratory Manual (MNDOT 2005). Limestone aggregates not meeting these requirements are not recommended in vehicular applications. Class C and D aggregates may be used in areas subject only to pedestrian traffic. | ||

===Underdrains=== | ===Underdrains=== | ||

Revision as of 14:01, 4 February 2013

The anticipated construction period for this page is January through March, 2013

The anticipated review period for this page is January through March, 2013

This section provides information on design considerations, criteria and specifications for permeable pavement.

Contents

Site design considerations

Permeable pavement is subject to the following design considerations, including benefits and constraints.

- Available Space – A significant advantage of permeable pavement is its ability to combine detention/ infiltration and pavement, thereby reducing or eliminating land required for detention facilities. This is especially important in urban areas with high land prices and highly developed sites with little or no space for stormwater detention.

- Soils – Soil conditions and infiltration rates determine the use of an underdrain. (NRCS Hydrologic Soil Group (HSG) C or D soils usually require an underdrain, whereas HSG A and B soils often do not.) Designers should evaluate existing soil properties during initial site layout with the goal of configuring permeable pavement that conserves and protects soils with the highest infiltration rates. In particular, areas of HSG A or B soils shown on soil surveys should be considered as primary locations for all types of infiltration practices.

Soil surveys and HSG classifications provide a general estimate of the soil's infiltration rate. Soil infiltration rates can also be estimated from soil classifications per ASTM D2487. However, it is best to verify rates using on-site infiltration testing per ASTM D3385 or D5093. In most cases, permeable pavement should not be situated above fill soils. Designs in compacted fill soils may require an impermeable liner and an underdrain. Permeable pavements should only be placed on fill soils when laboratory tests indicate the compacted fill will be stable when saturated and that slope stability of deep fills has been verified by a geotechnical engineer.

- Contributing Drainage Area – Permeable pavements sometimes capture runoff from adjacent areas, pavements, and roofs. The at-grade contributing drainage area into permeable pavement should generally not exceed twice the surface area of the permeable pavement. This guideline helps reduce the rate of surface sedimentation. The 2:1 ratio can be increased if (1) the permeable pavement is receiving runoff from roofs as it tends to be very low in sediment or (2) if runoff from ground level impervious surfaces is expected to remain unburdened with sediment. The best situation is when the design allows for a pre-treatment strip (e.g., stone, gravel, or turf) to control sediment run-on into the permeable pavement.

- Soil Subgrade Slope – The slope of the soil subgrade should be as flat as possible (i.e., 0% longitudinal slope) to enable even distribution and infiltration of stormwater. Lateral slopes should be 0%. Steep slopes can reduce the stormwater storage capacity of permeable pavement. Designers should consider using a terraced subgrade design for permeable pavement in sloped areas, especially when the local slope exceeds 3%.

- Surface Slope – Surface slopes for all permeable pavement types should be at least 1% to provide an alternate means for drainage should the surface become completely clogged due to lack of maintenance. Designs should provide an alternate means for stormwater to enter the aggregate reservoir if the pavement surface should ever become clogged, or for extreme storm events. For pervious concrete and porous asphalt without curbs, this can be a 2 foot wide stone edge connected to the reservoir. For curbed pavements, inlets may be used.

- Overflow Structures – Permeable pavements are not designed to store and infiltrate all stormwater from all storms. Therefore, an outlet or outlets are required to prevent water from rising into and over the surface. One type of outlet control would be a catch basin with an internal weir and low-flow orifice. The catch basin can also handle runoff from the surface should it become clogged.

- Minimum Depth to Seasonal High Water Table – A high groundwater table may cause seepage into the bottom of permeable pavement and prevent complete drainage. Also, soil acts as a filter for pollutants between the bottom of the pavement base and the water table. Therefore, a minimum vertical separation of 3 feet is required between the bottom of the permeable pavement reservoir layer and the seasonal high groundwater table.

- Setbacks –

To avoid harmful seepage, permeable pavement should not be hydraulically connected to building foundations unless an impermeable liner is placed against the foundation or basement wall. Even under these circumstances, great care should be taken to avoid creating a wet basement problem. If there is no liner, the permeable pavement base should be 10 feet or greater from structures (EPA recommends a minimum setback from building foundations of 10 feet down-gradient and 100 feet up-gradient. See EPA factsheet “Storm Water Technology Fact Sheet: Porous Pavement,” EPA 832-F-99-023). Again, it is the designer’s responsibility to avoid creating a wet basement problem. Likewise, permeable pavement bases should be hydraulically separated from adjacent road bases.

Permeable pavements without underdrains infiltrate stormwater and should follow requirements for wellhead protection (EPA recommends a minimum setback of 100 feet from water supply wells). Underground utility lines are best located away from permeable pavement bases. However, if they need to penetrate the base, consideration should be given to waterproofing (depending on the utility) or possible encasement using low-strength flowable concrete fill. Setbacks can be reduced at the discretion of the local authority for designs that use underdrains and/or liners.

- Informed Owner – The property owner should clearly understand the unique maintenance responsibilities inherent with permeable pavement, particularly for parking lot applications. The owner should be capable of performing routine and long-term actions (e.g., vacuuming) to maintain the pavement’s hydrologic functions, and avoid future practices (e.g., winter sanding, seal coating or repaving) that diminish or eliminate them. For porous asphalt a diluted emulsion fog can be used as needed. Maintenance agreements, covenants, maintenance easements or performance bonds are encouraged between the local authority and the property owner.

- Limitations – There are several limitations for use of permeable pavement, as summarized below.

- Permeable pavements should not be used in high pollutant loading sites. High pollutant loading sites are those that receive constant sediment or trash and/or debris. Places where fuels and chemicals are stored or handled can be potential stormwater hotspots and permeable pavement should not be constructed in these places. Likewise, areas subject to wind borne dust and sediment should not use permeable pavement unless the pavement can be vacuumed regularly. The following limitations should be considered before utilizing permeable pavements in any design.

- Permeable pavement is suitable for pedestrian-only areas, low-volume roads, low speed areas, overflow parking areas, residential driveways, alleys, and parking stalls. These can be residential collector roads or other applications with similar traffic loads.

- Permeable pavement can be prone to clogging from sand and fine sediments that fill void spaces and the joints between pavers. As a result, it should be used carefully where frequent winter sanding is necessary because the sand may clog the surface of the material. Periodic maintenance is critical, and surfaces should be cleaned with a vacuum sweeper at least two times a year.

- Fuel may leak from vehicles and toxic chemicals may leach from asphalt and/or binder surface. Porous pavement systems are not designed to treat these pollutants.

Design criteria

Base/subbase thickness is determined for support traffic using structural design methods and for water storage using hydrologic sizing and/or dynamic modeling over time. The thicker of the two resulting designs is used.

