Difference between revisions of "Design criteria for infiltration"

| (17 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | [[File:Pdf image.png|100px|thumb|left|alt=pdf image|<font size=3>[https://stormwater.pca.state.mn.us/index.php?title=File:Design_criteria_for_infiltration_-_Minnesota_Stormwater_Manual_June_2022.pdf Download pdf]</font size>]] | ||

[[File:Technical information page image.png|100px|left|alt=image]] | [[File:Technical information page image.png|100px|left|alt=image]] | ||

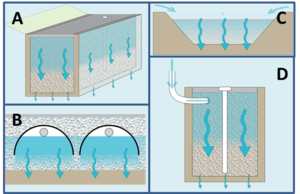

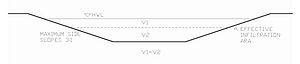

[[file:Schematic of practices.png|300px|thumb|alt=schematic of infiltration practices|<font size=3>Schematic illustrating A)infiltration trench, B) underground infiltration, C) infiltration basin, and D) dry well.</font size>]] | [[file:Schematic of practices.png|300px|thumb|alt=schematic of infiltration practices|<font size=3>Schematic illustrating A)infiltration trench, B) underground infiltration, C) infiltration basin, and D) dry well.</font size>]] | ||

| Line 34: | Line 35: | ||

*providing easy site access (''REQUIRED''); | *providing easy site access (''REQUIRED''); | ||

*providing <span title="Pretreatment reduces maintenance and prolongs the lifespan of structural stormwater BMPs by removing trash, debris, organic materials, coarse sediments, and associated pollutants prior to entering structural stormwater BMPs. Implementing pretreatment devices also improves aesthetics by capturing debris in focused or hidden areas. Pretreatment practices include settling devices, screens, and pretreatment vegetated filter strips."> [https://stormwater.pca.state.mn.us/index.php?title=Pretreatment '''pretreatment''']</span> (''REQUIRED''); and | *providing <span title="Pretreatment reduces maintenance and prolongs the lifespan of structural stormwater BMPs by removing trash, debris, organic materials, coarse sediments, and associated pollutants prior to entering structural stormwater BMPs. Implementing pretreatment devices also improves aesthetics by capturing debris in focused or hidden areas. Pretreatment practices include settling devices, screens, and pretreatment vegetated filter strips."> [https://stormwater.pca.state.mn.us/index.php?title=Pretreatment '''pretreatment''']</span> (''REQUIRED''); and | ||

| − | *utilizing <span title="A species that has been observed in the form of a naturally occurring and self-sustaining population in historical times. Non-natives do not meet this definition."> '''native species plantings'''</span> (see [ | + | *utilizing <span title="A species that has been observed in the form of a naturally occurring and self-sustaining population in historical times. Non-natives do not meet this definition."> '''native species plantings'''</span> (see [https://stormwater.pca.state.mn.us/index.php?title=Minnesota_plant_lists Plants for Stormwater Design]). |

For more information on design information for individual infiltration practices, [http://stormwater.pca.state.mn.us/index.php/Category:Design_criteria link here]. | For more information on design information for individual infiltration practices, [http://stormwater.pca.state.mn.us/index.php/Category:Design_criteria link here]. | ||

| Line 96: | Line 97: | ||

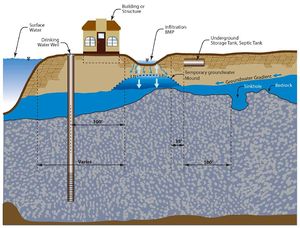

===Wellhead Protection Areas=== | ===Wellhead Protection Areas=== | ||

| − | See stormwater and <span title="The surface and subsurface area surrounding a well or well field that supplies a public water system, through which contaminants are likely to move toward and reach the well or well field (Minnesota Statutes, section 103I.005, subdivision 24)."> [https://stormwater.pca.state.mn.us/index.php?title=Stormwater_and_wellhead_protection '''wellhead protection''']</span> for guidance and recommendations for determining the appropriateness of infiltrating stormwater in a [http://stormwater.pca.state.mn.us/index.php/Stormwater_and_wellhead_protection Drinking Water Supply Management Area] (DWSMA). For more information on source water protection see [ | + | See stormwater and <span title="The surface and subsurface area surrounding a well or well field that supplies a public water system, through which contaminants are likely to move toward and reach the well or well field (Minnesota Statutes, section 103I.005, subdivision 24)."> [https://stormwater.pca.state.mn.us/index.php?title=Stormwater_and_wellhead_protection '''wellhead protection''']</span> for guidance and recommendations for determining the appropriateness of infiltrating stormwater in a [http://stormwater.pca.state.mn.us/index.php/Stormwater_and_wellhead_protection Drinking Water Supply Management Area] (DWSMA). For more information on source water protection see [https://www.health.state.mn.us/communities/environment/water/swp/index.htm Minnesota Department of Health]. |

