Difference between revisions of "Alleviating compaction from construction activities"

(Created page with "Information on alleviating compaction from construction activities is scattered in different places within this manual. This page brings that information together. It is not i...") |

m |

||

| Line 15: | Line 15: | ||

{{:Application guidelines}} | {{:Application guidelines}} | ||

| + | |||

| + | ==References and fact sheets for alleviating compaction at construction sites== | ||

| + | *[http://your.kingcounty.gov/solidwaste/greenbuilding/documents/Post-Construction-Soil-Standard.pdf Achieving the Post-construction Soil Standard] - provides guidance for preserving and restoring healthy soils on developments. | ||

| + | *[http://edis.ifas.ufl.edu/ss529 Soil Compaction in the Urban Landscape] | ||

| + | *[http://ag.udel.edu/udbg/sl/soils/combating_soil_compaction.pdf Combating Soil Compaction] | ||

| + | *[http://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/nrcs142p2_053278.pdf Urban Soil Compaction] | ||

Revision as of 19:01, 28 September 2015

Information on alleviating compaction from construction activities is scattered in different places within this manual. This page brings that information together. It is not intended to be a comprehensive review and set of recommendations for alleviating compaction resulting from construction activities. Until such a review occurs however, this page provides basic information and recommendations for alleviating compaction.

Contents

Alleviating compaction resulting from construction

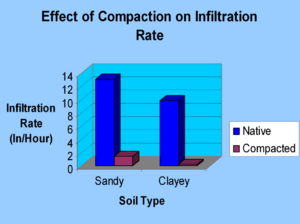

Alleviation of compaction of disturbed soil is crucial to the installation of successful vegetated stormwater infiltration practices. Typical bulk densities for non-compacted soils are in the range of 1.0 to 1.50 grams per cubic centimeter. Urban soils typically have bulk densities greater than this. Construction activities can increase bulk densities by 20 percent or more. The compaction can extend up to two feet into the soil profile, often resulting in bulk densities that do not readily support healthy plant growth.

Comparison of bulk densities for undisturbed soils and common urban conditions. (Source: Schueler, T. 2000. The Compaction of Urban Soils: Technical Note #107 from Watershed Protection Techniques. 3(2): 661-665. Center for Watershed Protection, Ellicott City, MD.)

For information on alleviating soil compaction, see Alleviating compaction from construction activities

Link to this table

| Undisturbed soil type or urban condition | Surface bulk density (grams / cubic centimeter |

|---|---|

| Peat | 0.2 to 0.3 |

| Compost | 1.0 |

| Sandy soil | 1.1 to 1.3 |

| Silty sands | 1.4 |

| Silt | 1.3 to 1.4 |

| Silt loams | 1.2 to 1.5 |

| Organic silts / clays | 1.0 to 1.2 |

| Glacial till | 1.6 to 2.0 |

| Urban lawns | 1.5 to 1.9 |

| Crushed rock parking lot | 1.5 to 2.0 |

| Urban fill soils | 1.8 to 2.0 |

| Athletic fields | 1.8 to 2.0 |

| Rights of way and building pads (85% compaction) | 1.5 to 1.8 |

| Rights of way and building pads (95% compaction) | 1.6 to 2.1 |

| Concrete pavement | 2.2 |

| Quartzite (rock) | 2.65 |

Increase in soil bulk density as a result of different land uses or activities.

Link to this table

| Land use or activity | Increase in bulk density (grams / cubic centimeter | Source (link to Reference list) |

|---|---|---|

| Grazing | 0.12 to 0.20 | Smith, 1999 |

| Crops | 0.25 to 0.35 | Smith, 1999 |

| Construction, mass grading | 0.34 to 0.35 | Randrup, 1998; Lichter and Lindsey, 1994 |

| Construction, no grading | 0.20 | Lichter and Lindsey, 1994 |

| Construction traffic | 0.17 to 0.40 | Lichter and Lindsey, 1994; Smith, 1999; Friedman, 1998 |

| Athletic fields | 0.38 to 0.54 | Smith, 1999 |

| Urban lawn and turf | 0.30 to 0.40 | Various sources |

While natural processes can alleviate soil compaction, additional techniques to alleviate soil compaction are often desirable because

- it can take many years for natural processes to loosen up soil;

- natural processes operate primarily within the first foot or so of soil, and compaction from development can extend to two feet deep; and

- once soil compaction becomes so severe that plants and soil microbes can no longer thrive, natural processes are no longer able to reduce soil compaction.

