Difference between revisions of "Construction specifications for bioretention"

m |

|||

| Line 154: | Line 154: | ||

*Filter fabric specifications | *Filter fabric specifications | ||

| − | === | + | ===Alleviating compaction resulting from construction=== |

| + | |||

| + | Alleviation of compaction of disturbed soil is crucial to the installation of successful vegetated stormwater infiltration practices. | ||

| + | |||

| + | |||

| + | While natural processes can alleviate soil compaction, additional techniques to alleviate soil compaction are often desirable because:*it can take many years for natural processes to loosen up soil; | ||

| + | |||

| + | *natural processes operate primarily within the first foot or so of soil, and compaction from development can extend to two feet deep; and | ||

| + | |||

| + | *once soil compaction becomes so severe that plants and soil microbes can no longer thrive, natural processes are no longer able to reduce soil compaction | ||

| + | |||

| + | The most effective method for alleviating compaction is to add [[Turf#Compost|compost]] amendment. An additional technique for alleviating compaction is subsoiling or soil ripping. Ripping is most effective when used in conjunction with compost and/or sand amendment. | ||

| + | |||

| + | |||

| + | ===Soil ripping=== | ||

| + | The goal of soil ripping or subsoiling is to fracture compacted soil. Soil compaction occurs most frequently with soils having a high clay content. Fracturing compacted soil promotes root penetration by reducing soil density and strength, improving moisture infiltration and retention, and increasing air spaces in the soil. Compacted layers typically develop 12 to 22 inches below the surface when heavy equipment is used. Conventional cultivators cannot reach deep enough to break up this compaction. Subsoilers (rippers) can break up the compacted layer without destroying soil aggregate structure, surface vegetation, or mixing soil layers (Kees, 2008). | ||

| + | How effectively compacted layers are fractured depends on the soil's moisture, structure, texture, type, composition, porosity, density, and clay content. Success depends on the type of equipment selected, its configuration, and the speed with which it is pulled through the ground. No one piece of equipment or configuration works best for all situations and soil conditions, making it difficult to define exact specifications for subsoiling equipment and operation. | ||

| + | Shank design affects subsoiler performance, shank strength, surface and residue disturbance, effectiveness in fracturing soil, and the horsepower required to pull the subsoiler. According to Kees (2008), “Parabolic shanks require the least amount of horsepower to pull. In some forest applications, parabolic shanks may lift too many stumps and rocks, disturb surface materials, or expose excess subsoil. Swept shanks tend to push materials into the soil and sever them. They may help keep the subsoiler from plugging up, especially in brush, stumps, and slash. Straight or "L" shaped shanks have characteristics that fall somewhere between those of the parabolic and swept shanks.” | ||

| + | Shanks are available with winged tips and conventional tips. Winged tips cost more than conventional tips and require more horsepower, but can often be spaced farther apart. Increasing wing width also increases critical depth – the depth below which little soil loosening occurs (Owen 1987, Spoor 1978). Using shallow leading tines ahead of deeper tines also increases required shank spacing (Spoor 1978). According to Kees (2008), the shank’s tip should run to a depth of 1-2 inches below the compacted layer (see Figure 6.4). Kees (2008) alsorecommends making sure that the shanks on the subsoiler are spaced so that they run in the tracks of the tow vehicle, because the equipment used to pull subsoilers is heavy enough to create compaction itself. | ||

| + | |||

| + | |||

| + | Kees (2008) recommends following ground contours whenever possible when subsoiling to “increase water capture, protect water quality, and reduce soil erosion.” He also states that “in some cases, two passes at an angle to each other may be required to completely fracture compacted soil.” Spoor and Godwin (1978) also found that “Relatively closely spaced tines, staggered to prevent blockage, are more efficient at producing complete loosening than repeated passes with tines at wider spacings.” | ||

| + | Soils should be mostly dry and friable. Urban (2008) describes ideal conditions for compaction reduction as follows: “soil moisture must be between field capacity and wilt point during compactionreduction for maximum effectiveness. | ||