==Major design elements - Practice and site considerations== | ==Major design elements - Practice and site considerations== | ||

| Line 257: | Line 258: | ||

:'''Infiltration basin''' | :'''Infiltration basin''' | ||

:*1 to 3-foot thick layer of double-washed, uniform (<span title="A numerical expression of the variety in particle sizes in mixed natural soils, defined as the ratio of the sieve size through which 60% (by weight) of the material passes to the sieve size that allows 10% of the material to pass.> '''uniformity coefficient'''</span> of 2 or smaller with a void ratio of 0.40) aggregate between 1.5 and 3.0 inch diameter | :*1 to 3-foot thick layer of double-washed, uniform (<span title="A numerical expression of the variety in particle sizes in mixed natural soils, defined as the ratio of the sieve size through which 60% (by weight) of the material passes to the sieve size that allows 10% of the material to pass.> '''uniformity coefficient'''</span> of 2 or smaller with a void ratio of 0.40) aggregate between 1.5 and 3.0 inch diameter | ||

| − | :*[ | + | :*[https://www.dot.state.mn.us/pre-letting/spec/ MNDOT Coarse Aggregate Bedding (Section 3149 G.2)] ranging 1-2 inch in gradation |

:'''Infiltration trench''' | :'''Infiltration trench''' | ||

| Line 273: | Line 274: | ||

===Filter fabric=== | ===Filter fabric=== | ||

:'''Infiltration basin''' | :'''Infiltration basin''' | ||

| − | :*Top of geotextile should be 6-12 inches below upper surface of drainage media with 12 | + | :*Top of geotextile should be 6-12 inches below upper surface of drainage media with 12 inch overlap of fabric seams |

:*Fabric should be placed between side walls and between stone and gravel layers but not on the basin bottom | :*Fabric should be placed between side walls and between stone and gravel layers but not on the basin bottom | ||

| − | :*Geotextile must meet MNDOT Type I Non-woven geotextile | + | :*Geotextile must meet [http://dot.state.mn.us/mnroad/nrra/structure-teams/geotechnical/files/specifications/mndot-guidelines-geotextiles-for-soil-field-personnel-pavements-draft-6-12-2020.pdf MNDOT Type I Non-woven geotextile] |

:*Examples: Mirafi 140N, Amoco 4547, and Geotex 451 | :*Examples: Mirafi 140N, Amoco 4547, and Geotex 451 | ||

:'''Infiltration trench''' | :'''Infiltration trench''' | ||

| − | :*Surround fill on sides with filter fabric with 12 | + | :*Surround fill on sides with filter fabric with 12 inch overlap of fabric seams. A separate piece should be used for the top layer to act as a failure plane |

:*Fabric should be placed between side walls and between stone and gravel layers but not on the trench bottom | :*Fabric should be placed between side walls and between stone and gravel layers but not on the trench bottom | ||

:*Geotextile must meet MNDOT Type I non-woven geotextile | :*Geotextile must meet MNDOT Type I non-woven geotextile | ||

| Line 285: | Line 286: | ||

:'''Underground infiltration''' | :'''Underground infiltration''' | ||

| − | :*Surround fill on sides with filter fabric with 12 | + | :*Surround fill on sides with filter fabric with 12 inch overlap of fabric seams |

:*Geotextile must meet MNDOT Type I non-woven geotextile | :*Geotextile must meet MNDOT Type I non-woven geotextile | ||

:*Examples: Mirafi 140N, Amoco 4547, and Geotex 451 | :*Examples: Mirafi 140N, Amoco 4547, and Geotex 451 | ||

| Line 300: | Line 301: | ||

:*3/8 inch pea gravel | :*3/8 inch pea gravel | ||

:*6-12 inch layer of MNDOT Fine Filter Aggregate (Section 3149 J.2) | :*6-12 inch layer of MNDOT Fine Filter Aggregate (Section 3149 J.2) | ||

| − | :*12 | + | :*12 inch of gravel or sand (good for cold climates) |

===In-situ soils=== | ===In-situ soils=== | ||

| Line 309: | Line 310: | ||

:*All material must be placed such that compaction is avoided. See the [http://stormwater.pca.state.mn.us/index.php/Construction_specifications_for_infiltration Construction Specifications] webpage for more details | :*All material must be placed such that compaction is avoided. See the [http://stormwater.pca.state.mn.us/index.php/Construction_specifications_for_infiltration Construction Specifications] webpage for more details | ||

