Difference between revisions of "Overview for pretreatment settling devices"

m |

m |

||

| Line 1: | Line 1: | ||

[[File:General information page image.png|left|100px|alt=image]] | [[File:General information page image.png|left|100px|alt=image]] | ||

| + | |||

| + | {{alert|''Reference to any specific commercial product, process, or service by trade name, trademark, service mark, manufacturer, or otherwise does not constitute or imply endorsement, recommendation, or favoring by the Minnesota Pollution Control Agency. ''|alert-info}} | ||

| + | |||

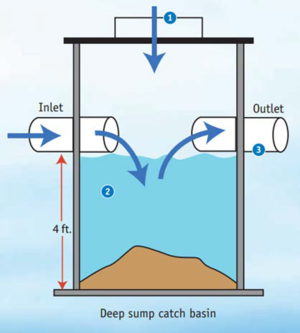

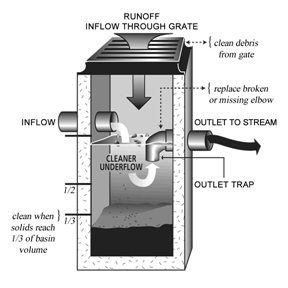

[[file:Catch basin nonproprietary settling.png|300px|thumb|alt=image of catch basin|<font size=3>Schematic of a catch basin. Stormwater enters through the grate or inflow pipe and larger solids settle out at the bottom of the basin. Source: [http://www.aerosnow.com/dejanaservices/catch-basin.html Dejana Industries]</font size>]] | [[file:Catch basin nonproprietary settling.png|300px|thumb|alt=image of catch basin|<font size=3>Schematic of a catch basin. Stormwater enters through the grate or inflow pipe and larger solids settle out at the bottom of the basin. Source: [http://www.aerosnow.com/dejanaservices/catch-basin.html Dejana Industries]</font size>]] | ||

Revision as of 23:51, 18 January 2022

It is strongly recommended that pretreatment devices be certified through Washington State's TAPE or New Jersey's NJCAT programs, be modeled using SHSAM, or follow guidance in this manual for vegetated filter strips and forebays.

It is important to tailor a pretreatment practice to the specific site and the structural stormwater best management practice (BMP) receiving water from the pretreatment device. Many factors influence the choice of pretreatment practices, including but not limited to: (1) contributing area characteristics (drainage area, connected imperviousness, land uses, soils, slopes, dominant vegetation, source controls in place, and availability of public lands ); (2) existing infrastructure (above and below ground); and (3) type of structural stormwater BMP. Infiltration/filtration BMPs have the greatest need for removal of solids prior to treatment areas. The following section describes the specific strengths, weaknesses, and applicability of pretreatment settling devices.

Contents

Processes

Settling devices rely primarily on sedimentation, in which coarse sediments and debris sink or fall out of the collected stormwater. Some settling devices also provide secondary screening to improve the capture of floatables and sediment. Stormwater management processes not provided in settling devices include volume reduction, peak flow reduction (minimal), infiltration (typically very minimal), filtration, sorption and biological treatment.

Applicability and suitability

Pretreatment practices are NOT stand-alone treatment practices and should only be installed in conjunction with a treatment practice immediately downstream. The applicability of pretreatment settling devices with regard to the cold climate considerations, retrofits, ultra-urban settings and other considerations is presented below.

Cold climate suitability

Some settling devices are designed to be installed below ground and are often installed below the frost line. If they are installed below the frost line, settling devices will likely perform their designed function during the winter, which is an advantage compared to other pretreatment devices. Settling devices exposed to atmospheric air temperatures through open grates and stormsewers will be affected by freeze/thaw cycles if ice develops within the structure and causes short-circuiting (bypassing) or damages the structure or its components. In addition, settling devices that are small will be overwhelmed by high runoff volumes and pollutant loads from major thaw events and spring snowmelt. As a result, more frequent maintenance is often necessary prior to and during these conditions. Settling devices may capture less sediment during cold climate conditions due to reduced settling velocities.

