MS4 fact sheet - Winter Road Materials Management

The concentration of chloride is increasing in our surface and ground water largely due to stormwater runoff from road salt storage piles, areas of excessive application, or simply from years of repeated application since chloride does not degrade in soil and water. Chloride in road salt and road salt additives (e.g. ferrocyanide for anti-caking) can create toxic conditions for fish, insects and vegetation.

Sodium from road salt can compromise soil structure thereby reducing its water retention capacity and increasing the potential for erosion. It can also reach levels in ground water that pose drinking water problems. Associated materials that could also pose water quality problems could include sand (anti-skid agent) and phosphorus related to both the salt and the sand.

This fact sheet provides guidance on the management of winter road materials.

Contents

Benefits and pollution reduction

Minnesota Statute 160.215 states that the application of salt and chemicals for snow removal and road de-icing shall be restricted to reduce the pollution of waters. Proper road salt storage, handling, and application reduce the risk of downstream water resources pollution and can reduce die-off of exposed vegetation, fish, and other aquatic organisms. Best management practices (BMPs) can also protect ground water supplies from contamination Groundwater is the source of approximately 70 percent of the drinking water in Minnesota. Efficient storage, handling, and application rates can also reduce materials costs. Details on the nature of the salt problem and possible approaches to controlling it are contained here.

Program development and implementation

Salt management plans

A municipal salt management plan is a commitment to implementing BMPs while fulfilling a community’s obligation to provide safe, efficient and cost-effective roads. The plan should identify BMPs to reduce the negative environmental impacts of road salt. The plan should apply to all winter maintenance personnel including staff and contractors. The Canadian Public Works Association (CPWA) and Transportation Association of Canada (TAC) provide helpful guidance on salt management plans. The CPWA and TAC recommend the following framework for a salt management plan:

- Salt management policy and objectives - Adopt a salt management policy that commits to measurable improvements in salt management practices.

- Review of current practices - Inventory current practices to form a benchmark against which progress can be measured and tracked. Consider current application rates for each material, percentage of fleet with electronic spreader controls, BMPs implemented in salt-vulnerable areas, percentage of sand/salt piles covered, percentage of snow disposal sites with water management systems, and percentage and frequency of staff receiving training.

- Documentation of policies, procedures and guidelines - Level of service for each roadway type, salt/sand application rates, managed salt/sand storage, good housekeeping practices, equipment calibration and re-calibration, training, snow disposal, incorporation of salt management consideration into road design and construction, and salt vulnerable areas.

- Proposed approaches, including BMPs and assigned responsibilities - Identify clear tasks, schedules with milestones, budget considerations and assigned responsibilities for implementing BMPs. Address the following four areas of concern: general road use, salt use in salt vulnerable areas, salt storage and mixing, and snow storage and disposal.

- Training - Include a comprehensive education and training program that demonstrates the value of new procedures and ensures that managers, supervisors, and operators are competent in delivering the new program. The training program should also include a public element whereby the public is educated on proposed and existing winter maintenance practices. Public education could include adjusting driving behavior based on roadway conditions. Training is available through MnDOT and MPCA Road Salt Education Program.

- Monitoring, reporting and analysis - In order to identify progress as compared to benchmarks, measure and assess the indicators identified based on a ‘review of current practices.’ Assign responsibility for monitoring and recording to ensure the task is accomplished. As an example, the type of benchmark data collected could include: the amount of salt/sand applied by driver and road covered, the calibration and maintenance history for each application vehicle, or the annual amount of salt applied per unit of weather/precipitation, such as degrees below 32ºF or inch of snow. Any data that help the community track use and allow for increased efficiency and decreased overall salt use will be helpful to document.

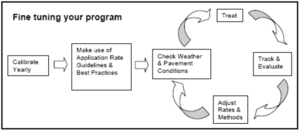

- Management review - Annually review the previous year’s salt management practices and results to review progress. Communicate progress to staff, senior management, the public and local politicians. Use the annual review to guide next year’s plan and identify new opportunities for BMPs. Update the plan with new protocol and train staff and contractors accordingly.

