Construction specifications for bioretention

This page provides construction details, materials specifications and construction specifications for bioretention systems.

Construction details

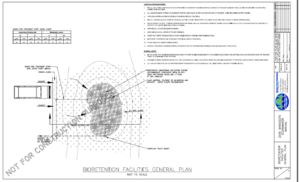

CADD based details for bioretention are contained in the Computer-aided design and drafting (CAD/CADD) drawings section. The following details, with specifications, have been created for bioretention systems:

- Bioretention Facilities General Plan

- Bioretention Facilities Performance Types Cross-Sections

- Infiltration / Recharge Facility

- Filtration / Partial Recharge Facility

- Infiltration / Filtration / Recharge Facility

- Filtration Only Facility

Materials specifications

Soil medium / filter media content

Mix A: Water quality blend

A well blended, homogenous mixture of 55 to 65 percent construction sand: 10-20percent top soil; and 25 to 35percent organic leaf compost is necessary to provide a soil medium with a high infiltration/filtration capacity.

- Sand: Provide clean construction sand, free of deleterious materials. AASHTO M-6 or ASTM C-33 with grain size of 0.02 to 0.04 inches

- Top Soil: Sandy loam, loamy sand, or loam texture per USDA textural triangle with less than 5 percent clay content

- Organic Leaf Compost: (MnDOT Grade 2) 2 (see also the section on Using Compost as a Soil Amendment

Mix B: Enhanced filtration blend

A well-blended, homogenous mixture of 50-70% construction sand and 30-50% organic leaf compost is necessary to provide a soil medium with a higher infiltration/filtration capacity.

- Sand: Provide clean construction sand, free of deleterious materials. AASHTO M-6 or ASTM C-33 with grain size of 0.02”-0.04”

- Organic Leaf Compost: Mn/DOT Grade 2

- Topsoil in the mix will help with some nutrient removal, especially nutrients, but extra care must be taken during construction to inspect the soils before installation and to avoid compaction.

Soil medium / filter media depth

Field experiments show that pollutant removal is accomplished within the top 30 inches of soil depth with minimal additional removal beyond that depth (Prince George’s County, 2002). Therefore, the recommended depth of the prepared soil is 30 inches. However, if large trees are preferred in the design, a soil depth of 48 to 52 inches should be utilized. The soil depth generally depends upon the root depth of the prescribed vegetation and content of underlying soils.

Gravel Filter Specifications - Underdrain gravel blanket shall be double washed stone, 1 to 1½ inches in size. Pea Gravel shall be washed, river-run, round diameter, ¼ - ½ inch in size.

Mulch Content and Depth - Fresh shredded bark mulch (Mn/DOT Type 6) should be used when possible to maximize nitrogen retention. If aged mulch is used, use the shredded type instead of the “chip” variety to minimize floating action. The mulch layer should not exceed 3 inch in depth. Too much mulch can restrict oxygen flow to roots. In addition, mulch should not be mounded around the base of plants since this encourages damage from pests and diseases.

Construction specifications

Given that the construction of bioretention practices incorporates techniques or steps which may be considered non-traditional, it is recommended that the construction specifications include the following format and information:

A. Temporary erosion control

- Install prior to site disturbance

- Protect catch basin/inlet

- It is HIGHLY RECOMMENDED that future bioretention locations not be used as temporary sedimentation basins. If used as temporary sedimentation basins, the bioretention practice should be over excavated a minimum of 18 inches below sedimentation basin grade.

B. Excavation, backfill and grading

- Timing of grading of infiltration practices relative to total site development

- Use of low-impact, earth moving equipment (wide track or marsh track equipment, or light equipment with turf-type tires)

- Do not over-excavate

- Restoration in the event of sediment accumulation during construction of practice

- Alleviate any compacted soil (compaction can be alleviated at the base of the practice by using a primary tilling operation such as a chisel plow, ripper or sub-soiler to a minimum 12 inch depth

- Gravel backfill specifications

- Gravel filter specifications

- Filter fabric specifications

C. Native plants, planting and transplanting

- Site preparation of planting areas

- Timing of native seeding and native planting

- Weed control

- Watering of plant material

D. Construction sequence scheduling

- Temporary construction access

- Location of silt fence installation to protect BMPs and downstream receiving waters

- Removal and storage of excavated material

- Installation of underground utilities

- Rough grading

- Seeding and mulching disturbed areas

- Road construction

- Final grading

- Site stabilization

- Installation of semi-permanent and permanent erosion control measures

- Silt fence removal

E. Construction observation

- Adherence to construction documents

- Verification of physical site conditions

- Erosion control measures installed appropriately