Infiltration trench

The anticipated construction period for this page is January through March, 2013

Contents

- 1 Infiltration Overview

- 2 Suitability

- 3 Design Variants

- 3.1 Infiltration Basin

- 3.2 Infiltration Trench (a.k.a. infiltration gallery)

- 3.3 Dry Wells (a.k.a. infiltration tubes, french drains, soak-away pits or soak holes)

- 3.4 Underground Infiltration Systems

- 3.5 Retrofit Suitability

- 3.6 Special Receiving Waters Suitability

- 3.7 Cold Climate Suitability

- 3.8 Water Quantity Treatment

- 3.9 Water Quality Treatment

- 3.10 Limitations

- 4 Major Design Elements

- 4.1 Physical Feasibility Initial Check

- 4.2 Conveyance

- 4.3 Treatment

- 4.4 Landscaping

- 4.5 Safety

- 4.6 Construction Details

- 4.7 Construction Specifications

- 4.8 Temporary Erosion Control

- 4.9 Excavation, Backfill and Grading

- 4.10 Native Plants, Planting and Transplanting

- 4.11 Construction Sequence Scheduling

- 4.12 Construction Observation

- 5 Operation and Maintenance

- 5.1 Overview

- 5.2 Design Phase Maintenance Considerations

- 5.3 Construction Phase Maintenance Considerations

- 5.3.1 Avoid excessive compaction

- 5.3.2 Stabilize Vegetation Before and After Construction

- 5.3.3 Correctly Install Filter Fabrics

- 5.3.4 Carefully Finish Final Grading

- 5.3.5 Keep Infiltration Practices “Off-line” until Construction Is Complete

- 5.3.6 Establish Permanent Vegetation

- 5.3.7 Post-Construction Operation and Maintenance

- 6 Construction and Maintenance Costs

- 7 Design Procedure

- 8 Design Steps

- 9 Links to Other Manuals

- 10 References

Infiltration Overview

Natural or constructed depressions located in permeable soils that capture, store and infiltrate the volume of stormwater runoff associated with a particular design event.

Design Criteria:

- Contributing drainage area

- Underlying soil types

- Depth to the water table, bedrock or other impeding layer

- Proximity to buildings, drinking water supplies, Karst features, etc.

- Source of stormwater runoff

Benefits

- Reduces volume of stormwater runoff

- Increases ground water recharge

- Improves surface water quality

- Provides thermal benefits (e.g. to cold water fisheries)

- Mimics pre-development hydrology

Limitations

- Unusual construction considerations

- Potential for ground water contamination

- Tendency to lose effectiveness over time due to clogging – if not properly constructed or maintained

- Not recommended for areas with steep slopes

- May require landscaping: consideration should be given to periods on inundation and drought

Description

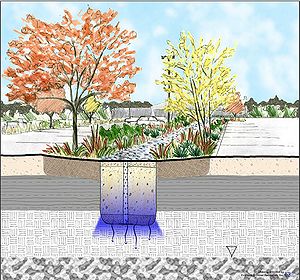

In general terms, infiltration systems can be described as natural or constructed depressions located in permeable soils that capture, store and infiltrate stormwater runoff within 48 hours. These depressions can be located at the surface of the ground (e.g. infiltration basin) or they can be designed as underground facilities (e.g. structural chamber or excavated pit filled with aggregate such as an infiltration trench). Typically, infiltration systems are designed with one or more pre-treatment facilities or they are designed as off-line facilities.

[[alert|Infiltration systems should be located in permeable soils and a minimum 3-foot distance is REQUIRED from the bottom of the seasonally high water table, bedrock or other impeding layer per the Minnesota Pollution Control Agency Construction General Permit (CGP)|alert-danger]]. Dry wells and Trenches should be designed to handle the smaller, more frequent rainfall events. Stormwater associated with the larger rainfall events should bypass these practices by a separate pipe or an overflow device. Infiltration basins and underground infiltration systems should be designed to handle both the water quality volume and as the water quantity volume.

Infiltration systems can be designed to address a number of stormwater management issues including: water quality, stormwater runoff reduction, flow attenuation, thermal impacts to cold water fisheries, and ground water recharge.

Maintenance Requirements

- Establishment of native vegetation may require weeding, watering, pumping, replacement of plants and tree/shrub trimming

- Inspection and removal of sediment accumulation

- Street sweeping of impervious areas adjacent to infiltration practices

- Avoid the application of fertilizer or herbicide in or near infiltration practices

SITE FACTORS

- Max Drainage Areas: Dry Well/ Trench/ Basin = 1/ 5/ 50 AC

- Max. Site Slope = 20%

- Min. Depth to Bedrock = 3’

- Min. Depth to Seasonally High Water Table = 3’

- NRCS Soil Type *C & D soils have limited infiltration ability but can be used to match predevelopment conditions = A,B,C*,& D

- Freeze/ Thaw Suitability = Poor - Good

- Potential Hotspot Runoff = NO

MANAGEMENT SUITABILITY

- Water Quality (Vwq) = High

- Med. Channel Protection (Vcp)

- Overbank Flood Protection (Vp10) = Low/Med.

- Extreme Flood Protection (Vp100) = Low

- Recharge Volume (Vre) = High

MECHANISMS

- Screening/ Filtration

- Temperature Control

- Transpiration *if vegetated

- Soil Adsorption

- Biological/ Micro. Uptake

POLLUTION REMOVAL*

- Total Suspended Solids = 100%

- Nutrients - Total Phosphorus/ = 100%

- Total Nitrogen = 100%

- Metals - Cadmium, Copper, Lead, and Zinc = 100%

- Pathogens - Coliform, Streptococci, E. Coli = 100%

- Toxins - Hydrocarbon = 100%

Pollution removal addresses only the impact on surface water, as there could be some transfer of pollution to the soil layer and groundwater

Suitability

General

Stormwater infiltration practices capture and temporarily store stormwater before allowing it to infiltrate into the soil. Design variants include; the infiltration basin, the infiltration trench, the dry well and the underground infiltration system. As the stormwater penetrates the underlying soil, chemical, biological and physical processes remove pollutants and delay peak stormwater flows.

Infiltration practices are applicable to sites with naturally permeable soils and a suitable distance to the seasonally high ground-water table, bedrock or other impermeable layer. They may be used in residential and other urban settings where elevated runoff volumes, pollutant loads, and runoff temperatures are a concern. In applications where the stormwater runoff has a particularly high pollutant load or where the soils have very high infiltration rates, a significant amount of pre-treatment should be provided to protect the ground-water quality. Sources that include potential stormwater should not be introduced to infiltration systems. Sources that include potential stormwater hotsposts (PSH) should not be introduced to infiltration areas.

Function Within Stormwater Treatment Train

Infiltration practices may be located at the end of the treatment train or they can be designed as off-line configurations where the water quality volume is diverted to the infiltration practice. In any case, the practice may be applied as part of a stormwater management system to achieve one or more of the following objectives:

- Reduce stormwater pollutants

- Increase ground-water recharge

- Decrease runoff peak flow rates

- Decrease the volume of stormwater runoff

- Preserve base flow in streams

- Reduce thermal impacts of runoff.

