Design criteria for stormwater and rainwater harvest and use/reuse

Stormwater harvest and use can be implemented at a variety of scales, from individual parcels to regional scales, and in a variety of contexts, from ultra-urban settings to new development. The scale and complexity of any harvest and use project depends on several factors, including source water quality, intended application, and water quality recommendations and/or regulations. The design process for each project must be flexible and rigorous enough to address these factors.

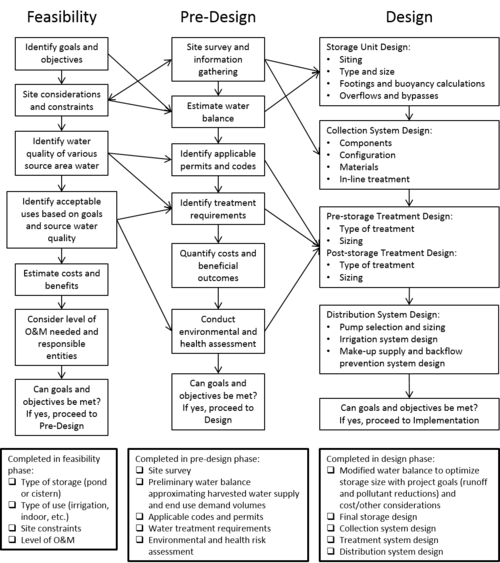

Although there is a wealth of information on selection and design of system components (collection, storage, treatment, and distribution systems), guidance offering a concept-to-finish perspective is limited (Met Council, 2011; NC DEQ, 2017; Water Sensitive SA). The design process described in this report uses four broad phases: feasibility, pre-design, design, and implementation. In practice the distinction between phases is not strict. Design is an iterative process which should include several rounds of review beginning in the feasibility phase.

The following discussion includes a description of each design phase, a list of activities typically included in each phase, design guidance, and key resources for individual activities.

Contents

- 1 Overview of broad phases of design

- 2 Feasibility phase

- 2.1 Identify harvest and use system goals and objectives

- 2.2 Additional Resources

- 2.3 Consider site opportunities and constraints

- 2.4 Additional Resources

- 2.5 Identify source areas and expected source water quality

- 2.6 Determine acceptable use(s) of stormwater based on the needs of each use on site

- 2.7 Consider level of operation and maintenance needed

- 2.8 Decide whether to proceed to pre-design

- 3 Pre-design phase

- 4 Design phase

- 4.1 Storage

- 4.1.1 Determining the appropriate storage size

- 4.1.2 Determining the siting of the storage system

- 4.1.3 Storage siting additional resources

- 4.1.4 Selecting and designing the storage unit

- 4.1.5 Storage tanks and cisterns

- 4.1.6 Stormwater ponds

- 4.1.7 Design resources

- 4.1.8 Footings and buoyancy calculations

- 4.1.9 Overflows and bypass

- 4.1.10 Design considerations

- 4.1.11 Design resources

- 4.2 Collection

- 4.3 Treatment

- 4.4 Distribution

- 4.1 Storage

- 5 Design considerations for ponds used for harvest and use

- 6 Implementation phase

- 7 References

- 8 Related pages

Overview of broad phases of design

The four broad phases of design include feasibility, pre-design, design, and implementation. This section provides a summary list of components of each design phase. These are discussed in greater detail in the following section. Implementation is discussed only briefly in this section and is covered in greater detail in the construction section.

Feasibility phase

During the feasibility phase, opportunities for stormwater harvest and use are identified and evaluated at a basic level, taking into consideration site characteristics, expected source water quality, and constraints imposed by various use applications. The goal of this phase is to determine if a project is feasible and, if it is, what constraints might exist. Typical feasibility phase activities include the following:

- Identify system goals & objectives

- Consider site opportunities and constraints

- Identify source areas and expected source water quality

- Determine acceptable use(s) of stormwater

- If appropriate, contact a professionally licensed civil, environmental and/or mechanical engineer, irrigation contractor, landscape architect, professional system supplier.

- Develop schematic designs and, if a licensed engineer is hired, have them review the schematics

- Consider the level of operation and maintenance needed

- Identify regulatory agencies and applicable codes

- Decide whether to proceed to Pre-design

Pre-design phase

During the pre-design phase, stormwater harvest and use opportunities that were identified in the feasibility phase are evaluated at greater depth to determine the most feasible option or best application. Typical pre-design phase activities include the following:

- Complete a site survey and information gathering

- Estimate the water balance for the site

- Estimate the total dynamic head of the plumbing system. Report pumping requirements in gallons per minute (gpm) and pounds per square inch (psi). Refine system requirements in design phase.

- Identify required permits

- Identify water treatment requirements

- Conduct an environmental and health risk assessment

- Hold a pre-design meeting with the civil, environmental or mechanical engineer, system supplier or other accredited professional.

- Submit feasibility findings for review

- Refine goals and objectives

- Decide whether to proceed to Design

Design phase

The design phase includes the selection, sizing, siting, and design of stormwater harvest and use system components. Generalized design steps are listed below. In practice, design is an iterative process and steps will likely be revisited as the system design is refined in conjunction with site, cost, regulatory, or other considerations.

- Storage system: tank or pond

- Collection system: rooftop or ground collection system

- Treatment systems: pre-storage or post-storage

- Distribution system

- Makeup water supply system and backflow prevention

- System Controls

- Determine construction phasing

- Complete external review process

- Revise design if necessary including integrating civil, mechanical and irrigation plans.

- For commercial rainwater harvesting systems, it is highly recommended to develop or work with an experienced system manufacturer to refine a detailed written specification to be incorporated with the design drawings. The majority of commercial systems involve the integration of many separate components that integrate the pumping, treatment and control of the system.

Implementation phase

The implementation phase includes all post-design work including construction and installation; operations, maintenance, and monitoring; and additional activities which are included in project objectives. Typical implementation phase activities include the following

- Hold a preconstruction meeting with the civil and mechanical engineer, system supplier, plumbers, irrigation consultant, electrician and excavator (or anyone involved in the physical installation of the systems)

- Construction activities

- Permitting

- Install appropriate signage & safety features (See Section 1702.8 Minnesota Plumbing Code)

- Perform all necessary testing for pressure testing of tanks (if required), cross connection tests and RPZ or air gap tests.

- Commission system.

- Implement O&M and monitoring plans (See Section 1702.12 Minnesota Plumbing Code)

- Implement cooperative goals (education & outreach, etc.)

- Commissioning

The implementation phase is discussed in detail in the sections on construction and on operation and maintenance.

Additional resources

More information on the design process and design sequencing can be found in the following resources:

- Metropolitan Council. Fall 2011. Stormwater Reuse Guide, prepared by Camp Dresser & McKee, Inc. and others. St. Paul, MN.

- City of Bellingham, Public Works Department. March, 2012. Rainwater Harvesting, Guidance towards a Sustainable Water Future. City of Bellingham, WA.

- Department of Environment and Conservation, New South Wales. April 2006. Managing Urban Stormwater: Harvesting and Reuse. Sydney, Australia, ISBN 1 74137 875 3.

- Department of Planning and Local Government (DPLG). December 2010. Water-Sensitive Urban Design Technical Manual for the Greater Adelaide Region; Chapter 8 - Urban Water Harvesting and Reuse. Government of South Australia.

- North Carolina Department of Environmental Quality (NC DEQ). April 2014. North Carolina Stormwater BMP Manual, Chapter 25, Rainwater Harvesting. Draft document.