:*For infiltration trench and underground infiltration, plastic, aluminum, or concrete gallery frames can be inserted to increase the runoff capture storage volume. | :*For infiltration trench and underground infiltration, plastic, aluminum, or concrete gallery frames can be inserted to increase the runoff capture storage volume. | ||

| − | |||

| − | |||

{{:Infiltration media and material specifications }} | {{:Infiltration media and material specifications }} | ||

==Materials specifications - filter media== | ==Materials specifications - filter media== | ||

| − | Infiltration practices do not typically use engineered filter media. If engineered media is used, all media should meet the specifications listed in the design criteria for bioretention basin webpage. Links are provided below. | + | Infiltration practices do not typically use engineered filter media. If <span title="Engineered media is a mixture of sand, fines (silt, clay), and organic matter utilized in stormwater practices, most frequently in bioretention practices. The media is typically designed to have a rapid infiltration rate, attenuate pollutants, and allow for plant growth."> [https://stormwater.pca.state.mn.us/index.php?title=Design_criteria_for_bioretention#Materials_specifications_-_filter_media '''engineered media''']</span> is used, all media should meet the specifications listed in the design criteria for bioretention basin webpage. Links are provided below. |

*[http://stormwater.pca.state.mn.us/index.php/Design_criteria_for_bioretention#Filter_media_depth Filter media depth] | *[http://stormwater.pca.state.mn.us/index.php/Design_criteria_for_bioretention#Filter_media_depth Filter media depth] | ||

*[http://stormwater.pca.state.mn.us/index.php/Design_criteria_for_bioretention#Performance_specifications Performance specifications] | *[http://stormwater.pca.state.mn.us/index.php/Design_criteria_for_bioretention#Performance_specifications Performance specifications] | ||

| Line 328: | Line 327: | ||

==Design procedure - design steps== | ==Design procedure - design steps== | ||

| − | The following steps outline a recommended design procedure for infiltration practices in compliance with the [ | + | The following steps outline a recommended design procedure for infiltration practices in compliance with the [https://stormwater.pca.state.mn.us/index.php?title=Construction_stormwater_program MPCA Construction Stormwater General Permit] for new construction. Design recommendations beyond those specifically required by the permit are also included and marked accordingly. |

When riser pipe outlets are used in infiltration basins, it is ''HIGHLY RECOMMENDED'' that they be constructed with manholes that either have locks or are sufficiently heavy to prevent easy removal. | When riser pipe outlets are used in infiltration basins, it is ''HIGHLY RECOMMENDED'' that they be constructed with manholes that either have locks or are sufficiently heavy to prevent easy removal. | ||

| Line 351: | Line 350: | ||

===Step 5. Determine infiltration type and size practice=== | ===Step 5. Determine infiltration type and size practice=== | ||

| − | Once the physical suitability evaluation is complete (Step 3), it is ''HIGHLY RECOMMENDED'' that the designer apply the better site design principles in sizing and locating the infiltration practice(s) on the development site. | + | Once the physical suitability evaluation is complete (Step 3), it is ''HIGHLY RECOMMENDED'' that the designer apply the [https://stormwater.pca.state.mn.us/index.php?title=Better_site_design better site design] principles in sizing and locating the infiltration practice(s) on the development site. |

====Select design variant==== | ====Select design variant==== | ||

After following the steps outlined above, the designer will presumably know the location of naturally occurring permeable soils, the depth to the water table, bedrock or other impermeable layer, and the contributing drainage area. Given the steps performed in the physical suitability evaluation (Step 3), identify the most suitable location for the infiltration practice. Given the water quality volume and the drainage area, select the appropriate infiltration practice for the first iteration of the design process. See the section on [http://stormwater.pca.state.mn.us/index.php/BMPs_for_stormwater_infiltration#Infiltration_trench BMPs for stormwater infiltration] for more information. | After following the steps outlined above, the designer will presumably know the location of naturally occurring permeable soils, the depth to the water table, bedrock or other impermeable layer, and the contributing drainage area. Given the steps performed in the physical suitability evaluation (Step 3), identify the most suitable location for the infiltration practice. Given the water quality volume and the drainage area, select the appropriate infiltration practice for the first iteration of the design process. See the section on [http://stormwater.pca.state.mn.us/index.php/BMPs_for_stormwater_infiltration#Infiltration_trench BMPs for stormwater infiltration] for more information. | ||