Winter road materials BMPs

- Salt, sand and chemical storage - Provide cover and impervious pads for salt, sand and chemical storage areas. This will reduce the possibility for contamination of downstream water bodies while preventing formation of lumpy salt that is difficult to handle and reducing salt loss through dissolving and runoff. It is also important to collect runoff from storage areas.

- Ideally, all mixing of salt/sand mixes and all loading should also be done under cover. If space and cost factors do not allow for total inside operation, runoff collection and post-operation clean-up should be standard procedures. No mixed salt/sand piles should be left exposed between operations. For additional information on proper storage and handling of these materials see the appropriate Hazardous Material Storage and Handling fact sheet (sodium chloride; magnesium chloride; calcium chloride; calcium magnesium acetate; potassium acetate).

- Anti-icing techniques Liquid anti-icing chemicals are applied to the pavement before a storm in order to prevent or minimize the bonding of snow and ice with the pavement surface. This reduces the salt application required after the storm event. The liquid is contained within tanks on the application vehicle and can include any of a number of products or mixes available (see the Additional Resources section).

- Application BMPs Application BMPs for the state of Minnesota are provided in two manuals. The Minnesota Snow and Ice Control: Field Handbook for Snowplow Operators was developed by the University of Minnesota Center for Transportation Studies, the Minnesota Department of Transportation, and the Minnesota Local Road Research Board. The Winter Parking Lot and Sidewalk Maintenance Manual was developed by the MPCA and others providing a tool for training snowplow operators, based on the research conducted for the Field Handbook.

- The following topics are a subset of those covered in The Winter Parking Lot and Sidewalk Maintenance Manual:

- Selection and use of materials

- Practical melting temperature of deicers

- Materials testing

- Spreader calibration

- Measuring pavement temperature

- Weather conditions

- Snow removal

- Loading/hauling materials

- Prewetting and pretreating salt and sand

- Deicing and anti-icing guidelines

- Deicing and anti-icing application rates

- Documentation

- Case Studies from application of the guidelines

- Treatment and recycling of salt truck wash water - Salt truck wash water and runoff from salt storage facilities can contain high levels of sodium, chloride, cyanide, and other associated pollutants. Capture, treat, and recycle salt-containing wash water or storage facility runoff for use as salt-brine in salt pre-wetting and anti-icing materials, or properly route the collected runoff to a wastewater treatment facility. For additional information regarding wash water containment and recycling see the Vehicle Washing fact sheet.

- Training - As part of the MPCA Road Salt Education Program, a road salt applicator training program is offered based on the Winter Parking Lot and Sidewalk Maintenance Manual. Over 1,500 road salt applicators have received certification. Entities with certified personnel include, but are not limited to, cities, public works, private companies, counties and MnDOT.

Snow management plans and private operations

Each MS4 should examine its approach to managing the accumulation, removal and potential collection of snow so that procedures are in place for both during and after a snowfall event. This plan should not only address MS4 operations, but also examine how commercial entities are conducting their operations. Many commercial applicators apply excessive salt to assure the public’s safety in well traveled areas. Education or possible regulation of these applicators could help reduce pollutants entering the MS4 community drainage system that eventually flow to sensitive receiving waters.

Maintenance considerations

All application equipment must be well maintained and calibrated in order to operate effectively. Proper documentation should be part of this maintenance program, as described previously. Inspection and maintenance of storage areas should be provided to minimize contact of stored or spilled materials with stormwater.

Typical cost

The Winter Parking Lot and Sidewalk Maintenance Manual identifies the cost savings experienced by those who underwent the road salt applicator training program. Rather than creating an additional expense, implementation of BMPs reduced material usage by 33 percent to 51 percent. Materials reductions translate directly into cost savings. Increased efficiencies from operator training can similarly save an MS4 both staff and materials costs.

This page was last edited on 23 January 2023, at 23:02.