Difference between revisions of "Pretreatment - Hydrodynamic separation devices"

m |

|||

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:General information page image.png|left|100px|alt=image]] | [[File:General information page image.png|left|100px|alt=image]] | ||

| + | |||

| + | {{alert|''Reference to any specific commercial product, process, or service by trade name, trademark, service mark, manufacturer, or otherwise does not constitute or imply endorsement, recommendation, or favoring by the Minnesota Pollution Control Agency. ''|alert-info}} | ||

| + | |||

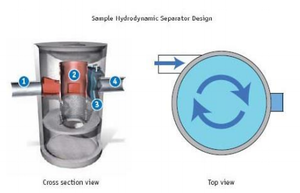

[[File:Figure for hydrodynamic separator.png|300px|thumb|alt=image of hydrodynamic separator|<font size=3>Renderings of an example hydrodynamic separator. The water enters the chamber at an angle, creating the vortex. The particles settle out into a bottom chamber, and some models include a top chamber to capture floatables (image courtesy: Iowa Storm Water Management Manual, 2009).</font size>]] | [[File:Figure for hydrodynamic separator.png|300px|thumb|alt=image of hydrodynamic separator|<font size=3>Renderings of an example hydrodynamic separator. The water enters the chamber at an angle, creating the vortex. The particles settle out into a bottom chamber, and some models include a top chamber to capture floatables (image courtesy: Iowa Storm Water Management Manual, 2009).</font size>]] | ||

| Line 10: | Line 13: | ||

==System and Component Sizing== | ==System and Component Sizing== | ||

| − | The <span title="Sizing refers to the physical dimensions of a stormwater treatment practice or device needed to meet a water quality or quantity goal. For example, stormwater BMPs may be sized to treat a volume of runoff, a flow rate, or to meet a pollutant removal target."> '''sizing'''</span> of a hydrodynamic separation system can be estimated using various tools, formulae, or guidance documents. Most manufacturers have a design tool or calculator for determining the size of device that may be needed; however modeled flow rates or the <span title="The Rational Method is a simple hydrologic calculation of peak flow based on drainage area, rainfall intensity, and a non-dimensional runoff coefficient. The peak flow is calculated as the rainfall intensity in inches per hour multiplied by the runoff coefficient and the drainage area in acres. The peak flow, Q, is calculated in cubic feet per second (cfs) as Q = CiA where C is the runoff coefficient, i is the rainfall intensity, and A is the drainage area. A conversion factor of 1.008 is necessary to convert acre-inches per hour to cfs, but this is typically not used. This method is best used only for simple approximations of peak flow from small watersheds."> '''Rationale Method'''</span> can be used to estimate the runoff flow rates. Additionally, guidance from the [http://www.njcat.org/ State of New Jersey Department of Environmental Protection] and [ | + | The <span title="Sizing refers to the physical dimensions of a stormwater treatment practice or device needed to meet a water quality or quantity goal. For example, stormwater BMPs may be sized to treat a volume of runoff, a flow rate, or to meet a pollutant removal target."> '''sizing'''</span> of a hydrodynamic separation system can be estimated using various tools, formulae, or guidance documents. Most manufacturers have a design tool or calculator for determining the size of device that may be needed; however modeled flow rates or the <span title="The Rational Method is a simple hydrologic calculation of peak flow based on drainage area, rainfall intensity, and a non-dimensional runoff coefficient. The peak flow is calculated as the rainfall intensity in inches per hour multiplied by the runoff coefficient and the drainage area in acres. The peak flow, Q, is calculated in cubic feet per second (cfs) as Q = CiA where C is the runoff coefficient, i is the rainfall intensity, and A is the drainage area. A conversion factor of 1.008 is necessary to convert acre-inches per hour to cfs, but this is typically not used. This method is best used only for simple approximations of peak flow from small watersheds."> '''Rationale Method'''</span> can be used to estimate the runoff flow rates. Additionally, guidance from the [http://www.njcat.org/ State of New Jersey Department of Environmental Protection] and [https://ecology.wa.gov/Regulations-Permits/Guidance-technical-assistance/Stormwater-permittee-guidance-resources/Emerging-stormwater-treatment-technologies Washington State Department of Ecology] provide additional considerations based on performance of these devices. In addition, [https://shsam.barr.com/ SHSAM] (Sizing Hydrodynamic Separators And Manholes) is a computer program for predicting the amount of suspended sediments removed from stormwater runoff by a given hydrodynamic separator/standard sump over a given period of time. SHSAM uses a continuous runoff model and sediment removal responses to predict the <span title="Pollutant removal efficiency, usually represented by a percentage, specifically refers to the pollutant reduction from the inflow to the outflow of a system"> '''removal efficiency'''</span> of the hydrodynamic separator device. |