Structural Design

The structural design process for supporting vehicles varies according to the type of pavement selected. The pervious concrete industry is in the process of developing ASTM test methods for characterizing compressive or flexural strengths of pervious concrete. These tests are needed to model fatigue under loads. As an interim step, fatigue equations published by the American Concrete Pavement Association (ACPA 2010) assume such inputs to be comparable in nature (but not magnitude) to those used for conventional concrete pavements. The ACPA design method should be consulted for further information as well as pervious concrete industry software. General guidelines for pervious concrete surface thickness are published by the National Ready Mix Concrete Association and the Portland Cement Association (Leming 2007).

Porous asphalt (Hansen 2008) and permeable interlocking pavements (Smith 2011) use flexible pavement design methods adopted from the 1993 AASHTO Guide for Design of Pavement Structures (AASHTO 1993). In addition, MnDOT design methods, approved mechanistic principles, and manufacturer’s specific recommendations should be consulted.

There has been limited research on full-scale testing of the structural behavior of open-graded bases used under permeable pavements to better characterizing relationships between loads and deformation. Therefore, conservative values (i.e., AASHTO layer coefficients) should be assumed for open-graded base and subbase aggregates in permeable pavement design.

Regardless of type of permeable pavement, structural design methods consider the following in determining surface and base thicknesses to support vehicular traffic:

- Pavement life and total anticipated traffic loads expressed as 18,000 lb equivalent single axle loads or ESALs (This method of assessing loads accounts for the additional pavement wear caused by trucks.)

- Soil strength expressed as the soaked California Bearing Ratio (CBR), R-value or resilient modulus (Mr)

- Strength of the surfacing, base and subbase materials

- Environmental factors including freezing climates and extended saturation of the soil subgrade

Soil stability under traffic should be carefully reviewed for each application by a qualified geotechnical or civil engineer and lowest anticipated soil strength or stiffness values under saturated conditions used for design. Structural design for vehicular applications should generally be on soil subgrades with a CBR (96-hour soaked per ASTM D 1883 or AASHTO T 193) of 4%, or a minimum R-value = 9 per ASTM D 2844 or AASHTO T-190, or a minimum Mr of 6,500 psi (45 MPa) per AASHTO T-307. Soils with lower strengths typically require thickened permeable bases or those using cement or asphalt stabilized open-graded aggregates per Mn/DOT Pavement Manual, Section 3-3.01.02 Treated Base.

Soil compaction required to achieve these soil strengths will reduce the infiltration rate of the soil. Therefore, the permeability or infiltration rate of soil should be assessed at the density required to achieve one of these values. If soils under vehicular traffic have lower strengths than those noted above, or are expansive when wet, there are several options, including

- use underdrains

- thicken the base/subbase layer(s)

- stabilize the base layers with cement or asphalt, and

- stabilize the soil with lime or cement.

These options are typically used in combination. Pedestrian applications can be placed on lower strength soils than those noted.

Pedestrian applications can be placed on lower strength soils than those noted.

Hydrologic Sizing

The soil subgrade infiltration rate typically is far lower than the flow rate through the pavement, so some reservoir storage will usually be required to maximize the stormwater benefit of permeable pavement. Often times permeable pavement is designed to store a given design storm. For instance, Minnesota’s Minimal Impact Design Standards (MIDS) require a performance goal of managing 1.1 inches of runoff from the tributary impervious surfaces. For this design standard, the volume of the reservoir layer will be required to store 1.1 inches of stormwater runoff entering from the impervious area plus rainfall directly into the permeable pavement itself.

Infiltration of runoff into the subgrade provides more stormwater treatment benefit than filtering through the base and exiting via underdrains. For this reason, adding and underdrain at the bottom of the storage reservoir (on top of the subgrade soil) at sites with HSG A or B subgrade soil is typically not recommended. This is sometimes done to provide a “factor of safety.” This is often unnecessary and reduces the overall effectiveness of permeable pavement as a BMP.

\(D_p = (d_c R) + P – (i/2 t_f) / V_r\)

where

- Dp = the depth of the reservoir layer (feet);

- dc = the depth of runoff from the contributing drainage area (not including the permeable paving surface) for the design storm (feet);

- R = Ac/Ap The ratio of the contributing drainage area (Ac, not including the permeable paving surface) to the permeable pavement surface area (Ap);

- P = the rainfall depth for the Treatment Volume (1.1 inch), or other design storm (feet);

- i = the field-verified infiltration rate for native soils (feet per day);

- tf = the time to fill the reservoir layer (day) – typically 2 hours or 0.083 day; and

- Vr</sub> = the void ratio for the reservoir layer (typically 0.4).

The maximum allowable depth of the reservoir layer is constrained by the maximum allowable drain time, which is calculated using the following equation.

\(D_{p-max} = (i/2 t_d) / V_r\)

where

- Dp-max = the maximum depth of the reservoir layer (feet); and

- td = the maximum allowable time to drain the reservoir layer, typically 1 to 2 days

The following design assumptions apply to the previous equations:

- The contributing drainage area (Ac) does not contain pervious areas.

- Compacted pervious areas that contribute runoff are included as a portion of the contributing drainage area (Ac)

- For design purposes, the subgrade soil infiltration rate (i) should be the lesser of either (1) a field-tested soil infiltration rate with a correction factor applied as recommended by the MN Stormwater Manual or (2) the typical infiltration rate for the given HSG as stated in the MN Stormwater Manual

- The void ratio (Vr) for the base and subbase stone layers = 0.4.

- The maximum drain time for the reservoir layer should be not less than 24 hours or greater than 48 hours after the initial 24-hour storm event.

If the depth of crushed stone below the pavement (depth of reservoir, dp) is greater than the maximum allowable depth of reservoir, dp-max an underdrain should be added at the elevation of dp-max to provide an overflow. The storage volume in the pavements must account for the underlying infiltration rate and outflow through the underdrain. In this case, the design storm should be routed through the pavement to accurately determine the required reservoir depth.

Infiltration of runoff into the subgrade provides more stormwater treatment benefit than filtering through the base and exiting via underdrains. For this reason, adding and underdrain at the bottom of the storage reservoir (on top of the subgrade soil) at sites with HSG A or B subgrade soil is typically not recommended. This is sometimes done to provide a “factor of safety.” This is often unnecessary and reduces the overall effectiveness of permeable pavement as a BMP.

