Difference between revisions of "Design guidelines for soil characteristics - tree trenches and tree boxes"

m (→Guidelines) |

m |

||

| Line 290: | Line 290: | ||

*Smiley, E. Thomas, Lisa Calfee, Bruce R. Fraedrich, and Emma J. Smiley. 2006. Comparison of Structural and Noncompacted Soils for Trees Surrounded by Pavement. Arboriculture & Urban Forestry 32(4): 164-169. | *Smiley, E. Thomas, Lisa Calfee, Bruce R. Fraedrich, and Emma J. Smiley. 2006. Comparison of Structural and Noncompacted Soils for Trees Surrounded by Pavement. Arboriculture & Urban Forestry 32(4): 164-169. | ||

*Urban, J. 1992. Bringing Order to the Technical Dysfunction Within the Urban Forest. Journal of Arboriculture 18(2): 85-90. | *Urban, J. 1992. Bringing Order to the Technical Dysfunction Within the Urban Forest. Journal of Arboriculture 18(2): 85-90. | ||

| + | |||

| + | <!-- | ||

| + | |||

| + | |||

| + | |||

| + | I. Soil QualitySpecification | ||

| + | |||

| + | |||

| + | |||

| + | Atthis time, most LID manuals only address trees in traditional bioretentionpractices, i.e. they do not provide separate soil specifications for systemsthat use only urban trees (i.e. without herbaceous vegetation.) In nature,trees typically grow with herbaceous vegetation in the same soils, butgenerally drier climates have fewer trees (i.e. more areas of herbaceousvegetation without trees) than wetter climates. I.e. in general tree soils needmore moisture holding capacity than soils that just support herbaceous plants(depending on the tree and herbaceous species). | ||

| + | |||

| + | |||

| + | |||

| + | Manufacturersof proprietary tree Stormwater BMP’s such as, for example, Silva Cells treesoil systems and CU structural soils, provide recommendations for soils to beused in their systems (see Task 5 for of those systems). | ||

| + | |||

| + | |||

| + | |||

| + | ThePuget Sound manual has a separate section on Urban trees (Hinman and Wulkan 2012) andprovides some guidance on soil quality and volume for trees, but does notinclude a soil specification for urban trees. | ||

| + | |||

| + | |||

| + | |||

| + | Manyjurisdictions have their own soil specifications for urban tree planting thatare not specifically targeted towards stormwater management and provideexcellent guidance regarding tree needs. | ||

| + | |||

| + | |||

| + | |||

| + | Manybooks about trees and soils also address what trees need in soil, such as, forexample, Urban 2008. | ||

| + | |||

| + | |||

| + | |||

| + | Thegoal of this draft report is to synthesize existing literature and research onsoils designed to optimize tree growth and soils designed for optimizedbioretention function. | ||

| + | |||

| + | |||

| + | |||

| + | Literature review of soils optimized for Tree Growth | ||

| + | |||

| + | |||

| + | |||

| + | Examplesof soil guidelines and specifications for optimized tree growth include thefollowing: | ||

| + | |||

| + | |||

| + | |||

| + | Toronto Street Trees.Guide to Standard Planting Options. 2010. City of Toronto Urban DesignStreetscape Manual. In collaboration with Parks, Forestry & Recreation.Downloaded September 2013 from: | ||

| + | |||

| + | http://wx.toronto.ca/inter/plan/streetscape.nsf/d2ee0d49ba602f3e85257457005a208d/491C15A190DCC0A7852576EB0066D3C5/$file/T-G-TreeGuide.pdf | ||

| + | |||

| + | |||

| + | |||

| + | High-quality soil shall consist of a minimum 0.9m and maximum1.2m depth, over and above any required drainage system and/or granularmaterial, be uncompacted, and be sandy loam with the following composition: | ||

| + | |||

| + | Sand (50%-60%) | ||

| + | |||

| + | Silt (20%-40%) | ||

| + | |||

| + | Clay (6%-10%) | ||

| + | |||

| + | Organic (2%-5%) | ||

| + | |||

| + | pH = 7.5 or less | ||

| + | |||

| + | |||

| + | |||

| + | DTAH et al 2013 treemanual for Toronto: | ||

| + | |||

| + | |||

| + | |||

| + | Recommends: | ||

| + | |||

| + | · pH 6.0 to 7.8 | ||

| + | |||

| + | · Drainage rates of between 12 mm and 75 mm per hourare considered optimum. Drainage rates must be measured in the field, however,soil can be tested in the lab if it is compacted to a prescribed density. | ||

| + | |||

| + | · Soil organic matter should be between 3% and 5%dry weight in the upper layer of the profile at the time the soil is installed.Organic matter in the lower soil level should be between 1.5% and 3% dry weight.This difference can be accomplished by making two different soils or simplytilling additional compost into the surface of the soil. | ||

| + | |||

| + | · See pages 56-62 for detailed conceptualexplanation of other tree soil requirements, including, for example, theimportance of soil structure and obtaining unscreened soil with soil pedstructure intact, recommendations for soil mixes and proportion of coarse tomedium sands; difference between natural soil organic matter and compost. | ||

| + | |||

| + | |||

| + | |||

| + | Urban 2008 book about urban trees: Up byRoots: Healthy Soils and Trees in the built environment | ||

| + | |||

| + | |||

| + | |||

| + | · Contains extensive explanations of tree soilneeds | ||

| + | |||

| + | · Some of the relevant highlights include: | ||

| + | |||

| + | |||

| + | |||

| + | · “The goal is to develop a soil that has gooddrainage capability, while providing adequate moisture and nutrient holdingcapacity for the plants.” | ||

| + | |||

| + | · “When sand is added to a soil, be sure that thefinal coarse to medium size sand content exceeds 50 percent. At lower amountsof sand, drainage rates are not increased.” | ||

| + | |||

| + | · “As the sand and aggregate content increasesabove 55 percent, the water-and nutrient holding capacity goes down and thedrainage rate goes up.” | ||

| + | |||

| + | · “High sand content soils are reliably drainedand more tolerant of a wide range of compaction rates. These soils are lesslikely to become over compacted, but require a continuous supply of water andnutrients, which increases maintenance.” [commentsfrom Kestrel team: directing stormwater to these soils lessens this problembecause it increases water and nutrient supply, though the trees will likelystill be exposed to periodic droughts] | ||

| + | |||

| + | · “As the sand is reduced in the mix, close to the55 percent threshold, compaction rates become critical. Too much compaction,and the drainage rates in finer-grained soil slow to unacceptable levels. Toolittle compaction in finer grained soil and soil settlement can unacceptable.The window between too much and too little compaction is hard to manage duringconstruction.” | ||

| + | |||

| + | · “Soil mix design is a multi-step process anddoes not end with the publication of specifications. The specifications shouldset performance standards and the types of mix components to be used. At thetime of writing the specifications the designer cannot know the actual sourceof the soil or organic amendment. Minor variations in these materials willchange the mix proportions.” | ||