Most important for the sizing is the anticipated frequency of operation and maintenance as well as the protection of downstream BMPs and <span title="A stream, river, lake, ocean, or other surface or groundwaters into which treated or untreated wastewater is discharged"> '''receiving water'''</span>. Sizing is usually based on <span title="the rate of flow which a device is designed to handle"> '''design flow'''</span> rather than <span title="the volume of flow which a device is designed to handle"> '''design flow'''</span>. Most have configurations to bypass additional flow without <span title="a renewed suspension of insoluble particles after they have been precipitated"> '''resuspending'''</span> solids. Some devices have “enhancements” that can provide other treatment mechanisms beyond <span title="Pretreatment reduces maintenance and prolongs the lifespan of structural stormwater BMPs by removing trash, debris, organic materials, coarse sediments, and associated pollutants prior to entering structural stormwater BMPs. Implementing pretreatment devices also improves aesthetics by capturing debris in focused or hidden areas. Pretreatment practices include settling devices, screens, and pretreatment vegetated filter strips."> [https://stormwater.pca.state.mn.us/index.php?title=Pretreatment '''pretreatment''']</span>. These can provide an additional level of treatment such as <span title="Filtration Best Management Practices (BMPs) treat urban stormwater runoff as it flows through a filtering medium, such as sand or an organic material. They are generally used on small drainage areas (5 acres or less) and are primarily designed for pollutant removal. They are effective at removing total suspended solids (TSS), particulate phosphorus, metals, and most organics. They are less effective for soluble pollutants such as dissolved phosphorus, chloride, and nitrate."> '''filtration'''</span>, <span title="removal of floatables (e.g. oil) from water"> '''skimming'''</span> (in addition to settling or screening), chemical treatment/<span title="absorption and adsorption considered as a single process"> '''sorption'''</span>, or <span title="the decomposition of organic material by microorganisms"> '''biodegradation'''</span>. This is denoted [https://stormwater.pca.state.mn.us/index.php?title=Hydrodynamic_separation_devices_-_system_and_component_sizing table on system and component sizing]. | Most important for the sizing is the anticipated frequency of operation and maintenance as well as the protection of downstream BMPs and <span title="A stream, river, lake, ocean, or other surface or groundwaters into which treated or untreated wastewater is discharged"> '''receiving water'''</span>. Sizing is usually based on <span title="the rate of flow which a device is designed to handle"> '''design flow'''</span> rather than <span title="the volume of flow which a device is designed to handle"> '''design flow'''</span>. Most have configurations to bypass additional flow without <span title="a renewed suspension of insoluble particles after they have been precipitated"> '''resuspending'''</span> solids. Some devices have “enhancements” that can provide other treatment mechanisms beyond <span title="Pretreatment reduces maintenance and prolongs the lifespan of structural stormwater BMPs by removing trash, debris, organic materials, coarse sediments, and associated pollutants prior to entering structural stormwater BMPs. Implementing pretreatment devices also improves aesthetics by capturing debris in focused or hidden areas. Pretreatment practices include settling devices, screens, and pretreatment vegetated filter strips."> [https://stormwater.pca.state.mn.us/index.php?title=Pretreatment '''pretreatment''']</span>. These can provide an additional level of treatment such as <span title="Filtration Best Management Practices (BMPs) treat urban stormwater runoff as it flows through a filtering medium, such as sand or an organic material. They are generally used on small drainage areas (5 acres or less) and are primarily designed for pollutant removal. They are effective at removing total suspended solids (TSS), particulate phosphorus, metals, and most organics. They are less effective for soluble pollutants such as dissolved phosphorus, chloride, and nitrate."> '''filtration'''</span>, <span title="removal of floatables (e.g. oil) from water"> '''skimming'''</span> (in addition to settling or screening), chemical treatment/<span title="absorption and adsorption considered as a single process"> '''sorption'''</span>, or <span title="the decomposition of organic material by microorganisms"> '''biodegradation'''</span>. This is denoted [https://stormwater.pca.state.mn.us/index.php?title=Hydrodynamic_separation_devices_-_system_and_component_sizing table on system and component sizing]. | ||

| Line 64: | Line 67: | ||

*[[Photo gallery for pretreatment]] | *[[Photo gallery for pretreatment]] | ||

| − | [[Category:Pretreatment]] | + | [[Category:Level 3 - Best management practices/Pretreatment practices/Hydrodynamic separation devices]] |

</noinclude> | </noinclude> | ||

Latest revision as of 17:27, 28 January 2023

Hydrodynamic separators are flow-through, often proprietary structures that establish a high-speed rotating flow within a cylindrical chamber. Larger particles in the rotating stream have greater density than smaller particles to follow the tight curve of the stream, and thus strike the outside wall, falling to the bottom of the chamber where they can be later removed. While this means of settling does not always occur in this manner, generally the larger, more dense particles well settle to the bottom of these devices.