| + | Always know where utilities are buried prior to subsoiling. Avoid subsoiling in area that have buried utilities, wires, pipes, culverts, or diversion channels (Kees 2008, Urban 2008). | ||

| + | Soil ripping will generally be more effective with the addition of an amendment. This can be either sand or compost. Tilling in compost amendment may not be desirable on sites with steep slopes, a high water table, wet saturated soils, or downhill slope toward a house foundation (Schueler Technical Note #108) or where there are tree roots or utilities, or where nutrients leaching from compost would pose a problem. Since soil restoration techniques will need to be tailored to site conditions, a prescriptive soil restoration specification is not recommended. However, Pennsylvania, Virginia, and Washington State have specifications for soil amendment and restoration and these may be used as guidance in determining how to amend a compacted soil. | ||

| + | Cost for subsoiling varies by project. The Pennsylvania Stormwater Best Management Practices Manual estimates the cost of tilling soils ranges from $800 to $1000 per acre, while the cost of compost amending soil is about the same. | ||

| + | |||

| + | |||

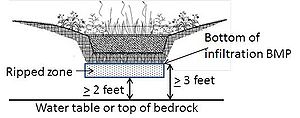

| + | [[File:Illustration of depth to bedrock or wt.jpg|300px|thumb|alt=schematic illustrating separation distance from bottom of infiltration BMP and soil ripped zones to water table or top of bedrock|<font size=3>Schematic illustrating separation distance from bottom of infiltration BMP and soil ripped zones to water table or top of bedrock</font size>]] | ||

| + | |||

| + | |||

| + | |||

| + | For basins larger than 1000 square feet, if compaction is above ideal bulk density indicated in the table below the soil should be remediated as follows: | ||

| + | |||

| + | *Rip to a depth of 18 inches where feasible | ||

| + | |||

| + | *For clay subsoil, incorporate 2 inches of sand. For bioretention without an underdrain,MnDOT Type 2 compost may be incorporated instead of sand. | ||

| + | |||

| + | *Maintain a 3 foot minimum separation distance between the bottom of the infiltration practice andthe seasonally high water table or bedrock. If soil ripping is utilized, the requirement is a 2 foot minimum between the bottom of the ripped zone and a 3 foot minimum from the bottom of the infiltration practice to the water table or top of bedrock. If there is only a 3 foot separation distance betweenthe bottom of the infiltration practice and the elevation of the seasonallyhigh water table or bedrock, limit ripping depth to 1 foot (12 inches). | ||

| + | |||

| + | [[General relationship of soil bulk density to root growth based on soil texture]] | ||

| + | |||

| + | ===Native plants, planting and transplanting=== | ||

*Site preparation of planting areas | *Site preparation of planting areas | ||

*Timing of native seeding and native planting | *Timing of native seeding and native planting | ||

| Line 160: | Line 202: | ||

*Watering of plant material | *Watering of plant material | ||

| − | === | + | ===Construction sequence scheduling=== |

*Temporary construction access | *Temporary construction access | ||

*Location of silt fence installation to protect BMPs and downstream receiving waters | *Location of silt fence installation to protect BMPs and downstream receiving waters | ||

| Line 173: | Line 215: | ||

*Silt fence removal | *Silt fence removal | ||

| − | === | + | ===Construction observation=== |

*Adherence to construction documents | *Adherence to construction documents | ||

*Verification of physical site conditions | *Verification of physical site conditions | ||

Revision as of 18:37, 11 February 2014

This page provides construction details, materials specifications and construction specifications for bioretention systems.