- American Rainwater Catchment System Association and American Society of Plumbing Engineers. 2013. ARCSA/ASPE/ANSI Standard 63-2013. Rainwater Catchment Systems

- American Rainwater Catchment System Association and American Society of Plumbing Engineers. 2015. ARCSA/ASPE78: Stormwater Harvesting System Design for Direct End‐Use Applications

- American Rainwater Catchment System Association. 2015. ARCSA Rainwater Harvesting Manual. 1st Edition

- Despins, Christopher. 2010. Ontario Guidelines for Residential Rainwater Harvesting Systems. Eds. Leidl, C., and K. Farahbakhsh

Feasibility phase

During the feasibility phase, project objectives are defined and opportunities for stormwater harvest and use are evaluated at a preliminary level. Preliminary evaluations should take into consideration site characteristics, expected source water quality, and constraints imposed by various harvest and use applications. The goal of the feasibility phase is to identify stormwater harvest and use opportunities that are suitable for in-depth feasibility analysis or determine that harvest and use is not feasible.

Identify harvest and use system goals and objectives

The first step in the project is to define objectives. Objectives are typically driven by regional or organizational goals, including the following:

- decrease the quantity of potable water used;

- adding resiliency into the water supply system;

- utilizing stormwater as a resource, instead of a waste product;

- pollution prevention by capturing rainwater prior to contact with surface;

- decrease stormwater runoff volumes and/or stormwater runoff rates; and

- decrease pollutant loads associated with stormwater runoff.

Specific, quantifiable goals which address project objectives should be used to evaluate the feasibility of the proposed system. Examples include the following:

- capture 90 percent of annual stormwater runoff from a site;

- capture sufficient water to meet ½ of the irrigation demand for a golf course;

- reduce phosphorus loading from a site by 80 percent; or

- capture sufficient water to meet ½ of the toilet flushing demand for a business.

In Minnesota, capture and use of stormwater irrigation use is increasingly being used to meet runoff and phosphorus reductions goals. Irrigation practices utilize evapotranspiration losses of water and plant uptake and soil adsorption of the dissolved fraction of phosphorus. The determination of project objectives and goals may be an iterative process in which project objectives are modified based on feasibility, cost, or other concerns. Identifying project objectives which align with broad regional or organizational goals may be important in garnering stake-holder support or procuring funding for the project.

Additional Resources

- Department of Environment and Conservation, New South Wales. April 2006. Managing Urban Stormwater: Harvesting and Reuse. Sydney, Australia, ISBN 1 74137 875 3.

- Department of Planning and Local Government. December 2010. Water-Sensitive Urban Design Technical Manual for the Greater Adelaide Region; Chapter 8 - Urban Water Harvesting and Reuse. Government of South Australia.

Consider site opportunities and constraints

At the feasibility phase, a preliminary assessment of site conditions provides an understanding of stormwater harvest and use constraints and opportunities. More in-depth analysis of site conditions and constraints will be required during pre-design and design phases. The following table describes some site considerations and identifies potential constraints.

Water reuse key site considerations

Link to this table

| Consideration | Notes | Potential constraints |

|---|---|---|

| Catchment boundaries | Identify the area(s) from which water can be captured. This is necessary to compute capture volumes, identify site constraints, and determine water quality. | Does the amount of water that can be captured affect the type of possible end use and the size of storage unit? |

| Existing drainage patterns | Identify how water will drain from the catchment area(s). | Do any additional drainage features need to be constructed to centralize runoff collection? |

| Buffers and Setbacks | Identify wetlands, streams, shorelines, and buildings/structures in the potential receiving area and determine setbacks from these, including buffer zones. Identify setback distances for infiltration practices described in the Minnesota Stormwater Manual and determine if these are applicable to the project. | Are there any portions of the irrigation area that fall within a setback? |

| Proximity to water supply wells or sensitive water bodies | Identify setback distances for infiltration practices described in the Minnesota Stormwater Manual and determine if these are applicable to the project. | Are there any setback distances from supply wells or sensitive water bodies to consider? |

| Existing and adjacent land use/ stormwater hot spots | Water quality varies with land use and will impact the level of treatment needed. Runoff from confirmed stormwater hotspots should not be used for harvest and use unless treated to appropriate standards. May need appropriate bypass systems. | Are there any portions of the catchment area that need to be bypassed from the collection system or that require additional treatment prior to use? |

| Future land use changes | Changes in the land use of the source area or irrigation areas may change opportunities and hurdles to implementation, such as level of treatment needed or availability of green space for irrigation. | Are there any future land use changes that may prohibit or alter the proposed stormwater harvest and use system? (e.g. stormwater hotspots) |

| Existing infrastructure | Maintain easements/appropriate distance from sewer lines, fiber optic cables, etc. | Is there any infrastructure that needs to be avoided? |

| Site slopes | Slope may affect runoff calculations and affect the system design (e.g. location of storage tank). | Can sufficient runoff be collected from the source area? Can the cistern be placed at the lowest point on site? If not, what modifications need to be made to the collection system to route stormwater to the cistern? |

| Soil type | Infiltration capacity affects runoff calculations and irrigation demand assumptions. | Can sufficient runoff be collected from the source area? How do the irrigation area soils affect irrigation demand? |

| Proximity to building foundations & utilities | Leakage from storage tanks could damage building foundations or utilities. Geotechnical engineering may be needed to ensure sufficient support for tanks and to prevent damage to adjacent foundations. | Are there any setback distances from building foundations or utilities to consider? |

| Seasonal high water table | Underground components may be constrained by the seasonal high water table. Above-ground systems are generally unaffected by the seasonal high water table. | Will the seasonal high water table level affect any underground components? |

| Maintenance access | Need space for maintenance access. | Is there sufficient space for maintenance access? |

| Code or System Expansion | Configure the system to allow for expansion if space is available. Follow national standards and simple steps of including a pipe stub in or designed plumbing system to allow for future incorporation of indoor uses in a phased fashion | Should we stub in a pipe in case a code or owner changes to allow other uses? Can we configure the plumbing to adapt for indoor use in a second phase or when funding is available? |

Additional Resources

- Metropolitan Council. Fall 2011. Stormwater Reuse Guide, prepared by Camp Dresser & McKee, Inc. and others. St. Paul, MN.

- North Carolina Department of Environmental Quality (NCDEQ). April 2014. North Carolina Stormwater BMP Manual, Chapter 25, Rainwater Harvesting. Draft document.

- City of Bellingham, Public Works Department. March, 2012. Rainwater Harvesting, Guidance towards a Sustainable Water Future. City of Bellingham, WA.

- Department of Planning and Local Government (DPLG). December 2010. Water-Sensitive Urban Design Technical Manual for the Greater Adelaide Region; Chapter 8 - Urban Water Harvesting and Reuse. Government of South Australia.

- Cabell Brand Center, 2009

Identify source areas and expected source water quality

Expected stormwater quality from various source areas is described in detail in the section on water quality considerations. Snowmelt from ground surfaces tends to have higher pollutant concentrations compared to runoff at other times of the year (EOR and CWP, 2005). Oberts (2000) discussed the dynamics of snowmelt runoff quality, indicating the initial melt (snow and ice from pavement) can have very high concentrations of soluble pollutants, which can be difficult to remove in traditional stormwater BMPs. Depending on the use of harvested stormwater, it may be desirable to provide a bypass or use a pre-tank filter for spring snowmelt, particularly the initial phase of the melt. Typical pollutants found in stormwater collected from different source areas are summarized in the table below.

Typical pollutants found in stormwater collected from different source areas

Link to this table

| Source Area | Solids | Total suspended solids | Nutrients | Bacteria | Metals | Chloride | Grease, Oil | Pesticides | Other chemicals |

|---|---|---|---|---|---|---|---|---|---|

| Hard Roofs1 | |||||||||

| Green and Brown Roofs2 | |||||||||

| Paved Surfaces (parking lots, sidewalks, driveways and roadways) | |||||||||

| Green Spaces (lawns and park areas) |

● = relatively high concentrations

○ = relatively low concentrations

1Metals are highly dependent on roof type-only certified membrane roofs are currently approved for potable through NSF.

2Vegetated roofs and pervious pavers have had poor performance due to discoloration of water and difficulty filtering the water to levels that the UV treatment is effective.

Determine acceptable use(s) of stormwater based on the needs of each use on site

Potential uses of harvested stormwater include the following.