| + | |||

| + | · “Testing of the soil to be used in the mix mustinclude the measuring of the difference sizes of sand particles, known as sandfractions.” | ||

| + | |||

| + | “A good measure to evaluate theperformance of a soil mix is its infiltration rate when compacted to a knownlevel. A developing standard is to test infiltration at 80 and 85 percent ofmaximum dry density as measured by the Proctor test.” | ||

| + | |||

| + | |||

| + | |||

| + | Literature review of soils optimized for bioretention | ||

| + | |||

| + | Usingtrees as stormwater BMP’s adds the following soil requirements to those oftraditional street trees that are not planted for stormwater management: | ||

| + | |||

| + | |||

| + | |||

| + | As more stormwater is directed to the trees, there is more danger of soils clogging, so limiting the fines content of the soil becomes more crucial. However, research shows that while the hydraulic conductivity of a bioretention practice typically decreases initially, hydraulic conductivity goes back up as plants and microbes improve soil structure over time and infiltration rate does not decrease significantly long term (Hatt et al 2009, Jenkins et al. 2010, Li & Davis 2008b, Barrett et al 2011). Where nutrient reduction in stormwater runoff is a goal, limiting nutrient content of the soil is required to minimize nutrient leaching from the soil. | ||

| + | |||

| + | |||

| + | |||

| + | Arepresentative sampling of the most recent and comprehensive literature onbioretention media guidelines is summarized below. | ||

| + | |||

| + | |||

| + | |||

| + | North CarolinaBioretention Soil Specification (referenced e.g. in North CarolinaDepartment of Environment and Natural Resources. 2009. Stormwater BMP ManualChapter 12: Bioretention. Revised 07-24-09. http://portal.ncdenr.org/c/document_library/get_file?uuid=199a62d4-3066-4e24-a3f1-088c6932483a&groupId=38364) | ||

| + | |||

| + | · One of the most widely used bioretention mediaspecifications in the US (i.e. several other states have also adopted it). | ||

| + | |||

| + | · May clog more easily in northern climates wherede-icers are used (Bannerman 2013, personal communication). [Note from Kestrelteam: recommend research to see if flushing salts out of the soil in spring withwater eliminates SAR effect). | ||

| + | |||

| + | · North Carolina’s bioretention standards recommendincorporating trees in all bioretention practices except for grassed cells: “Aminimum of one (1) tree, three (3) shrubs, and three (3) herbaceous speciesshould be incorporated in the bioretention planting plan unless it is a grassedcell.” | ||

| + | |||

| + | · Although there is some concern among treespecialists that this soil may have too little organic matter to grow healthytrees, this soil has been used extensively to grow trees with success in NorthCarolina (Winston and Hunt, 2013, personal communication). North Carolina doesreceive more annual precipitation than Minnesota, so moisture retention is morecrucial in Minnesota than in North Carolina and tree may not perform as well inMinnesota as in North Carolina in a soil with low moisture content. Research byFassman et al (2013), however, indicates that sand based bioretention media canhave as much plant available water as horticultural soils with less sand andmore organic matter. | ||

| + | |||

| + | Australian researchon using trees for bioretention: Breen 2004, Denman 2006, Denman 2011 (alldescribing same experiment) | ||

| + | |||

| + | Trees grew equally well in soils of a wide range of saturated hydraulic conductivities, and grew better irrigated with stormwater than irrigated with tapwater. “Trees were grown outdoors in experimental biofiltration systems, constructed with 240mm [9.45 inch] diameter columns, cut into 600mm[23.6 inch] lengths. The constructed soil profiles were 500mm [20 inch] deep with 10% (v:v) composted green waste added to the surface 200mm [8 inch]. The three soils used were sands with saturated hydraulic conductivities (SHC) of 4, 95 and 170mm per hour [0.16, 3.75 and 6.7 inches per hour] and the soils are referred to as low, medium and high SHC soil respectively.” “Tree growth was similar in the three soils studied.” (Denman 2006) Trees grew taller and had greater root density when irrigated with stormwater compared to tapwater. “The low SHC soil was more effective in reducing nitrogen losses, particularly the inorganic forms.” (Denman 2006) “Averaged across all species, planting results in an increase in infiltration rate compared to the unplanted control.” Breen et al 2004 | ||

| + | |||

| + | · See Task 2 Water Quality Draft Report for moreon this experiment. | ||

| + | |||

| + | |||

| + | |||

| + | Fassman et al 2013Bioretention Report for New Zealand | ||

| + | |||

| + | |||

| + | |||

| + | · 115 page report including: | ||

| + | |||

| + | · aliterature review of bioretention media | ||

| + | |||

| + | · a summaryof trends in how bioretention media specifications are changing over time basedon recent research and experience | ||

| + | |||

| + | · research to determine best bioretention mediafor New Zealand. | ||

| + | |||

| + | |||

| + | |||

| + | · Summary of Fassman et al (2013) literature review (see their report formuch more!): | ||

| + | |||

| + | · Common reasons for hydraulic failure ofbioretention media include: | ||

| + | |||

| + | · “Incorrect media specification, where the mediahas incorrect physical/chemical properties for removing targeted pollutants. | ||

| + | |||

| + | · Incorrect media specification, where the mediamay have high clay content or extremely fine particles, and vulnerability tocompaction which cause inadequate drainage and over-extended ponding. | ||

| + | |||

| + | · Incorrect compaction, often resulting from poorcompaction specifications or using media vulnerable to compaction. The media iseither under-compacted and too loose resulting in low contact time, orover-compacted and too dense resulting in inadequate drainage and over-extendedponding. | ||

| + | |||

| + | · Clogging, where excessive sediment loads restrictthe pores of the media, hindering infiltration and causing inadequate drainageand over-extended ponding. Clogging most commonly occurs at the surface ascrusting, capping, or sealing. Sediment from unstable catchments, catchmentswith active construction, or fine particles within the filter media contributeto clogging.” | ||

| + | |||

| + | · Cites that Warynski and Hunt (2011) “performed an inspection of 20 bioretention cellsthroughout the state. They found 82% of bioretention cell filter media havingincorrect particle size distributions (PSD), and 44% of bioretention cellshaving incorrect permeabilities. Furthermore, 50% of bioretention cells wereundersized.” | ||

| + | |||

| + | · Summarizes the following sampling of typicalbioretention media composition specifications: | ||

| + | |||

| + | · Saturated Hydraulic Conductivity: | ||

| + | |||

| + | § “Whilehydraulic conductivity initially declines as the filter media is compacted (seesection 5.5), FAWB (2009a) and Barret et al. (2011) found it often recoversback to the design value over time as increased plant root growth counters theeffects of compaction and clogging.” | ||

| + | |||

| + | § Summarizesworldwide sampling of typical bioretention media hydraulic conductivity specifications in Table x: | ||

| + | |||

| + | · Particle size distribution: | ||

| + | |||

| + | § “Particlesize distribution (PSD) is used as a gauge of a potential filter media’shydraulic performance of a filter media in several international guidelines.” | ||

