Pretreatment - Additional considerations

Contents

Construction Considerations

While some pretreatment devices are inserted into or around existing inlets or manholes, some will require more involved activities such as excavation. Grading may also be necessary and is important to control velocity into and out of pretreatment systems. This level of site modification raises erosion issues that may pose problems for the functioning and maintenance of the site and the project. Proper design and installation of a pretreatment device protects both. Actions for the preservation of the practice and the site include but are not limited to: soil stabilization, alleviation of compaction, tree protection, use of low ground pressure (LGP) construction equipment, staging of the site so that equipment does not intrude on the device footprint, and proper re-use of excavated soil on-site (if applicable)(Construction of bioretention systems. National Standard of Canada W201-18. Standards Council of Canada. October 2018).

Some actions may be taken before construction even begins in order to mitigate these issues. These include careful site selection, placement on the site, and compatibility of the device and the site. For example, steep slopes around the pretreatment site should be avoided as they may introduce difficulties in maintaining a gradual grade and may contribute to local sediment and erosion control problems within the pretreatment system. For sites with steep grades, consider an underground or below grade pretreatment system. Once the site and practice are selected, a thoughtful site layout is key to allowing for utilities as well as future maintenance activities.

The sequence of site construction is an important aspect of protecting downstream practices. As such, it may be important to bring pretreatment systems on line (and even oversize for containment of construction site runoff) prior to the downstream practice to protect from sediment prior to stabilization of the surrounding area. If this is done, cleaning of the pretreatment system must occur prior to bringing the entire treatment system on line. To avoid overwhelming pretreatment practices, proper stabilization of the surrounding area including the watershed to avoid larger loads of sediment during construction. Proper vehicle access and access lane stabilization is necessary.

The following during-construction activities should be considered and evaluated for relevance to the project. Avoidance of soil compaction can be achieved by keeping excavation vehicles on the perimeter of the site, using LGP equipment, and ensuring the conditions are as dry as possible. If necessary, mitigation of this compaction is possible by subsoil ripping, fracturing, or trenching when the soil is neither saturated nor frozen. If applicable, geotextiles or liners should be arranged and secured in place according to the manufacturer’s instructions to prevent wrinkling. An industry standard is to install from uphill to downhill, constructing the higher elevation components at the proper elevation then install downward as per manufacturer’s recommendations. Underdrains, valves, and piping should also be installed according to manufacture guidance and should have smooth connections, meet minimum slope requirement, and be kept free of debris. Elevations of inlets and outlets should be verified (Construction of bioretention systems. National Standard of Canada W201-18. Standards Council of Canada. October 2018).

Sediment and erosion control should be addressed specifically. To maintain an off-line device during construction, flow should be routed around the unit and avoid the downstream BMP. Flow routing, soil protection/stabilization, and run-on/run-off management can prevent the incomplete device from becoming compromised during a storm event. Examples of erosion control include conveyance channels, diversion berms, soil roughening, soil binders, and cover layers. Sediment control measures include perimeter controls sch as silt fences, check structures such as check dams, inlet barriers such as inserts should be used. Stabilized of construction access points should have proper controls such as tire washing (Construction of bioretention systems. National Standard of Canada W201-18. Standards Council of Canada. October 2018).

Often, construction site dewatering and erosion and sediment control basins may be converted into stormwater practices. If infiltration or other mechanism, dependent on infiltration is planned, proper reduction in site compaction must be considered to ensure adequate infiltration.

Maintenance Specifications

In addition to the device-specific information in the tables, proper disposal procedures for solids removed from the pretreatment device during routine cleanings requires careful consideration. Currently, sediment removed from flow-through structures is not generally considered to be potentially hazardous and is not subject to testing for proper disposal [1]. However, guidance is available for sediment removed from stormwater pond, which may be loosely adapted to determine representative contaminant concentrations for other sediment-generating stormwater devices [2]. Proper care should be taken for all other trash, debris, and other potential pollutants. All applicable local, state and federal laws should be followed in the disposal of accumulated sediments, trash, debris, floatables including hydrocarbons, and other pollutants of concern.