- Outdoor use

- Sanitary sewer flushing

- Irrigation (low or high exposure risk)

- Vehicle/building washing

- Fire fighting

- Water features

- Street cleaning/dust control

- Indoor use

- Fire suppression

- Cooling

- Process/boiler water

- Flushing

- Washing (e.g. bathing, laundry, dishwashing)

- Drinking water

General considerations for the use of harvested stormwater are described here. See also the Source and Use Worksheet, C.1w, from the 2011 Met Council Reuse Guide. In addition, if the harvest and use system is required to follow the Minnesota Plumbing Code, check Section 1702.9.3 for prohibited collection surfaces and discharges.

Harvested stormwater beneficial uses

Link to this table

| Beneficial Uses | Stormwater from rooftops only (rainwater) | Stormwater | |||

|---|---|---|---|---|---|

| Health Criteria Level | Expected level of effort | Health Criteria Level | Expected level of effort | ||

| Outdoor | Sanitary sewer flushing | Limited human exposure at point of use and limited exposure to pathogens upstream of point of use | No treatment needed | Limited human exposure at point of use and limited exposure to pathogens upstream of point of use | Minimal (pretreatment) |

| Irrigation – low exposure risk | Limited human exposure at point of use and limited exposure to pathogens upstream of point of use. | Minimal (pretreatment)1 | Limited human exposure at point of use and limited exposure to pathogens upstream of point of use.1 | Medium (pretreatment + disinfection OR pretreatment + treatment) | |

| Irrigation – high exposure risk | Limited human contact and controlled access at point of use.1 | Medium (pretreatment + disinfection OR pretreatment + treatment) | Limited human contact and controlled access at point of use.1 | High (pretreatment + treatment + disinfection) | |

| Vehicle/building washing | Limited human contact and controlled access at point of use.1 | Medium (pretreatment + disinfection OR pretreatment + treatment) | Limited human contact and controlled access at point of use.1 | Medium (pretreatment + disinfection OR pretreatment + treatment) | |

| Fire fighting | Limited human contact and controlled access at point of use.1 | Minimal (pretreatment) | Limited human contact and controlled access at point of use.1 | Medium (pretreatment + disinfection OR pretreatment + treatment) | |

| Water features (uncontrolled access) | Limited human contact and controlled access at point of use. | Medium (pretreatment + disinfection OR pretreatment + treatment) | Limited human contact and controlled access at point of use. | Medium (pretreatment + disinfection OR pretreatment + treatment) | |

| Street cleaning/ dust control | Limited human contact and controlled access at point of use.1 | Medium (pretreatment + disinfection OR pretreatment + treatment) | Limited human contact and controlled access at point of use.1 | Medium (pretreatment + disinfection OR pretreatment + treatment) | |

| Indoor | Fire suppression | Limited human contact and controlled access at point of use. | Medium (pretreatment + disinfection OR pretreatment + treatment) | Limited human contact and controlled access at point of use. | Medium (pretreatment + disinfection OR pretreatment + treatment) |

| Cooling | Limited human contact and controlled access at point of use.1 | Medium (pretreatment + disinfection OR pretreatment + treatment) | Limited human contact and controlled access at point of use.1 | High (pretreatment + treatment + disinfection) | |

| Process /Boiler Water | Limited human contact and controlled access at point of use.1 | Medium (pretreatment + disinfection OR pretreatment + treatment) | Limited human contact and controlled access at point of use.1 | High (pretreatment + treatment + disinfection) | |

| Flushing | Uncontrolled access at point of use1 | Medium (pretreatment + disinfection OR pretreatment + treatment) | Uncontrolled access at point of use1 | High (pretreatment + treatment + disinfection) | |

| Washing | Uncontrolled access at point of use | Medium (pretreatment + disinfection OR pretreatment + treatment) | Uncontrolled access at point of use1 | High (pretreatment + treatment + disinfection) | |

| Drinking water | Drinking water standards | Drinking water standards | Drinking water standards | Drinking water standards | |

1A higher level of treatment that may be required depending on context

Note: In practice, all indoor non potable uses are typically treated to water quality requirements in code and currently require disinfection.

Consider level of operation and maintenance needed

Key operation and maintenance (O&M) questions to consider during the feasibility phase include:

- Who will be responsible for O&M?

- Is there a need for a licensed professional to do certain components of O&M?

- How often does O&M need to occur?

- How intensely must the system be operated and maintained?

See the section on operation and maintenance for detailed information pertaining to these questions.

Decide whether to proceed to pre-design

If the goals and objectives are compatible with the identified site constraints, source areas, and appropriate uses, proceed to Pre-design.

Pre-design phase

Complete site survey & information gathering

The following information may be useful or necessary when designing a harvest and use system. Some of the information is general and should be used for initial screening. The information should be recorded in a form (see link; Data Collection Worksheet, C.2w, items 1-3, from the 2011 Met Council Reuse Guide).

- System maps and surveys

- Municipal storm sewer maps illustrate stormwater drainage and treatment features, including piping, sewer inlets, treatment devices, and outfalls. These maps can be used to determine drainage patterns and potential catchments for the harvest system. Storm sewer maps are not readily available. Consult with the local municipality to determine if these maps are available. Example maps can be found in the Storm Water Master Plan for the University of Minnesota Twin Cities Campus (2012).

- Topographic information is used to determine elevations, drainage patterns, and slope. USGS topographic maps illustrate these features and also illustrate other features, such as surface waters. Light Detection and Ranging (LIDAR) allows for high-resolution topographic mapping.

- FEMA floodplain maps are used to indicate if the site is located in a floodplain. Sites located in floodplains may necessitate specific design considerations and may utilize floodwater as part of the harvest system.

- County soils maps can be used to determine the permeability of soils and estimate other soil properties, such as depth to water.

- Karst maps indicate the location of active karst areas. Irrigation over active karst is not recommended without site specific investigation.

- Municipal, county, and MnDOT highway maps are used to help determine the catchment area.

- Hazardous waste site maps indicate the location of hazardous waste facilities or hazardous waste sites (e.g. Superfund sites). The MPCA’s What’s in My Neighborhood tool can be used to identify these sites. This manual provides guidance for infiltration on sites with potential or confirmed soils or groundwater contamination.

- Wellhead protection areas/drinking water supply management areas.

- Studies and reports

- Runoff monitoring data and reports for the area or site provide information on stormwater runoff quantity and water quality, which can be used in determining appropriate level of treatment.

- Hydrology analyses define rate and volume of stormwater runoff, which can be used in runoff calculations.

- Stormwater design data for sites with pre-existing stormwater collection systems can be used in laying out the components of the harvest and use system.

- Pre-existing permits for use in identifying limitations to the project. Permits include but are not limited to land use, zoning, building, plumbing, and stormwater discharge permits (e.g. MS4 permit).

- Pre-existing site soil borings and other geotechnical analyses that help determine soil infiltration properties, depth to bedrock, depth to water, and other similar features.

- Site specific data and surveys

- Site plans or site surveys identify existing structures, roof areas, impervious surfaces, slopes, and drainage patterns.

- Gopher State One-Call for locating above- and below-ground utilities.

- Storm sewer surveys include determining the location of stormwater infrastructure, including pipes, inlets, outlets, storage, and treatment structures. Note the size and type of these structures.

- Dimensions, depth, structures, and operating requirements for stormwater ponds or other BMPs located on the site.

- Pre-existing storage tank properties including dimensions, control valves, cover, fencing, elevations, access, inlets, outlets, and condition.

- Presence and location of wells. County Well Index (is now the Minnesota Well Index) is a tool that can be used to identify wells.

- Building plans that show roof structures, materials, and drainage systems.

- Precipitation data is used for runoff calculations. Use site information, if available, or data from the nearest station having long-term records.