MPCA Permit Applicability

One of the goals of this Manual is to facilitate understanding of and compliance with the MPCA General Stormwater Permit for Construction Activity (MN R100001), commonly called the Construction General Permit (CGP), which includes design and performance standards for permanent stormwater management systems. The permit and related documentation can be found online at http://www.pca.state.mn.us/water/stormwater/stormwater-c.html. These standards must be applied in all projects in which at least one acre of new impervious area is being created, and the permit stipulates certain standards for various categories of stormwater management practices.

For regulatory purposes, infiltration practices fall under the “Infiltration / Filtration” category described in Part III.C.2 of the permit. If used in combination with other practices, credit for combined stormwater treatment can be given as described in Part III.C.4. Due to the statewide prevalence of the MPCA permit, design guidance in this section is presented with the assumption that the permit does apply. Also, although it is expected that in many cases infiltration will be used in combination with other practices, standards are described for the case in which it is a stand alone practice.

The following terms are thus used in the text to distinguish various levels of stormwater pond design guidance:

REQUIRED: Indicates design standards stipulated by the MPCA Permit (or other consistently applicable regulations).

HIGHLY RECOMMENDED: Indicates design guidance that is extremely beneficial or necessary for proper functioning of the infiltration practice, but is not specifically required by the MPCA permit.

RECOMMENDED: Indicates design guidance that is helpful for infiltration performance but not critical to the design.

Of course, there are situations, particularly retrofit projects, in which an infiltration facility is constructed without being subject to the conditions of the MPCA permit. While compliance with the permit is not required in these cases, the standards it establishes can provide valuable design guidance to the user. It is also important to note that additional and potentially more stringent design requirements may apply for a particular infiltration facility, depending on where it is situated both jurisdictionally and within the surrounding landscape.

Of course, there are situations, particularly retrofit projects, in which an infiltration facility is constructed without being subject to the conditions of the MPCA permit. While compliance with the permit is not required in these cases, the standards it establishes can provide valuable design guidance to the user. It is also important to note that additional and potentially more stringent design requirements may apply for a particular infiltration facility, depending on where it is situated both jurisdictionally and within the surrounding landscape.

Design Variants

Infiltration Basin

An infiltration basin is a natural or constructed impoundment that captures, temporarily stores and infiltrates the design volume of water over several days. In the case of a constructed basin, the impoundment is created by excavation or embankment. Infiltration basins are commonly used for drainage areas of 5 to 50 acres with land slopes that are less than 20 percent. Typical depths range from 2 to 12 feet, including bounce in the basin. An infiltration basin construction detail is located in Appendix D.

Infiltration Trench and infiltration basin - Construction inspection checklists.

Link to this table

To access an Excel version of form (for field use), click here.

| Project: | ||

| Location: | ||

| Site Status: | ||

| Date: | ||

| Time: | ||

| Inspector: | ||

| Construction Sequence | Satisfactory / Unsatisfactory | Comments |

|---|---|---|

| 1. Pre-Construction | ||

| Pre-construction meeting | ||

| Runoff diverted | ||

| Soil permeability verified | ||

| Groundwater / bedrock verified | ||

| Project benchmark established | ||

| Facility location staked out | ||

| Temporary erosion and sediment control established | ||

| 2. Excavation | ||

| Size and location per plans | ||

| Side slopes stable | ||

| Depth adjusted to soil layer with specified soil type and permeability | ||

| Sub-soil not adjacent to excavation area and stabilized with vegetation and/ or silt fence | ||

| Stockpile location not adjacent to excavation area and stabilized with vegetation and/ or silt fence | ||

| 3. Filter Fabric Placement | ||

| Fabric per specifications | ||

| Fabric per specifications | ||

| Placed per plan location | ||

| 4. Aggregate Material | ||

| Size as specified | ||

| Clean / washed material | ||

| Placed properly | ||

| 5. Observation Well | ||

| Pipe size per plans | ||

| Under-drain installed per plans | ||

| Inlet installed per plans | ||

| Pre-treatment devices installed per plans | ||

| 6. Vegetation | ||

| Complies with planting specifications | ||

| Topsoil complies with composition and placement in specifications | ||

| Permanent erosion control measures in place | ||

| 7. Final Inspection | ||

| Dimensions per plans | ||

| Check dams operational | ||

| Inlet / outlet operational | ||

| Effective stand of vegetation and stabilization | ||

| Contributing watershed stabilized before flow is routed to the facility | ||

| Comments: | ||

| Actions to be taken: | ||

Infiltration Trench (a.k.a. infiltration gallery)

An infiltration trench is a shallow excavated trench, typically 3 to 12 feet deep, that is backfilled with a coarse stone aggregate allowing for the temporary storage of runoff in the void space of the material. Discharge of this stored runoff occurs through infiltration into the surrounding naturally permeable soil. Trenches are commonly used for drainage areas less than 5 acres in size.

Dry Wells (a.k.a. infiltration tubes, french drains, soak-away pits or soak holes)

A dry well or soak away pit is a smaller variation of an infiltration trench. It is a subsurface storage facility (a structural chamber or an excavated pit backfilled with a coarse stone aggregate) that receives and temporarily stores stormwater runoff. Discharge of this stored runoff occurs through infiltration into the surrounding naturally permeable soil. Due to their size, dry wells are typically designed to handle stormwater runoff from smaller drainage areas, less than one acre in size (e.g. roof tops).

Underground Infiltration Systems

Several underground infiltration systems, including pre-manufactured pipes, vaults, and modular structures, have been developed as alternatives to infiltration basins and trenches for space-limited sites and stormwater retrofit applications. These systems are similar to infiltration basins and trenches in that they are designed to capture, temporarily store and infiltrate the design volume of stormwater over several days. Underground infiltration systems are generally applicable to small development sites (typically less than 10 acres) and should be installed in areas that are easily accessible to routine and non-routine maintenance. These systems should not be located in areas or below structures that cannot be excavated in the event that the system needs to be replaced.

Retrofit Suitability

The narrow and versatile shape of infiltration trenches and dry wells makes them well suited for retrofit projects. For example, infiltration practices can be situated along the margin or perimeter of a developed site or roadway in many cases. They are particularly desirable as retrofit practices in watersheds or catchments that are targeting volume reduction practices to help minimize channel erosion.

Generally, infiltration should not be used to treat runoff from manufacturing or industrial sites or other areas with high pollutant concentrations unless correspondingly high levels of pretreatment are provided.

Special Receiving Waters Suitability

The BMP design restrictions for special watersheds table below provides guidance regarding the use of infiltration practices in areas upstream of special receiving waters. This table is an abbreviated version of a larger table in which other BMP groups are similarly evaluated. The corresponding information about other BMPs is presented in the respective sections of this Manual.

BMP design restrictions for special watersheds

Cold Climate Suitability

Various options for use of infiltration are available for treating snowmelt runoff. Some of the installations are built below the frost line (trenches, sub-grade proprietary chambers) and do not need further adaptation for the cold. However, some special consideration as described in the Cold climate impact on runoff management section is HIGHLY RECOMMENDED for surface systems. The problem with infiltration in cold weather is the ice that forms both over the top of the facility and within the soil interstices. To avoid these problems to the extent possible, it is HIGHLY RECOMMENDED that the facility be actively managed to keep it dry before it freezes in the late fall. This can be done by various methods, including limiting inflow, under-drainage, and surface disking.