\(D_p = (d_c R) + P – (i/2 t_f) / V_r\)

where

- Dp = the depth of the reservoir layer (feet);

- dc = the depth of runoff from the contributing drainage area (not including the permeable paving surface) for the design storm (feet);

- R = Ac/Ap The ratio of the contributing drainage area (Ac, not including the permeable paving surface) to the permeable pavement surface area (Ap);

- P = the rainfall depth for the Treatment Volume (1.1 inch), or other design storm (feet);

- i = the field-verified infiltration rate for native soils (feet per day);

- tf = the time to fill the reservoir layer (day) – typically 2 hours or 0.083 day; and

- Vr</sub> = the void ratio for the reservoir layer (typically 0.4).

The maximum allowable depth of the reservoir layer is constrained by the maximum allowable drain time, which is calculated using the following equation.

\(D_{p-max} = (i/2 t_d) / V_r\)

where

- Dp-max = the maximum depth of the reservoir layer (feet); and

- td = the maximum allowable time to drain the reservoir layer, typically 1 to 2 days

The following design assumptions apply to the previous equations:

- The contributing drainage area (Ac) does not contain pervious areas.

- Compacted pervious areas that contribute runoff are included as a portion of the contributing drainage area (Ac)

- For design purposes, the subgrade soil infiltration rate (i) should be the lesser of either (1) a field-tested soil infiltration rate with a correction factor applied as recommended by the MN Stormwater Manual or (2) the typical infiltration rate for the given HSG as stated in the MN Stormwater Manual

- The void ratio (Vr) for the base and subbase stone layers = 0.4.

- The maximum drain time for the reservoir layer should be not less than 24 hours or greater than 48 hours after the initial 24-hour storm event.

If the depth of crushed stone below the pavement (depth of reservoir, dp) is greater than the maximum allowable depth of reservoir, dp-max an underdrain should be added at the elevation of dp-max to provide an overflow. The storage volume in the pavements must account for the underlying infiltration rate and outflow through the underdrain. In this case, the design storm should be routed through the pavement to accurately determine the required reservoir depth.

Outflow Rate and Volume Through Underdrains

If the depth of the base/subbase for the full infiltration system is excessive, (i.e. dp exceeds dmax) because, as an example, the design subgrade soil infiltration rate is not adequate to remove the water from the design storm within the designated period of time, then the design should include underdrains. The following procedure is for sizing the base/subbase for partial infiltration designs (i.e. contains underdrains). The same symbols apply, but with the following additions:

- qu = outflow through underdrain, feet/hour

- k = Coefficient of permeability for each 6 inch diameter underdrain, feet/hour

- m = underdrain pipe slope, feet/feet

- n = number of underdrain pipes

- Tfill = effective filling time of the base/subbase which is at or above the underdrain(s), hours.

- T1 = the storage time during which the water is at or above the underdrain(s), hours.

- Dbelow = depth of the subbase below the underdrains, feet

The outflow rate from underdrain(s) can be approximated by

\(q_u = k x m\)

This equation is based on Darcy’s Law, which summarizes several properties that groundwater exhibits while flowing in aquifers. Although the hydraulic conductivity (measure of the ease with which water can move through pore spaces of a material) of the aggregate subbase is very high (approximately17,000 feet/day or 8,500 inches/hour), the discharge rate through underdrains is limited by the cross sectional area of the pipe. As the storage volume above/around the underdrain(s) decreases (i.e., the hydraulic head or water pressure decreases), the base/subbase and in turn the underdrain(s) will drain increasingly slower. To account for this change in flow conditions within the subbase and underdrain(s) over time, a very conservative coefficient of permeability (k) of 100 feet/day per pipe can be used to approximate the average underdrain outflow rate.

Once the outflow rate through each underdrain has been approximated, the depth of the base/subbase needed to store the design storm can be determined by

\(d_p = D Q_u R + (P – fT) – q_u (T_{fil})n / V_r\)

To estimate the number of underdrain pipes (n), take the dimension of the parking lot in the direction the pipes are to be placed and divide by the desired spacing between pipes – round down to the nearest whole number.

Tfill = T when the underdrains are at the bottom of the subbase. Tfil = ½T (approximation) when the underdrains are raised.

With full infiltration systems, the maximum allowable drain time (dmax) needs to be calculated to make sure the stored water within the base/subbase does not take too long to infiltrate into the soil subgrade. However, for partial infiltration systems, there is a second method of storage water discharge, namely the underdrains. The depth and number of underdrains are variables that can be adjusted (unlike the infiltration rate into the soil subgrade) so that the actual drain time equals or is less than the maximum allowable drain time. If the discharge of the underdrains is included, then

\(d_{max} = fT_s+ q_uT_1 n / V_r = d_p\)

Rearranging the previous equation, the storage time during which the water is at or above the underdrain(s) (hours) is given by \(T<sub>1</sub> = / V<sub>r</sub> d<sub>p</sub>–fT<sub>s</sub> / q<sub>u</sub>n\)

The elevation of the pipe above the soil subgrade is then given by

\(d_{below} = f(T_s – T_1) / V_r\)

Permeable pavement can also be designed to augment detention storage needed for channel protection and/or flood control. The designer can model various approaches by factoring in storage within the base/subbase, expected infiltration and any outlet structures used as part of the design.

Once runoff passes through the surface of the permeable pavement system, designers should calculate outflow pathways to handle subsurface flows. Subsurface flows can be regulated using underdrains, the volume of storage in the reservoir layer, the bed slope of the reservoir layer, and/or a control structure at the outlet.

Once runoff passes through the surface of the permeable pavement system, designers should calculate outflow pathways to handle subsurface flows. Subsurface flows can be regulated using underdrains, the volume of storage in the reservoir layer, the bed slope of the reservoir layer, and/or a control structure at the outlet.

Design for Nutrient and TSS Reductions

Permeable pavements can be designed to reduce nutrient loadings to the ground or surface waters. The design needs to be specifically designed to capture nitrogen and/or phosphorus. It is important to note that nitrogen and phosphorus each require specific designs to facilitate their removal from stormwater. The following paragraphs describe the design characteristics necessary for the removal of phosphorus and nitrogen.

Permeable pavement nitrate reduction capabilities can be enhanced in partial infiltration designs that detain water in the base/subbase for over 24 hours. This duration of time is required to ensure de-nitrification occurs. However, a study by Bean et al. (2007a) showed higher nitrate concentrations in the exfiltrate which was possibly due to the nitrification process.

PICP can use specially coated aggregates in the joints and bedding and all systems can use them in the base to reduce phosphorous. Coated aggregates (sometimes called “engineered aggregates”) have an effective life of seven to ten years and target the removal of dissolved phosphorous.

A filter layer made of sand or fine aggregate placed under or sandwiched within permeable pavement bases are occasionally used as a means to reduce nutrients. This layer can be enhanced with iron filings for phosphorous reduction (Erickson 2010). Their effectiveness, initial cost, and maintenance costs should be weighed against other design options for nutrient reductions. Sand filters will incur additional construction expense and this can be reduced by placing sand filters under the subbase at the down slope end of a permeable pavement. The disadvantage of sand filters is that they will eventually require removal and restoration if continued phosphorus reduction credit is desired. Concentrating their location in the down slope areas of the site can help reduce future maintenance costs and site disruptions.