Harvested stormwater site survey and information worksheet

Link to this table

| Item | Comments / notes | Used |

|---|---|---|

| Storm sewer maps | ||

| Topographic maps | ||

| Floodplain maps | ||

| Soil maps | ||

| Karst maps | ||

| Highway maps | ||

| Hazardous waste site maps | ||

| Runoff monitoring data | ||

| Hydraulic analyses | ||

| permits | ||

| Soil borings/geotechnical analyses | ||

| Site plans | ||

| Gopher State One call | ||

| Storm sewer surveys | ||

| Presence of wells | ||

| Building plans | ||

| Precipitation data | ||

| Existing information on stormwater ponds | ||

| Existing information on storage tanks |

Estimate the water balance for the site

A water balance must be calculated to determine if the desired capture volumes can be achieved and to properly size the system. A water balance consists of estimating the amount of water that can be captured and the amount of water that is used. Key considerations include balancing the amount of storage unit overflow with the size of the storage unit, and limiting or eliminating the need for a secondary water supply.

For stormwater management, it is recommended to evaluate source areas (harvest and use supply) first and then identify candidate use applications. Calculations of water captured are a function of rainfall and runoff potential from the site.

Detailed information for estimating a water balance is found at the page titled Estimating the water balance for a stormwater and rainwater harvest and use/reuse site. That page provides information on calculating a watershed budget and a phosphorus budget. The page includes equations for calculating water and phosphorus budgets and water demand. The page also provides links, including links to calculators.

Identify required permits and applicable codes

Required permits and applicable codes include the following: (note that not all may apply to every situation)

- Municipal zone and zoning codes – contact the municipality in which the project occurs to determine if zoning review is required or zoning codes are applicable for harvest systems

- Municipal permits

- Plumbing permits may be required for new or altered underground and interior piping. Contact the local building department for more information.

- Building permits – contact the local Zoning Administrator to determine if a building permit is required.

- Erosion and sediment control permits may be required. A State Construction Stormwater permit is required if the project results in land disturbance of equal to or greater than one acre or a common plan of development or sale that disturbs greater than one acre. Some municipalities and watershed organizations have more stringent requirements. Contact local units of government to determine if local erosion and sediment control permits are required.

- Site plan approval is required to ensure compliance with local ordinances. Site plan review and approval is often conducted by a city planner. Contact the appropriate local entity for site plan review and approval.

- Storm/sanitary/water connections permits are required for new connections to a storm or sanitary sewer system.

- Minnesota Plumbing Code

- Watershed District or Watershed Management Organization Rules

- County Health Department permits

- Minnesota Pollution Control Agency (MPCA)

- MPCA’s jurisdiction is typically over the water quality reaching the waters of the state and to ultimately protect the water quality in the lakes, streams, and groundwater. In terms of stormwater management, this typically applies to construction sites disturbing more than one acre of soil, industrial sites that currently have an industrial stormwater permit, or MS4s (Municipal Separate Storm Sewer System operators) trying to meet the requirements of their permits (which can include TMDL—Total Maximum Daily Load—wasteload allocations). Unless the stormwater harvesting and reuse systems for irrigation system is intended to demonstrate compliance with any of the above permits and stormwater management requirements, the MPCA would not be involved in the review of these systems.

- Minnesota Department of Natural Resources (MDNR) (Per 6/14/17 email conversation with Dan Miller, MDNR).

- A water appropriations permit is required from the MDNR for all users withdrawing more than 10,000 gallons per day or 1 million gallons per year from waters of the state. The term “waters of the state” is defined by statute as “surface or underground waters, except surface waters that are not confined but are spread and diffused over the land.” This includes water in ponds and basins.

- However, a law enacted by the 2017 legislative session exempts stormwater control and reuse facilities from the water appropriation permit requirement. It specifically exempts “appropriation or use of storm water collected and used to reduce storm-water runoff volume, treat storm water, or sustain groundwater supplies when water is extracted from constructed management facilities for storm water.” “Constructed management facilities for storm water” is defined as “ponds, basins, holding tanks, cisterns, infiltration trenches and swales, or other best management practices that have been designed, constructed, and operated to store or treat storm water in accordance with local, state, or federal requirements.”

- Previously, a permit was required to use stormwater for irrigation or other uses. Existing water appropriation permits using stormwater for irrigation will be canceled, effective July 1, 2017. Stormwater reuse facilities that use natural, non-constructed water features for irrigation or other uses may still require water appropriation permits from the DNR. If you have any questions contact Dan Miller with the DNR (651-259-5731).

In general, if water is pumped out of a stormwater basin, an appropriation permit is required. If the water is temporarily drained out of the basin via an operable outlet structure, an appropriation permit is not required. However, Minnesota law now provides an incentive for stormwater capture and reuse. Legislation adopted in 2014 directs the Department of Natural Resources to “waive the water use permit fee for installations and projects that use storm water runoff or where public entities are diverting water to treat a water quality issue and returning the water to its source without using the water for any other purpose, unless the commissioner determines that the proposed use adversely affects surface water or groundwater.” (MS §103G.271, subd. 6(g); emphasis added). Therefore, stormwater reuse is exempt from the annual water use reporting fee, although an one-time application fee is required. Under the appropriation permit, monthly water use is measured and reported annually.

A general permit for temporary projects (General Permit 1997-0005) authorizes temporary water use of up to 50 million gallons per year for activities such as construction dewatering, landscaping, dust control, firefighting, and hydrostatic testing of pipelines, tanks and wastewater ponds, provided that activities are completed within one year.

The DNR is currently requesting comments on a proposed general permit for stormwater use In MS4-regulated communities. The general permit would authorize stormwater use for irrigation of residential landscaped areas, cemeteries, golf courses, athletic fields, and similar sites. The MS4-regulated community can utilize the general permit as a method to more quickly get approval of stormwater use projects. In addition, the MS4 community could coordinate the application and reporting of stormwater use projects from private entities, if desired. For further information, contact Dan Miller at Dan.W.Miller@state.mn.us

Identify water treatment requirements

See the section on water quality considerations.

Conduct an environmental and health risk assessment

See the section on environmental concerns.

Decide whether to proceed to design

Use the Pre-design phase checklist to determine whether to proceed to the design phase. In general, you can proceed to the Design Phase if

- no major site constraints were identified during site survey and information gathering, or if these constraints can be overcome;

- the harvested water supply is sufficient to meet identified use demands based on available storage, or if not sufficient, a supplemental supply can be used to meet the demands;

- water treatment requirements and codes can be met;

- required permits can be obtained; and

- environmental and health risks are acceptable.

Design phase

The design phase involves identifying the specific components of the harvest and use system.

Storage

Storage is the central and often most expensive component in a stormwater harvesting and use system. Several factors must be considered, including size, type, siting and materials certification (e.g. NSF 61) of the storage system.

Determining the appropriate storage size

Decision-making on storage size can have a strong impact on the economic feasibility of stormwater harvesting (VA DCR, 2009). During the pre-design phase, a water balance should have been completed. This water balance should be refined during the Design Phase to incorporate other factors such as cost, site constraints, aesthetic concerns, or water quality criteria. For these reasons, the selection and sizing of storage units may be an iterative process. Work with an engineer, system supplier or accredited professional with experience using stormwater harvest and use calculators to appropriately size storage units for your stormwater harvest and use system.

For information and guidance on determining approrpiate storage size, see the page titled Determining the appropriate storage size for a stormwater and rainwater harvest and use/reuse system. Methods for sizing tanks are discussed in the section on water balance.

Determining the siting of the storage system

Storage options for stormwater harvesting systems include above- or below-ground tanks or cisterns which are closed to the environment, and above-ground open storage, such as a stormwater retention or detention pond. Depending on the type of storage system, considerations for siting storage units include the following.

For all storage systems

- Ensure the location allows for proper drainage of rainwater through the conveyance network and the stormwater discharge location.

- Ensure that inflow and overflow are the same diameter.

- Ensure the location can accommodate the desired storage capacity.