Contents

- 1 Construction details

- 2 Materials specifications - filter media

- 2.1 Filter media depth

- 2.2 Performance specifications

- 2.3 Guidance for bioretention media composition

- 3 Construction specifications

- 4 Related pages

Construction details

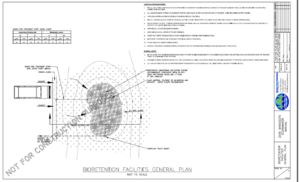

CADD based details for bioretention are contained in the Computer-aided design and drafting (CAD/CADD) drawings section. The following details, with specifications, have been created for bioretention systems:

- Bioretention Facilities General Plan

- Bioretention Facilities Performance Types Cross-Sections

- Infiltration / Recharge Facility

- Filtration / Partial Recharge Facility

- Infiltration / Filtration / Recharge Facility

- Filtration Only Facility

Materials specifications - filter media

The anticipated review period for this page is through March 2014

Filter media depth

Research has shown that minimum bioretention soil media depth needed varies depending on the target pollutant(s).

Minimum bioretention soil media depths recommended to target specific stormwater pollutants. From Hunt et al. (2012) and Hathaway et al., (2011). NOTE: The Construction Stormwater permit requires a 3 foot separation from the bottom of an infiltration practice and bedrock or seasonally saturated soils.

Link to this table

| Pollutant | Depth of Treatment with upturned elbow or elevated underdrain | Depth of Treatment without underdrain or with underdrain at bottom | Minimum depth |

|---|---|---|---|

| Total suspended solids (TSS) | Top 2 to 3 inches of bioretention soil media | Top 2 to 3 inches of bioretention soil media | Not applicable for TSS because minimum depth needed for plant survival and growth is greater than minimum depth needed for TSS reduction |

| Metals | Top 8 inches of bioretention soil media | Top 8 inches of bioretention soil media | Not applicable for metals because minimum depth needed for plant survival and growth is greater than minimum depth needed for metals reduction |

| Hydrocarbons | 3 to 4 inch Mulch layer, top 1 inch of bioretention soil media | 3 to 4 inches Mulch layer, top 1 inch of bioretention soil media | Not applicable for hydrocarbons because minimum depth needed for plant survival and growth is greater than minimum depth needed for hydrocarbons reduction |

| Nitrogen | From top to bottom of bioretention soil media; Internal Water Storage Zone (IWS) improves exfiltration, thereby reducing pollutant load to the receiving stream, and also improves nitrogen removal because the longer retention time allows denitrification to occur underanoxic conditions. | From top to bottom of bioretention soil media | Retention time is important, so deeper media is preferred (3 foot minimum) |

| Particulate phosphorus | Top 2 to 3 inches of bioretention soil media. | Top 2 to 3 inches of bioretention soil media. | Not applicable for particulate phosphorus because minimum depth needed for plant survival and growth is greater than minimum depth needed for particulate phosphorus reduction |

| Dissolved phosphorus | From top of media to top of submerged zone. Saturated conditions cause P to not be effectively stored in submerged zone. | From top to bottom of bioretention soil media | Minimum 2 feet, but 3 feet recommended as a conservative value; if IWS is included, keep top of submerged zone at least 1.5 to 2 feet from surface of media |

| Pathogens | From top of soil to top of submerged zone. | From top to bottom of bioretention soil media | Minimum 2 feet; if IWS is included, keep top of submerged zone at least 2 feet from surface of media |

| Temperature | From top to bottom of bioretention soil media; Internal Water Storage Zone (IWS) improves exfiltration, thereby reducing volume of warm runoff discharged to the receiving stream, and also improves thermal pollution abatement because the longer retention time allows runoff to cool more before discharge. | From top to bottom of bioretention soil media | Minimum 3 feet, with 4 feet preferred |

Performance specifications

The following performance specifications are applicable to all bioretention media.

- Growing media must be suitable for supporting vigorous growth of selected plant species.

- The pH range (Soil/Water 1:1) is 6.0 to 8.5

- Soluble salts (soil/Water 1:2) should not to exceed 500 parts per million

- All bioretention growing media must have a field tested infiltration rate between 1 and 8 inches per hour. Growing media with slower infiltration rates could clog over time and may not meet drawdown requirements. Target infiltration rates should be no more than 8 inches per hour to allow for adequate water retention for vegetation as well as adequate retention time for pollutant removal. The following infiltration rates should be achieved if specific pollutants are targeted in a watershed.