| − | Note: Information collected during the site suitability evaluation (see Steps 1 and 3) should be used to explore the potential for multiple infiltration practices versus relying on a single infiltration facility. The use of smaller infiltration practices dispersed around a development is usually more sustainable than a single regional facility that is more likely to have maintenance and groundwater mounding problems (Source: [https://dnr.wi.gov/topic/Stormwater/standards/postconst_standards.html Stormwater post-construction technical standards, Wisconsin Department of Natural Resources Conservation Practice Standards]. See [http://stormwater.pca.state.mn.us/index.php/Using_the_treatment_train_approach_to_BMP_selection Using the treatment train approach to BMP selection] for more information on selecting multiple BMPs at a site. | + | Note: Information collected during the site suitability evaluation (see Steps 1 and 3) should be used to explore the potential for multiple infiltration practices versus relying on a single infiltration facility. The use of smaller infiltration practices dispersed around a development is usually more sustainable than a single regional facility that is more likely to have maintenance and groundwater <span title="The localized temporary rise in the groundwater surface below an area of infiltration"> '''[https://stormwater.pca.state.mn.us/index.php?title=Stormwater_infiltration_and_groundwater_mounding mounding]'''</span> problems (Source: [https://dnr.wi.gov/topic/Stormwater/standards/postconst_standards.html Stormwater post-construction technical standards, Wisconsin Department of Natural Resources Conservation Practice Standards]. See [http://stormwater.pca.state.mn.us/index.php/Using_the_treatment_train_approach_to_BMP_selection Using the treatment train approach to BMP selection] for more information on selecting multiple BMPs at a site. |

{{alert|Infiltration practices shall discharge through the soil or filter media in 48 hours or less. Additional flows that cannot be infiltrated or filtered in 48 hours should be routed to bypass the system through a stabilized discharge point.|alert-danger}} | {{alert|Infiltration practices shall discharge through the soil or filter media in 48 hours or less. Additional flows that cannot be infiltrated or filtered in 48 hours should be routed to bypass the system through a stabilized discharge point.|alert-danger}} | ||

| Line 368: | Line 367: | ||

====Size infiltration practice==== | ====Size infiltration practice==== | ||

| − | To meet requirements of the [ | + | To meet requirements of the [https://stormwater.pca.state.mn.us/index.php?title=Construction_stormwater_program Stormwater General Permit] (CSW permit), the surface area (A<sub>s</sub>, in square feet) of an infiltration practice is given by |

<math>A_s = V_w / D_o</math> | <math>A_s = V_w / D_o</math> | ||

| Line 534: | Line 533: | ||

===Step 8. Determine pretreatment volume and design pretreatment measures=== | ===Step 8. Determine pretreatment volume and design pretreatment measures=== | ||

| − | See the section on [ | + | See the section on [https://stormwater.pca.state.mn.us/index.php?title=Design_criteria_for_infiltration#Pretreatment pretreatment] for specific pretreatment design guidance |

===Step 9. Check volume, peak discharge rates and drawdown time against State, local and watershed organization requirements=== | ===Step 9. Check volume, peak discharge rates and drawdown time against State, local and watershed organization requirements=== | ||

| Line 541: | Line 540: | ||

Perform hand calculations or model the proposed development scenario using a surface water model appropriate for the hydrologic and hydraulic design considerations specific to the site (see also the section on [[Introduction to stormwater modeling|stormwater modeling]]). This includes defining the parameters of the infiltration practice defined above: elevation and area (defines the storage volume), infiltration rate and method of application (effective infiltration area), and outlet structure and/or flow diversion information. The results of this analysis can be used to determine whether or not the proposed design meets the applicable requirements. If not, the design will have to be re-evaluated (back to Step 5). | Perform hand calculations or model the proposed development scenario using a surface water model appropriate for the hydrologic and hydraulic design considerations specific to the site (see also the section on [[Introduction to stormwater modeling|stormwater modeling]]). This includes defining the parameters of the infiltration practice defined above: elevation and area (defines the storage volume), infiltration rate and method of application (effective infiltration area), and outlet structure and/or flow diversion information. The results of this analysis can be used to determine whether or not the proposed design meets the applicable requirements. If not, the design will have to be re-evaluated (back to Step 5). | ||

| − | The following items are specifically ''REQUIRED'' by the [ | + | The following items are specifically ''REQUIRED'' by the [https://stormwater.pca.state.mn.us/index.php?title=Construction_stormwater_program MPCA Permit] |