| + | |||

| + | § “ParticleSize Distribution (PSD) may be a useful gauge of the potential hydraulicperformance of a filter media, but it should not be used to replace hydraulicconductivity testing.” | ||

| + | |||

| + | § “Aswell as meeting gradation limits, media should be well-graded over the entirerange to avoid structural collapse due to particle migration (FAWB, 2009a).” | ||

| + | |||

| + | · Compaction during construction: a worldwidesampling of specifications for compaction during construction is summarized intable x: | ||

| + | |||

| + | · Summary of Fassman et al (2013) results (see their report for muchmore!): | ||

| + | |||

| + | · Compaction of bioretention media: | ||

| + | |||

| + | § “If specificcompaction details (such as water content) are not designed for, filter mediamay easily be over or under compacted, leading to an undesirable hydraulicconductivity and potential failure of the bioretention cell. An advantage ofmaterials that are relatively insensitive to compaction is a greater certaintyof achieving design conductivity range.” | ||

| + | |||

| + | § “thedensity of predominantly sand based media are less susceptible to the effectsof compaction and water content.” | ||

| + | |||

| + | |||

| + | |||

| + | · Particle Size Distribution: | ||

| + | |||

| + | § Mixesthat met the author’s desired hydraulic conductivity range did not meetinternational Particle Size Distribution guidelines. The 3 that best fit theirdesired hydraulic conductivity range had higher fines than the recommendedguidelines, while two out of three are poorly graded. The authors conclude that“With this result, it is clear the PSD-based guidelines should not be used as asubstitute to hydraulic conductivity testing.” | ||

| + | |||

| + | § “A coarse sand (all passing 2 mm, with U 3) or highsilt/clay component (considered to be >20%, as might be found in naturalsoils) will be susceptible to the field installation compaction method, andhence so will be the hydraulic conductivity. In practice, if these materialsare used, careful installation procedures and post-installation testing ofinfiltration and/or bulk density would be strongly recommended.” | ||

| + | |||

| + | § “mixes that satisfied aggregate PSDs tended to produceextremely high hydraulic conductivities, even when mixed with relatively highlevels of compost (which also violates many international guidelines).” | ||

| + | |||

| + | |||

| + | |||

| + | · Plant Growth Trials | ||

| + | |||

| + | § Becausethe sand based bioretention media developed in this project had low organicmatter content (<10% v/v compost, equating to 1 - 3% g/g total carbon), andalso had very low clay and silt components, it was expected that plants mightnot grow well in them because they were thought to have little ability to storeand supply water and nutrients to the plants. Therefore the authors tested twoof their sand based mixes for plant growth compared to a rich horticulturalsoil mix, containing 30% compost by volume, known to grow vigorous plants. Theygrew 2 bioretention plant species for 6 months in pots of each of the threesoils, with a low rate of 9 month slow release fertilizer added to the sandbased mixes only. No differences in plant growth or plant available water wereobserved between the plants growing in sand based mixes vs. the horticulturalmix. They concluded that: “the volume of stored water that plants can accessfor growth is similar in all substrates, being 21 to 24% of the total soilvolume. This is because the two commercial mixes have a large amount of waterthat is held very tightly (to the organic matter) and therefore inaccessible toplants… It is unlikely the three sand-based mixes developed will be any moredrought prone than existing commercial mixes with high organic contents, as allstore similar volumes of plant-available water per unit depth...” If theseresults also hold true in longer term field experiments, plants should be ableto grow just as well in bioretention media with low organic matter content asin horticultural mixes designed for vigorous plant growth. Minimizing soilorganic matter content is crucial to maximize nutrient reduction bybioretention systems and to minimize nutrient leaching from the soil. | ||

| + | |||

| + | |||

| + | |||

| + | Australian guidelinesfor bioretention media (FAWB 2009) | ||

| + | |||

| + | · Based on extensive research | ||

| + | |||

| + | · Requires three layers of media: | ||

| + | |||

| + | · the filter media itself (400-600 mm [15.75 to23.62 inches] deep or as specified in the engineering design), | ||

| + | |||

| + | · a transition layer (100 mm [4 inches] deep), | ||

| + | |||

| + | · a drainage layer (50 mm [2 inches] minimum coverover underdrainage pipe). | ||

| + | |||

| + | · The biofiltration system will operate so thatwater will infiltrate into the filter media and move vertically down throughthe profile. | ||

| + | |||

| + | · “ required to support a range of vegetationtypes (from groundcovers to trees) that are adapted to freely draining soilswith occasional wetting” | ||

| + | |||

| + | · “ The material should be based on natural oramended natural soils or it can be entirely engineered… In the caseof natural or amended natural soils, the media should be a loamy sand.” | ||

| + | |||

| + | · “ In general, the media should have anappropriately high permeability under compaction and should be free of rubbish,deleterious material, toxicants, declared plants and local weeds (as listed inlocal guidelines/Acts), and should not be hydrophobic.” | ||

| + | |||

| + | · “ The filter media should contain some organicmatter for increased water holding capacity but be low in nutrient content.”Requires minimum 3% organic matter by weight; does NOT specify maximum organiccontent, just maximum nutrient content. [Note: research in North Carolinaindicates that using trees with suspended pavement and soils higher in organicmatter content can still attain good nutrient reduction if soil nutrientcontent is below NC standards, Jonathan Page, NC State, 2013, personal communication]. | ||

| + | |||

| + | · “Maintaining an adequate infiltration capacityis crucial in ensuring the long-term treatment efficiency of the system. Theability of a biofiltration system to detain and infiltrate incoming stormwateris a function of the filter surface area, extended detention (ponding) depth,and the hydraulic conductivity of the filter media. Most importantly, design ofa biofiltration system should optimize the combination of these three designelements.” | ||

| + | |||

| + | · “For a biofiltration system in a temperateclimate with an extended detention depth of 100 – 300 mm [4 -12 inches]and whose surface area is approximately 2% of theconnected impervious area of the contributing catchment, the prescribedhydraulic conductivity will generally be between 100 – 300 mm/hr [4 -12 inches/hr] in order to meet bestpractice targets... This configuration supports plant growth without requiringtoo much land space (italics added).” | ||

| + | |||

| + | · “The infiltration capacity of the biofiltrationsystem will initially decline during the establishment phase as the filtermedia settles and compacts, but this will level out and then start to increaseas the plant community establishes itself and the rooting depth increases”(FAWB 2009 based on research by Hatt et al 2009). | ||

| + | |||

| + | · “The hydraulic conductivity of potential filtermedia should be measured using the ASTM F1815-06 method. This test method usesa compaction method that best represents field conditions and so provides amore realistic assessment of hydraulic conductivity than other test methods.Note: if a hydraulic conductivity lower than 100 mm/hr [4 inches/hr] isprescribed, the level of compaction associated with this test method may be toosevere and so underestimate the actual hydraulic conductivity of the filtermedia under field conditions. However, FAWB considers this to be anappropriately conservative test, and recommends its use even for lowconductivity media.” [note from Kestrelteam, this is the same recommendation as in Urban 2008) | ||