A second approach useful for nutrient and TSS reduction can occur on sloping sites by creating intermittent berms in the soil subgrade. These enable settlement of suspended solids and encourage de-nitrification if appropriately designed. A third alternative is using a “treatment train” approach where a permeable pavement initially filters runoff and the remaining water outflows to bioswales or rain gardens adjacent to the pavement for additional processing and nutrient reduction. There may be additional BMPs used to remove nutrients as the water moves through the watershed.

Soil Infiltration Rate Testing

Prior to infiltration testing, several soil borings should be taken with an auger to assess the consistency of the soil type and horizons. Boring depths should be at least 2 feet deeper than the anticipated depth of the permeable pavement. At least one soil boring must be taken to confirm the underlying soil properties at the depth where infiltration is designed to occur (i.e., to ensure that the depth to water table, depth to bedrock, or karst is defined). The depth to bedrock can be highly variable over small areas, so soil borings should be conducted where the permeable pavement will be constructed. For sites with a consistent soil type, a minimum of one soil permeability test per ASTM D3385 or D5093 must be taken per 25,000 square feet of planned permeable pavement surface area. In most cases where the soil type is consistent throughout the site, a single soil test is sufficient for applications less than 25,000 sf. Additional infiltration tests are required per 25,000 square feet of planned permeable pavement area if the soil borings reveal changes in soil type. The median test result from all infiltration test values should be used as the design infiltration rate. Soil infiltration testing should be conducted within any confining layers that are found within five feet of the bottom of a proposed permeable pavement system.

Conveyance and Overflow

Permeable pavement designs should include methods to convey larger storms (e.g., 2-year, 10-year) to the storm drain system. The following is a list of methods that accomplish this:

- Place a perforated pipe horizontally near the top of the reservoir layer to pass excess flows after water has filled the base. The placement and/or design should be such that the incoming runoff is not captured (e.g., placing the perforations on the underside only). Pipe placement should be away from wheel loads to prevent damage.

- Increase the thickness of the top of the reservoir layer.

- Create underground detention within the reservoir layer of the permeable pavement system. Reservoir storage may be augmented by corrugated metal pipes, plastic or concrete arch structures, etc.

- Route excess flows to another detention or conveyance system that is designed for management of extreme event flows.

- Set the storm drain inlets level with the elevation of the permeable pavement surface to effectively convey excess stormwater runoff past the system. The design should also make allowances for relief of unacceptable ponding depths during larger rainfall events.

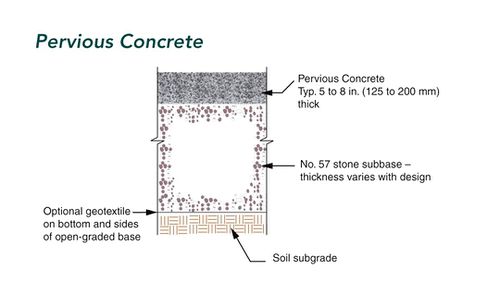

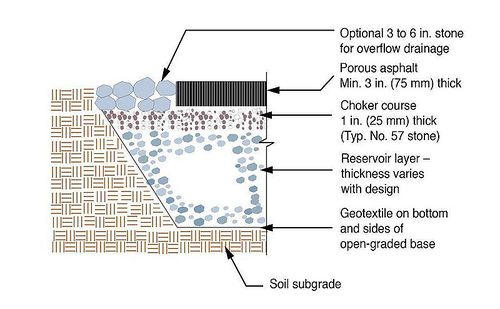

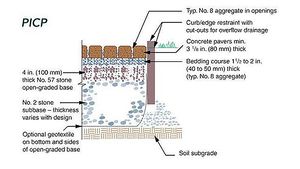

Reservoir Layer

The reservoir below the permeable pavement surface should be composed of clean, washed crushed stone aggregate and thickness sized for both the storm event to be stored and the structural requirements of the expected traffic loading. The recommended minimum void ratio should be 40% per ASTM C29. Reservoir base layers for pervious concrete are typically washed AASHTO No. 57 stone and those for porous asphalt are AASHTO No. 2, 3, or 5. PICP uses AASHTO No. 2, 3, or 4 stone.

If exposed to vehicular loads, all crushed stone should be Minnesota Department of Transportation (MnDOT) Class A or B coarse aggregate, minimum 80% crushed, typically granite, basalt, gneiss, trap rock, diabase, gabbro, or similar material. The maximum Los Angeles Rattler Loss should be 35% per AASHTO T-96 and no greater loss than 10% per AASHTO T-104 Magnesium Sulfate Soundness Test on the non-igneous portions and as modified by the MnDOT Laboratory Manual (MNDOT 2005). Limestone aggregates not meeting these requirements are not recommended in vehicular applications. Class C and D aggregates may be used in areas subject only to pedestrian traffic.

Underdrains

Underdrains install quickly when placed on or in the soil subgrade, surrounded by stone base or subbase materials. The outflow portion at the end is not perforated and is raised to a designed height allow for some water detention prior to outflow. Placement at this elevation also protects the pipe with aggregate during base compaction. An underdrain(s) can also be installed and capped at a downstream structure as an option for future use if maintenance observations indicate a reduction in the soil permeability.

Maintenance

Some key actions help ensure the long-term performance of permeable pavement. The most frequently cited maintenance problem is surface clogging caused by organic matter and sediment, which can be reduced by the following measures:

- Observation Well – Typically this consists of a well-anchored, six-inch diameter perforated PVC pipe that extends vertically to the bottom of the reservoir layer. This is installed at the down slope end of the permeable pavement. The observation well should be fitted with a lockable cap installed flush with the ground surface (or under the pavers) to facilitate periodic inspection and maintenance. The observation well is used to observe the rate of drawdown within the reservoir layer following a storm event.

- Overhead Landscaping – Some communities require a certain percentage of parking lots to be landscaped. Large-scale permeable pavement should be carefully planned to integrate landscaping in a manner that maximizes runoff treatment and minimizes risk of sediment, mulch, grass clippings, crushed leaves, nuts, and fruits inadvertently clogging the surface.

Design specifications

Permeable pavement material specifications vary according to the specific pavement product selected. Note that the size of stone materials used in the reservoir and filter layers may differ depending whether the system is pervious concrete, porous asphalt or permeable interlocking pavers. Designers should consult industry association and manufacturer’s technical specifications for specific criteria and guidance.