Even if the infiltration properties of an infiltration practice are marginal for snowmelt runoff, the storage available in the facility will provide some storage if it is dry entering the melt season. Routing the first highly-soluble portions of snowmelt to an infiltration facility provides the opportunity for soil treatment (such as filtration, adsorption, microbial activity) of these solubles. Again, however, flow originating in an industrial area, a high traffic area where large amounts of salt are added, or another PSH should be diverted away from infiltration systems.

Proprietary, sub-grade infiltration systems provide an alternative to standard surface based systems. Essentially, these systems provide an insulated location for pre-treated snowmelt to be stored and slowly infiltrated, or simply filtered and drained away if ground-water sensitivity is an issue. The insulating value of these systems adds to their appeal as low land consumption alternatives to ponds and surface infiltration basins.

Water Quantity Treatment

The amount of stormwater volume infiltrated depends on the design variant selected. Smaller infiltration practices (e.g. infiltration trenches) should either be designed off-line using a flow diversion, or designed to safely pass large storm flows while still protecting the infiltration area. In limited cases (e.g. extremely permeable soils), these smaller infiltration practices can accommodate the channel protection volume, Vcp, in either an off- or on-line configuration.

In general, supplemental stormwater practices will be necessary to satisfy channel and flood protection requirements when smaller infiltration practices are used. However, these practices can help reduce detention requirements for a site through volume reduction.

Due to their size, the larger infiltration practices (e.g. infiltration basins and underground infiltration systems) have the potential to provide greater water quantity benefits. Surcharge storage above the practice bottom is available for detention. Outlet structures can be sized to partially or fully accommodate larger storm peak discharge control while allowing the volume below the outlet to infiltrate.

Water Quality Treatment

Infiltration practices can remove a wide variety of stormwater pollutants through chemical and bacterial degradation, sorption, and filtering. Surface water load reductions are also realized by virtue of the reduction in runoff volume.

There are few data available demonstrating the load reductions or outflow concentrations of larger-scale infiltration practices such as infiltration trenches. Similarly, few sampling programs collect infiltrating water that flows through an infiltration system.

For properly designed, operated, and maintained infiltration systems, all water routed into them should be “removed” from stormwater flow, resulting in 100% efficiency relative to volume and pollutant reduction. For this reason, any infiltration BMP performance table should show all 100% entries. This logic assumes that stormwater is the beneficiary of any infiltration system, but ignores the fact that pollution, if any remains after the internal workings of the infiltration BMP itself (see later discussion in this chapter), is being transferred into the shallow groundwater system. Good monitoring data on the groundwater impact of infiltrating stormwater are rare, but there are efforts underway today to document this, so future Manual revisions should be able to include some data updates.

Properly designed infiltration systems discussed later in this chapter will accommodate a design volume based on the required water quality volume. Excess water must be by-passed and diverted to another BMP so that the design infiltration occurs within 48 hours if under state regulation, or generally within 72 hours under certain local and watershed regulations. In no case should the by-passed volume be included in the pollutant removal calculation.

Data that are reported in performance literature for infiltration systems, unless reporting 100% effectiveness for surface water or documenting outflow water downward, are not accurately representing behavior, or are representing the excess flow (overflow) from a system. Design specifications in the following sections of this chapter should prevent putting contaminated runoff and excess water beyond that which will infiltrate within the given timeframe. Any runoff containing toxic material or excess volume that cannot infiltrate should be diverted away from the infiltration system and reported as inflow to another treatment device.

Foloow guidance and carefully use of infiltration BMPs to make sure they are not transporting highly loaded or toxic contaminants into the groundwater system. These sections address the pollution remediation processes at work in infiltration systems to reduce or totally remove pollutants that move through them. However, extreme caution must be exercised and serious planning undertaken to assure that no highly contaminating material is routed into these BMPs. Of particular concern are toxic organics (gasoline, solvents) and high levels of chloride.

Appendix N contains details on how design and operations can either raise or lower the expected level of performance for infiltration BMPs.

Limitations

The following general limitations should be recognized when considering installation of infiltration practices:

- Limited monitoring data are available and field longevity is not well documented.

- Failure can occur due to improper siting, design, construction and maintenance.

- Systems are susceptible to clogging by sediment and organic debris

- There is a risk of ground-water contamination depending on subsurface conditions, land use and aquifer susceptibility.

- They are not ideal for stormwater runoff from land uses or activities with the potential for high sediment or pollutant loads.

- They are not recommended for areas with steep slopes

- Please not that even though there are potential pollution and physical clogging problems with infiltration, it is one of the most important elements in the stormwater runoff treatment train. Fear of the limitations should not prevent well designed systems from being used.

As noted in various sections, discussion of BMP selection, the benefits associated with infiltration BMPs should only be accrued based on the amount of water actually passing through the BMP. Excess runoff beyond that designed for the BMP should not be routed through the system because of the potential for hydraulic and particulate over-loading, both of which will adversely impact the life and operation of the BMP.

For example, an infiltration device designed to treat the first 0.5” of runoff from a fully impervious surface will catch about 30% of the volume of runoff in the Twin Cities. This means that 70% of the runoff volume should be routed around the filtration system and will not be subject o the removals reflected in the above tables. Attributing removal to all runoff just because a BMP is in place in a drainage system is not a legitimate claim.

Major Design Elements

Physical Feasibility Initial Check

Drainage Area:' It is HIGHLY RECOMMENDED that the following infiltration practices be designed with the indicated maximum drainage areas:

- Dry well – 1 acre.

- Infiltration Trench – 5 acres.

- Underground Infiltration System – 10 acres.

- Infiltration Basin – between 5 and 50 acres.

Site Topography and Slopes: Unless slope stability calculations demonstrate otherwise, it is HIGHLY RECOMMENDED that infiltration practices be located a minimum horizontal distance of 200 feet from down-gradient slopes greater than 20%, and that slopes in contributing drainage areas be limited to 15%.

Soils: It is HIGHLY RECOMMENDED that native soils in proposed infiltration areas have a minimum infiltration rate of 0.2 inches per hour (typically Hydrologic Soil Group A, B and C soils). Initially, soil infiltration rates can be estimated from NRCS soil data, and confirmed with an on-site infiltration evaluation or geotechnical investigation (see Step 6 of the Design Procedures section for investigation procedures). It is HIGHLY RECOMMENDED that native soils have silt/clay contents less than 40% and clay content less than 20%, and that infiltration practices not be situated in fill soils.

Depth to Ground Water Table and Bedrock: It is REQUIRED that infiltration practices be designed with a minimum vertical distance of 3 feet between the bottom of the infiltration practice and the seasonally high water table or bedrock layer (see also Step 8 under the Design Procedure section). Local authorities may require greater separation depths.