The most effective method for alleviating compaction is to add compost amendment. Other amendments, such as sand (in clay soils), can significantly reduce compaction since sandy soils are more resistant to compaction. An additional technique for alleviating compaction is subsoiling or soil ripping, although ripping by itself appears to have limitations. Ripping is most effective when used in conjunction with compost and/or sand amendment.

Schueler (Technical Note 108) concludes that “Based on current research, it appears that the best construction techniques are only capable of preventing about a third of the expected increase in bulk density during construction.”

Reported Activities that Restore or Decrease Soil Bulk Density

Link to this table

| Land use or activity | Decrease in bulk density (gms/cc) | Source |

|---|---|---|

| Tilling of soil | 0.00 to 0.02 | Randrup, 1918. Patterson and Bates, 1994 |

| Spedialized soil loosening | 0.05 to 0.15 | Rolf, 1998 |

| Selective grading | 0.00 | Randrup, 1998 and Lichter and Linsy, 1994 |

| Soil amendments | 0.17 | Patterson and Bates, 1994 |

| Compost amendments | 0.25 to 0.35 | Kolsti et al. 1995 |

| Time | 0.20 | Legg et al, 1996 |

| Reforestration | 0.25 to 0.35 | Article 36 |

Soil ripping

The goal of soil ripping or subsoiling is to fracture compacted soil without adversely disturbing plant life, topsoil, and surface residue. Soil compaction occurs most frequently with soils having a high clay content. Fracturing compacted soil promotes root penetration by reducing soil density and strength, improving moisture infiltration and retention, and increasing air spaces in the soil. Compacted layers typically develop 12 to 22 inches below the surface when heavy equipment is used. Conventional cultivators cannot reach deep enough to break up this compaction. Subsoilers (rippers) can break up the compacted layer without destroying soil aggregate structure, surface vegetation, or mixing soil layers (Kees, 2008).

How effectively compacted layers are fractured depends on the soil's moisture, structure, texture, type, composition, porosity, density, and clay content. Success depends on the type of equipment selected, its configuration, and the speed with which it is pulled through the ground. No one piece of equipment or configuration works best for all situations and soil conditions, making it difficult to define exact specifications for subsoiling equipment and operation.

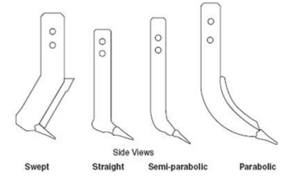

Subsoilers are available with a wide variety of shank designs. Shank design affects subsoiler performance, shank strength, surface and residue disturbance, effectiveness in fracturing soil, and the horsepower required to pull the subsoiler. According to Kees (2008), “Parabolic shanks require the least amount of horsepower to pull. In some forest applications, parabolic shanks may lift too many stumps and rocks, disturb surface materials, or expose excess subsoil. Swept shanks tend to push materials into the soil and sever them. They may help keep the subsoiler from plugging up, especially in brush, stumps, and slash. Straight or "L" shaped shanks have characteristics that fall somewhere between those of the parabolic and swept shanks.”

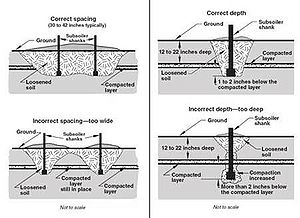

Researchers have found that there is a “critical depth”, and according to Spoor and Godwin (1978) this “critical depth is dependent upon the width, inclination and lift height of the tine foot and on the moisture and density status of the soil.” Spoor and Godwin (1978) explainthat tine depth is crucial because “At shallow working depths the soil is displaced forwards, side-ways and upwards (crescent failure), failing along well defined rupture planes which radiate from just above the tine tip to the surface at angles of approximately 45” to the horizontal. Crescent failure continues with increasing working depth until, at a certain depth, the critical depth, the soil at the tine base begins to flow forwards and sideways only (lateral failure) creating compaction at depth.” They found that below the critical depth “compaction occurs rather than effective soil loosening.” They also found that “The wetter and more plastic a soil is, the shallower is thecritical depth.” An approach developed by Silsoe College, Cranfield University, in collaboration with Transco UK, for use on pipeline sites, was to work progressively deeper with repeated passes, up to 5 or 6 under extreme conditions, with the tractor operating on the same tramline/traffic lane on each pass (Spoor & Foot, 1998).”