{{alert| | {{alert| | ||

| Line 553: | Line 552: | ||

===Step 10. Prepare Vegetation and Landscaping Plan=== | ===Step 10. Prepare Vegetation and Landscaping Plan=== | ||

| − | A landscaping plan for an infiltration trench should be prepared to indicate how the enhanced [ | + | A landscaping plan for an infiltration trench should be prepared to indicate how the enhanced <span title="Are configured as shallow, linear channels. They typically have vegetative cover such as turf or native perennial grasses"> [https://stormwater.pca.state.mn.us/index.php?title=Dry_swale_(Grass_swale) '''swale''']</span> system will be stabilized and established with vegetation. Landscape design should specify proper grass species and wetland plants based on specific site, soils and hydric conditions present along the channel. Further information on plant selection and use occurs in the [[Minnesota plant lists]] section. |

===Step 11. Prepare Operation and Maintenance (O&M) Plan=== | ===Step 11. Prepare Operation and Maintenance (O&M) Plan=== | ||

| Line 583: | Line 582: | ||

*Cold climate considerations for infiltration practices - See [http://stormwater.pca.state.mn.us/index.php/Cold_climate_impact_on_runoff_management#Infiltration], [http://stormwater.pca.state.mn.us/index.php/Cold_climate_impact_on_runoff_management#Infiltration_practices] | *Cold climate considerations for infiltration practices - See [http://stormwater.pca.state.mn.us/index.php/Cold_climate_impact_on_runoff_management#Infiltration], [http://stormwater.pca.state.mn.us/index.php/Cold_climate_impact_on_runoff_management#Infiltration_practices] | ||

| − | [[ | + | [[Category:Level 3 - Best management practices/Specifications and details/Design criteria]] |

</noinclude> | </noinclude> | ||

Latest revision as of 18:45, 29 December 2022

This page provides a discussion of design elements and design steps for infiltration practices. These practices include infiltration trench, infiltration basin, dry wells, and underground infiltration practices, although many of the design guidelines can be applied to other practices where infiltration can occur. For a descriptions of different types of infiltration practices to which these design guidelines apply, link here.

Contents

- 1 Permit requirements

- 2 Terminology

- 3 Details and CADD images

- 4 Design phase maintenance considerations

- 5 Major design elements - Physical feasibility initial check

- 6 Major design elements - Practice and site considerations

- 7 Materials specifications

- 8 Materials specifications - filter media

- 9 Design procedure - design steps

- 9.1 Step 1. Make a preliminary judgment

- 9.2 Step 2. Confirm design criteria and applicability

- 9.3 Step 3. Perform field verification of site suitability

- 9.4 Step 4. Compute runoff control volumes

- 9.5 Step 5. Determine infiltration type and size practice

- 9.6 Step 6. Size outlet structure and/or flow diversion structure, if needed

- 9.7 Step 7. Perform ground-water mounding analysis

- 9.8 Step 8. Determine pretreatment volume and design pretreatment measures

- 9.9 Step 9. Check volume, peak discharge rates and drawdown time against State, local and watershed organization requirements

- 9.10 Step 10. Prepare Vegetation and Landscaping Plan

- 9.11 Step 11. Prepare Operation and Maintenance (O&M) Plan

- 9.12 Step 12. Prepare Cost Estimate

- 10 Related pages

Permit requirements

Link here for requirements of the Construction Stormwater General Permit for infiltration systems

Terminology

The following terminology is used throughout this page.

REQUIRED - Indicates standards stipulated by the CGP or other consistently applicable regulations.

HIGHLY RECOMMENDED - Indicates guidance or other information that is extremely beneficial or necessary, but not specifically required by the MPCA CGP.

RECOMMENDED - Indicates guidance or other information that is helpful but not critical.