Site Location / Minimum Setbacks: It is HIGHLY RECOMMENDED that infiltration practices not be hydraulically connected to structure foundations or pavement, to avoid seepage and frost heave concerns, respectively. If ground water contamination is a concern, it is RECOMMENDED that ground water mapping be conducted to determine possible connections to adjacent ground water wells.

Recommended minimum setback requirements. This represents the minimum distance from the infiltration practice to the structure of concern. If the structure is aboveground, the distance is measured from the edge of the permeable pavement to the structure. If the structure is underground, the setback distance represents the distance from the point of infiltration through the bottom of the permeable pavement system to the structure.

Link to this table

| Setback from | Minimum Distance [feet] |

|---|---|

| Property Line | 10 |

| Building Foundation* | 10 |

| Private Well | 50 |

| Septic System Tank/Leach Field | 35 |

| * Minimum with slopes directed away from the building. | |

Karst: It is HIGHLY RECOMMENDED that infiltration practices not be used in active karst formations without adequate geotechnical testing.

Conveyance

It is HIGHLY RECOMMENDED that a flow splitter or diversion structure be provided to divert the Vwq to the infiltration practice and allow larger flows to bypass the practice, unless the infiltration practice is sized to retain Vcp, Vp10 or Vp100. Where a flow splitter is not used, it is HIGHLY RECOMMENDED that contributing drainage areas be limited to the appropriate size given the BMP and an overflow be provided within the practice to pass part of the Vwq to a stabilized watercourse or storm drain. It is also HIGHLY RECOMMENDED that overflow associated with the Vp10 or Vp100 storm (depending on local drainage criteria) be controlled such that velocities are non-erosive at the outlet point (to prevent downstream slope erosion), and that when discharge flows exceed 3 cfs, the designer evaluate the potential for erosion to stabilized areas and infiltration facilities.

Pre-treatment

It is HIGHLY RECOMMENDED that the following pre-treatment sizing guidelines be followed:

- Before entering an infiltration practice, stormwater should first enter a pre-treatment practice sized to treat a minimum volume of 25% of the Vwq.

- If the infiltration rate of the native soils exceeds 2 inches per hour a pre-treatment practice capable of treating a minimum volume of 50% of the Vwq should be installed.

- If the infiltration rate of the native soils exceeds 5 inches per hour a pre-treatment practice capable of treating a minimum volume of 100% of the Vwq should be installed.

It is HIGHLY RECOMMENDED that pre-treatment practices be designed such that exit velocities from the pre-treatment systems are non-erosive (less than 3 fps) and flows are evenly distributed across the width of the practice (e.g., by using a level spreader).

Treatment

Space Occupied: Space varies depending on the depth of the practice. Typically, infiltration trenches are three to twelve feet deep with a width less than 25 feet. A dry well is essentially a smaller version of an infiltration trench, consistent with the fact that the drainage area to an infiltration trench is typically five times greater (or larger) than that of a dry well. Underground infiltration systems are larger practices that range in depth from approximately 2 to 12 feet. The surface area of all infiltration practices is a function of MPCA’s 48-hour drawdown requirement and the infiltration capacity of the underlying soils.

Practice Slope: It is RECOMMENDED that the bottom of all infiltration practices be flat, in order to enable even distribution and infiltration of stormwater. It is RECOMMENDED that the longitudinal slope range only from the ideal 0% up to 1%, and that lateral slopes be held at 0%.

Side Slopes: It is HIGHLY RECOMMENDED that the maximum side slopes for an infiltration practice be 1:3 (V:H).

Depth: The depth of an infiltration practice is a function of the maximum drawdown time and the design infiltration rate. The REQUIRED drawdown time for infiltration practices is 48 hours or less, and so the depth of the practice should be determined accordingly.

Aesthetics: Infiltration basins can be effectively integrated into the site planning process, and aesthetically designed as attractive green spaces planted with native vegetation. Infiltration trenches are less conducive to site aesthetics, but the surface of trenches can be designed with turf cover crops if desired.

Landscaping

It is REQUIRED that impervious area construction be completed and pervious areas established with dense and healthy vegetation prior to introduction of stormwater into an infiltration practice.

It is RECOMMENDED that vegetation associated with infiltration practices be established to blend into the surrounding area, that native species be used wherever possible. It is HIGHLY RECOMMENDED that deep rooted plants such as prairie grass be used, because they increase the infiltration capacity of the underlying soils. Dry wells and infiltration trenches can be covered with permeable topsoil and planted with grass to match the surrounding landscape.

Due to soil compaction concerns, it is HIGHLY RECOMMENDED that infiltration areas not be used for recreational purposes unless a soil amendment is used to off-set compaction.

It is HIGHLY RECOMMENDED that vegetation associated with infiltration practices be regularly maintained and bare areas seeded. Mowing practices can be used to maintain native vegetation.

It is RECOMMENDED that soil testing be conducted in infiltration practices, to determine if fertilizer application is warranted. Incorporating mulch or compost into the soil or planting with salt tolerant grasses can counter soil fertility problems caused by high chloride concentrations

Safety

Dry wells, infiltration trenches and subsurface infiltration systems do not pose any major safety hazards. Infiltration basins should have similar side slope considerations as ponds and wetlands.

If a dry well or infiltration trench is greater than five feet deep, it is REQUIRED that OSHA health and safety guidelines be followed for safe construction practices. Additional information on safety for construction sites is available from OSHA.

When riser pipe outlets are used in infiltration basins, it is HIGHLY RECOMMENDED that they be constructed with manholes that either have locks or are sufficiently heavy to prevent easy removal.

Fencing of dry wells and infiltration trenches is neither necessary nor desirable. Infiltration basins may warrant fencing in some situations.

Construction Details

CADD based details for pond systems are contained in the section on Computer-aided design and drafting (CAD/CADD) drawings. The following details, with specifications, have been created for infiltration systems:

- Infiltration Basin

- Infiltration Trench

- Subsurface Infiltration System

- Inlet/outlet Structures

Construction Specifications

Given that the construction of infiltration practices incorporates techniques or steps which may be considered non-standard, it is RECOMMENDED that the construction specifications include the following format and information:

Temporary Erosion Control

- Installation prior to site disturbance

- Catch basin/inlet protection

- Use of BMP as temporary sedimentation basin

Excavation, Backfill and Grading

- Timing of grading of infiltration practices (relative to total site development)

- Use of low-impact, earth moving equipment

- Controls to ensure site is not over-excavated

- Restoration in the event of sediment accumulation during construction of practice

- Gravel backfill specifications

- Gravel filter specifications

- Filter fabric specifications

- Observation well specifications

Native Plants, Planting and Transplanting

- Site preparation of planting areas

- Timing of native seeding and native planting

- Weed control

- Watering of plant material

Construction Sequence Scheduling

- Temporary construction access

- Location of silt fence installation to protect BMPs and downgradient receiving waters

- Removal and storage of excavated material

- Installation of underground utilities

- Rough grading

- Seeding and mulching disturbed areas

- Road construction

- Final grading

- Site stabilization

- Installation of semi-permanent and permanent erosion control measures

- Silt fence removal (often forgotten but an essential step)

Construction Observation

- Adherence to construction documents

- Verification of physical site conditions

- Erosion control measures installed appropriately

Operation and Maintenance

Overview

Effective long-term performance of infiltration practices requires an infiltration management plan (HIGHLY RECOMMENDED)and performance monitoring (HIGHLY RECOMMENDED).