Agreements, Easements, and Deed Restrictions

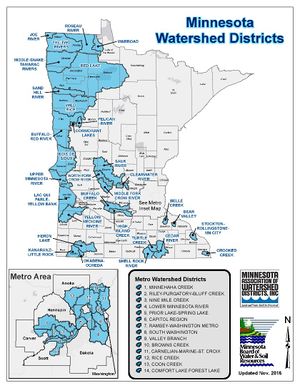

Public entities seeking to install and manage pretreatment devices on private property will engage in a maintenance agreement, the terms of which can vary widely. In Minnesota, these public entities may include cities, watershed districts, watershed management organizations, water conservations districts, and soil and water conservation districts. The agreements (see example here) detail the distribution of responsibilities for operation and maintenance of the practice. This helps ensure that the pretreatment devices are functioning at a satisfactory level so that the effectiveness and lifetime of both the pretreatment and downstream BMP are maximized. To achieve this, the agreements may extend from transferring complete responsibility from the public entity to the landowner after 1-5 years, to assigning that responsibility to the district or to the private property owner in perpetuity. In the case where the city chooses to leave maintenance with a landowner, they will not be required to perform and record maintenance, but they will forfeit the MS4 credits. With the later situation, where the public entity maintains responsibility, a maintenance fee may be assessed and collected from the property owner. The longevity of the agreement may be preserved by tying the maintenance agreement to the deed of the property, so that it transfers with ownership. Districts vary in how they manage these agreements. Some require them to be written and may take the initiative to prepare and provide them to the landowner. The adjacent map shows the watershed districts for reference [3].

Glossary

- Berm – a small earthen barrier that directs, diverts, or captures flow

- Biodegradation – decomposition of organic material by microorganisms, which generally requires a longer detention time than standard pretreatment allows

- Check dam – A check dam is a small dam constructed across a drainage ditch, swale, or channel to lower the velocity of flow, which allows sediment to settle out.

- Floating Boom – a temporary floating barrier used to contain floating trash, organic matter, oil, and other buoyant pollutants

- Forebay – a small pool where sediment can settle out

- Hydrodynamic Separation – a pretreatment mechanism that reduces the sediment and total suspended solids load in stormwater by harnessing the movement of the water into the unit to establish a high-speed rotating flow within a cylindrical chamber. Larger particles in the rotating stream have too much inertia to follow the tight curve of the stream, and thus strike the outside wall, then fall to the bottom of the chamber where they can be removed.

- Skimming – a pretreatment mechanism that removes floatables from the water surface

- Sump – a sunken area at the bottom of a catch basin or manhole where sediment and pollutants that settle out of the water column are stored

- Water Quality Volume - 1 inch of runoff per impervious acre

Related pages

- Pretreatment selection tool

- Overview and methods of pretreatment

- Overviews for different types of pretreatment practices

- Information for specific types of pretreatment practices

- Design, construction, operation and maintenance specifications for pretreatment vegetated filter strips

- Pretreatment - Hydrodynamic separation devices

- Pretreatment - Screening and straining devices, including forebays

- Pretreatment - Above ground and below grade storage and settling devices

- Pretreatment - Filtration devices and practices

- Pretreatment - Other pretreatment water quality devices and practices

- To see the above pages as a single page, link here

Pretreatment sizing for basins and filters strips

Guidance for managing sediment and wastes collected by pretreatment practices

Tables

- Pretreatment tables - link to tabled information for pretreatment practices

- Hydrodynamic separator tables

- Screening and straining devices tables

- Above ground and below grade storage and settling tables

- Filtration tables

- Other water quality devices tables

Other information and links

This page was last edited on 5 December 2022, at 23:55.