Some devices include other treatment and removal mechanisms such as the ability to trap floatables and/or provide a higher level of filtration or screening. These units are typically installed underground, frequently in existing sump manhole.

Contents

Hydrodynamic separation devices - system design

Many hydrodynamic separators are well-suited for use in or retrofitting existing manholes that service small to moderate-sized catchments (<5 acres). Devices are available in a variety of sizes and corresponding flow capacities. For some devices, the different models and corresponding dimensions can be accessed using the hyperlinks shown in this table.

System and Component Sizing

The sizing of a hydrodynamic separation system can be estimated using various tools, formulae, or guidance documents. Most manufacturers have a design tool or calculator for determining the size of device that may be needed; however modeled flow rates or the Rationale Method can be used to estimate the runoff flow rates. Additionally, guidance from the State of New Jersey Department of Environmental Protection and Washington State Department of Ecology provide additional considerations based on performance of these devices. In addition, SHSAM (Sizing Hydrodynamic Separators And Manholes) is a computer program for predicting the amount of suspended sediments removed from stormwater runoff by a given hydrodynamic separator/standard sump over a given period of time. SHSAM uses a continuous runoff model and sediment removal responses to predict the removal efficiency of the hydrodynamic separator device.

Most important for the sizing is the anticipated frequency of operation and maintenance as well as the protection of downstream BMPs and receiving water. Sizing is usually based on design flow rather than design flow. Most have configurations to bypass additional flow without resuspending solids. Some devices have “enhancements” that can provide other treatment mechanisms beyond pretreatment. These can provide an additional level of treatment such as filtration, skimming (in addition to settling or screening), chemical treatment/ sorption, or biodegradation. This is denoted table on system and component sizing.

Installation and Maintenance Recommendations

Proprietary hydrodynamic separators are generally designed to be easy to measure solids accumulation with access for maintenance from the street level. Manufactures often recommend more frequent inspections for a period after installation in order to gauge sediment and debris accumulation rates that may depend on factors such as nearby construction, winter or rainy conditions, street sanding, or a highly erosive drainage area. The information gained during this time is the primary indicator for how often inspections and cleanings may require to be scheduled. An initial estimate is usually available from the manufacturer. Manufacturers also have maintenance manuals or guides available, which can be accessed in the hyperlink within the table on maintenance recommendations. Generally, hydrodynamic separators are designed for quick and simple, but more frequent, maintenance than other practices. An advantage of hydrodynamic separators is that they are designed to minimize washout and sediment scouring within the system. In many locations, disposal of sediments removed may be handled in the same manner as disposal of sediments from catch basins (see here). Hydrodynamic separators generally are for areas without steep grading.

Links to tables with information on hydrodynamic devices

Below are links to several tables containing information on hydrodynamic separators. To see all tables on a single page, link here. To see the information in a single spreadsheet click on the following link: File:Hydronamic separation table all data.xlsx

- Hydrodynamic separation devices - pollutant removal characteristics

- Hydrodynamic separation devices - system design information

- Hydrodynamic separation devices - system and component sizing

- Hydrodynamic separation devices - installation and maintenance recommendations

Related pages

- Pretreatment selection tool

- Overview and methods of pretreatment

- Overviews for different types of pretreatment practices

- Information for specific types of pretreatment practices

- Design, construction, operation and maintenance specifications for pretreatment vegetated filter strips

- Pretreatment - Hydrodynamic separation devices

- Pretreatment - Screening and straining devices, including forebays

- Pretreatment - Above ground and below grade storage and settling devices

- Pretreatment - Filtration devices and practices

- Pretreatment - Other pretreatment water quality devices and practices

- To see the above pages as a single page, link here

Pretreatment sizing for basins and filters strips

Guidance for managing sediment and wastes collected by pretreatment practices

Tables

- Pretreatment tables - link to tabled information for pretreatment practices

- Hydrodynamic separator tables

- Screening and straining devices tables

- Above ground and below grade storage and settling tables

- Filtration tables

- Other water quality devices tables

Other information and links

This page was last edited on 28 January 2023, at 17:27.