Summary of specifications for materials under the pavement surface. For more information, see the footnote (1). Reference or links to any specific commercial product, process, or service by trade name, trademark, service mark, manufacturer, or otherwise does not constitute or imply endorsement, recommendation, or favoring by the Minnesota Pollution Control Agency.

Link to this table

| Bedding/choker layer |

|

Washed free of fines |

| Reservoir Layer |

|

Stone layer thickness based on the pavement structural and hydraulic requirements. Stonewashed and free of fines. Recommended minimum void ratio = 0.4. |

| Underdrain (optional) | Use 4 to 6 inch diameter perforated PVC (AASHTO M-252) pipe or corrugated polyethylene pipe. Perforated pipe installed for the full length of the permeable pavement cell, and non-perforated pipe, as needed,connected to storm drainage system. | |

| Filter Layer (optional) | Sand filter layeris separated from base above and native soils with geotextile. Sand layer typically ASTM C33 gradation, 6 to 12 inches thick. | The Filter Layer is REQUIRED if using the permeable pavement system to meet permit requirements. The sand layer may require a choker layer on surface to provide transition to base layerstone. |

| Geotextile(optional) | Comply with AASHTO M-288 Standard Specification for Geotextile Specification for Highway Applications, drainage and separation applications, Class I or II. Porous asphalt industry recommends non-woven geotextile. | |

| Impermeable Liner | Use a minimum 30mil PVC liner covered by 12 ounce/square yard non-woven geotextile. EPDM and HDPE liner material is also acceptable. | |

| Observation Well | Use a perforated 4 to 6 inch vertical PVC pipe (AASHTO M-252) with a lockable cap, installedflush with the surface (or under pavers). | |

1for additional information on materials referenced in this table (e.g. stone dimensions), see the following links:

This table shows summarizes specifications for permeable pavement.

Link to this table.

| Permeable Pavers | Surface open area: typically 5% to 15%; minimum thickness: 3 inches for vehicles; minimum compressive strength: 8,000 psi | Concrete pavers conform to ASTM C936 and clay pavers C1272. Reservoir layer required to support the structural load. |

| Pervious Concrete |

|

May not require a reservoir layer to support loads, but a layer is required for storage/infiltration. In no case should plain steel rebar or mesh be used in pervious concrete as this invites corrosion. |

| Porous Asphalt |

|

Reservoir layer contributes to structural load support. |

Other design considerations

There are additional design considerations for permeable pavement, including use of permeable pavement in karst terrain and winter considerations.

Karst terrain

A detailed geotechnical investigation may be required for any kind of stormwater design in karst terrain. Permeable pavements, as with other infiltration practices, are not recommended at sites with known karst features as they can cause the formation of sinkholes and can provide a direct link for stormwater to access groundwater without providing any treatment.

Winter considerations

Plowed snow piles should be located in adjacent grassy areas so that sediments and pollutants in snowmelt are partially treated before they reach all permeable pavements. Sand is not recommended for winter traction over permeable pavements. If sand is applied, it must be removed with vacuum cleaning in the spring. Traction can be accomplished on PICP using jointing stone materials, some of which will find its way into the joints by springtime. Deicing material use on permeable pavement is not recommended to minimize build up in soil and outflows. A significant winter advantage or permeable pavements is that they require less deicing materials than their impervious counterparts.

Site design considerations

Permeable pavement is subject to the following design considerations, including benefits and constraints.

- Available Space – A significant advantage of permeable pavement is its ability to combine detention/ infiltration and pavement, thereby reducing or eliminating land required for detention facilities. This is especially important in urban areas with high land prices and highly developed sites with little or no space for stormwater detention.

- Soils – Soil conditions and infiltration rates determine the use of an underdrain. (NRCS Hydrologic Soil Group (HSG) C or D soils usually require an underdrain, whereas HSG A and B soils often do not.) Designers should evaluate existing soil properties during initial site layout with the goal of configuring permeable pavement that conserves and protects soils with the highest infiltration rates. In particular, areas of HSG A or B soils shown on soil surveys should be considered as primary locations for all types of infiltration practices.

Soil surveys and HSG classifications provide a general estimate of the soil's infiltration rate. Soil infiltration rates can also be estimated from soil classifications per ASTM D2487. However, it is best to verify rates using on-site infiltration testing per ASTM D3385 or D5093. In most cases, permeable pavement should not be situated above fill soils. Designs in compacted fill soils may require an impermeable liner and an underdrain. Permeable pavements should only be placed on fill soils when laboratory tests indicate the compacted fill will be stable when saturated and that slope stability of deep fills has been verified by a geotechnical engineer.

- Contributing Drainage Area – Permeable pavements sometimes capture runoff from adjacent areas, pavements, and roofs. The at-grade contributing drainage area into permeable pavement should generally not exceed twice the surface area of the permeable pavement. This guideline helps reduce the rate of surface sedimentation. The 2:1 ratio can be increased if (1) the permeable pavement is receiving runoff from roofs as it tends to be very low in sediment or (2) if runoff from ground level impervious surfaces is expected to remain unburdened with sediment. The best situation is when the design allows for a pre-treatment strip (e.g., stone, gravel, or turf) to control sediment run-on into the permeable pavement.

- Soil Subgrade Slope – The slope of the soil subgrade should be as flat as possible (i.e., 0% longitudinal slope) to enable even distribution and infiltration of stormwater. Lateral slopes should be 0%. Steep slopes can reduce the stormwater storage capacity of permeable pavement. Designers should consider using a terraced subgrade design for permeable pavement in sloped areas, especially when the local slope exceeds 3%.

- Surface Slope – Surface slopes for all permeable pavement types should be at least 1% to provide an alternate means for drainage should the surface become completely clogged due to lack of maintenance. Designs should provide an alternate means for stormwater to enter the aggregate reservoir if the pavement surface should ever become clogged, or for extreme storm events. For pervious concrete and porous asphalt without curbs, this can be a 2 foot wide stone edge connected to the reservoir. For curbed pavements, inlets may be used.

- Overflow Structures – Permeable pavements are not designed to store and infiltrate all stormwater from all storms. Therefore, an outlet or outlets are required to prevent water from rising into and over the surface. One type of outlet control would be a catch basin with an internal weir and low-flow orifice. The catch basin can also handle runoff from the surface should it become clogged.

- Minimum Depth to Seasonal High Water Table – A high groundwater table may cause seepage into the bottom of permeable pavement and prevent complete drainage. Also, soil acts as a filter for pollutants between the bottom of the pavement base and the water table. Therefore, a minimum vertical separation of 3 feet is required between the bottom of the permeable pavement reservoir layer and the seasonal high groundwater table.