Forebays are effective in cold climates when properly designed, such as incorporating additional space for the accumulation of snow and ice as well as meltwaters from major thaw events and spring runoff. Forebays may also be used for snow storage in winter months, adding to their overall functionality, provided they are designed to account for the additional volume of snow and ice and that snow storage does not impede flow into or out of the forebay during major thaw events and spring snowmelt.

Retrofit Suitability

Settling devices can often be installed within existing infrastructure and during redevelopment with constraints.

Ultra-urban Suitability

Underground settling devices are highly suitable for ultra-urban settings because they require a small (underground) footprint and settled materials are stored out of sight prior to removal. Above ground settling devices, including forebays, are suitable for ultra-urban applications if adequate space is available and forebay aesthetics are acceptable. Routine removal of trash and accumulated debris are a common factor for all pretreatment devices.

Other considerations

Some underground settling devices have limited storage capacities and a limited range of design flows. As such, these devices should be sized appropriately for the contributing watershed characteristics. If these characteristics exceed their design capabilities, a different pretreatment practice should be selected. In addition, some devices allow captured sediment to be susceptible to resuspension and discharge to the structural stormwater BMP during high-flow events. Such settling devices should be installed off-line or with bypasses to avoid washouts during these high-flow events.

Permit applicability

If designed properly, this practice meets the intent as pretreatment for an infiltration or filtration system in section III.D.1.d of the construction stormwater permit.

Advantages and limitations

The advantages and limitations of settling devices with regard to the pollutant removal capabilities, cost, ease of construction and maintenance, space and other design considerations and compatibility are presented below.

Advantages

Underground structures with surface manholes provide access for maintenance staff to inspect sediment and debris accumulations, and with the proper equipment such as a vacuum truck, maintenance is relatively easy and inexpensive. These devices often allow easy placement within the existing stormwater infrastructure in many situations. Underground devices are space efficient and out of sight which allows for use in areas where there is little or no surface area for installation of a pretreatment practice. Because accumulated sediment and debris are stored underground and out of public sight, these devices are also beneficial in areas with strict aesthetic requirements.

If designed properly and easily accessible, maintenance for above ground settling devices is relatively simple and inexpensive. A visible forebay will also facilitate visual inspection to determine when maintenance is necessary. Installing a depth gauge to measure sediment depth will aid in efficient visual assessment of accumulated material. Some settling devices are configured to capture floatables including oil and grease.

Limitations

Contributing area characteristics (size, land use, underlying soils, etc.) will affect sizing, design and the configuration of pretreatment settling devices. Pollutant removal is typically limited to coarse sediments and debris, although some devices also capture floatables, oil, and grease. Fine sediments and associated pollutants such as metals and nutrients are not effectively treated by settling devices and are more vulnerable to high flow events causing resuspension and discharge of previously captured sediments. Dissolved pollutants are not to be considered treated/removed by pretreatment settling devices. Pretreatment settling devices installed offline or with a bypass mechanism result in some fraction of the event delivered to the downstream BMP without pretreatment. In certain conditions, organic debris stored underwater in underground devices produce biological activity, anoxic conditions, or both and result in conversion of particulate pollutants into dissolved forms (e.g., particulate phosphorus into dissolved phosphorus). Stagnant water in some underground devices can also become mosquito habitat, but local organizations (e.g., Metropolitan Mosquito Control District) are often available to provide design input for treatment (e.g., access ports). Some proprietary devices are expensive and require heavy equipment for installation. When underground utilities conflict with underground practices, the cost and difficulty of design and installation increase. Other potential site-specific challenges include presence of bedrock and high groundwater. Maintenance costs for underground devices increase if a vacuum truck is not available, because third-party contracts or capital investments in equipment and personnel training (particularly if involving confined space entry) are required. If located in a high-traffic area, requisite safety and traffic controls are necessary to allow access for maintenance. A poorly maintained forebay filled with debris is often aesthetically displeasing. If the settling device does not have the REQUIRED maintenance access, sediment removal is more difficult and expensive. It is also REQUIRED that a maintenance plan be developed and followed, because these devices are often neglected.