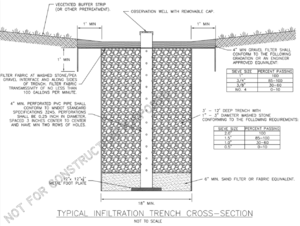

Details and CADD images

- CADD dwg file for infiltration basin plan and profile

- CADD images

- Infiltration basin plan and profile: File:Infiltration Basin INFILTRATION BASIN PLAN & PROFILE (1).pdf

- Infiltration subsurface layout: File:Infiltration Subsurface Layout2 (1).pdf

- Infiltration trench section: File:INFILTRATION TRENCH INFILTRATION TRENCH SECTION (1).pdf

- Details for underground systems: Underground systems are proprietary devices. Detail varies between each practice. We therefore include links to examples of commonly used devices. We acknowledge there are many more of these devices and reference to any specific commercial product, process, or service by trade name, trademark, service mark, manufacturer, or otherwise does not constitute or imply endorsement, recommendation, or favoring by the Minnesota Pollution Control Agency.

Design phase maintenance considerations

Implicit in the design guidance is the fact that many design elements of infiltration systems can minimize the maintenance burden and maintain pollutant removal efficiency. Key examples include

- limiting contributing drainage area;

- providing easy site access (REQUIRED);

- providing pretreatment (REQUIRED); and

- utilizing native species plantings (see Plants for Stormwater Design).

For more information on design information for individual infiltration practices, link here.

Major design elements - Physical feasibility initial check

Before deciding to use an infiltration practice for stormwater management, it is helpful to consider several items that bear on the feasibility of using such a device at a given location. This section describes considerations in making an initial judgment as to whether or not an infiltration practice is the appropriate BMP for the site. The following links provide additional information on specific constraints to infiltration.

- Karst

- Shallow soils and shallow depth to bedrock

- Shallow groundwater

- Soils with low infiltration capacity

- Separation distances

- Potential stormwater hotspots

- Wellhead protection

- Contaminated soils and groundwater

- Procedures for investigating sites with potential constraints

Contributing drainage area

Contributing drainage area is defined as the total area, including pervious and impervious surfaces, contributing to a best management practice (BMP). It is assumed that in most cases, with the exception of green roofs and many permeable pavement systems, impervious surfaces will constitute more than 50 percent of the contributing area to the BMP and that most of this impervious is directly connected impervious. The recommended contributing area to a BMP may be modified for the following conditions.

- The recommended contributing area may be increased if pervious surfaces constitute the majority of the contributing area and soils are hydrologic soil group (HSG) A or B

- The recommended contributing area should be decreased if impervious surfaces contribute more than 80 percent of the contributing area or if the entire impervious surface is directly connected and routed to the BMP

- The recommended contributing area should be decreased or may be increased based on pollutant loading (decrease with higher pollutant loads)

Runoff coefficients may be calculated for an area contributing to a BMP. Runoff coefficients greater than about 0.55 are typical of urban areas having 50 percent or more impervious surface. Typical runoff coefficients are shown on these pages ([1], [2]) and discussed here. To see how runoff curve number is associated with impervious percentages, see at this link.

It is HIGHLY RECOMMENDED that the following infiltration practices be designed with the indicated maximum drainage areas. See the table below for recommended contributing drainage areas for all infiltration BMPs.

- Dry well – 1 acre or less; rooftop only

- Infiltration Trench – 5 acres or less

- Underground Infiltration System – 10 acres or less

- Infiltration Basin – 50 acres or less. Contributing drainage areas should have a maximum 5:1 ratio of impervious area to infiltration area.

Infiltration practices must meet the required 48 hour drawdown time and must be sized in order to allow for adequate maintenance without increasing compaction. Information on recommended contributing drainage areas for all infiltration practices is shown in the following table.

Stormwater infiltration BMPs - contributing drainage area

Link to this table

| Stormwater BMP | Recommended contributing area | Notes |

|---|---|---|

| Infiltration Basin | 50 acres or less | A natural or constructed impoundment that captures, temporarily stores and infiltrates the design volume of water into the surrounding naturally permeable soil over several days. In the case of a constructed basin, the impoundment is created by excavation or embankment. |

| Bioinfiltration Basin | 5 acres or less | Bioinfiltration basins must meet the required 48 hour drawdown time and must be sized in order to allow for adequate maintenance. It is HIGHLY RECOMMENDED that bioinfiltration basins be designed to prevent high levels of bounce as submerging vegetation may inhibit plant growth. A maximum wet storage depth of 1.5 feet is HIGHLY RECOMMENDED. |