The infiltration management plan (operation plan) should address the following items: periods of inundation, wet/dry cycling of soils, operating instructions for drawdown valves, gates and removable weirs.

The monitoring plan should address the following items: inspection and efficiency assessment, water quality monitoring, monitoring of ground-water elevations, long-term infiltration capacity and plant tolerances.

Elements to be considered for the development of a maintenance plan are broken into the following categories: Design Phase Maintenance Considerations; Construction Phase Maintenance Considerations; and Post-Construction Maintenance Considerations. In general terms, the most frequently cited maintenance concern for infiltration practices is clogging caused by organic matter and fine silts. Common operational problems include:

- Clogging and sediment deposition

- Erosion of contributing land or in channels leading to the practice

- Maintaining appropriate surface vegetation

The table below provides a summary of common problems for infiltration trenches and basins.

Summary of infiltration practices cost components.

Link to this table

| Implementation Stage | Primary Cost Components | Basic Cost Estimate | Other Considerations |

|---|---|---|---|

| Site Preparation | Tree & plant protection | Protection Cost ($/acre) * Affected Area (acre) | Removal of existing structures, topsoil removal and stockpiling |

| Infiltration area protection | Silt fence cost ($/’foot) * Perimeter of infiltration area | ||

| Clearing & grubbing | Clearing Cost ($/acre) * Affected Area (acre) | ||

| Topsoil salvage | Salvage Cost ($/acre) * Affected Area | ||

| Site Formation | Excavation / grading | X-ft Depth Excavation Cost ($/acre) * Area (acre) | Soil & rock fill material, tunneling |

| Hauling material offsite | Excavation Cost * (% of Material to be hauled away) | ||

| Structural Components | Vault structure (for underground infiltration) | ($/structure) | Pipes, catchbasins, manholes, valves, vaults |

| Media (for infiltration trenches) | Media cost ($/cubic yard) * filter volume (cubic yard) | ||

| Geotextile | Geotextile cost ($/cy) * area of trench, including walls | ||

| inlet structure | ($/structure) | ||

| Overflow structure | ($/structure) | ||

| Observation well | ($/structure) | ||

| Site Restoration | Soil preparation | Topsoil or amendment cost ($/acre) * Area (acre) | Tree protection, soil amendments, seed bed preparation, trails |

| Seeding | Seeding Cost ($/acre) * Seeded Area (acre) | ||

| Filter strip | Sod cost ($/square foot) * filter strip area | ||

| Planting / transplanting | Planting Cost ($/acre) * Planted Area (acre) | ||

| Annual Operation, Maintenance, and Inspection | Sediment removal | Removal Cost ($/acre) * Area (acre) * Frequency (1 time per 5 years) | Vegetation maintenance, cleaning of structures |

| Debris removal | Removal Cost ($/acre) * Area (acre) * Frequency (2 time per year) | ||

| Inspection | Inspection Cost ($) * Inspection Frequency (6 times per year) | ||

| Mowing (for some vegetative filters) | Mowing Cost ($) * Mowing Frequency (6 times per year) |

Design Phase Maintenance Considerations

Implicit in the design guidance in the previous sections is the fact that many design elements for infiltration systems can minimize the maintenance burden and maintain pollutant removal efficiency. Among them are:

- Open lawn areas are RECOMMENDED locations for infiltration practices because of their accessibility.

- It is HIGHLY RECOMMENDED that every dry well, infiltration trench and subsurface infiltration system design include an observation well consisting of an anchored six-inch diameter perforated PVC pipe fitted with a cap to facilitate periodic inspection and maintenance. It is also HIGHLY RECOMMENDED that infiltration basins include a draw down device that can be used for winter diversion and to conduct regular maintenance.

- It is HIGHLY RECOMMENDED that a mechanism such as a multi-stage outlet structure be incorporated into the design of the pre-treatment and infiltration practices to facilitate draining for maintenance purposes.

Construction Phase Maintenance Considerations

Infiltration practices are particularly vulnerable during the construction phase for two reasons. First, if the construction sequence is not followed correctly, construction sediment can clog the practice. In addition, heavy construction can result in compaction of the soil, which can then reduce the soil’s infiltration rate. For this reason, a careful construction sequence needs to be followed. Critical construction elements for infiltration practices are as follows:

Avoid excessive compaction

In addition, it is HIGHLY RECOMMENDED that the side walls of dry wells and infiltration trenches be roughened if they have been smeared by heavy equipment

Stabilize Vegetation Before and After Construction

Excessive sediment loadings can occur without the use of proper erosion and sediment control practices during the construction process.

Correctly Install Filter Fabrics

Large tree roots should be trimmed flush with the sides of dry wells and infiltration trenches to prevent puncturing or tearing of the filter fabric during subsequent installation procedures. When laying out the geotextile, the width should include sufficient material to compensate for perimeter irregularities in the dry well or trench and for a 6-inch minimum top overlap. The filter fabric itself should be tucked under the sand layer on the bottom of the dry well of infiltration trench, and stones or other anchoring objects should be placed on the fabric at the trench sides to keep the excavation open during windy periods. Voids may occur between the fabric and the excavated sides of the practice. Natural soils should be placed in any voids to ensure fabric conformity to the excavation sides.

Carefully Finish Final Grading

Initial infiltration basin excavation should be carried to within 2 feet of the final elevation of the basin floor.

The final phase excavation should remove all accumulated sediment and be done by light tracked equipment to avoid compaction of the basin floor and provide a well-aerated, highly porous surface texture.

Keep Infiltration Practices “Off-line” until Construction Is Complete

It is HIGHLY RECOMMENDED that construction of infiltration practices be suspended during snowmelt or rainfall, in order to prevent soil smearing, clumping, or compaction.

Establish Permanent Vegetation

- Establishing dense vegetation on the basin side slopes is HIGHLY RECOMMENDED, to reduce erosion and sloughing and

- Provide a natural means of maintaining relatively high infiltration rates. Vegetative cover at inflow points to the basin is also HIGHLY RECOMMENDED to provide erosion protection and reduce sediment accumulation. The use of native grasses is RECOMMENDED for seeding primarily due to their adaptability to local climates and soil conditions.

- Inspections during construction are needed to ensure that the infiltration practice is built in accordance with the approved design and standards and specifications. Detailed inspection checklists should be used that include sign-offs by qualified individuals at critical stages of construction to ensure that the contractor’s interpretation of the plan is acceptable to the designer.

Post-Construction Operation and Maintenance

Effective long-term operation of infiltration practices necessitates a dedicated and routine maintenance schedule with clear guidelines and schedules. Some important post-construction maintenance considerations are provided below.

- A legally binding and enforceable maintenance agreement should be executed between the practice owner and the local review authority.

- Adequate access must be provided for all infiltration practices for inspection, maintenance, and landscaping upkeep, including appropriate equipment and vehicles.