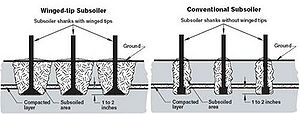

Shanks are available with winged tips and conventional tips. Winged tips cost more than conventional tips and require more horsepower, but can often be spaced farther apart. Increasing wing width also increases critical depth – the depth below which little soil loosening occurs (Owen 1987, Spoor 1978). Using shallow leading tines ahead of deeper tines also increases required shank spacing (Spoor 1978). According to Kees (2008), the shank’s tip should run to a depth of 1 to 2 inches below the compacted layer. Kees (2008) also recommends making sure that the shanks on the subsoiler are spaced so that they run in the tracks of the tow vehicle, because the equipment used to pull subsoilers is heavy enough to create compaction itself. Ideal shank spacing will depend on soil moisture, soil type,degree of compaction, and the depth of the compacted layer. Spacing should be adjustable so the worked area can be fractured most efficiently. Because ideal shank configuration will vary with varying soil textures and moisture, shank spacing and height should be adjustable in the field (Kees 2008).

Kees (2008) recommends following ground contours whenever possible when subsoiling to “increase water capture, protect water quality, and reduce soil erosion.” He also states that “in some cases, two passes at an angle to each other may be required to completely fracture compacted soil.” Spoor and Godwin (1978) also found that “Relatively closely spaced tines, staggered to prevent blockage, are more efficient at producing complete loosening than repeated passes with tines at wider spacings.”

Travel speed of the subsoiler also affects subsoiling disturbance. “Travel speed that is too high can cause excessive surface disturbance, bring subsoil materials to the surface, create furrows, and bury surface residues. Travel speed that is too slow may not lift and fracture the soil adequately” (Kees2008).

Soils should be mostly dry and friable. Urban (2008) describes ideal conditions for compaction reduction as follows: “soil moisture must be between field capacity and wilt point during compaction reduction for maximum effectiveness."

Always know where utilities are buried prior to subsoiling. Avoid subsoiling in area that have buried utilities, wires, pipes, culverts, or diversion channels (Kees 2008, Urban 2008).

Soil ripping will generally be more effective with the addition of an amendment. This can be either sand or compost. Tilling in compost amendment may not be desirable on sites with steep slopes, a high water table, wet saturated soils, or downhill slope toward a house foundation (Schueler Technical Note #108) or where there are tree roots or utilities, or where nutrients leaching from compost would pose a problem. Since soil restoration techniques will need to be tailored to site conditions, a prescriptive soil restoration specification is not recommended. However, Pennsylvania, Virginia, and Washington State have specifications for soil amendment and restoration and these may be used as guidance in determining how to amend a compacted soil.

According to Spoor and Godwin (1978) “The number of variables involved and soil variation make the accurate prediction of the critical depth for field conditions impractical. Simple field modifications are available, however, such as increasing tine foot width and lift height or loosening the surface layers, to allow rapid implement adjustment to satisfy a range of field conditions.”

If subsoiling was effective, “The ground should be lifted slightly and remain relatively even behind the subsoiler, without major disruption of surface residues and plants. No more than a little subsoil and a few rocks should be pulled to the surface. If large furrows form behind the subsoiler, the shanks may not be deep enough, the angle on winged tips may be too aggressive, or the travel speed may be too high” (Kees 2008).

Cost for subsoiling varies by project. The Pennsylvania Stormwater Best Management Practices Manual estimates the cost of tilling soils ranges from $800 to $1000 per acre, while the cost of compost amending soil is about the same.

An extensive literature review of the effects of soil ripping can be found in File:Bioretention task 6 soil ripping.docx.

Recommendations for soil ripping to alleviate compaction

For basins larger than 1000 square feet, if compaction is above ideal bulk density indicated in the table below the soil should be remediated as follows:

- Rip to a depth of 18 inches where feasible

- For clay subsoil, incorporate 2 inches of sand. For bioretention without an underdrain, MnDOT Type 2 compost may be incorporated instead of sand.

- Maintain a 3 foot minimum separation distance between the bottom of the infiltration practice and the seasonally high water table or bedrock. If soil ripping is utilized, the requirement is a 2 foot minimum between the bottom of the ripped zone and a 3 foot minimum from the bottom of the infiltration practice to the water table or top of bedrock. If there is only a 3 foot separation distance between the bottom of the infiltration practice and the elevation of the seasonally high water table or bedrock, limit ripping depth to 1 foot (12 inches).