Water quantity treatment

Stormwater volume reduction is not provided by settling devices as all of the water that flows into the device exits the device after settling occurs.

Water quality treatment

The Minnesota Pollution Control Agency does not have a formal process or policy for acceptable pretreatment practices. Pretreatment practices do not receive credits for volume or pollutant removal.

The following information may be useful for selecting appropriate pretreatment practices.Proprietary settling devices are designed to remove suspended sediments and floatables such as trash and debris through gravitational settling and/or cyclonic separation. They are capable of removing nutrients, bacteria and hydrocarbons when these pollutants are bound to larger sediment particles. Proprietary settling devices can play an important role in reducing the amount of metals, particularly toxic metals, when these constituents are bound to larger particles. Underground settling devices are sometimes referred to as vaults or sumps and can be used to remove hydrocarbons through gravity separation and coalescence (DDOE, 2013; TRPA, 2014). Underground vaults may be designed with or without baffles. Vaults without baffles are primarily used to settle out sediments upstream of an infiltration BMP (DDOE, 2013). Hydrocarbons may be captured in an underground vault if baffles and coalescing plates are used to slow flow and allow hydrocarbons to float to the surface (TRPA, 2014). Non-proprietary settling devices can also be used in conjunction with or as a part of proprietary settling devices to increase performance. One such configuration could include a hydrodynamic separator followed by a sedimentation vault. This system could remove trash, sediment, debris and hydrocarbons from stormwater. In general, the sediment removal rate of proprietary and non-proprietary devices decreases as flow increases through the device (Taylor et al., 2003).

The sediment removal efficiency of forebays depends upon the size and design of the forebay, as well as sediment loading (Maniquiz-Redillas et al., 2014). In order to achieve maximum sediment removal, forebays are typically designed to contain 10 percent of the water quality volume, should be deep enough to prevent resuspension of settled solids (Horsley Witten Group, University of New Hampshire Stormwater Center, and Loon Environmental, 2010; Virginia DEQ, 2011) depending on frequency of maintenance, and are designed to withstand velocities of incoming runoff from the design storm without scouring (Massachusetts Department of Environmental Protection, 2008). It is important that forebays include a zone for energy dissipation and a zone for settling of sediments.

Performance of proprietary settling devices

The following discussion provides a summary of information found in the literature. The information provides a general summary and indication of the range of pollutant removal and should not be used for design purposes.

There are several testing programs that provide certification or verification of performance of proprietary technologies. For example, the Washington Department of Ecology certifies proprietary stormwater treatment devices. In order to receive certification for pretreatment, a proprietary device must achieve at least 50 percent removal of total suspended solids (TSS) when the influent TSS is greater than 100 milligrams per liter. An effluent TSS concentration of 50 milligrams per liter or less is required if influent TSS is between 50 and 100 milligrams per liter (Ecology, 2015). For Technology Assessment Protocol – Ecology from the state of Washington’s Department of Ecology (TAPE) certification, laboratory testing must use Sil-Co-Sil 106 particles. Field testing of the technology is also required and particle size will vary under field conditions. No other contaminant is required to be tested for the TAPE pretreatment certification. Similarly, the New Jersey Department of Environmental Protection (NJDEP) requires manufactured treatment devices to be verified by the New Jersey Corporation for Advanced Technology (NJCAT). NJCAT tests devices based on the Technology Acceptance Reciprocity Partnership (TARP), whereby devices are tested to verify the manufacturer’s performance claim (NJCAT, 2015). Information on performance can be found by these two verification programs or other third party verification programs when considering which proprietary settling devices might be best suited for pretreatment. For best performance always follow manufacturer specifications for design, installation and maintenance. Finally, the SHSAM program can be used to estimate suspended solids removal based on drainage area and the size of the practice. The SHSAM software provides a useful tool for assessing the performance of a limited number of hydrodynamic devices and standard sumps. To assess the performance of hydrodynamic separators which are not included in the SHSAM software, the devices should be evaluated using the testing methods described in ASTM Standards C1746 and C1745. Subsequently, the device performance can be assessed based on the site specific conditions