- Ensure sufficient access around the perimeter of the storage system to install, inspect and maintain the system and all its components, including access for equipment.

- Does the storage system require specific location or proximity to source areas and overflow pathways or electrical and water utilities to service pumps, controls, and makeup water supply?

- Should an outdoor system be provided with a large pump to do all the work or is it more cost effective to pump and treat at a slower rate to a day tank? For flows above 50 gallons per minute, use of a day tank reduces the size of the treatment system, initial cost and long term maintenance costs.

- Should the storage system be placed so that it can be expanded later? For example, if another tank is added later, should the tanks be configured to deliver and receive overflow?

- Ensure the location is permitted by applicable provincial codes and regulations and municipal zoning bylaws. Consult local building authorities for details.

- Consider site topography and storage tank location, which will affect pumping requirements. Locating storage tanks in low areas will make it easier to get water into the cisterns; however, it will increase the amount of pumping needed to distribute the harvested stormwater back into the building or to irrigated areas situated on higher ground. Conversely, placing storage tanks at higher elevations may require larger diameter pipes with smaller slopes but will generally reduce the amount of pumping needed for distribution (Draft District of Columbia Stormwater Management Guidebook).

- Consider siphonic roof drainage to reduce conveyance pipe costs and when elevation issues are present.

- Consider if weather proofing of the tank is necessary; will the tank be operational during the winter months to service the stormwater use?

For underground storage tanks

- Avoid potential conflicts with underground utilities.

- Provide a union disconnect inside of the access cover that allows disconnection of the pump without entering the tank. After the union, the pump line can exit deep in the tank below frost line for year round applications.

- Underground, outdoor tanks may need to be located below the frost line, drained or decommissioned during the cold season. The entire tank may not need to be under the frost line. For example, smaller systems may be designed with 2 inches of rigid insulation above the tank and utilization of the Ontario freeze model to identify thickness, depth and flaring of the insulation. Pump lines need to be below the frost line or freeze protected. Systems with bypass or prefiltration with a blind insert can divert water away from the system and do not need to be disconnected in the winter.

- Are there any safety issues like soil settling, proximity to basements, or others issues that would preclude a tank location?

- Areas with vehicle traffic should be avoided or the tank needs to be structurally strong enough to support the traffic load. If pre-filtration is used, specify the proper filter top based on the traffic loads present.

For aboveground storage tanks

- Aboveground outdoor tanks may need to be properly insulted, or drained and decommissioned during the cold season if not placed in a conditioned space.

- Are there any safety issues like soil settling, blocking access, or others issues that would preclude a tank location?

- Are there objections from homeowner associations or neighbors concerning locations of the storage system and can these objections be overcome?

- Are there aesthetic considerations, such as locating the storage system so that it is out of view or does not block features such as windows or shrubs?

- Will you be using gravity flow to deliver water, which may affect the height at which the storage system is located?

For indoor tanks

- Review guidelines for underground and aboveground storage tanks to determine if they apply (see above).

- Ensure provisions (such as floor drains and/or sump pump) are in place to handle potential leaks and overflows from the storage tank.

- Consult a structural engineer regarding the design and location of all integrated tanks, as well as indoor tanks located anywhere other than the basement or garage.

- Locate the tank in a temperature-controlled environment such as a heated garage or basement to prevent tank freezing. If the tank is not located in a temperature-controlled environment and is at risk for freezing, winterizing or decommissioning must be performed in accordance with the guidelines below.

Storage siting additional resources

- North Carolina Stormwater BMP Manual, Chapter 25, Rainwater Harvesting: Section 25.4.18, Provide Maintenance Access. This section of the North Carolina manual provides a list of considerations for maintenance access, but note that this manual does not provide adequate guidance on cold climate considerations.

- City of Bellingham, WA Rainwater Harvesting Guidance: Part B, Integrating rainwater harvesting with other parts of site design, site structures; Step 8, Determine possible tank location and overflow location

- Ontario Residential Rainwater Harvesting Systems Handbook: 2.4 -3, Determine the location of the rainwater storage tank

Selecting and designing the storage unit

Storage options for stormwater harvesting systems include above- or below-ground tanks or cisterns which are closed to the environment, and above-ground open storage, such as a stormwater retention or detention pond. Storage tanks or cisterns are commonly used in rainwater harvesting systems and are used for both indoor and outdoor stormwater use applications. Tanks or cisterns will likely provide the best option for indoor stormwater use applications due to ease of siting storage close to point of use. Stormwater ponds are commonly used for outdoor irrigation and in retrofit applications with existing stormwater ponds.

Advantages and disadvantages of above- or below-ground tanks and stormwater ponds are summarized below. The City of Bellingham, WA Rainwater Harvesting Guidance provides a comparison of characteristics of aboveground and belowground tanks (See Table 2 in Appendix A).

Advantages and disadvantages of above- or below-ground tanks and stormwater ponds

Link to this table

| Type of storage system | Advantages | Disadvantages |

|---|---|---|

| Open systems (e.g. ponds) |

|

|

| Below-ground, closed systems |

|

|

| Above-ground, closed systems |

|

|

Storage tanks and cisterns

General design considerations include the following.

- Ensure that tank size is appropriate to meet use demand (see above)

- Ensure tank location has been determined (see above)

- Select the type of tank

- Safety considerations

The suitability of different storage tank options is evaluated based on three main criteria: required capacity, potential location, and choice of materials (VA DEQ, 2009). Certain storage tank types may not provide adequate storage volume or structural integrity for large capacity systems. Site constraints may limit the size of above- or below-ground storage units, and tank materials can influence water quality. The following table summarizes comparisons of tank materials. If planned for potable water, tank material should be certified to NSF Standard 61.

Comparison of properties of different types of storage tanks

Link to this table

| Tank material | Advantages | Disadvantages |

|---|---|---|

| Plastic | ||

| Fiberglass |

|

|

| Polyethylene, polypropylene |

|

|

| Barrels and trash cans |

|

|

| Metal | ||

| Galvanized steel tanks |

|

|

| Steel drums (55-gallon) |

|

|

| Concrete and masonry | ||

| Ferroconcrete |

|

|

| Monolithic/poured-in-place |

|

|

| Stone, concrete block |

|

|

| Wood | ||

| Pine, redwood, cedar, cypress |

|

|

Design considerations for above and below-ground tanks are summarized below.

- Aboveground tanks:

- Outdoor tanks should be opaque to prevent algae growth

- Use material that is resistant to degradation (UV, corrosion)

- To avoid freeze damage:

- Outdoor pipes must be drained seasonally and/or insulated;

- All gutter systems should freely drain (i.e. the use of wet conveyance is highly discouraged

- First flush systems should not be used

- Provide adequate ventilation

- Provide adequate maintenance access

- Assess the need for a foundation based on the weight of the tank when full of water. The Minnesota State Building Code requires foundations not designed by a structural engineer to have a minimum footing depth of 3 feet in the Twin Cities.

- Locate foundations away from natural drainage pathways

- Situate smaller tanks without concrete foundations on a compacted subgrade of granular material such as aggregate

- Minnesota State Building Code requires storage covers be able to withstand a snow load of 50 pounds per square foot.

- Create accessible locations for valves and other maintenance devices

- See and follow all tank installation guidelines. Most manufacturers of commercial tanks can provide stamped foundation plans for review by the engineer of record.

- Below-ground storage tanks

- Polypropylene, fiberglass, and concrete are the materials commonly used for below-ground storage tanks. Concrete may need to be used if the tank has to be buried deeper or if the tank is to store a large volume.

- Tanks should not be buried below the water table unless an adequate foundation drain has been designed to convey the water away from the tank excavation.

- Tanks that will be used year-round should be located below the frost line and/or be insulated

- Maintain appropriate distance from underground utilities

- Tank footing must comply with Minnesota State Building Code

- The load bearing capacity of the tank must take into account above ground loads

- Air ventilation, overflow piping, and clean-out ports must be provided for safety and maintenance

- Assess the need for a foundation based on the weight of the tank when full of water. The Minnesota State Building Code requires foundations not designed by a structural engineer to have a minimum footing depth of 3 feet in the Twin Cities.