- Setbacks –

To avoid harmful seepage, permeable pavement should not be hydraulically connected to building foundations unless an impermeable liner is placed against the foundation or basement wall. Even under these circumstances, great care should be taken to avoid creating a wet basement problem. If there is no liner, the permeable pavement base should be 10 feet or greater from structures (EPA recommends a minimum setback from building foundations of 10 feet down-gradient and 100 feet up-gradient. See EPA factsheet “Storm Water Technology Fact Sheet: Porous Pavement,” EPA 832-F-99-023). Again, it is the designer’s responsibility to avoid creating a wet basement problem. Likewise, permeable pavement bases should be hydraulically separated from adjacent road bases.

Permeable pavements without underdrains infiltrate stormwater and should follow requirements for wellhead protection (EPA recommends a minimum setback of 100 feet from water supply wells). Underground utility lines are best located away from permeable pavement bases. However, if they need to penetrate the base, consideration should be given to waterproofing (depending on the utility) or possible encasement using low-strength flowable concrete fill. Setbacks can be reduced at the discretion of the local authority for designs that use underdrains and/or liners.

- Informed Owner – The property owner should clearly understand the unique maintenance responsibilities inherent with permeable pavement, particularly for parking lot applications. The owner should be capable of performing routine and long-term actions (e.g., vacuuming) to maintain the pavement’s hydrologic functions, and avoid future practices (e.g., winter sanding, seal coating or repaving) that diminish or eliminate them. For porous asphalt a diluted emulsion fog can be used as needed. Maintenance agreements, covenants, maintenance easements or performance bonds are encouraged between the local authority and the property owner.

- Limitations – There are several limitations for use of permeable pavement, as summarized below.

- Permeable pavements should not be used in high pollutant loading sites. High pollutant loading sites are those that receive constant sediment or trash and/or debris. Places where fuels and chemicals are stored or handled can be potential stormwater hotspots and permeable pavement should not be constructed in these places. Likewise, areas subject to wind borne dust and sediment should not use permeable pavement unless the pavement can be vacuumed regularly. The following limitations should be considered before utilizing permeable pavements in any design.

- Permeable pavement is suitable for pedestrian-only areas, low-volume roads, low speed areas, overflow parking areas, residential driveways, alleys, and parking stalls. These can be residential collector roads or other applications with similar traffic loads.

- Permeable pavement can be prone to clogging from sand and fine sediments that fill void spaces and the joints between pavers. As a result, it should be used carefully where frequent winter sanding is necessary because the sand may clog the surface of the material. Periodic maintenance is critical, and surfaces should be cleaned with a vacuum sweeper at least two times a year.

- Fuel may leak from vehicles and toxic chemicals may leach from asphalt and/or binder surface. Porous pavement systems are not designed to treat these pollutants.

Design criteria

Base/subbase thickness is determined for support traffic using structural design methods and for water storage using hydrologic sizing and/or dynamic modeling over time. The thicker of the two resulting designs is used.

Structural Design

The structural design process for supporting vehicles varies according to the type of pavement selected. The pervious concrete industry is in the process of developing ASTM test methods for characterizing compressive or flexural strengths of pervious concrete. These tests are needed to model fatigue under loads. As an interim step, fatigue equations published by the American Concrete Pavement Association (ACPA 2010) assume such inputs to be comparable in nature (but not magnitude) to those used for conventional concrete pavements. The ACPA design method should be consulted for further information as well as pervious concrete industry software. General guidelines for pervious concrete surface thickness are published by the National Ready Mix Concrete Association and the Portland Cement Association (Leming 2007).

Porous asphalt (Hansen 2008) and permeable interlocking pavements (Smith 2010) use flexible pavement design methods adopted from the 1993 AASHTO Guide for Design of Pavement Structures (AASHTO 1993). In addition, MnDOT design methods, approved mechanistic principles, and manufacturer’s specific recommendations should be consulted.

There has been limited research on full-scale testing of the structural behavior of open-graded bases used under permeable pavements to better characterizing relationships between loads and deformation. Therefore, conservative values (i.e., AASHTO layer coefficients) should be assumed for open-graded base and subbase aggregates in permeable pavement design.

Regardless of type of permeable pavement, structural design methods consider the following in determining surface and base thicknesses to support vehicular traffic:

- Pavement life and total anticipated traffic loads expressed as 18,000 lb equivalent single axle loads or ESALs (This method of assessing loads accounts for the additional pavement wear caused by trucks.)

- Soil strength expressed as the soaked California Bearing Ratio (CBR), R-value or resilient modulus (Mr)

- Strength of the surfacing, base and subbase materials

- Environmental factors including freezing climates and extended saturation of the soil subgrade

Soil stability under traffic should be carefully reviewed for each application by a qualified geotechnical or civil engineer and lowest anticipated soil strength or stiffness values used for design. Structural design for vehicular applications should generally be on soil subgrades with a CBR (96-hour soaked per ASTM D 1883 or AASHTO T 193) of 4%, or a minimum R-value = 9 per ASTM D 2844 or AASHTO T-190, or a minimum Mr of 6,500 psi (45 MPa) per AASHTO T-307.

Soil compaction required to achieve these soil strengths will reduce the infiltration rate of the soil. Therefore, the permeability or infiltration rate of soil should be assessed at the density required to achieve one of these values. If soils under vehicular traffic have lower strengths than those noted above, or are expansive when wet, there are several options, including

- use underdrains

- thicken the base/subbase layer(s)

- stabilize the base layers with cement or asphalt, and

- stabilize the soil with lime or cement.

These options are typically used in combination. Pedestrian applications can be placed on lower strength soils than those noted.

Pedestrian applications can be placed on lower strength soils than those noted.

Hydrologic Sizing

Permeable pavement will likely be designed to store more than 1.1 inch of stormwater from the site. In addition, a mix of adjacent pervious and impervious surfaces contributing runoff will require that the base storage volume to hold water depths over 1.1 inches, especially if volume and peak discharge reductions are design objectives. The soil subgrade infiltration rate typically will be less than the flow rate through the pavement, so some reservoir storage will usually be required. When working with HSG A or B soils, designers should initially assume that there is no outflow through underdrains. The following equation can be used to determine the depth of the reservoir layer, assuming runoff fully infiltrates into the underlying soil.

\(D_p = (d_c R) + P – (i/2 t_f) / V_r\)

where

- Dp = the depth of the reservoir layer (feet);

- dc = the depth of runoff from the contributing drainage area (not including the permeable paving surface) for the design storm (feet);

- R = Ac/Ap The ratio of the contributing drainage area (Ac, not including the permeable paving surface) to the permeable pavement surface area (Ap);

- P = the rainfall depth for the Treatment Volume (1.1 inch), or other design storm (feet);

- i = the field-verified infiltration rate for native soils (feet per day);

- tf = the time to fill the reservoir layer (day) – typically 2 hours or 0.083 day; and

- Vr</sub> = the void ratio for the reservoir layer (0.4).