| + | |||

| + | · “Particle size distribution (PSD) is ofsecondary importance compared with hydraulic conductivity. A material whose PSDfalls within the following recommended range does not preclude the need forhydraulic conductivity testing i.e., it does not guarantee that the materialwill have a suitable hydraulic conductivity. However, the following compositionrange (percentage w/w) provides a useful guide for selecting an appropriatematerial: | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | Clay and silt are important for water retention and sorption of dissolvedpollutants, however they substantially reduce the hydraulic conductivity of thefilter media. This size fraction also influences the structural stability ofthe material (through migration of particles to block small pores and/orslump). It is essential that the total clay and silt mix is less than 3% (w/w) toreduce the likelihood of structural collapse of such soils. The filter mediashould be well-graded i.e., it should have all particle size ranges presentfrom the 0.075 mm to the 4.75 mm sieve (as defined by AS1289.3.6.1 - 1995).There should be no gap in the particle size grading, and the composition shouldnot be dominated by a small particle size range. This is important for preventingstructural collapse due to particle migration.” | ||

| + | |||

| + | · “Total Nitrogen (TN) Content – <1000 mg/kg.“ | ||

| + | |||

| + | · “Orthophosphate (PO43-) Content – <80 mg/kg.Soils with total phosphorus concentrations >100 mg/kg should be tested forpotential leaching. Where plants with moderate phosphorus sensitivity are to beused, total phosphorus concentrations should be <20 mg/kg.“ [note fromKestrel team, this is higher than NC State recommendations] | ||

| + | |||

| + | · For engineered media, they recommend: | ||

| + | |||

| + | · “A washed, well-graded sand with an appropriatehydraulic conductivity should be used as the filter medium.” | ||

| + | |||

| + | · “The top 100 mm [4 inches] of the filter medium shouldthen be ameliorated with appropriate organic matter, fertiliser and traceelements... This amelioration is required to aid plant establishment and isdesigned to last four weeks; the rationale being that, beyond this point, theplants receive adequate nutrients via incoming stormwater.” [note from Kestrel team: this is similar tothe mixes being tested in MN and WI described in task 8 of Objective 2,bioretention, in that organic matter is included only in the top 4 inches] | ||

| + | |||

| + | --> | ||

Revision as of 01:14, 5 January 2014

The anticipated construction period for this page is through January, 2014

Contents

- 1 Soil volume guidelines

- 2 Soil quality guidelines

- 3 Definitions

- 4 References

Soil volume guidelines

Providing adequate rootable soil volume is crucial to growing healthy trees. Several researchers have investigated minimum soil volumes needed to grow healthy trees. Results from these studies have been used to develop the following guidelines. (See summary of research)

Recommended minimum soil volume requirements for urban trees

Based on research the recommended minimum soil volume is 2 cubic feet of rootable soil volume per square foot of mature tree canopy size. This soil is considered essential to healthy growth of trees. (See canopy size for several common tree species).

Stormwater volume credits for tree trenches and tree boxes include

- storage of water in the planting media;

- interception of rain water by the tree canopy; and

- evapotranspiration from the tree(s).

If only rock-based structural soil is used, the volume credit is limited to water storage in the media. The rock component of the structural soil should not be included in the volume calculation for evapotranspiration. The decrease in stormwater volume retained is assumed to be linear with decreases in soil volume below the minimum recommended volume. For example, if a rock-based structural soil is used that contains 80 percent rock and 20 percent soil, only the 20 percent soil component counts toward the evapotranspiration volume credit. This approach is utilized within the Minimal Impact Design Standards (MIDS) calculator.

Summary of literature review on soil volume

An extensive literature review was completed prior to developing the minimum soil volume recommendation discussed above.

Summary of research on minimum soils volumes needed

Minimum soil volume needed to grow healthy trees has been studies several ways, including

- field surveys investigating minimum soil volumes that grew healthy trees;

- calculation of minimum soil volume needed based on tree water requirements; and

- calculation of minimum soil volume needed based on tree nitrogen requirements (Kopinga 1991).

Each of these techniques indicates similar ranges of minimum soil volume needed:

- 1 to 3 cubic feet of soil per square foot of canopy; and

- 1000 to 2100 cubic feet of soil for a large tree (median of 1500 cubic feet and mean of 1506 cubic feet).

To put these numbers in perspective in relation to tree size and typical street tree spacing:

- Using the above numbers, a tree with 2 cubic feet of soil per square foot of canopy would need 1413 cubic feet of soil to grow 30 feet wide.

- Assuming 2 cubic feet of soil per square foot of canopy, 1,500 cubic feet of soil would be able to support a 31 foot wide tree.

Precedents for minimum soil volume standards

Because of the importance of providing adequate rootable soil volume to grow healthy trees, several jurisdictions have enacted minimum soil volume policies. These are summarized in the following table.

Examples of jurisdictions with minimum tree soil volume requirements

Link to this table.

| Jurisdiction | Minimum tree soil volume |

|---|---|

| Kitchener, Ontario, Canada |

|

| Emeryville, CA |

|

| Toronto, Ontario, Canada |

|

| Markham and Oakville, Ontario, Canada; Burnaby MetroTown Development Area, British Columbia, Canada |

|

| North Vancouver Lonsdale Street Guideline, British Columbia, Canada | 15 cubic meters (530 cubic feet) per tree for trees with shared volume |

| Calgary, Alberta, Canada | Provide for a volume of soil suitable for a 25 year tree life span, this is approximately 14 cubic meters [494 c.f.) for a single tree. An additional 7 cubic meters [247 c.f.] of soil is required for each additional tree in interconnected plantings |

| Langley, British Columbia, Canada |

|

| Winnipeg, Manitoba, Canada, Tree Planting Details and Specifications, Downtown Area and Regional Streets |

|

| Denver, CO | Internal (city) standard: 750 c.f. of soil volume per tree |

| University of Florida Extension Recommendations (Urban Design for a Wind Resistant Forest) |

|

| Minnesota B3 Guidelines |

|

Comparison of rock based structural soil and traditional tree soils

Research that compares rock based structural soil to loam soil indicates that significantly larger soil volumes are needed to produce the same size tree using structural soil vs. loam soils. Based on plant available water holding capacity alone, it would appear that approximately 1.5 times the amount of Cornell University (CU) structural soil is needed as needed to grow the same size tree growing in sandy loam (Bassuk 2010).

However, a pot study that compared growth of trees in CU structural soil to trees growing in loam indicates that tree growth in CU structural soil vs. loam soil is likely limited by more than just plant available water holding capacity, as the pot study found that 5 parts of structural soil were needed to provide the soil value of 1 part of loam soil (Loh et al, 2003). The pot study compared the growth of fig trees in structural soil and loam soil in pots over 500 days. Tree growth was compared in the following soil types and volumes:

- 0.4 cubic feet of loam soil (small loam soil)

- 0.4 cubic feet of structural soil(small structural soil)

- 2 cubic feet of loam soil (large loam soil)

- 2 cubic feet of structural soil (large structural soil).