- Avoid underground storage in areas that have highly expansive types of clay due to the potential for damage caused by swelling of the clay. If tanks must be installed in areas having expansive clay, utilize specific installation specifications such as a foundation drain in the base of any subsurface tank.

- Review utility plans to avoid conflicts and/or the need to relocate utilities

- Avoid locating the tank where traffic or other heavy loads can cross above the tank. Heavy loads may require the load bearing capacity of the tank to be increased.

For additional information, see Section 2.3 of the Ontario Guidelines and Procedure Tool I.2 from the Metropolitan Council Stormwater Reuse Guide. Section 2.4 Of the Ontario Guidelines for Residential Rainwater Harvesting provides a detailed summary of design and installation guidelines for above- and below-ground storage tanks. The guidelines can be summarized as follows:

- Determine the rainwater storage tank capacity (see above)

- Determine the type of material utilized for the rainwater tank (see above)

- Determine the location of the rainwater storage tank (see above)

- Provide tank frost protection

- Winterize by providing a heating system to maintain air temperature, a heating system directly inside the tank, or by insulating the tank.

- Drain the tank prior to the onset of freezing temperatures and ensure no water will enter the tank during cold weather months.

- Provide a minimum access opening of 18 inches unless local codes and standards require otherwise. Ensure the openings have drip-proof, non-corrosive covers that are lockable.

- Below-ground tanks should be vented from the top of the tank to a minimum of 6 inches above grade. The vent pipe should be a minimum 3 inch diameter (based on inlet size) and terminate in a gooseneck fitting with a screen to prevent entry of birds, rodents, and insects. Note: we recommend using a stainless steel screen and 2 inch diameter vent pipe.

- Indoor tanks must be properly vented to the outside of the building.

The Metropolitan Council Reuse Guide includes these additional design considerations.

- For small site storage, consider pre-assembled stormwater / rainwater collection storage systems that include pumps.

- Recommended detention times are 50 days at an average daily temperature of 59oF, 30 days at 68oF, and 20 days at 77oF.

- Consider using the storage tank as a sedimentation basin to provide additional treatment . Locate the drawdown valve a minimum of 1 foot above the bottom of the tank to allow for sediment settling. Provide access for cleaning and debris removal.

- Seal unnecessary tank openings with a gasket and bolts.

- Protect the inlet of the tank from mosquitoes and other insects by using a mesh with spacing no more than 1/16 inches wide.

- Consider energy dissipation, such as internal baffles or calming inlet, to prevent sediment re-suspension.

- Provide oxygenation/aeration to the storage system to prevent anaerobic conditions.

- Design an overflow system for when the tank reaches capacity; the overflow pipe diameter should be the same as the inlet pipe diameter and should be directed away from the foundation and towards a surface that will not erode.

- Create operation and maintenance accessibility, including a manhole for larger tanks or access for a hose/siphoning equipment for smaller tanks.

- Provide back-flow prevention valves if system has cross-connection with potable water supply.

- Consult with Minnesota Plumbing Code for other requirements.

- Submit plans to the Department of Labor and Industry, or designated municipality, for compliance with Minnesota Plumbing Code.

- Develop an operations and maintenance plan that includes

- an inspection schedule;

- a cleaning schedule;

- a winterization plan and schedule;

- a pump maintenance schedule; and

- a site plan.

See the section on operation and maintenance for more detailed guidance on developing an operations and maintenance plan.

Stormwater ponds

Stormwater ponds can be used as the storage component of a stormwater harvest and use system. These ponds are multi-purpose, providing stormwater retention, sedimentation, and storage for later use. In this way, stormwater harvest and use systems can be part of a treatment train approach for stormwater management. Existing ponds can be retrofitted to serve as a water source for a harvest and use system.

Design considerations:

- Adequate sediment storage must be provided to preserve reservoir capacity for intended use(s)

- Pond must be properly designed. This includes consideration of local codes and watershed district rules, water quality targets for both the intended use, and water quality goals for water captured by the pond but not used for the intended use (e.g. water discharged to a surface water body via the storm sewer system).

- Is lining the pond with topsoil or clay necessary to hold water for use or prevent infiltration in Groundwater Protection Areas? If soil infiltration rates are high in the underlying soils, have infiltration BMPs been considered for stormwater management?

- What is the depth of the pond at natural water level (NWL) and after drawdown for irrigation?

- Does a drawdown limit need to be set with a flow to maintain sufficient water levels for pond aesthetics? Can a buffer of tall, native vegetation be used to improve aesthetics during drawdown?

- Will there be limitations to vegetation established due to water level bounce and drawdown?

- Consider the potential for erosion from inlets under low pond water levels.

- To discourage the growth of algae and other microorganisms, ponds should be sized such that detention times are not excessive during warm weather. As temperatures increase, the recommended maximum detention time decreases (Met Council, 2011). The following table is from the Met Council Reuse Guide Storage Systems Toolbox I.2, originally adapted from New South Wales Department of Environment and Conservation, Managing Urban Stormwater, Harvesting and Reuse, April 2006:

Maximum Detention Time - Average Daily Temperature

Link to this table

| Maximum Detention Time (days) to limit algae blooms: | Average Daily Temperature (F) |

|---|---|

| 50 | 59 |

| 30 | 68 |

| 20 | 77 |

Design resources

- See Storage Systems Toolbox I.2 in the 2011 Met Council Reuse Guide

- Design criteria for stormwater ponds

Footings and buoyancy calculations

Footing (above and below ground tanks) and buoyancy (partly submerged below ground tanks) calculations are required for safe design of stormwater harvesting systems that use tanks. All below ground tank companies will provide information on buoyancy. The designer must consult appropriate standards in designing footings and determining tank buoyancy. The civil engineers will confirm that the weight of the specified backfill counteracts the buoyant force of the tank. Simple tank buoyancy calculations can be found in the literature (US EPA; FEMA (example C7); Oregon DEQ; ExcelCalcs; ARCSA/ASPE 63).

Overflows and bypass

All harvest and use systems have a limited capacity to convey and store harvested stormwater. For this reason, stormwater harvesting systems must include a bypass valve or overflow structure to safely convey excess stormwater to downstream stormwater flow paths and networks when runoff exceeds design capacity.

Design considerations

- Overflow should be directed to pervious areas, a storm sewer system (which may include traditional stormwater treatment practices such as bioretention), or an infiltration system (including soakaway pits). Advantages and disadvantages of these alternatives are summarized in the following table (Source: Ontario Guidelines for Residential Rainwater Harvesting Systems Handbook).

- Adequate erosion control should be provided for surface overflow pathways.

- Storage tank outflow capacity should meet or exceed inflow capacity.

- The location of storage tank outlet/overflows should be easily accessible.

- Overflow should not pose a risk of cross-contamination with drinking water supplies and may require backflow prevention.

- If the bypass of the system runs to daylight, provide a backflow prevention valve to keep rodents or other animals out of the tank.