In a study to validate the performance of a hydrodynamic separator, larger particles (150 microns to 600 microns) were removed at rates between 60 and 98 percent while flow rate was varied between 154 and 650 gallons per minute. Smaller particles (75 microns) were removed at 62 to 69 percent at flow rates of 154 to 157 gallons per minute, and 40 to 46 percent at flow rates of 360 to 371 gallons per minute (Taylor et al., 2003).

Nutrient removal depends upon the relationship between phosphorus or nitrogen attachment and sediment size of the particles in the runoff. Kayhanian, et al. (2007) analyzed the results from 34 highway water quality stations and a total of 634 storms to determine the mean and median concentrations of stormwater pollutants. They report that the mean and median concentrations of Ortho-Phosphorus (Ortho-P) were 0.11 and 0.06 milligrams per liter, respectively, with a standard deviation of 0.2 milligrams per liter. For total phosphorus, the mean and median concentrations were 0.29 and 0.18 milligrams per liter, respectively, with a standard deviation of 0.4 milligrams per liter. Maestre and Pitt (2005) found similar results for runoff in municipalities throughout the United States, which had median concentrations of 0.13 and 0.27 milligrams per liter for Ortho-P and total phosphorus, respectively. For nitrogen, Kayhanian, et al. (2007) report that the mean and median concentrations of nitrate were 1.07 and 0.6 milligrams per liter with a standard deviation of 2.6 milligrams per liter, and were 2.06 and 1.4 with a standard deviation of 1.9 milligrams per liter for were total Kjeldahl nitrogen (TKN), respectively. Maestre and Pitt (2005) found similar results with median concentrations of 0.44, 0.60, and 1.4 milligrams per liter for Ammonia (NH3), Nitrite + Nitrate (NO2 + NO3), and TKN, respectively. Some studies, however, have shown that much of the nitrogen present in stormwater in the dissolved form of nitrate (Taylor et al., 2005). This suggests that nitrate is roughly half of total (Kjeldahl) nitrogen concentrations, but varies substantially, both between storms and between locations. Typically, little to no nitrogen is removed from stormwater runoff through proprietary settling devices, other than sediment or organic bound material. Stormwater manuals from California, Virginia, and New Hampshire credit proprietary settling devices with approximately 15 to 40 percent removal of phosphorus, but only 5 to 10 percent of nitrogen (California Department of Transportation, 2004; Virginia Department of Ecology, 1999; Comprehensive Environmental Inc. and New Hampshire Department of Environmental Services, 2008).

Performance of forebays

The Massachusetts Department of Environmental Protection assigns forebays a 25 percent removal credit for TSS when they are designed to hold 0.1 inch per impervious acre (Massachusetts Department of Environmental Protection, 2008). Many stormwater manuals do not give separate TSS removal credit for forebays, but rather include the TSS removed by the forebay in the performance of the downstream BMP (Virginia DEQ, 2011). Minnesota does not provide credit for TSS removal for a pretreatment practice.

Another factor that may influence TSS removal efficiency is sediment loading. A study by Maniquiz-Redillas et al. (2014) found that 15 to 35 percent of sediment was captured in a forebay when TSS loading ranged from 10 x 103 to 85 x 103 kilograms per year. According to the study, a majority of the sediments captured had a diameter ranging from 0.075 to 2 millimeters. Particles less than 0.075 millimeters constituted only 7 percent of the captured sediments (Maniquiz-Redillas et al., 2014). More detailed studies should be reviewed or conducted to understand the performance if the sediment loading size is different.

