Types of filtration

As filtration becomes a more common tool in stormwater management, and as the number of design variants increases, so does the number of names for each of these variants. For example:

- Sand filters are also referred to as filtration basins, filter systems, first-flush filtration, or media filtration systems.

- Grass channels are also referred to as biofilters. (Seattle METRO, 1992 from CWP)

- Dry swales are also referred to as grassed or vegetated swales.

The following types of filtration systems are appropriate for Minnesota, depending upon project scale and site conditions.

(Information on this page is adapted from the Georgia Stormwater Manual and Center for Watershed Protection)

Contents

Media Filters

Media filters treat stormwater through a variety of different filtering materials whose purpose is to remove pollution from runoff. Variants includes surface sand filters, underground sand filters and perimeter sand filters.

Surface Sand Filter

For a surface sand filter, a flow splitter is used to divert runoff into an off-line sedimentation chamber. The chamber may be either wet or dry, and is generally used for pre-treatment. Runoff is then distributed into the second chamber, which consists of a sand filter bed (~18 inches) and temporary runoff storage above the bed. Pollutants are trapped or strained out at the surface of the filter bed. The filter bed surface may have a sand or grass cover. A series of perforated pipes located in a gravel bed collect the runoff passing through the filter bed, and return it to the stream or channel at a downstream point. If underlying soils are permeable, and groundwater contamination unlikely, the bottom of the filter bed may have no lining, and the filtered runoff may be allowed to infiltrate. See Computer-aided design and drafting (CAD/CADD) drawings for design drawing.

Underground Sand Filter

The underground sand filter was adapted for sites where space is at a premium. In this design, the sand filter is placed in a 3 chamber underground vault accessible by manholes or grate openings. The vault can be either on-line or off-line in the storm drain system. The first chamber is used for pre-treatment and relies on a wet pool as well as temporary runoff storage. It is connected to the second sand filter chamber by an inverted elbow, which keeps the filter surface free from trash and oil. The filter bed is 18 inches in depth and may have a protective screen of gravel or permeable geotextile to limit clogging. During a storm, the water quality volume is temporarily stored in both the first and second chambers. Flows in excess of the filter’s capacity are diverted through an overflow weir. Filtered runoff is collected, using perforated underdrains that extend into the third “overflow” chamber. See Computer-aided design and drafting (CAD/CADD) drawings for design drawing.

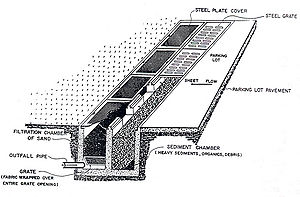

Perimeter Sand Filter

The perimeter sand filter consists of two parallel trench-like chambers that are typically installed along the perimeter of a parking lot (See schematic of Delaware sand filter). Parking lot runoff enters the first chamber, which has a shallow permanent pool of water. The first trench provides pre-treatment before the runoff spills into the second trench, which consists of a sand layer (12 inches to 18 inches). During a storm event, runoff is temporarily ponded above the normal pool and sand layer, respectively. When both chambers fill up to capacity, excess parking lot runoff is routed to a bypass drop inlet. The remaining runoff is filtered through the sand, and collected by underdrains and delivered to a protected outflow point. See Computer-aided design and drafting (CAD/CADD) drawings for design drawing.

Vegetative Filters

Vegetative filters provide removal of sediment, nutrients, or pollutants by plant structures

Grass Channels

Grass channels are designed to meet a runoff velocity target for a water quality storm as well as the peak discharge from a 2-year design storm. The runoff velocity should not exceed 1.0 feet per second (fps) during the water quality storm. Grass channels can be designed to pass larger storms and serve as conveyance tools. Pre-treatment can be created by placing checkdams across the channel below pipe inflows, and at various other points along the channel. Grass channels do not provide adequate pollutant removal benefits to act as a stand-alone BMP.

Dry Swales

In dry swales, the entire water quality volume is temporarily retained by checkdams during each storm. Unlike the grass channel, the filter bed in the swale is 30 inches of prepared soil. Water is filtered through the sandy loam to underdrains and the swale is quickly dewatered. In the event that surface soils clog, the dry swale has a pea gravel window on the downstream side of each checkdam to route water to the underdrain. Dry swales are often preferred in residential areas because they prevent standing water. See Computer-aided design and drafting (CAD/CADD) drawings for design drawing.

Wet Swales

Wet swales occur when the water table is located very close to the surface. This wet swale acts as a very long and linear shallow wetland treatment system. Like the dry swale, the entire water quality treatment volume is stored within a series of cells created by checkdams. Cells may be planted with emergent wetland plant species to improve pollutant removal.

Filter Strips

Filter strips rely on the use of vegetation to slow runoff velocities and filter out sediment and other pollutants from urban stormwater.

To be effective, however, filter strips require the presence of sheet flow across the entire strip. Once flow concentrates to form a channel, it effectively short-circuits the filter strip. In the most common design, runoff is directed from a parking lot into a long filtering system composed of a stone trench, a grass strip and a longer naturally vegetative strip. The grass portion of the filter strip provides pre-treatment for the wooded portion. In addition, a stone drop can be located at the edge of the parking lot and the filter strip to prevent sediments from depositing at this critical entry point. The filter strip is typically an on-line practice, so it must be designed to withstand the full range of storm events without eroding. Filter strips do not provide adequate pollutant removal benefits to act as a stand-alone BMP. See Computer-aided design and drafting (CAD/CADD) drawings for design drawing.

Other Filters Not Approved For Minnesota

The following filters are not recommended for use in Minnesota due to high probability of failure under cold climate conditions. They are included here for informational purposes only.

Organic Filter

The organic filter functions in much the same way as the surface sand filter, but uses leaf compost or a peat/sand mixture as the filter media instead of sand (compost and peat should not be used when the target pollutant for removal is a dissolved nutrient. The organic material enhances pollutant removal by providing adsorption of heavy metals. In an organic filter, runoff is diverted with a flow splitter into a pre-treatment chamber, from which it passes into one or more filter cells. Each filter bed contains a layer of leaf compost or the peat/sand mixture, followed by a filter fabric and perforated pipe and gravel. Runoff filters through the organic media to the perforated pipe and ultimately to the outlet. The filter bed and subsoils can be separated by an impermeable polyliner to prevent movement into groundwater.

It is HIGHLY RECOMMENDED that the facility be actively managed to keep it dry before it freezes in the late fall.

Pocket Filter

Pocket sand filters are intended as an inexpensive variation of a sand filter where sediment loads do not warrant a sedimentation chamber and can suffice with a grass filter strip and a plunge pool. The filter bed is comprised of a shallow basin containing the sand filter medium. The filter surface is a layer of soil and a grass cover. In order to avoid clogging the filter has a pea gravel “window” which directs runoff into the sand and a cleanout and observation well. Typically the filtered runoff is allowed to exfiltrate to ground water, although underdrains may be needed if the soils are not suitably permeable.

Submerged Gravel Wetland

Submerged gravel filters consist of a series of cells that are filled with crushed rock or gravel. The standpipe from each cell is set at an elevation that keeps the rock or gravel submerged. Wetland plants are rooted in the media, where they can directly take up pollutants. The anaerobic conditions on the bottom of the filter can foster the de-nitrification process. Submerged gravel wetlands are not recommended for stormwater quality in cold climate conditions, although they do have been used in Minnesota for effluent polishing of wastewater.