The maximum allowable depth of the reservoir layer is constrained by the maximum allowable drain time, which is calculated using the following equation.

\(D_{p-max} = (i/2 t_d) / V_r\)

where

- Dp-max = the maximum depth of the reservoir layer (feet); and

- td = the maximum allowable time to drain the reservoir layer, typically 1 to 2 days (days)

The following design assumptions apply to the previous equations:

- The contributing drainage area (Ac) does not contain pervious areas.

- For design purposes, the native soil infiltration rate (i) should be the field-tested soil infiltration rate divided by a factor of safety of 2.

- The void ratio (Vr) for the base and subbase stone layers = 0.4.

- The maximum drain time for the reservoir layer should be not less than 24 hours or greater than 48 hours after the initial 24-hour storm event.

If the depth of the reservoir layer is too great (i.e. dp exceeds dp-max), then the design method typically changes to account for underdrains. The storage volume in the pavements must account for the underlying infiltration rate and outflow through the underdrain. In this case, the design storm should be routed through the pavement to accurately determine the required reservoir depth.

Outflow Rate and Volume Through Underdrains

If the depth of the base/subbase for the full infiltration system is excessive, (i.e. dp exceeds dmax) because, as an example, the design subgrade soil infiltration rate is not adequate to remove the water from the design storm within the designated period of time, then the design should include underdrains. The following procedure is for sizing the base/subbase for partial infiltration designs (i.e. contains underdrains). The same symbols apply, but with the following additions:

- qu = outflow through underdrain, ft/hr

- k = Coefficient of permeability for each 6 inch diameter underdrain, ft/hr

- m = underdrain pipe slope, ft/ft

- n = number of underdrain pipes

- Tfill = effective filling time of the base/subbase which is at or above the underdrain(s), hours.

- T1 = the storage time during which the water is at or above the underdrain(s), hours.

- Dbelow = depth of the subbase below the underdrains, ft

Equation 3 can be used to approximate the outflow rate from underdrain(s). This equation is based on Darcy’s Law, which summarizes several properties that groundwater exhibits while flowing in aquifers. Although the hydraulic conductivity (measure of the ease with which water can move through pore spaces of a material) of the aggregate subbase is very high (approximately 17,000 feet/day or 8,500 inches/hour), the discharge rate through underdrains is limited by the cross sectional area of the pipe. As the storage volume above/around the underdrain(s) decreases, i.e., the hydraulic head or water pressure decreases; the base/subbase and in turn the underdrain(s) will drain increasingly slower. To account for this change in flow conditions within the subbase and underdrain(s) over time, a very conservative coefficient of permeability (k) of 100 feet/day 8.33 feet/hour) per pipe can be used to approximate the average underdrain outflow rate.

- Equation 3

Once the outflow rate through each underdrain has been approximated, Equation 4 can be used to determine the depth of the base/subbase needed to store the design storm. To estimate the number of underdrain pipes (n), take the dimension of the parking lot in the direction the pipes are to be placed and divide by the desired spacing between pipes – round down to the nearest whole number.

- Equation 4

Tfil = T when the underdrains are at the bottom of the subbase. Tfil = ½T (approximation) when the underdrains are raised.

With full infiltration systems, the maximum allowable drain time (dmax) needs to be calculated to make sure the stored water within the base/subbase does not take too long to infiltrate into the soil subgrade. However, for partial infiltration systems, there is a second method of storage water discharge, namely the underdrains. The depth and number of underdrains are variables that can be adjusted (unlike the infiltration rate into the soil subgrade) so that the actual drain time equals or is less than the maximum allowable drain time. If the discharge of the underdrains is added to Equation 1, then:

Rearranging the previous creates Equation 5, with the only remaining variable (T1) being on the left hand side.

- Equation 5

The elevation of the pipe above the soil subgrade is then calculated using Equation 6.

- Equation 6

Permeable pavement can also be designed to augment detention storage needed for channel protection and/or flood control. The designer can model various approaches by factoring in storage within the base/subbase, expected infiltration and any outlet structures used as part of the design. For example, some applications in the Chicago, Illinois area are designed to detain and partially infiltrate the 100-year storm for managing combined sewer overflows.

Once runoff passes through the surface of the permeable pavement system, designers should calculate outflow pathways to handle subsurface flows. Subsurface flows can be regulated using underdrains, the volume of storage in the reservoir layer, the bed slope of the reservoir layer, and/or a control structure at the outlet.

Design for Nutrient and TSS Reductions

Permeable pavement nutrient reduction capabilities can be enhanced in partial infiltration designs that detaining water in the base/subbase for over 24 hours for de-nitrification. Any infiltration will reduce the water volumes and mass outflow of nutrients and suspended solids. PICP can use specially coated aggregates in the joints and bedding and all systems can use them in the base to reduce nutrients. Coated aggregates (sometimes called ‘engineered aggregates’) have an effective life of seven to ten years.

A filter layer made of sand or fine aggregate placed under or sandwiched within permeable pavement bases are occasionally used to as a means to reduce nutrients. This layer can be enhanced with iron filings for phosphorous reduction (Erickson 2010). Their effectiveness, initial and maintenance costs should be weighed against other design options for nutrient reductions. Sand filters will incur additional construction expense and this can be reduced by placing sand filters under the subbase at the down slope end of a permeable pavement. The disadvantage of sand filters is that they will eventually require removal and restoration. Therefore concentrating their location in the down slope areas of the site can help reduce future maintenance costs and site disruptions. Simply storing water for and slowly releasing it over 48 hours can be less expensive alternative for nitrogen reduction as long as there is a carbon source in the base/subbase.

A second approach useful for nutrient reduction can occur on sloping sites by creating intermittent berms in the soil subgrade. These enable settlement of suspended solids and encourage de-nitrification. A third alternative is using a “treatment train” approach where a permeable pavement initially filters runoff and the remaining water outflows to bioswales or rain gardens adjacent to the pavement for additional processing and nutrient reduction. There may be additional BMPs used to remove nutrients as the water moves through the watershed.

Soil Infiltration Rate Testing

A minimum of one test per ASTM D3385 or D5093 must be taken per 7,000 square feet of planned permeable pavement surface area. In most cases, a single soil test is sufficient for small-scale applications. At least one soil boring must be taken to confirm the underlying soil properties at the depth where infiltration is designed to occur (i.e., to ensure that the depth to water table, depth to bedrock, or karst is defined). Soil infiltration testing should be conducted within any confining layers that are found within 5 feet of the bottom of a proposed permeable pavement system.