- General infiltration trench maintenance activities and schedule are provided in the table below

Typical maintenance problems for infiltration trenches and basins.

Link to this table

| Problem | Practices Applied To | Comments |

|---|---|---|

| Clogging, sediment deposition | Both | Key issue for infiltration practice. Requires vigilant inspection and maintenance. |

| Surface Vegetation | Both | Often important to maintain vigorous growth at the base of infiltration practices (basins). Important to restrict woody vegetation from the surface of infiltration trenches. |

| Erosion of contributing land or in channels leading to practice | Both | In these practices, it is important to monitor not only the practice itself, but also upland infiltration to minimize the sediment load. |

| Damage to filter fabric | Trench | Infrequent but important maintenance concern. |

| Scouring at Inlet | Both | Similar issues to Ponds. Need to promote non-erosive flows that are evenly distributed |

| Access Issues | Both | Similar issues to Ponds. Need access for inspection and maintenance. |

| Concrete Failure | Basins, if they include a riser structure | Similar issues to ponds and wetlands. |

| Problems with the Embankment | Basins | Similar issues to dry ponds. |

Typical maintenance activities for infiltration trenches and infiltration basins.

Link to this table

| Activity | Schedule |

|---|---|

| Replace pea gravel/topsoil and top surface filter fabric (when clogged). | As needed |

|

Ensure that contributing area, practice and inlets are clear of debris. Ensure that the contributing area is stabilized. Remove sediment and oil/grease from pre-treatment devices, as well as overflow structures. Mow grass filter strips should be mowed as necessary. Remove grass clippings. Repair undercut and eroded areas at inflow and outflow structures |

Monthly |

| Inspect pre-treatment devices and diversion structures for sediment build-up and structural damage. Remove trees that start to grow in the vicinity of the trench. | Semi-annual Inspection |

| Disc or otherwise aerate basin bottom. De-thatch basin bottom. | Annually |

| Scrape basin bottom and remove sediment. Restore original crosssection and infiltration rate. Seed or sod to restore ground cover. | Every 5 years |

| Perform total rehabilitation of the trench to maintain design storage capacity. Excavate trench walls to expose clean soil | Upon Failure |

Construction and Maintenance Costs

Chapter 6 outlines a cost estimation method which site planners could use to compare the relative construction and maintenance costs for structural best management practices. These curves are excellent for purposes of comparison; however, it is recommended that construction and maintenance budgets should be based on site specific information. Utilizing the table below and the cost estimation worksheet, will allow designers to avoid over or under estimation of fixed costs.

The table below lists the specific site components that are specific to infiltration practices. Not included in this table are those cost items that are common to all construction projects, such as mobilization, traffic control, erosion and sediment control, permitting, etc.

Design Procedure

The following steps outline a recommended design procedure for infiltration practices in compliance with the MPCA Permit for new construction. Design recommendations beyond those specifically required by the permit are also included and marked accordingly.

Design Steps

Step 1. Make a preliminary judgment as to whether site conditions are appropriate for the use of an infiltration practice, and identify the function of the practice in the overall treatment system.

A. Consider basic issues for initial suitability screening, including:

- Site drainage area (See the Summary of infiltration practices for given drainage areas table below)

- Site topography and slopes

- Soil infiltration capacity

- Regional or local depth to groundwater and bedrock

- Site location/ minimum setbacks

- Presence of active Karst

B. Determine how the infiltration practice will fit into the overall stormwater treatment system:

- Decide whether the infiltration practice is the only BMP to be employed, or if are there other BMPs addressing some of the treatment requirements.

- Decide where on the site the infiltration practice is most likely to be located.

Summary of infiltration practices for given drainage areas.

Link to this table

| Infiltration Practice | Drainage Area |

|---|---|

| Infiltration Basin | 5 to 50 acres |

| Infiltration Trench | less than 5 acres |

| Dry Wells | less than one acre |

| Underground Infiltration Systems | less than 10 acres |

Step 2. Confirm design criteria and applicability.

A. Determine whether the infiltration practice must comply with the MPCA Permit.

B. Check with local officials, watershed organizations, and other agencies to determine if there are any additional restrictions and/or surface water or watershed requirements that may apply.

Step 3. Perform field verification of site suitability.

If the initial evaluation indicates that an infiltration practice would be a good BMP for the site, it is RECOMMENDED that a minimum of three soil borings or pits be dug (in the same location as the proposed infiltration practice) to verify soil types and infiltration capacity characteristics and to determine the depth to ground-water and bedrock.

It is RECOMMENDED that the minimum depth of the soil borings or pits be five feet below the bottom elevation of the proposed infiltration practice.

It is HIGHLY RECOMMENDED that soil profile descriptions be recorded and include the following information for each soil horizon or layer (Source: Site Evaluation for Stormwater Infiltration, Wisconsin Department of Natural Resources Conservation Practice Standards, 2004):

- Thickness, in inches or decimal feet

- Munsell soil color notation

- Soil mottle or redoximorphic feature color, abundance, size and contrast

- USDA soil textural class with rock fragment modifiers

- Soil structure, grade size and shape

- Soil consistency, root abundance and size

- Soil boundary

- Occurrence of saturated soil, impermeable layers/lenses, ground-water, bedrock or disturbed soil

- It is HIGHLY RECOMMENDED that the field verification be conducted by a qualified geotechnical professional.

Step 4. Compute runoff control volumes.

Calculate the Water Quality Volume (Vwq), Channel Protection Volume (Vcp), Overbank Flood Protection Volume (Vp10), and the Extreme Flood Volume (Vp100) (see Chapter 10).

If the infiltration practice is being designed to meet the requirements of the MPCA Permit, the REQUIRED treatment volume is the water quality volume of ½ inch of runoff from the new impervious surfaces created from the project (or 1 inch for certain protected waterbodies). If part of the overall Vwq is to be treated by other BMPs, subtract that portion from the Vwq to determine the part of the Vwq to be treated by the infiltration practice.

The design techniques in this section are meant to maximize the volume of stormwater being infiltrated. If the site layout and underlying soil conditions permit, a portion of the Channel Protection Volume (Vcp), Overbank Flood Protection Volume (Vp10), and the Extreme Flood Volume (Vp100) may also be managed in the infiltration practice (see Step 7).

Details on the Unified Stormwater Sizing Criteria are found in the Unified sizing criteria section.

Step 5. Select design variant based on Physical Suitability Evaluation.

Once the Physical Suitability Evaluation is complete, it is HIGHLY RECOMMENDED that the designer apply the better site design principles in sizing and locating the infiltration practice(s) on the development site. Given the water quality volume and the drainage area, select the appropriate infiltration practice for the first iteration of the design process.

Note: Information collected during the site suitability evaluation (see Steps 1 and 3) should be used to explore the potential for multiple infiltration practices versus relying on a single infiltration facility. The use of smaller infiltration practices dispersed around a development is usually more sustainable than a single regional facility that is more likely to have maintenance and ground-water mounding problems (Source: Site Evaluation for Stormwater Infiltration, Wisconsin Department of Natural Resources Conservation Practice Standards, 2004).