Rainwater harvesting overflow discharge location - methods

Link to this table

| Overflow Discharge Locations / Methods | Advantages | Disadvantages |

|---|---|---|

| Discharge to grade via gravity flow (most recommended |

|

|

| Discharge to storm sewer via gravity flow |

|

|

| Discharge to soakaway pit via gravity flow |

|

|

Design resources

- Toolbox I.1b, Bypass/Overflow in the 2011 Met Council Reuse Guide

- Appendix D: Overflow Provisions and Stormwater Management (Ontario Guidelines for Residential Rainwater Harvesting Systems Handbook)

- Design guide: Overflow (2009 Virginia Rainwater Harvesting Manual)

- Comparing Rainwater Storage Options - HarvestH2o

- Water Storage Extras: Tank Calculator, Research Notes on Effect of Tank Materials on Water Quality - Oasis Design

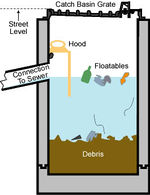

Collection

In a stormwater harvest and use system, flowing stormwater must be intercepted and conveyed to storage through a collection system: gutters, downspouts, pipes, drains, channels, or swales. The character of the collection system is determined in large part by the source area - rooftop runoff is typically conveyed via roof drains, gutters and downspouts which may be internal or external to the building structure; ground surface runoff is typically conveyed via pipes and channels. Collection system design is also influenced by the size, type, and location of the storage unit – pipes to underground storage tanks must be water tight to prevent leakage that results in saturation of soils and damage to building foundations. Site topography also affects the storage system. The elevation drops associated with the various components of a stormwater harvesting system and the resulting invert elevations should be considered early in the design, in order to ensure that the stormwater harvesting system is feasible for the particular site. The collection area may also affect treatment requirements if there are locations in the treatment area that will contribute larger quantities of pollutants. The collection system may include multiple treatment practices.

For the harvesting system to perform as intended, the sizing of conveyances must take into account both the volume and flow rate of intercepted stormwater. Intense rain storms may cause damage or pose a safety risk if conveyances and contingency overflows are undersized or otherwise deficient. Designers must follow appropriate design protocols and standards of practice in the sizing and design of all conveyances and fittings. Guidance on sizing and design of conveyances and fittings can be found here.

Ground surface collection

The design of ground surface conveyance systems should follow established stormwater management design standards and protocols. Water harvested from ground surface source areas is typically stored in stormwater BMPs (stormwater ponds) or underground tanks rather than aboveground tanks. The conveyance of stormwater to the storage system is via standard stormwater practices (stormsewers, ditches, and swales) and treatment is provided by the conveyance system (e.g. swales) or storage system (e.g. constructed stormwater ponds).

Design considerations:

- Catchment peak runoff rate (catchment area, slope, runoff coefficients)

- Local hydrology – number and size of high-intensity storms

- Conveyance to tank – wet or dry conveyance, conveyance slope

- Debris filtration and removal – Need for first-flush diverters, in-line debris removal, or filtration strategies. Debris filters should be installed upstream of first flush diversion

- Position of tank relative to other components - piped inflow to tanks should be calmed to minimized water agitation

- Relative size of inflow and outflow pipes – overflow pipe capacity must be greater than or equal to inflow capacity

Design resources:

- Minnesota Stormwater Manual (section on stormwater ponds)

- MnDOT Drainage Manual

- NRCS Engineering Field Handbook

- American Society for Civil Engineers (ASCE), Standard Guidelines for Design of Urban Stormwater Systems

Rooftop runoff collection

- System components: A typical rooftop conveyance system uses gutters and/or scupper and downspouts to convey stormwater from rooftops to the harvest system storage unit. Gutters, which are mounted to the eaves of a building, are typically used for a pitched roof since water can be easily conveyed directly from the roof to the gutter trough. Gutters must be hardy enough to withstand the weight of water delivered from rooftop and must have adequate flow capacity to capture runoff generated during typical rainstorms or system design storms. Scuppers, which are used to drain flat roofs, may be used in conjunction with gutters or may drain directly to external or internal downspouts. The appropriate size of gutters and downspouts depends on the roof surface area, slope, and configuration; design rainfall intensity; the number of downspouts; and the number of type of in-line treatment components that will be incorporated. Gutters and downspouts can be sized using manufacturer’s sizing chart for a given set of sizing criteria. Sizing criteria should be chosen based on local codes and regulation, local rainfall characteristics, and storage capacity. For roofs that experience problems with ice dams, additional considerations may be necessary, such as using heated gutter guards.

- Collection system materials: Common materials for gutters and downspouts include PVC, vinyl, aluminum, and galvanized steel (Lawrence et al., 2009). Designers should consult local building and plumbing codes and health codes in choosing conveyance materials. Some materials, such as those containing copper and lead, should not be used.

- In-line treatment components: Depending on the roof type and the intended use application, treatment components may be included in-line with rooftop runoff conveyance. Debris or leaf screens are commonly integrated in gutter systems. First flush diverters and filtration units can be incorporated along downspouts upstream of the storage unit and should be able to be operated year round. Vortex filters are typically used when multiple downspouts are joined above or below grade. Rooftop stormwater treatment should be designed in conjunction with the collection and in tank smoothing inlet and overflow siphon system.

Roofs - design considerations

- Consider siphonic roof drainage to reduce conveyance pipe costs and when elevation issues are present. Applicable rules include Minnesota State Statute 4715.2790- Siphonic Roof Drainage System. The Minnesota Department of Labor has published a design checklist for siphonic roof drainage systems based on this statute.

- Non-porous roofing materials, such as metal roofs, will provide a greater runoff yield for harvest than porous material such as wood shingles.

- Some degree of pitch is advantageous for rooftop collection. Runoff flows more easily across a pitched roof. Flat roofs may require roof drains. Flat roofs may also be more susceptible to build up of organic debris and dirt than pitched roofs.

- Roof pitch influences design flow rates of gutters and downspouts, with roofs having a greater pitch delivering water faster to the gutter system.

- Certain roof materials impact water quality adversely and are not suitable for harvesting. These types include asphalt or asbestos shingles, wood shingles, roofs containing copper, lead or other toxic metals, and other roofing materials which contain chemicals that pose health risks (see the section on WQ Considerations). Other examples to consider include roofs that have cooling units on them-units that leak or discharge chemicals as they are operating or roofs that function as a programmed space such as a rooftop patio with a grill.

- If the harvesting and use system is required to follow Minnesota Plumbing Code, only roof surfaces without a prohibited discharge are acceptable for collection (Section 1702.9.3). Prohibited discharges include: overflows and bleed-off pipes from roof-mounted equipment and appliances, condensate, and other waste disposal (Section 1702.9.3.1).

- Green roofs will have a lower yield of runoff and, if soil based, may produce discolored runoff suitable for irrigation only (Lawrence et al., 2009). Green roof runoff may also have elevated concentrations of phosphorus and nitrogen or discolor water so that a finer micron filter will be required for disinfection.

- Consider the potential for leaf litter and debris to collect on the roof and select appropriate in-line treatment devices that are compatible with the conveyance system (see Pre-storage treatment section).

- Roof catchment characteristics are described in the Virginia Rainwater Harvesting Manual, 2nd Edition: Design Guide, pp 22 – 25, ‘Roof’

Gutters and downspouts - design considerations

- Gutters and downspout sizing

- Rainfall intensity must be considered in the sizing of gutters, scuppers, and downspouts. Design guides generally recommend using a rainfall intensity associated with a 10-year or greater return period for a short duration storm (1 hour or less). Local rainfall characteristics should be taken into account in this consideration. Gutters can be sized using gutter sizing tables. Sizing information is also available through manufacturers.

- Example gutter and downspout sizing

- Step 1. Identify the rainfall design criteria – rainfall return period and storm duration - to be used for gutter sizing. In general, for a given return period, higher rainfall intensity is experienced during storms of short duration. For siphonic roof drainage systems, per Minnesota statute 4715.279, the minimum pipe size must accommodate a rainfall rate of 4 inches per hour. For gutters and downspouts, the appropriate design criteria may vary depending on the application and setting. Rainfall depths for various return periods and durations for a given location in Minnesota can be retrieved from NOAA’s National Weather Service NOAA Atlas 14 Pont Precipitation Frequency Estimates. The average rainfall intensity (in/min or in/hr) can be calculated by dividing the design storm rainfall depth (in) by the storm duration (min, hr).

- Step 2. Calculate the roof catchment area (Area = Length x Width).

- Step 3. Use standard hydrologic and hydraulic methods and published sizing tables to choose appropriate size/geometry of gutters based on rainfall intensity and gutter slope. Gutter sizing tables can be found through manufacturers or gutter sizing design guides (see design resources for examples).