Conveyance and Overflow

Permeable pavement designs should include methods to convey larger storms (e.g., 2-year, 10-year) to the storm drain system. The following is a list of methods that can be used to accomplish this:

- Place a perforated pipe horizontally near the top of the reservoir layer to pass excess flows after water has filled the base. The placement and/or design should be such that the incoming runoff is not captured (e.g., placing the perforations on the underside only). Pipe placement should be away from wheel loads to prevent damage.

- Increase the thickness of the top of the reservoir layer.

- Create underground detention within the reservoir layer of the permeable pavement system. Reservoir storage may be augmented by corrugated metal pipes, plastic or concrete arch structures, etc.

- Route excess flows to another detention or conveyance system that is designed for management of extreme event flows.

- Set the storm drain inlets flush with the elevation of the permeable pavement surface to effectively convey excess stormwater runoff past the system. The design should also make allowances for relief of unacceptable ponding depths during larger rainfall events.

Reservoir Layer

The reservoir below the permeable pavement surface should be composed of clean, washed crushed stone aggregate and thickness sized for both the storm event to be stored and the structural requirements of the expected traffic loading. The recommended minimum void ratio should be 40% per ASTM C29. Reservoir base layers for pervious concrete are typically washed ASTM No. 57 stone and those for porous asphalt are ASTM No. 2, 3, or 5. PICP uses ASTM No. 2,3 or 4 stone.

If exposed to vehicular loads, all crushed stone should be MnDOT Class A or B coarse aggregate, minimum 80% crushed, typically granite, basalt, gneiss, trap rock, diabase, gabbro or similar material. The maximum Los Angeles Rattler Loss should be 35% per AASHTO T-96 and no greater loss than 10% per AASHTO T-104 Magnesium Sulfate Soundness Test on the non-igneous portions and as modified by the MnDOT Laboratory Manual (MNDOT 2005). Limestone aggregates not meeting these requirements are not recommended in vehicular applications. Class C and D aggregates may be used in areas subject only to pedestrian traffic.

Underdrains

Underdrains install quickly when placed on or in the soil subgrade, surrounded by stone base or subbase materials. The outflow portion at the end is not perforated and is raised to a designed height allow for some water detention prior to outflow. Placement at this elevation also protects the pipe with aggregate during base compaction. An underdrain(s) can also be installed and capped at a downstream structure as an option for future use if maintenance observations indicate a reduction in the soil permeability.

Maintenance

Some key actions help ensure the long-term performance of permeable pavement. The most frequently cited maintenance problem is surface clogging caused by organic matter and sediment, which can be reduced by the following measures:

- Observation Well – Typically this consists of a well-anchored, six-inch diameter perforated PVC pipe that extends vertically to the bottom of the reservoir layer. This is installed at the down slope end of the permeable pavement. The observation well should be fitted with a lockable cap installed flush with the ground surface (or under the pavers) to facilitate periodic inspection and maintenance. The observation well is used to observe the rate of drawdown within the reservoir layer following a storm event.

- Overhead Landscaping – Some communities require a certain percentage of parking lots to be landscaped. Large-scale permeable pavement should be carefully planned to integrate landscaping in a manner that maximizes runoff treatment and minimizes risk of sediment, mulch, grass clippings, crushed leaves, nuts, and fruits inadvertently clogging the surface.

Design specifications

Permeable pavement material specifications vary according to the specific pavement product selected. Note that the size of stone materials used in the reservoir and filter layers may differ depending whether the system is pervious concrete, porous asphalt or permeable interlocking pavers. Designers should consult industry association and manufacturer’s technical specifications for specific criteria and guidance.

Summary of specifications for materials under the pavement surface. For more information, see the footnote (1). Reference or links to any specific commercial product, process, or service by trade name, trademark, service mark, manufacturer, or otherwise does not constitute or imply endorsement, recommendation, or favoring by the Minnesota Pollution Control Agency.

Link to this table

| Bedding/choker layer |

|

Washed free of fines |

| Reservoir Layer |

|

Stone layer thickness based on the pavement structural and hydraulic requirements. Stonewashed and free of fines. Recommended minimum void ratio = 0.4. |

| Underdrain (optional) | Use 4 to 6 inch diameter perforated PVC (AASHTO M-252) pipe or corrugated polyethylene pipe. Perforated pipe installed for the full length of the permeable pavement cell, and non-perforated pipe, as needed,connected to storm drainage system. | |

| Filter Layer (optional) | Sand filter layeris separated from base above and native soils with geotextile. Sand layer typically ASTM C33 gradation, 6 to 12 inches thick. | The Filter Layer is REQUIRED if using the permeable pavement system to meet permit requirements. The sand layer may require a choker layer on surface to provide transition to base layerstone. |

| Geotextile(optional) | Comply with AASHTO M-288 Standard Specification for Geotextile Specification for Highway Applications, drainage and separation applications, Class I or II. Porous asphalt industry recommends non-woven geotextile. | |

| Impermeable Liner | Use a minimum 30mil PVC liner covered by 12 ounce/square yard non-woven geotextile. EPDM and HDPE liner material is also acceptable. | |

| Observation Well | Use a perforated 4 to 6 inch vertical PVC pipe (AASHTO M-252) with a lockable cap, installedflush with the surface (or under pavers). | |

1for additional information on materials referenced in this table (e.g. stone dimensions), see the following links:

This table shows summarizes specifications for permeable pavement.

Link to this table.

| Permeable Pavers | Surface open area: typically 5% to 15%; minimum thickness: 3 inches for vehicles; minimum compressive strength: 8,000 psi | Concrete pavers conform to ASTM C936 and clay pavers C1272. Reservoir layer required to support the structural load. |

| Pervious Concrete |

|

May not require a reservoir layer to support loads, but a layer is required for storage/infiltration. In no case should plain steel rebar or mesh be used in pervious concrete as this invites corrosion. |

| Porous Asphalt |

|

Reservoir layer contributes to structural load support. |

Other design considerations

There are additional design considerations for permeable pavement, including use of permeable pavement in karst terrain and winter considerations.

Karst terrain

A detailed geotechnical investigation may be required for any kind of stormwater design in karst terrain. Permeable pavements, as with other infiltration practices, are not recommended at sites with known karst features as they can cause the formation of sinkholes and can provide a direct link for stormwater to access groundwater without providing any treatment.

Winter considerations

Plowed snow piles should be located in adjacent grassy areas so that sediments and pollutants in snowmelt are partially treated before they reach all permeable pavements. Sand is not recommended for winter traction over permeable pavements. If sand is applied, it must be removed with vacuum cleaning in the spring. Traction can be accomplished on PICP using jointing stone materials, some of which will find its way into the joints by springtime. Deicing material use on permeable pavement is not recommended to minimize build up in soil and outflows. A significant winter advantage or permeable pavements is that they require less deicing materials than their impervious counterparts.