There were no significant differences in above ground growth between trees in the small loam soil pots and the ones in the large structural soil, indicating that 5 times the amount of structural soil was needed to produce the same size tree grown in the small loam soil. As only 1/5 of structural soil is composed of soil, it appears that perhaps only the soil component of the structural soil is useable to the tree as growing medium. Longer term studies are recommended to confirm the exact proportion ofstructural soil needed to provide the value of 1 cubic foot of loam soil.

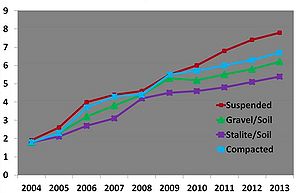

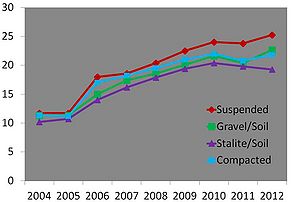

A study by Bartlett Tree Research Laboratories is finding that trees growing in loam soils in suspended pavement are growing better than trees grown in rock based structural soil (Smiley et al 2006, Smiley 2013). Since 2004, they have been comparing tree growth in natural soil under suspended pavement compared to growth of trees grown using other ways to prevent rooting volume compaction under pavements: stalite soil, and gravel soil (i.e. structural soil), as well as to trees grown in compacted soil. Each tree was provided 5.7 cubic meters (200 cubic feet) of rooting space. Throughout the 9 years since the trees were planted, Elm growth (trunk diameter and tree height) has been best in the suspendedpavement with natural soil.

Soil quality guidelines

At this time, most Low Impact Development (LID) manuals only address trees in traditional bioretention practices (i.e. they do not provide separate soil specifications for systems that use only urban trees without herbaceous vegetation). In nature, trees typically grow with herbaceous vegetation in the same soils, but generally drier climates have fewer trees (i.e. more areas of herbaceous vegetation without trees) than wetter climates. In general tree soils need more moisture holding capacity than soils that just support herbaceous plants (depending on the tree and herbaceous species). Manufacturers of proprietary tree Stormwater BMP’s such as, for example, Silva Cells tree soil systems and Cornell University (CU) structural soils, provide recommendations for soils to be used in their systems. The Puget Sound manual has a separate section on Urban trees (Hinman and Wulkan 2012) and provides some guidance on soil quality and volume for trees, but does not include a soil specificationfor urban trees. Many jurisdictions have their own soil specifications for urban tree planting that are not specifically targeted towards stormwater management but provide excellent guidance regarding tree needs. Books, such as Urban (2008), also address soil needs for trees.

This section provides a discussion of existing literature and research on soils designed to optimize tree growth and soils designed for optimized bioretention function.

Recommended soil for trees for stormwater

Bioretention Soil Mix D is recommended for bioretention with trees. Mixes B or C could also be used for bioretention with trees, but if mix B or C is used, limit the saturated hydraulic conductivity to a maximum of 4 inches per hour. Rock based structural soil may be used if volume provided conforms to tree soil volume requirements.

Bioretention Mix D consists of sand, unscreened topsoil, and compost per the guidelines below. It uses unscreened topsoil and recommends blending using a front end loader to preserve topsoil peds as much as possible. In an undisturbed soil, soil particles are clumped together into large units called peds. Peds range in size from the size of a large sand grain to several inches, so ped structure significantly increases pore space in the soil compared to a screened soil without peds. Pore spacesbetween soil peds improve air and water movement, water holding capacity, as well as root growth. Preserving ped structure is especially important in finer soils, because finer soils without ped structure have only very small pores and therefore lack permeability. Using an unscreened topsoil and preserving ped structure as much as possible allows for a higher clay content in Bioretention Soil Mix A compared to typical bioretention mixes because the ped structure maintains pore space and infiltration rates despite the higher clay content. The higher clay and silt content (25-40 percent by dry weight) is beneficial because it provides higher cation exchange capacity (for increased nutrientretention beneficial for plant growth and for increased pollutant removal) and higher water holding capacity (beneficial for plant growth).

Comparison of pros and cons of bioretention soil mixes

Link to this table.

| Mix | Composition in original Manual | Proposed updated composition | Pros | Cons |

|---|---|---|---|---|

| A |

|

|

Likely to sorb more dissolved P and metals than mix B because it contains some fines; best for growth of most plants | Likely to leach P; if topsoil exceeds maximum allowed clay content, higher fines content could result in poor hydraulic performance and long drawdown times |

| B |

|

|

Easy to mix; least likely to clog | Likely to leach P, lack of fines in mix results in less dissolved pollutant removal; harder on most plants than mix A because it dries out very quickly |

| C | Not in original MN Stormwater Manual |

|

Likely to sorb more dissolved P and metals than mix B because it contains some fines; less likely to leach P than mix B because of low P content | Harder on most plants than mix A because it dries out very quickly. Research in Wisconsin indicates that in cold climates, excess of Na ions can promote displacement of Mg and Ca in the soil, which breaks down soil structure and decreases infiltration rate, and can also cause nutrient imbalances1 |

| D | Not in original MN Stormwater Manual |

|

Best for pollutant removal, moisture retention, and growth of most plants; less likely to leach P than mix B because of low P content | Harder to find. Research in Wisconsin indicates that in cold climates, excess of Na ions can promote displacement of Mg and Ca in the soil, which breaks down soil structure and decreases infiltration rate, and can also cause nutrient imbalances |

| E | Not in original manual |

|

High infiltration rates, relatively inexpensive | As compost breaks down, nutrients available for plants decreases |

| F | Not in original manual |

|

Finer particles in loamy sand holds moisture for better plant growth | Lower infiltration rates, requires careful soil placement to avoid compaction, requires custom mixing |

1This problem can be avoided by minimizing salt use. Sodium absorption ratio (SAR) can be tested; if the SAR becomes too high, additions of gypsum (calcium sulfate) can be added to the soil to free the Na and allow it to be leached from the soil (Pitt et al in press).

2MnDOT Grade 2 compost is recommended.

General guidelines

The following guidelines are written in a format similar to a specification, and can serve as a basis for a specification, however, they are NOT a finished specification. Any specification for construction must be developed specifically for that project by a person skilled in writing specifications and construction documents. Additional items are needed particularly in Part One – General. Terminology and requirements in the final specifications must be consistent with the terminology in other parts of the construction documents including plans and detail nomenclature. Unless otherwise stated, the guidelines apply to growing media D.

Scheduling

Schedule all utility installations prior to beginning work in this section.

Submittals

Soil test analysis

Submit soil testing results from an approved soil-testing laboratory for each soil mix for approval. Soil suppliers that regularly prepare Bioretention Soil Mix D that meets these requirements may submit past testing of current production runs to certify that the mix to be supplied meets the requirements provided the testing results are less than 12 months prior to the submission date.