- Total suspended solids: Any rate is sufficient, 2 to 6 inches recommended

- Pathogens: Any rate is sufficient, 2 to 6 inches recommended

- Metals: Any rate is sufficient, 2 to 6 inches recommended

- Temperature: slower rates are preferable (less than 2 inches per hour)

- Total nitrogen (TN): 1 to 2 inches per hour, with 1 inch per hour recommended

- Total phosphorus (TP): 2 inches per hour

The following additional bioretention growing media performance specifications are required to receive P reduction credit.

- Option A - use bioretention soil with phosphorus content between 12 and 30 mg/kg per Mehlich III test

- Option B - include a soil amendment that facilitates adsorption of phosphorus

Cation exchange capacity (CEC) is a measure of a soil's ability to adsorb and exchange cations. A CEC of 10 milliequivalents or greater per gram of soil is recommended.

Guidance for bioretention media composition

Mix A: Water quality blend

A well blended, homogenous mixture of

- 60 to 70 percent construction sand;

- 15 to 25 percent top soil; and

- 15 to 25 percent organic matter.

- Sand: Provide clean construction sand, free of deleterious materials. AASHTO M-6 or ASTM C-33 washed sand.

- Top Soil: Sandy loam, loamy sand, or loam texture per USDA textural triangle with less than 5 percent clay content

- Organic Matter: MnDOT Grade 2 compost is recommended. (see also the section on Using Compost as a Soil Amendment

It is assumed this mix will leach phosphorus. When an underdrain is utilized a soil phosphorus test is needed to receive water quality credits for the portion of stormwater captured by the underdrain. The phosphorus index (P-index) for the soil must be low, between 10 and 30 milligrams per kilogram when using the Mehlich-3 test. This is enough phosphorus to support plant growth without exporting phosphorus from the cell.

Mix B: Enhanced filtration blend

A well-blended, homogenous mixture of

- 70 to 85 percent construction sand; and

- 15 to 30 percent organic matter.

- Sand: Provide clean construction sand, free of deleterious materials. AASHTO M-6 or ASTM C-33 washed sand.

- Top Soil in the mix will help with some nutrient removal, especially nutrients, but extra care must be taken during construction to inspect the soils before installation and to avoid compaction.

- Organic Matter: MnDOT Grade 2 compost is recommended. (see also the section on Using Compost as a Soil Amendment

It is assumed this mix will leach phosphorus. When an underdrain is utilized a soil phosphorus test is needed to receive water quality credits for the portion of stormwater captured by the underdrain. The phosphorus index (P-index) for the soil must be low, between 10 and 30 milligrams per kilogram when using the Mehlich-3 test. This is enough phosphorus to support plant growth without exporting phosphorus from the cell.

Mix C: North Carolina State University water quality blend (North Carolina Department of Environment and Natural Resources. 2009)

This mix is a homogenous soil mix of

- 85 to 88 percent by volume sand (USDA Soil Textural Classification);

- 8 to 12 percent fines by volume (silt and clay); and

- 3 to 5 percent organic matter by weight (ASTM D 2974 Method C) MnDOT Grade 2 compost is recommended.

A higher concentration of fines (12 percent) should be reserved for areas where nitrogen is the target pollutant. In areas where phosphorus is the target pollutant, a lower concentration of fines (8 percent) should be used. A soil phosphorus test using the Mehlich-3 method is recommended but not required to receive water quality credits. The phosphorus index (P-index) for the soil must be low, between 10 and 30 milligrams per kilogram. This is enough phosphorus to support plant growth without exporting phosphorus from the cell. It is assumed this mix will not exceed the upper range of recommended values (30 milligrams per kilogram), although at lower concentrations of organic matter a soil test may be needed to confirm there is adequate phosphorus for plant growth.