Design assistance using SHSAM

The Saint Anthony Falls Laboratory (SAFL) of University of Minnesota has performed extensive full-scale testing of many different types of flow-through structures to determine their removal efficiency functions that can assist the designer in selecting the appropriate type of flow-through structure and size the selected structure to meet the sediment removal goals. In 2012, ASTM International developed standards in testing removal efficiency of hydrodynamic separators (ASTM C1746/C1746M–12). The standard is primarily based on the testing conducted at the University of Minnesota. In addition to sediment removal, SAFL performed testing to determine the propensity for sediment washout under high flows for different structures.

The results of SAFL’s full-scale testing were used to build a computer program to predict the removal efficiency and washout for various flow-through devices under different conditions. The program is called SHSAM (Sizing Hydrodynamic Separators And Manholes).

SHSAM is a computer program for predicting the amount of suspended sediments removed from stormwater runoff by a given hydrodynamic separator/standard sump over a given period of time, e.g., 15 years. SHSAM is comprised of a simple continuous runoff model, a generic sediment removal response function, and a generic sediment washout function. The table below summarizes the flow-through structures available for water quality modeling by SHSAM and whether the model is able to determine sediment removal efficiency and/or washout. SHSAM can be downloaded at [1].

| Device | Removal efficiency considered | Washout considered |

|---|---|---|

| BaySaver | X | |

| CDS | X | |

| Downstream Defender | X | X |

| ecoStorm | X | X |

| Environment 21 | X | X |

| Stormceptor | X | X |

| Vortechs System | X | |

| Standard Sumps | X | X |

| Standard Sumps with SAFL Baffle | X | X |

| SciClone | X | X |

In order to assess the performance of hydrodynamic separators and sump manholes, the user of SHSAM should select local weather data and silica sand OK110 particle size distribution (PSD). The silica sand OK110 is a commercial particle size distribution used in testing these devices. This gradation has a median size of110 microns with 90 percent of particles between 100 and 240 microns, which represents fine sands in stormwater runoff. OK110 does not represent a typical particle size distribution of suspended sediments; rather, it provides an appropriate range of particle sizes that are expected to be removed by flow-through structures. The removal efficiencies achieved by flow-through structures using OK110 are not the removal efficiencies that these devices will achieve for a typical range of suspended sediment particle sizes. OK110 allows the designer to determine how well the pretreatment structure can remove coarse silt and sand which would in turn decrease the maintenance frequency of the downstream primary BMP.

Note that an ASTM standard is currently being developed for a consistent type of particle-size-distribution to be used for testing hydrodynamic separators.

Certification programs

Washington State and New Jersey have certification programs for stormwater treatment practices. Most of the certified practices would be considered pretreatment practices in Minnesota. The process for certifying practices in these two states is rigorous and the resulting certified practices are therefore considered appropriate pretreatment practices in Minnesota. For more information and a list of certified practices in these two states, see the following.

- State of Washington, Department of Ecology: Technology Assessment Protocol - Ecology (TAPE)

- New Jersey Corporation for Advanced Technology: NJCAT Stormwater verified technologies

Related pages

- Pretreatment selection tool

- Overview and methods of pretreatment

- Overviews for different types of pretreatment practices

- Information for specific types of pretreatment practices

- Design, construction, operation and maintenance specifications for pretreatment vegetated filter strips

- Pretreatment - Hydrodynamic separation devices

- Pretreatment - Screening and straining devices, including forebays

- Pretreatment - Above ground and below grade storage and settling devices

- Pretreatment - Filtration devices and practices

- Pretreatment - Other pretreatment water quality devices and practices

- To see the above pages as a single page, link here

Pretreatment sizing for basins and filters strips

Guidance for managing sediment and wastes collected by pretreatment practices

Tables

- Pretreatment tables - link to tabled information for pretreatment practices

- Hydrodynamic separator tables

- Screening and straining devices tables

- Above ground and below grade storage and settling tables

- Filtration tables

- Other water quality devices tables

Other information and links