General relationship of soil bulk density to root growth based on soil texture

Link to this table

| Soil texture | Ideal bulk densities (g/cm3) | Bulk densities that may affect plantgrowth (g/cm3) | Bulk densities that restrict root growth (g/cm3) |

|---|---|---|---|

| sands, loamy sands | <1.60 | 1.69 | >1.80 |

| sandy loams, loams | <1.40 | 1.63 | >1.80 |

| sandy clay loams, loams, clay loams | <1.40 | 1.60 | >1.75 |

| silts, silt loams | <1.30 | 1.60 | >1.75 |

| silt loams, silty clay loams | <1.40 | 1.55 | >1.65 |

| sandy clays, silty clays, clay loams with 35-45% clay | <1.10 | 1.49 | >1.58 |

| clays (>45% clay) | <1.10 | 1.39 | >1.47 |

Effect of ripping plus compost amendment on soil compaction

Compost aggregates soil particles (sand, silt, and clay) into larger particles (Cogger, 2005). Aggregation of soil particles creates additional porosity, which reduces the bulk density of the soil (Cogger, 2005). Compost can also reduce the bulk density of a soil by dilution of the mineral matter in the soil (Cogger, 2005). When the porosity of the soil increases and the particle surface area increases, water holding capacity is also increased (Cogger, 2005). Increases in macropore continuity have been found as well (Harrison et al., 1998). Studies have cited numerous beneficial abilities of compost: increased water drainage, increased water holding capacity, increased plant production, increased root penetrability, reduction of soil diseases, reduction of heavy metals, and the ability to treat many chemical pollutants (EPA, 1997; Harrison et al., 1998; WDOE Stormwater Management Manual, 2007; Olson 2010).

Studies show that tilling in compost is an effective technique to alleviate soil compaction. Two of these studies are summarized below.

- Olson (2010) found that plots where soil was ripped and amended with compost showed reduced soil strength, bulk densities were 18 to 37 percent lower on compost plots compared to controls, and the geometric mean of Ksat on the compost plots was 2.7 to 5.7 times that of the control plot.

- A study at Virginia Tech shows soils with compost incorporated into the soil to a depth of 2 feet has decreased bulk density in the subsoil and is accelerating the process of soil formation and long-term carbon storage compared to other treatments in the study. The result is that trees growing in the compost-amended soil have increased height, canopy diameter, and trunk diameter compred to trees in other treatments.

Precedents for soil restoration specifications

Since soil restoration techniques will need to be tailored to site conditions, a prescriptive soil restoration specification is not recommended. The 2006 Pennsylvania Stormwater Best Management Practices Manual’s chapter on soil amendment and restoration provides a sample specification for soil restoration. Their specification is not prescriptive, but does provide guiding principles, compost material specifications, and performance requirements. They require sub-soiling to loosen soil to less than 1400 kPa (200 psi) to a depth of 20 inches below final topsoil grade to reduce soil compaction in all areas where plant establishment is planned in areas where subsoil has become compacted by equipment operation, or has become dried out andcrusted, or where necessary to obliterate erosion hills.

The Virginia Tech Rehabilitation study website also provides a Soil Profile Rebuilding Specification based on their research. The basic steps in their specification are described below.

- Spread mature, stable compost to a 4 inch depth over compacted subsoil.

- Subsoil to a depth of 24 inches.

- Replace topsoil to 4 inches (6 to 8 inches if severely disturbed).

- Rototill topsoil to a depth of 6 to 8 inches.

- Plant with woody plants.

Washington State’s Department of Ecology’s Stormwater Management for Western Washington (Volume V: Runoff Treatment BMPs, Chapter 5, pages 5-7 to 5-10) also includes a very detailed soil restoration specification that includes the following.

- The topsoil layer has a minimum organic matter content of 10 percent dry weight in planting beds, 5 percent organic matter content in turf areas, and a pH from 6.0 to 8.0 or matching the pH of the undisturbed soil. The topsoil layer shall have a minimum depth of 8 inches except where tree roots limit the depth of incorporation of amendments needed to meet the criteria. Subsoils below the topsoil layer should be scarified at least 4 inches with some incorporation of the upper material to avoid stratified layers, where feasible.

- Mulch planting beds with 2 inches of organic material.

- Use compost and other materials that meet these organic content requirements.