Mix D

Bioretention Soil Mix D soil shall be a mixture of coarse sand, compost and topsoil in proportions which meet the following:

- silt plus sand (combined): 25 to 40 percent, by dry weight

- total sand: 60 to 75 percent, by dry weight

- total coarse and medium sand: minimum of 55 percent of total sand, by dry weight

- fine gravel less than 5 millimeters: up to 12 percent by dry weight (calculated separately from sand/silt/ clay total)

- organic matter content: 2 to 5 percent, percent loss on ignition by dry weight; MnDOT Grade 2 compost is recommended.

- saturated hydraulic conductivity: 1 to 4 inches per hour ASTM F1815. Note that although this infiltration rate is generally applicable at 85 percent compaction, Standard Proctor ASTM D968, this is an infiltration rate standard and not a compaction standard. Therefore, this infiltration rate may be met at lower levels of compaction.

Suggested mix ratio ranges are

- Coarse sand: 50 to 65 percent

- Topsoil: 25 to 35 percent

- Compost (assuming MnDOT Grade 2 compost is being used): 10 to 15 percent

A soil phosphorus test using the Mehlich-3 method is recommended but not required to receive water quality credits. The phosphorus index (P-index) for the soil must be low, between 10 and 30 milligrams per kilogram. This is enough phosphorus to support plant growth without exporting phosphorus from the cell. It is assumed this mix will not exceed the upper range of recommended values (30 milligrams per kilogram), although at lower concentrations of organic matter a soil test may be needed to confirm there is adequate phosphorus for plant growth.

Comparison of pros and cons of bioretention soil mixes

Link to this table.

| Mix | Composition in original Manual | Proposed updated composition | Pros | Cons |

|---|---|---|---|---|

| A |

|

|

Likely to sorb more dissolved P and metals than mix B because it contains some fines; best for growth of most plants | Likely to leach P; if topsoil exceeds maximum allowed clay content, higher fines content could result in poor hydraulic performance and long drawdown times |

| B |

|

|

Easy to mix; least likely to clog | Likely to leach P, lack of fines in mix results in less dissolved pollutant removal; harder on most plants than mix A because it dries out very quickly |

| C | Not in original MN Stormwater Manual |

|

Likely to sorb more dissolved P and metals than mix B because it contains some fines; less likely to leach P than mix B because of low P content | Harder on most plants than mix A because it dries out very quickly. Research in Wisconsin indicates that in cold climates, excess of Na ions can promote displacement of Mg and Ca in the soil, which breaks down soil structure and decreases infiltration rate, and can also cause nutrient imbalances1 |

| D | Not in original MN Stormwater Manual |

|

Best for pollutant removal, moisture retention, and growth of most plants; less likely to leach P than mix B because of low P content | Harder to find. Research in Wisconsin indicates that in cold climates, excess of Na ions can promote displacement of Mg and Ca in the soil, which breaks down soil structure and decreases infiltration rate, and can also cause nutrient imbalances |

| E | Not in original manual |

|

High infiltration rates, relatively inexpensive | As compost breaks down, nutrients available for plants decreases |

| F | Not in original manual |

|

Finer particles in loamy sand holds moisture for better plant growth | Lower infiltration rates, requires careful soil placement to avoid compaction, requires custom mixing |

1This problem can be avoided by minimizing salt use. Sodium absorption ratio (SAR) can be tested; if the SAR becomes too high, additions of gypsum (calcium sulfate) can be added to the soil to free the Na and allow it to be leached from the soil (Pitt et al in press).

2MnDOT Grade 2 compost is recommended.

Other media

Several other media are currently being tested. A few examples are listed below.

Wisconsin peat moss replacement (Bannerman, 2013)

The following mix utilizes peat moss instead of compost.

- 12 percent peat moss*2 percent Imbrium Sorptive®MEDIA*86 percent sand

This mix aims to maximize phosphorus removal in 2 ways:

- substituting peat moss for compost, since peat moss has lower phosphorus content than compost and does not leach phosphorus; and

- including Sorptive®MEDIA to sorb phosphorus and minimize phosphorus in effluent

Wisconsin layered system

This layered system is designed to minimize phosphorus in bioretention effluent.