- The testing laboratory shall be a member of the Soil Science Society of America's, North American Proficiency Testing Program (NAPT). The testing lab shall specialize in agricultural soil testing. Geotechnical engineering soil testing labs are not acceptable.

- Testing shall comply with the requirements of the Methods of Soil Analysis Part 1 and 3, published by the Soil Science Society of America, or the ASTM testing required.

- Testing of topsoil and Bioretention Soil Mix D shall be required as defined below:

- Physical analysis.

- USDA particle size analysis shall be include, gravel, clay, silt, and coarse, medium and fine sand fractions.

- Hydraulic Conductivity testing (Bioretention Soil Mix D only) using ASTM F1815 at 80 percent and 85 percent compaction at proctor density (ASTM D 698-91). This is a LABORATORY TEST to determine water flow at specified compaction rates. Laboratories that provide thistesting include:

- Hummel Soil Labs, www.turfdoctor.com; (607) 387-5694,35 King Street, PO Box 606, Trumansburg, NY, 14886.

- Turf Diagnostics & Design, www.turfdiag.com; (913)-723-3700, 613 E. 1st Street, Linwood, KS, 66052.

- Chemical analysis. Note that nutrient levels and chemical analysis shall include recommendations from the testing laboratory for ranges of each element appropriate for the types of plants to be grown in the soil mix.

- Nutrient levels by parts per million including phosphorus, potassium, calcium, magnesium, manganese, iron, copper, zinc and calcium

- Percent organic content

- pH

- Soluble salt by electrical conductivity

- Cation Exchange Capacity (CEC)Chemical analysis shall be interpreted by the Owner based on plant material specified and testingrecommendations.

- Physical analysis.

Product Data

For each type of product including, soil cells, structural soil, coarse sand and compost, submit the manufacturer's product literature with technical data sufficient to demonstrate that the product meets the requirements of the specification.

Samples for Verification

Submit one gallon minimum samples for the Coarse Sand, Compost, Topsoil, Bioretention Soil Mix A and Structural Soil. Label samples to indicate product name, source and contractor. Samples will be reviewed for appearance only. Delivered materials shall closely match the samples.

Cone Penetrometer reading certification

Submit for approval, a written certification that the Bioretention Soil Mix A was sufficiently compacted to fall within the required resistance ranges. The Owner may verify the certification prior to approval.

Bioretention Soil Mix D compaction testing

- Bioretention Soil Mix A shall be tested in-situ with a cone penetrometer, to the full depth of the installed soil profile or 30 inches deep, whichever is less. This is a field test to confirm correct compaction. One test shall be performed approximately once every 300 square feet of Bioretention Soil Mix A surface area. The cone penetrometer shall be available at the project site at all time when the contractor is working.

- Maintain a volumetric moisture meter on site to verify that moisture readings were within the required ranges during the installation and testing.

- The cone penetrometer shall be “Dickey-John Soil Compaction Tester”, or “AgraTronix Soil Compaction Meter,” both distributed by Ben Meadows www.benmeadows.com*The contractor shall certify that penetration resistance readings meet the requirements. The contractor’s penetrometer shall be made available to the owner, at all times, to confirm resistance readings.

Delivery, storage and handling

When warranties are required, verify with Owner's counsel that special warranties stated in this article are not less thanremedies available to Owner under prevailing local laws.

- Bulk Materials: Do not deliver or place backfill, soils and soil amendments in frozen, or when the material is overly wet defined as the material sticks to the hand when squeezed.Retain subparagraph below for bare-root stock ifrequired; this is not an ANSI Z60.1 requirement.

- Provide protection including tarps, plastic and or matting between all bulk materials and any finished surfaces sufficient to protect the finish material.

- Provide erosion-control measures to prevent erosion or displacement of bulk materials and discharge ofsoil-bearing water runoff or airborne dust to adjacent properties, water conveyance systems, and walkways. Provide sediment control to retain excavated material, backfill, soil amendments and planting mix within the project limits as needed.

Project conditions

THIS SECTION NOT NEEDED THIS SECTION NOT NEEDED THIS SECTION NOTNEEDED THIS SECTION NOT NEEDED When warranties are required, verify with Owner's counsel that special warranties stated in this article are not less than remedies available to Owner under prevailing local laws.Do not proceed with work when sub grade soil is frozen, or is overly wet defined as the sub grade material sticks to the hand when squeezed.

Excavation around utilities

- Contractor shall carefully examine the civil, record, and survey drawings to become familiar with the existing underground conditions before digging. Notification of Local Utility Locator Service is required prior to all excavation.

Product guidelines

Coarse sand

- Coarse sand, ASTM C-33 Fine Aggregate, with a Fines Modulus Index of 2.8 and 3.2.

- Sands shall be clean, sharp, natural sands free of limestone, shale and slate particles.

- Sand pH shall be lower than 7.5

- Provide the following particle size distribution:

| Sieve size | % passing |

|---|---|

| 3/8 inch | Example |

| #4 | 95 to 100 |

| #8 | 80 to 100 |

| #16 | 50 to 85 |

| #30 | 25 to 60 |

| #50 | 5 to 30 |

| #100 | 4 to 10 |

| 3200 | 2 to 4 |

- Complete submittals.

Compost

Compost shall meet the requirements of the US Composting Council “Landscape Architecture/Design Specifications for Compost Use”, section “Compost as a Landscape Backfill Mix Component”, with the following additional requirements:

- Compost feedstock shall be yard waste trimmings and/or source-separated municipal solid waste to produce fungi-dominated compost. Compost shall not be derived from biosolids or industrial residuals.

- Compost physical appearance: Compost shall be dark brown approximately the color of a 70 percent dark chocolate bar or darker. Particles of compost when broken shall be the same color inside as outside.

- Compost odor: Compost shall have a strong, sweet, aerobic odor indicating active biological activity. Compost with a sour anaerobic odor (indicating composting in excessive water) or an odor similar to denatured alcohol (indicating incomplete composting) shall be rejected

- Compost testing and analysis: Compost analysis shall be provided by the Compost supplier. Before delivery of the compost, the supplier must provide the following documentation:

- A statement that the Compost meets federal and state health and safety regulations.

- Compost testing methodologies and sampling procedures shall be as provided in Test methods for the Examination of Composting and Compost (TMECC), as published by the US Composting Council.

- Complete submittals.

Topsoil

Topsoil texture shall be a naturally produced soil of loam, sandy loam to sandy clay loam, within the following parameters, and suitable for the germination of seeds and the support of vegetative growth. *Topsoil may contain up to 5 percent by volume stones, roots or masonry debris. Topsoil shall not contain metal debris, glass other sharp objects. Topsoil shall not contain any chemicals at levels that are harmful to plants, fish or exceed EPA limitations for human contact.

- Topsoil should not be screened or processed in a manner that breaks down soil peds. Soil peds of 2 inches in diameter or greater should be visible throughout the source pile.

- Manufactured topsoil where sand or compost has been added to a soil material to meet the specificationshall be rejected. Clumps or peds of soil within the sample shall be the same color and texture on the inside as the outside of the clump or ped.