Step 6. Size infiltration practice (Note: Steps 6, 7, 8 and 9 are iterative).

After following the steps outlined above, the designer will presumably know the location of naturally occurring permeable soils, the depth to the water table, bedrock or other impermeable layer, and the contributing drainage area. While the first step in sizing an infiltration practice is selecting the type of infiltration practice for the site, the basic design procedures are very similar.

Infiltration Location: Given the steps performed in the Physical Suitability Evaluation, identify the most suitable location for the infiltration practice. Pre-treatment prior to infiltration is REQUIRED to remove total suspended solids and other pollutants associated with stormwater (see Step 9).

Infiltration Rates: If the infiltration rate is not measured, the Table 12.INF.7 provides infiltration rates for the design of infiltration practices. These infiltration rates represent the long-term infiltration capacity of a practice and are not meant to exhibit the capacity of the soils in the natural state. Select the design infiltration rate from the Table 12.INF.7 based on the least permeable soil horizon within the first five feet below the bottom elevation of the proposed infiltration practice.

The infiltration capacity and existing hydrologic regime of natural basins are inheritably different than constructed practices and may not meet the General Permit requirements for constructed practices. In the event that a natural depression is being proposed to be used as an infiltration system, the design engineer must demonstrate the following information: infiltration capacity of the system under existing conditions (inches/hour), existing drawdown time for the high water level (HWL) and a natural overflow elevation. The design engineer should also demonstrate that operation of the natural depression under post-development conditions mimics the hydrology of the system under pre-development conditions.

If the infiltration rates are measured the tests shall be conducted at the proposed bottom elevation of the infiltration practice. If the infiltration rate is measured with a double-ring infiltrometer the requirements of ASTM D3385 shall be used for the field test.

The measured infiltration rate shall be divided by a correction factor selected from Table 12.INF.8. The correction factor adjusts the measured infiltration rates for the occurrence of less permeable soil horizons below the surface and the potential variability in the subsurface soil horizons throughout the infiltration site. This correction factor also accounts for the long-term infiltration capacity of the stormwater management facility.

Total correction factors Ddvided into measured infiltration rates

To select the correction factor from Table 12.INF.8, determine the ratio of the design infiltration rates for each location an infiltration measurement was performed. To determine this ratio, the design infiltration rate (Table 12.INF.7) for the surface textural classification is divided by the design infiltration rate for the least permeable soil horizon. For example, a device with a loamy sand (0.8”/hr.) at the surface and least permeable layer of loam (0.3”/hr.) will have a design infiltration rate ratio of about 2.7 and thus a correction factor of 3.5. The depth of the least permeable soil horizon should be within five feet of the proposed bottom of the device or to the depth of a limiting layer. In this exercise, if an infiltration rate of 2.5”/hr is measured, the adjustment rate would be 0.71”/hr.

Depth: The depth of an infiltration practice is a function of the maximum drawdown time and the design infiltration rate. Given the assumed infiltration rate for the practice, determine the maximum depth as follows:

D = i x t

Where:

D = maximum depth of practice (inches)

i = infiltration rate (inches/hour)

t = maximum drawdown time (48 hours)

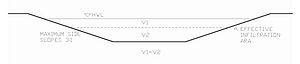

Effective Infiltration Area: Given the water quality volume (Vwq) and the maximum depth of the practice (D) calculate the effective infiltration area where the effective infiltration area is defined as the area of the facility that is used to infiltrate runoff and does not include the area used for site access, berms and/or pre-treatment. For above ground practices that are rectangular in nature (infiltration basins with 1V:3H side slopes or steeper)

Ai = Vw/D

Where:

Ai = effective infiltration area at the bottom of practice (ft2)

Vw = design volume (e.g. Vwq) (ft3)

D = maximum depth of practice (feet) Note: bottom of the infiltration practice must be at least three feet from the seasonally high ground-water table.

For above ground practices that have angular sides slopes (infiltration basins with sides slopes shallower that 1V:3H)

Ai = Vw/D

Where:

Ai = effective infiltration area at half the volume of the practice* (see figure below) (ft2)

Vw = design volume (e.g. Vwq) (ft3)

D = maximum depth of practice (feet) Note: bottom of the infiltration practice should be at least three feet from the seasonally high ground-water table.

Since there is potentially a significant amount of infiltration that could occur though the sides of the practice, the design engineer should take this surface area into consideration thereby potentially reducing the overall footprint of the stormwater infiltration practice.

For underground practices (e.g. infiltration trenches, dry wells, subsurface infiltration practices):

Ai = Vw/nD

Where:

Ai = effective infiltration area is the sum of the bottom area and the sides of the practice* (ft2)

Vw = design volume (e.g. Vwq) (ft3)

n = porosity of filter media (range of porosity values for sands and gravels: 0.25 to 0.5)

D = maximum depth of practice (feet) Note: maximum of 12 feet, and separated by at least three feet from seasonally high ground-water table

Since underground facilities have potentially more surface area in contact with permeable soils, these practices should take these areas into consideration. Only that portion of the sides that is in contact with naturally permeable material should be used in calculating the effective infiltration area of the practice.

For subsurface infiltration practices, use the procedure described above or technique recommended by manufacturer and approved by the local or state authority.

Volume: The preliminary volume of the infiltration practice is determined by multiplying the average basin area by the depth of the practice.

The total storage volume for infiltration basins and underground infiltration systems is:

V = A x D

Where:

V = Design volume for infiltration basin and underground infiltration system (ft3)

A = average basin area (square feet)

D = depth of practice (feet)

For those practices that do not involve a media filter (e.g. infiltration basin and underground infiltration systems) this volume represents the total storage volume (design volume) of the practice. For those practices which do involve a media filter (e.g. infiltration trenches and dry wells) this volume represents the void space and the total storage volume will be greater. The following formula can be used to determine the total storage volume (design volume):

The total storage volume for infiltration trenches and dry wells

Vt = A x n x Di

Where:

Vt = Design volume for infiltration trenches and dry wells (ft3)

A = average basin area (square feet)

n = porosity of filter media (range of porosity values for sands and gravels: 0.25 to 0.5)

D = depth of practice (feet)

Step 7. Size outlet structure and/or flow diversion structure, if needed (Note: Steps 6, 7, 8 and 9 are iterative).

It is HIGHLY RECOMMENDED that the outlet for the infiltration practice shall safely convey stormwater using all of the following mechanisms (Infiltration Basin, Wisconsin Department of Natural Resources Conservation Practice Standard, 10/04).

Drawdown valve: Infiltration systems may be designed with a drawdown valve for the removal of standing water for maintenance and winter diversion.

Emergency spillway: A means to release discharge in excess of the infiltration volume safely into the downstream stormwater conveyance system is REQUIRED.

Freeboard: It is HIGHLY RECOMMENDED that two feet of freeboard be provided from the 100-year flood elevation of the infiltration practice to the lowest basement floor elevation of residential, commercial, industrial and institutional buildings located adjacent to the BMP, unless local requirements recommend otherwise.