- Step 4. To ensure that rainfall will not backup in the system, calculate the pipe friction loss using standard hydraulic methods (equivalent length method, Hazen-Williams Equation; see Section 8.10.4 of MnDOT Drainage Manual)

- Design considerations

- To prevent flooding, downspout flow capacity must meet or exceed gutter capacity. Large roofs may require multiple downspouts to convey water safely to the storage unit.

- Friction loss in pipes should be accounted for to prevent water from backing up in pipes during high intensity rainfall events.

- Some materials, such as those containing copper or lead, are not suitable and should be avoided in choosing gutters, downspouts, and pipes.

- Material properties such as UV-resistance, temperature/corrosion tolerance, or flexibility/rigidity may be important considerations in material choice.

- Pre-storage treatment systems should be designed in conjunction with the conveyance systems since they are typically in-line with the conveyance system.

- Horizontal pipes should have a minimum slope of 1 percent and pipe capacity must meet or exceed upstream components. To achieve greater capacity downstream, the slope can be increased at the downstream end.

- Half-round and trapezoidal gutters are favored over square gutters because they drain a greater roof area with the same amount of material used to make the gutter.

- Siphonic roof drains generally require fewer and smaller downpipes and less underground piping compared to conventional roof drain systems. See page 27 of the Virginia Rainwater Harvesting Manual. These roof drains are approved in Minnesota Plumbing Code and function on the principal of full pipe flow. They are ideally suited for flat roof buildings that incorporate rainwater harvesting as the first stormwater BMP in a building. Local examples include IKEA and Target.

- Cold weather maintenance may be required for gutters and downspouts. Maintenance includes cleaning out all debris, removing ice/snow dams, inspecting seams and anchors to ensure there are no leaks, checking for and if necessary repairing any structural damage, and ensuring that downspouts and diverters are functioning properly. Gutters that experience ice dam problems may be outfitted with heat tape or other components designed to capture and melt a portion of snowfall.

- Design resources for siphonic roof drain systems

- Engineered Siphonic Roof Drainage System, Roof Drainage Checklist, MN Department of Labor and Industry.

- Chapter 16, Siphonic Roofwater Systems, Water Sensitive Urban Design Technical Manual, Greater Adelaide region.

- Design resources for Sizing gutters and downspouts

- Roof Gutter Design spreadsheet, NRCS Wisconsin Engineering Spreadsheets.

- Roof Gutter Design Method, Construction Details and Specifications, NRCS Maryland Design Guide #1.

- Chapter 4, Rainwater Harvesting and Hydraulic Calculations, ARCSA Rainwater Harvesting Manual (2015).

- Appendix A: Rainwater Catchment and Conveyance Ontario Guidelines for Residential Rainwater Harvesting Systems Handbook.

- MN Drainage Manual, Chapter 8 (Friction loss in pipes).

Implement cooperative goals (education and outreach, etc.)

While designing the controls system, specify if the system is to serve a public education objective. Controls packages can be delivered to tie to the internet and show the system operation in real time

Treatment

Stormwater harvesting and use systems will typically contain one or more water quality treatment components to protect equipment, meet stormwater treatment objectives, minimize risk of exposure to stormwater pollutants, or meet end use water quality criteria. Terminology on treatment can be confusing and there is no consistent terminology in the literature. The following discussion is based on the location where treatment occurs relative to storage.

- Pre-storage treatment occurs prior to water being delivered to the storage unit. Treatment is designed to remove trash, gross solids, and particulate matter. Treatment typically occurs with practices described in the pretreatment section of this manual.

- In-storage treatment typically consists of sedimentation practices and is most applicable to constructed ponds and wetlands, although some settling occurs in tanks.

- In-storage treatment in tanks may also occur by introducing oxygen to the bottom of the tank with the use of a smoothing inlet and the overflow and evacuation of pollens and floating debris with an overflow siphon.

- Post-storage refers to biological or chemical treatment as well as advanced filtration or disinfection practices located downstream of the primary storage component.

The type and number of treatment practices included in the system will depend both on the end use and the quality of runoff entering the system. The quality of harvested stormwater prior to any treatment is influenced by many factors including the catchment surface, surrounding land use, and drainage area activities (e.g. amount of road salt applied, presence of vehicle fueling areas, etc.). Information on typical pollutants found in stormwater can be found here. The following table summarizes typical pollutant concentrations in stormwater from different land uses. Harvesting stormwater from confirmed stormwater hotspots is not recommended.

In addition to source area considerations, harvesting and storing stormwater in a storage pond or basin may attract unwanted organisms which can degrade the quality of harvested water or the surrounding environment. Harvesting systems should be designed to minimize the potential for water quality to degrade during collection and storage. Some additional BMPs and maintenance guidelines for minimizing the risk of water quality degradation in harvesting systems are summarized in Table 3.4 (page 19) of the Ontario Residential Rainwater Harvesting Guidelines.

The Toolbox R.4: Treatment in the 2011 Metropolitan Council Stormwater Reuse Guide includes a comprehensive summary of treatment practices including target pollutants, treatment alternatives, pros and cons of treatment options, and considerations for the design, operation, and maintenance of treatment systems. The Minnesota Stormwater Manual contains a discussion of the applicability of several traditional stormwater BMPs and includes design information for these BMPs. Additional resources may need to be consulted for the proper design and sizing of treatment components not covered in the Minnesota Stormwater Manual. Source water quality, environmental concerns in harvesting and use systems, and operation and maintenance considerations are discussed in greater detail in the Water Quality Concerns, Environmental Concerns, and [Operation and Maintenance] sections, respectively.

Generalized steps in the design of water quality treatment systems for stormwater harvest and use (Ontario guide) include the following.

- Determine the quality of harvested stormwater.

- Determine the level of treatment required to meet end use water quality criteria.

- Select treatment components based on level of treatment needed and the harvest and use system design. Determine if there are constraints imposed by the designed system and ensure these constraints can be managed. Ensure there is maintenance access for water quality treatment components.

- Determine peak inflow and peak demand to size treatment components.

Pre-storage treatment

Pre-storage treatment practices are used upstream of the storage unit. These practices reduce particulate and particulate-bound pollutant loads, and remove gross solids from stormwater. By reducing particulate and gross solids loads, these practices also preserve the function and extend the maintenance life of downstream components in the system (tank, water treatment, distribution). For some outdoor use applications, pre-storage treatment will be sufficient to meet water quality regulations (Metropolitan Council, 2011). Treatment may be achieved using a single practice or more than one practice in series. Common treatment practices used in stormwater harvest and use systems are described in the table below.

Common pre-storage practices used in stormwater harvesting and use systems

Link to this table

| Practice | Description |

|---|---|

| Swales | A swale is a wide, shallow, vegetated depression in the ground designed to channel drainage of water. Swales can reduce the velocity of flowing stormwater which allows larger particle to drop out of suspension in the water column. Swales are considered permanent primary treatment practices. Information on design, construction, maintenance, and performance assessment can be found here. |

| BMPs with an underdrain |

BMPs having an underdrain are designed to filter water prior to being discharged to the underdrain. These BMPs include bioretention, permeable pavement, sand filters, and tree trenches/boxes. Most of the water entering these BMPs is passed to the underdrain. In a harvest and use system, water passing through the underdrain must be discharged back to the harvest and use system. As water passes through the filter media, particulates are trapped and nutrients are removed via plant uptake. Note that media mixes with high organic matter may contribute nutrients and impart a dark color to the discharge water. Information on design, construction, maintenance, and performance assessment can be found in the appropriate section of this manual. |

| Manufactured screens and filters |

Filtration practices make use of porous media, mesh, or screens to trap pollutant as water flows through the filter. Filtration practices utilize sand filters or bio-filters, and include a number of proprietary devices. These devices are typically classified as pretreatment screen practices. Information on design, construction, maintenance, and performance assessment can be found here. |

| Debris Screens |