Construction specifications

Given that the construction of bioretention practices incorporates techniques or steps which may be considered non-traditional, it is recommended that the construction specifications include the following format and information:

A. Temporary erosion control

- It is REQUIRED that future bioretention locations not be used as temporary sedimentation basins unless 3 feet of cover is left in place during construction.

- If the bioretention area is excavated to final grade (or within 3 feet of) it is REQUIRED that rigorous erosion prevention and sediment controls (e.g. diversion berms) are used to keep sediment and runoff completetly away from the bioretention area.

- Install prior to site disturbance

- Protect catch basin/inlet

- Cover erodible surfaces, for example with plastic covers, that can be re-used.

B. Excavation, backfill and grading

- It is HIGHLY RECOMMENDED that prior to beginning the installation, sufficient material quantities shall be onsite to complete the installation and stabilize exposed soil areas without delay. *It is HIGHLY RECOMMENDED that excavation, soil placement and rapid stabilization of perimeter slopes be completed before the next precipitation event*Timing of grading of infiltration practices relative to total site development

- Use of low-impact, earth moving equipment (wide track or marsh track equipment, or light equipment with turf-type tires)

- Do not over-excavate

- Restoration in the event of sediment accumulation during construction of practice

- Alleviate any compacted soil (compaction can be alleviated at the base of the practice by using a primary tilling operation such as a chisel plow, ripper or sub-soiler to a minimum 12 inch depth

- Gravel backfill specifications

- Gravel filter specifications

- Filter fabric specifications

Alleviating compaction resulting from construction

Alleviation of compaction of disturbed soil is crucial to the installation of successful vegetated stormwater infiltration practices.

While natural processes can alleviate soil compaction, additional techniques to alleviate soil compaction are often desirable because:*it can take many years for natural processes to loosen up soil;

- natural processes operate primarily within the first foot or so of soil, and compaction from development can extend to two feet deep; and

- once soil compaction becomes so severe that plants and soil microbes can no longer thrive, natural processes are no longer able to reduce soil compaction

The most effective method for alleviating compaction is to add compost amendment. An additional technique for alleviating compaction is subsoiling or soil ripping. Ripping is most effective when used in conjunction with compost and/or sand amendment.

Soil ripping

The goal of soil ripping or subsoiling is to fracture compacted soil. Soil compaction occurs most frequently with soils having a high clay content. Fracturing compacted soil promotes root penetration by reducing soil density and strength, improving moisture infiltration and retention, and increasing air spaces in the soil. Compacted layers typically develop 12 to 22 inches below the surface when heavy equipment is used. Conventional cultivators cannot reach deep enough to break up this compaction. Subsoilers (rippers) can break up the compacted layer without destroying soil aggregate structure, surface vegetation, or mixing soil layers (Kees, 2008). How effectively compacted layers are fractured depends on the soil's moisture, structure, texture, type, composition, porosity, density, and clay content. Success depends on the type of equipment selected, its configuration, and the speed with which it is pulled through the ground. No one piece of equipment or configuration works best for all situations and soil conditions, making it difficult to define exact specifications for subsoiling equipment and operation. Shank design affects subsoiler performance, shank strength, surface and residue disturbance, effectiveness in fracturing soil, and the horsepower required to pull the subsoiler. According to Kees (2008), “Parabolic shanks require the least amount of horsepower to pull. In some forest applications, parabolic shanks may lift too many stumps and rocks, disturb surface materials, or expose excess subsoil. Swept shanks tend to push materials into the soil and sever them. They may help keep the subsoiler from plugging up, especially in brush, stumps, and slash. Straight or "L" shaped shanks have characteristics that fall somewhere between those of the parabolic and swept shanks.” Shanks are available with winged tips and conventional tips. Winged tips cost more than conventional tips and require more horsepower, but can often be spaced farther apart. Increasing wing width also increases critical depth – the depth below which little soil loosening occurs (Owen 1987, Spoor 1978). Using shallow leading tines ahead of deeper tines also increases required shank spacing (Spoor 1978). According to Kees (2008), the shank’s tip should run to a depth of 1-2 inches below the compacted layer (see Figure 6.4). Kees (2008) alsorecommends making sure that the shanks on the subsoiler are spaced so that they run in the tracks of the tow vehicle, because the equipment used to pull subsoilers is heavy enough to create compaction itself.