Drop Structure: Infiltration trenches or subsurface infiltration systems may be designed with a drop structure sized to handle the overflow. This additional volume of stormwater may be directed into the existing stormwater system or it may be diverted to a downstream BMP

Step 8. Perform ground-water mounding analysis (Note: Steps 6, 7, 8 and 9 are iterative).

Ground water mounding, the process by which a mound of water forms on the water table as a result of recharge at the surface, can be a limiting factor in the design and performance of infiltraand seasonally saturated soils (or from bedrock) is REQUIRED (5 feet RECOMMENDED) to maintain the hydraulic capacity of the practice and provide adequate water quality treatment. A ground water mounding analysis is RECOMMENDED to verify this separation for infiltration practices.

The most widely known and accepted analytical methods to solve for ground water mounding are based on the work by Hantush (1967) and Glover (1960). The maximum ground water mounding potential should be determined through the use of available analytical and numerical methods. Detailed ground water mounding analysis should be conducted by a trained hydrogeologist or equivalent as part of the site design procedure.

Step 9. Determine pre-treatment volume and design pre-treatment measures (Note: Steps 6, 7, 8 and 9 are iterative).

See the section on pre-treatment earlier in this section for specific pre-treatment design guidance

Step 10. Check volume, peak discharge rates and period of inundation against State, local and watershed organization requirements (Note: Steps 6, 7, 8 and 9 are iterative).

Follow the design procedures identified in the Unified Sizing Criteria (Chapter 10) section of the Manual to determine the volume control and peak discharge requirements for water quality, recharge, channel protection, overbank flood and extreme storm.

Perform hand calculations or model the proposed development scenario using a surface water model appropriate for the hydrologic and hydraulic design considerations specific to the site (see also Chapter 8 and Appendix B of the Manual). This includes defining the parameters of the infiltration practice defined above: elevation and area (defines the storage volume), infiltration rate and method of application (effective infiltration area), and outlet structure and/or flow diversion information. The results of this analysis can be used to determine whether or not the proposed design meets the applicable requirements. If not, the design will have to be re-evaluated (back to Step 5).

The following items are specifically REQUIRED by the MPCA Permit:

Volume: Infiltration or filtration systems shall be sufficient to infiltrate or filter a water quality volume of ½ inch of runoff from the new impervious surfaces created by the project (or 1 inch for certain protected waterbodies). If this criterion is not met, increase the storage volume of the infiltration practice or treat excess water quality volume (Vwq) in an upstream or downstream BMP (see Step 5).

Peak Discharge Rates: Since most infiltration systems are not designed for quantity control they generally do not have peak discharge limits. However outflow must be limited such that erosion does not occur down gradient.

Period of Inundation: Infiltration practices shall discharge through the soil or filter media in 48 hours or less. Additional flows that cannot be infiltrated or filtered in 48 hours should be routed to bypass the system through a stabilized discharge point. This criterion was established to provide the following: wet-dry cycling between rainfall events; unsuitable mosquito breeding habitat; suitable habitat for vegetation; aerobic conditions; and storage for back-to-back precipitation events. The period of inundation is defined as the time from the high water level in the practice to 3 to 6 inches above the bottom of the facility. It is assumed that this range is less than 1/5 the bounce in the infiltration practice.

Other design requirements may apply to a particular site. The applicant should confirm local design criteria and applicability (see Step 3).

Step 11. Prepare Vegetation and Landscaping Plan.

A landscaping plan for an infiltration basin or trench should be prepared to indicate how the enhanced swale system will be stabilized and established with vegetation. Landscape design should specify proper grass species and wetland plants based on specific site, soils and hydric conditions present along the channel. Further information on plant selection and use occurs in Appendix E of the manual.

Step 12. Prepare Operation and Maintenance (O&M) Plan.

See Operation and Maintenance section for guidance on preparing an O&M plan.

Step 13. Prepare Cost Estimate.

See Cost Considerations section for guidance on preparing a cost estimate that includes both construction and maintenance costs.

Links to Other Manuals

Georgia Stormwater Management Manual. 2001. Atlanta Regional Commission. http://www.georgiastormwater.com/

Vermont Stormwater Management Manual. 2002. http://www.vtwaterquality.org/stormwater.htm.

Wisconsin DNR Site Evaluation for Stormwater Infiltration Conservation Practice Standard 1002. 2004. http://dnr.wi.gov/org/water/wm/nps/stormwater/techstds.htm#Post.

Wisconsin DNR Infiltration Basin Conservation Practice Standard 1003. 2004. http://dnr.wi.gov/org/water/wm/nps/stormwater/techstds.htm#Post.

References

ASTM standard D2487-00 Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System).

Bouwer, H. and R. C. Rice. 1989. Effect of Water Depth in Ground-water Recharge Basins on Infiltration. Journal of Irrigation and Drainage Engineering, Vol. 115, No. 4, pp. 556-567.

Georgia Stormwater Management Manual. 2001.

Glover, R., 1960. Mathematical Derivations as Pertain to Ground-water Recharge. Report CER60REG70. Agricultural Research Service, USDA, Fort Collins, Colorado. 81 pp.

Hantush, M., 1967. Growth and Decay of Ground-water-Mounds in Response to Uniform Percolation. Water Resources Research, 3(1): 227-234.

Rawls, W., D. Brakensiek, and K. Saxton, 1982. Estimation of Soil Water Properties, Transactions of the American Society of Agricultural Engineers. Vol. 25, No. 5, pp. 1316 – 1320 and 1328.

Rawls, W., D. Giminez, and R. Grossman, 1998. Use of Soil Texture, Bulk Density and Slope of water Retention Curve to Predict Saturated Hydraulic Conductivity, ASAE. Vol. 41(4), pp. 983 – 988.

Metropolitan Council Urban Small Sites Best Management Practice Manual. 2001.

Minnesota Pollution Control Agency Stormwater Best Management Practices Manual. 2000.

Natural Resources Conservation Service, 1986. Urban Hydrology for Small Watersheds, Technical Release 55 (TR-55). ftp://ftp.wcc.nrcs.usda.gov/downloads/hydrology_hydraulics/tr55/tr55.pdf

South Washington Watershed District (SWWD), 2005. 2004 Infiltration Monitoring Program Final Report. Emmons and Olivier Resources, Inc.

United States Department of Agriculture Natural Resources Conservation Service. TR-55, Urban Hydrology for Small Watersheds. Washington D.C., 1975.

U.S. Department of Agriculture, Natural Resources Conservation Service, 2005. National Soil Survey Handbook, title 430-VI. (Online) Available: http://soils.usda.gov/technical/handbook/.

U.S. Environmental Protection Agency, When are Storm Water Discharges Regulated as Class V Wells, June 2003

University of Wisconsin – Extension Wisconsin Storm Water Manual: Technical Design Guidelines for Storm Water Management Practices. 2000.

Winer, R. 2000. National Pollutant Removal Performance Database.

Wisconsin Department of Natural Resources Site Evaluation for Stormwater Infiltration Conservation Practice Standard 1002. 2004.

Wisconsin Department of Natural Resources Infiltration Basin Conservation Practice Standard 1003. 2004.

Wisconsin Department of Natural Resources. Personal conversation with Roger Bannerman. July 2005.