- The organic content for pre-approved amendment rates can be met only using compost that meets the definition of composted materials in WAC 173-350-100. The compost must also have an organic matter content of 40 to 65 percent and a carbon to nitrogen ratio below 25:1. The carbon to nitrogen ratio may be as high as 35:1 for plantings composed entirely of plants native to the Puget Sound Lowlands region.

- Calculated amendment rates may be met through use of composted materials meeting above conditions, or other organic materials amended to meet the carbon to nitrogen ratio requirements and meeting the contaminant standards of Grade A Compost. The resulting soil should be conducive to the type of vegetation to be established.

- The soil quality design guidelines listed above can be met by using one of the methods listed below.

- Leave undisturbed native vegetation and soil, and protect from compaction during construction.

- Amend existing site topsoil or subsoil either at default pre-approved rates, or at custom calculated rates based on tests of the soil and amendment.

- Stockpile existing topsoil during grading, and replace it prior to planting. Stockpiled topsoil must also be amended if needed to meet the organic matter or depth requirements, either at a default pre-approved rate or at a custom calculated rate.

- Import topsoil mix of sufficient organic content and depth to meet the requirements. More than one method may be used on different portions of the same site. Soil that already meets the depth and organic matter quality standards, and is not compacted, does not need to be amended.

Compost

Compost is the product resulting from the controlled biological decomposition of organic materials that has been sanitized through the generation of heat and stabilized to the point that it is beneficial to plant growth. It is an organic matter resource that has the unique ability to improve the chemical, physical, and biological characteristics of soil. It can be derived, for example, from composted yard waste, food waste, manure, leaves, grass clippings, straw, or biosolids.

Common development practices include removal of topsoil during grading and clearing, compaction of remaining soil, and planting into unimproved soil or shallow depths of poor quality imported topsoil. These conditions typically produce unhealthy plants that require excessive water, fertilizers and pesticides, further contaminating runoff. To maintain the natural soil qualities, impacts to undisturbed soils should be avoided and minimized during the construction process. When impacts are unavoidable and soils have been compacted or otherwise disturbed, compost can be used as an amendment to regain some of the characteristics of undisturbed soils.

Research studies illustrate the importance of compost on maintaining or improving soil infiltration rates. Olson showed that bulk densities in residential areas decreased from an average of 1.4 grams per cubic centimeter to 0.93 to 1.15 grams per cubic centimeter following amendment with compost. Saturated conductivities were 3.4 to 6.1 times greater following compost amendment. Olson et al. (2013) studied effects of tilling with and without compost on soil infiltration in compacted urban soils. The geometric mean of saturated hydraulic conductivity on the compost plots was 2.7 to 5.7 times that of the control plot. On soils with just tilling, the geometric mean of saturated hydraulic conductivity was 0.5 to 2.3 times that of the control plot, indicating little overall improvement. Compost addition was more effective than tilling by reducing the soil strength and compaction and increasing soil infiltration.

Credits for reduced stormwater runoff volume or reductions in phosphorus and TSS loading can be achieved with improved soil infiltration. This Manual also provides additional information on material specifications, application guidelines, and literature review for compost. The following table provides application guidelines for compost.

Application guidelines for compost.

Link to this table

| Planting areas | Turf areas | |

|---|---|---|

| High-traffic areas | (18 inch uncompacted depth) Incorporate 3 inches of compost into the top 5 inches of compacted soil to create a topsoil layer with a minimum depth of 8 inches. Soils below the top soil layer should be scarified to at least 10 inches. | Incorporate 1.75 inches of compost into the top 6.25 inches of compacted soil to create a topsoil layer with a minimum depth of 8 inches. Soils below the top soil layer should be scarified to at least 10 inches |

| Construction limits | (12 inch uncompacted depth) Incorporate 3 inches of compost into the top 5 inches of compacted soil to create a topsoil layer with a minimum depth of 8 inches. Soils below the top soil layer should be scarified to at least 4 inches | Incorporate 1.75 inches of compost into the top 6.25 inches of compacted soil to create a topsoil layer with a minimum depth of 8 inches. Soils below the top soil layer should be scarified to at least 4 inches |

References and fact sheets for alleviating compaction at construction sites

- Achieving the Post-construction Soil Standard - provides guidance for preserving and restoring healthy soils on developments.

- Soil Compaction in the Urban Landscape

- Combating Soil Compaction

- Urban Soil Compaction