- Physical Parameters

- Gravel: less than 10 percent by volume

- Sand: 30 to 70 percent by volume

- Silt: 10 to 50 percent by volume

- Clay: 10 to 25 percent percent by volume

- Chemical Parameters

- Organic Matter: 2 to 8 percent by dry weight

- pH: 5.0 to 7.3 (standard pH units)

- Phosphorous: Sufficient to meet the maximum requirements in the Plant/Bio-retention mix once the other products are added to the mix

- Complete submittals.

Bioretention Soil Mix D

Bioretention Soil Mix D soil shall be a mixture of coarse sand, compost and topsoil in proportions which meet the following:

- silt plus sand (combined) – 25 to 40 percent, by dry weight

- total sand – 60 to 75 percent, by dry weight

- total coarse and medium sand – minimum of 55 percent of total sand, by dry weight

- fine gravel less than 5 millimeters – up to 12 percent by dry weight (calculated separately from sand/silt/ clay total)

- organic matter content – 2 to 5 percent, percent loss on ignition by dry weight*saturated hydraulic conductivity – 1 to 4 inches per hour

- ASTM F1815 at 85 percent compaction, Standard Proctor ASTM D968*phosphorus between 12 and 36 parts per million (ppm)

- cation exchange capacity greater than 10 meq/g

Suggested mix ratio ranges are

- Coarse sand: 50 to 65 percent

- Topsoil: 25 to 35 percent

- Compost: 10 to 15 percent

It is understood that compost quality and particle size, coarse sand shape and variations in particle distribution , topsoil component, and silt / clay amounts within the tolerance will cause the soil blend within these suggested mix ratio ranges to drain too fast or too slow. The contractor shall adjust the final mix proportions to achieve the required drainage rate and percent organic matter. Any variation of required products, above or below the percentages listed below, needed to attain the required drainage rate or percent organic matter, shall not be grounds to change the agreed upon price of the installed material.

- Lightly mix the Bioretention Soil Mix A using a front end loader to preserve topsoil peds as much as possible. Topsoil peds 2 inches in diameter or larger should be visible in the finished stockpile. Do not over mix or screen the material.

- Submittals shall be completed per Section 1.4 and shall be interpreted by Owner based on plant material specified and testing recommendations.

Structural soil

- A mixture of stone and soil formulated to be compacted to 95% of maximum dry density, Standard Proctor and support tree roots.

- Structural Soil shall be “CU Soil” as manufactured by Amereq, Inc New York City, NY, or approved equal.

- Complete submittals.

Soil cells

Pre-engineered modular structures designed to hold up pavement and to be filled with soil to support tree roots and treat storm water, with the goal of protecting soil within the cells from compaction from the loads on the overlying pavement. Soil Cells shall be capable of supporting loads up to and including AASHTO H-20, when used in conjunction with approved pavement profiles.

Soil Cells shall meet the following requirements:

- The structure design shall permit an uninterrupted mass of soil throughout the structure. All openings between different cell units shall have a minimum area of 140 square inches to permit:

- a continuous mass of soil that allows for capillary transfer of water;

- fosters the growth of large tree roots including the zone of rapid taper roots that can become up to 12 inches in diameter at tree maturity; and permits the structure to be built around, over; under and thru existing and proposed utilities.

- Each cell stack shall be structurally independent of all adjacent stacks such that the cell layout can achieve maximum layout flexibility.

- The structure shall permit damp soils with large soil peds to be installed and the soil installed without vibrating the structure. The structural openings must allow all the soil to be checked for compaction and complete filling of all cell areas.

- The Soil Cell deck shall be perforated to allow the free flow of water thru the deck. Soil cell installation shall include all accessories, geotextiles, geogrids, and aggregate layers required by the Soil Cell manufacture.

- Complete submittals.

Execution guidelines

Site examination

Examine the surface grades and soil conditions for any circumstances that might bedetrimental to soil drainage.

Soil preparation

- Excavate to the proposed sub grade. Maintain all required angles of repose of the adjacent materials as shown on the drawings or as required to support adjacent materials or structures. Do not over excavate into compacted sub grades of adjacent pavement or structures. Remove all construction debris and material.

- Confirm that the sub grade is at the proper elevation and compacted as required. Sub grade elevations shall slope parallel to the finished grade and/or toward the subsurface drain lines as shown on the drawings.

- Protect adjacent walls, walks and utilities from damage or staining by the soil. Use ½ inch plywood and or plastic sheeting as directed to cover existing concrete, metal and masonry work and other items as directed during the progress of the work.

- Clean up any soil or dirt spilled on any paved surface, including at the end of each working day.

Soil cell installation

Install Soil Cells in accordance with the manufacturers requirements including all accessories, geotextile, geogrid, and aggregate layers.

Bioretention Mix D installation

- Loosen or till the subsoil of the sub grade to a depth of 2 to 3 inches, or as required, with a backhoe or other suitable device. Where required on the drawings or other requirements, loosen the subsoil to a depth of 18 to 24 inches below the required subgrade elevation to improve infiltration into the subgrade soil. Loosen the soilusing a backhoe by digging into the subgrade soil and lifting then dropping the soil in place. Do not over work the soil or break up the large clumps in the soil created by the process. Do not allow the loosened soil to become re-compacted by other work.

- Install all required drainage aggregate and drain lines.

- Install Bioretention Soil Mix A in approximately 12 inch lifts to the required depths. Lightly compact each lift with a maximum of two passes with a 5 HP vibrating plate tamper to achieve the required penetration resistance. Maintain volumetric soil moisture during installation and compaction at between 5 and 15 percent.

- Scarify the surface of each lift with the teeth of a back hoe or similar equipment prior to installing additional lifts.

- Do not drive over delivered soil to spread or grade. Install soil in narrow bands, working out from the installed soil such that soil delivery and spreading equipment does not have to pass over previously installed soil. The width of each band of installed soil shall not exceed the reach of the delivery equipment.

- Coordinate the installation of water harvesting distribution and drain lines within the Bioretention Soil Mix A.

- Install soil in Soil Cells according to the cell manufacturer’s requirements.

- Grade the finished surface of the Bioretention Soil Mix A to the grades indicated on the drawings plus extra soil for settlement as noted below.

- The Bioretention Soil Mix A when properly installed at the compaction levels indicated will continue to settle. It is not the intent of these requirements to construct a soil profile that is immediately stable. Add an additional 1 inch of soil for each 10 inches of installed soil depth. The grades shown on the drawings are the grades after the anticipated settlement.

- The tolerance for finished grades shall be plus or minus ½ inch in 10 feet.

Bioretention Soil Mix A compaction

Compact the Bioretention Soil Mix A so that the pressure reading of a cone penetrometer is between 75 and 200 psi with the volumetric soil moisture between 5 and 15 percent.

Structural soil installation

Install and compact Structural Soil in accordance with the manufactures requirements.

Cleanup

Once installation is complete, remove any excess soil and trash from pavements, structures or fixtures. Remove any spilled oil or other stains on surfaces caused by the work.