Kees (2008) recommends following ground contours whenever possible when subsoiling to “increase water capture, protect water quality, and reduce soil erosion.” He also states that “in some cases, two passes at an angle to each other may be required to completely fracture compacted soil.” Spoor and Godwin (1978) also found that “Relatively closely spaced tines, staggered to prevent blockage, are more efficient at producing complete loosening than repeated passes with tines at wider spacings.”

Soils should be mostly dry and friable. Urban (2008) describes ideal conditions for compaction reduction as follows: “soil moisture must be between field capacity and wilt point during compactionreduction for maximum effectiveness.

Always know where utilities are buried prior to subsoiling. Avoid subsoiling in area that have buried utilities, wires, pipes, culverts, or diversion channels (Kees 2008, Urban 2008).

Soil ripping will generally be more effective with the addition of an amendment. This can be either sand or compost. Tilling in compost amendment may not be desirable on sites with steep slopes, a high water table, wet saturated soils, or downhill slope toward a house foundation (Schueler Technical Note #108) or where there are tree roots or utilities, or where nutrients leaching from compost would pose a problem. Since soil restoration techniques will need to be tailored to site conditions, a prescriptive soil restoration specification is not recommended. However, Pennsylvania, Virginia, and Washington State have specifications for soil amendment and restoration and these may be used as guidance in determining how to amend a compacted soil.

Cost for subsoiling varies by project. The Pennsylvania Stormwater Best Management Practices Manual estimates the cost of tilling soils ranges from $800 to $1000 per acre, while the cost of compost amending soil is about the same.

For basins larger than 1000 square feet, if compaction is above ideal bulk density indicated in the table below the soil should be remediated as follows:

- Rip to a depth of 18 inches where feasible

- For clay subsoil, incorporate 2 inches of sand. For bioretention without an underdrain,MnDOT Type 2 compost may be incorporated instead of sand.

- Maintain a 3 foot minimum separation distance between the bottom of the infiltration practice andthe seasonally high water table or bedrock. If soil ripping is utilized, the requirement is a 2 foot minimum between the bottom of the ripped zone and a 3 foot minimum from the bottom of the infiltration practice to the water table or top of bedrock. If there is only a 3 foot separation distance betweenthe bottom of the infiltration practice and the elevation of the seasonallyhigh water table or bedrock, limit ripping depth to 1 foot (12 inches).

General relationship of soil bulk density to root growth based on soil texture

Native plants, planting and transplanting

- Site preparation of planting areas

- Timing of native seeding and native planting

- Weed control

- Watering of plant material

Construction sequence scheduling

- Temporary construction access

- Location of silt fence installation to protect BMPs and downstream receiving waters

- Removal and storage of excavated material

- Installation of underground utilities

- Rough grading

- Seeding and mulching disturbed areas

- Road construction

- Final grading

- Site stabilization

- Installation of semi-permanent and permanent erosion control measures

- Silt fence removal

Construction observation

- Adherence to construction documents

- Verification of physical site conditions

- Erosion control measures installed appropriately

Related pages

- Overview for bioretention

- Types of bioretention

- Design criteria for bioretention

- Construction specifications for bioretention

- Operation and maintenance of bioretention

- Cost-benefit considerations for bioretention

- External resources for bioretention

- References for bioretention

- Requirements, recommendations and information for using bioretention BMPs in the MIDS calculator