Protection

Protect work and materials from damage including: compaction, contamination, and erosion including due to operations by other Contractors or trespassers. Repair all damage and loosen compaction prior to acceptance.

Repair of settled Bioretention Soil Mix D

At the end of twelve months after the date of substantial completion of the Bioretention Soil Mix A installation work, inspect the site and restore any areas where the grades have settled beyond the elevations shown on the drawings by an amount greater than 5 percent of the soil depth.

Definitions

- Clay, silt and sand soil particles: Per USDA size designations. It is critical NOT to use testing laboratories that report results in engineering size designations such as the Unified or AASHTO systems.

- Coarse Sand: Process washed and graded sand from regional sand suppliers.

- Compost: Decomposed plant based biomass.

- Bioretention Soil Mix A: A mixture of Topsoil, Coarse Sand and Compost intended to fill bio- retention planters to support the treatment ofstorm water and the growth of trees and other plants.

- Screened Soil: Any soil run through any type of screen with a mesh size 3 inches square or smaller.

- Soil Cells: also called structural cells; pre-engineered structural system to hold up the sidewalk and be filled with soil to support tree rootsand treat storm water.

- Soil Peds: Clumps of soil that naturally aggregate during the soil building process.

- Structural Soil: A mixture of stone and soil formulated to be compacted to 95 percent of maximum dry density, Standard Proctor and support tree roots.

- Topsoil: Fertile, friable, loamy soil, harvested from natural topsoil sources.

References

- Bakker. J.W. 1983. Groeiplaats en watervoorziening van straatbomen. Groen, 39(6)205-207; OBIS, 1988. Bomen in straatprofielen – Voorbeelden – Groeiplaatsberekening. Uitgeverij van de Vereniging van de Nederlandse gemeenten, ‘s-Gravenhage 1988. 63 p. Cited in Kopinga 1991.

- Barret, M., Limouzin, M., & Lawler, D. (2011). Performance Comparison of Biofiltration Designs. World Environmental and Water Resources Congress 2011 (pp. 395-404).

- Bassuk, Nina. 2010. Using CU-Structural Soil to Grow Trees Surrounded by Pavement. In The Great Soil Debate Part II: Structural soils under pavement. ASLA Annual Meeting Handout. Available August 2013 from http://www.asla.org/uploadedFiles/CMS/Meetings_and_Events/2010_Annual_Meeting_Handouts/Sat-B1The%20Great%20Soil%20Debate_Structural%20Soils%20Under%20Pavement.pdf

- DTAH, Lead Consultant, ARUP, Engineering, and James Urban, Urban Trees + Soils Urban Forest Innovations, Arborist. 2013. Tree Planting Solutions in Hard Boulevard Surfaces Best Practices Manual. Project # A21065. Prepared for: City of Toronto.

- Facility for Advancing Water Biofiltration (FAWB), 2009. Biofiltration Filter Media Guidelines (Version 3.01) Downloaded August 2013 from http://graie.org/SOCOMA/IMG/pdf/FAWB_Filter_media_guidelines_v3_June_2009-2.pdf

- Fassman, EA, Simcock, R, Wang, S, (2013). Media specification for stormwater bioretention devices, Prepared by Auckland UniServices for Auckland Council. Auckland Counciltechnical report, TR2013/011. Downloaded August 2013 from http://www.google.com/url?sa=t&rct=j&q=&esrc=s&frm=1&source=web&cd=1&ved=0CCoQFjAA&url=http%3A%2F%2Fwww.aucklandcouncil.govt.nz%2FEN%2Fplanspoliciesprojects%2Freports%2Ftechnicalpublications%2FDocuments%2Ftr2013011mediaspecificationforstormwaterbioretentiondevices.pdf&ei=5F0fUuP_L-qK2wWqtYGwDg&usg=AFQjCNFp3kcfmdW_Go5LUhekP76T0n_2Yw&sig2=lDEFut2QUvSiA8P6nayUJg&bvm=bv.51495398,d.aWM

- Helliwell, D.R. 1986. The Extent of Tree Roots, Arboriculture Journal 10:341-347; updated in Letter to the Editor Arboricultural Journal: The International Journal of Urban Forestry, Volume 16, Issue 2,1992.

- Hinman, C., and B. Wulkan. 2012. Low Impact Development. Technical Guidance Manual for Puget Sound. Publication No. PSP 2012-3.

- Jenkins, J. K. G., Wadzuk, B. M., & Welker, A. L. (2010). Fines Accumulation and Distribution in a Storm-Water Rain Garden Nine Years Postconstruction. Journal of Irrigation and Drainage Engineering, 136(12), 862.

- Kent, D., S. Shultz, T. Wyatt, and D. Halcrow. 2006. Soil Volume and Tree Condition in Walt Disney World Parking Lots. Landscape Journal 25:1–06

- Kopinga, J. 1991. The Effect of Restricted Volumes of Soil on the Growth and development of Street Trees. Journal of Arboriculture 17(3): 57-63

- Li, H., & Davis, A. P. (2008b). Urban Particle Capture in Bioretention Media. I: Laboratory and Field Studies. Journal of Environmental Engineering, 134(6), 409.

- Lindsey, P. and N. Bassuk. 1991. Specifying Soil Volumes to Meet the Water Needs of Mature Urban Street Trees and Trees in Containers. Journal of Arboriculture 17(6):141-149.

- Loh, F. C. W.; Grabosky, J. C.; Bassuk, N. L. (2003) Growth Response of Ficus Benjamina to Limited Soil Volume and Soil Dilution in a Skeletal Soil Container Study. In Urban For. Urban Gree. 2 (1)53-62.

- Pitt, R., S. Clark, P. Johnson, and J. Voorhees. In Press. Evapotranspiration and Related Calculations for Bioretention Devices. CHI Monograph 14 Available October 2013 from http://rpitt.eng.ua.edu/Class/StormWaterManagement/Fall%202009/Pitt_Evapo_final__copy_changes_accepted.pdf*Schoenfeld, P.H. 1975. De groei van Hollandse iep in the kustprovincies van Nederalnd. Nederlands Bosbouw Tijdschrift 47:87-95. Cited in Kopinga 1991.

- Schoenfeld, P.H., and J. van den Burg. 1984. Voortijdige bladval en groeiafname bij ‘Heidemij’populier in beplantingen langs autowegen. Nederlands Bosbouw Tijdschrift 56:12-21. Cited in Kopinga 1991.

- Smiley, E. T. 2013. Bartlett Tree Research Lab, Charlotte North Carolina, Adjunct Professor Clemson Univ., unpublished data.

- Smiley, E. Thomas, Lisa Calfee, Bruce R. Fraedrich, and Emma J. Smiley. 2006. Comparison of Structural and Noncompacted Soils for Trees Surrounded by Pavement. Arboriculture & Urban Forestry 32(4): 164-169.

- Urban, J. 1992. Bringing Order to the Technical Dysfunction Within the Urban Forest. Journal of Arboriculture 18(2): 85-90.