| Infiltration Trench | 5 acres or less | |

| Dry Well Synonym: Infiltration Tube, French Drain, Soak‐Away Pits, Soak Holes | 1 acre or less (rooftop only) | |

| Underground Infiltration | 10 acres or less | Though feasible, larger underground infiltration systems may cause groundwater contamination as water is not able to infiltrate through a surface cover. In addition, wind flocculation, UV degradation, and bacterial degradation, which provide additional treatment in surface systems, do not occur in underground systems. Because performance research is lacking for larger features, it is HIGHLY RECOMMENDED that the contributing drainage area to a single device not exceed 10 acres. |

| Dry Swale with Check Dams | 5 acres or less | |

| Permeable Pavement | It is RECOMMENDED that external contributing drainage area not exceed the surface area of the permeable pavement. It is HIGHLY RECOMMENDED that external contributing drainage area not exceed twice the surface area of the permeable pavement | It is RECOMMENDED that external drainage area be as close to 100% impervious as possible. Field experience has shown that drainage area (pervious or impervious) can contribute particulates to the permeable pavement and lead to clogging. Therefore, sediment source control and/or pretreatment should be used to control sediment run-on to the permeable pavement section. |

| Tree Trench/Tree Box | up to 0.25 acres per tree |

References: Virginia, North Carolina, West Virginia, Maine, Lake Tahoe, Connecticut, Massachusetts, New York, Wisconsin, Vermont, New Hampshire, Ontario, Pennsylvania

Site Topography and Slopes

Unless slope stability calculations demonstrate otherwise (see [3], [4]), it is HIGHLY RECOMMENDED that infiltration practices be located a minimum horizontal distance of 200 feet from down-gradient slopes greater than 20 percent, and that slopes in contributing drainage areas be limited to 15 percent.

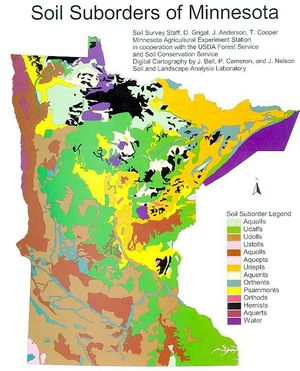

Soils

It is HIGHLY RECOMMENDED that native soils in proposed infiltration areas have a minimum infiltration rate of 0.2 inches per hour (typically hydrologic soil group A, B and C soils). Initially, soil infiltration rates can be estimated from NRCS soil data, and confirmed with an on-site infiltration evaluation or geotechnical investigation (see Step 5 of the Design procedures section for investigation procedures). It is HIGHLY RECOMMENDED that native soils have silt/clay contents less than 40 percent and clay content less than 20 percent, and that infiltration practices not be situated in fill soils.

Depth to groundwater table and bedrock

Note that if underlying soils are ripped to alleviate compaction, the requirement is a 2 foot minimum between the bottom of the ripped zone and a 3 foot minimum from the bottom of the infiltration practice. If there is only a 3 foot separation distance between the bottom of the infiltration practice and the elevation of the seasonally high water table or bedrock, limit ripping depth to 12 inches. See the alleviating compaction and soil ripping webpages for more detail on compaction prevention.

Site Location / Minimum Setbacks

The following table summarizes horizontal and vertical setback distances for required and recommended minimum distances from an infiltration practice to an above-ground or underground structure. It will be necessary to consult local ordinances for further guidance on siting infiltration practices.

Required and recommended minimum vertical and horizontal separation distances. This represents the minimum distance from the infiltration practice to the structure of concern. If the structure is above-ground, the distance is measured from the edge of the BMP to the structure. If the structure is underground, the vertical separation distance represents the distance from the point of infiltration through the bottom of the system to the structure, while the horizontal separation (often called setback) distance is the shortest distance from the edge of the system to the structure.

Link to this table

| Structure | Distance (feet) | Requirement or recommendation | Note(s) | |

|---|---|---|---|---|

| Vertical | Saturated soil | 3 | Requirement1 | |

| Bedrock | 3 | Requirement1 | ||

| Horizontal | Public supply well | 100 for sensitive wells; 50 for others3 | Requirement | |

| Building/structure/property line2 | 10 | Recommended | ||

| Surface water | none unless local requirements exist | If nearby stream is impaired for chloride, see [5] | ||

| Septic system | 35 | Recommended | ||

| Contaminated soil/groundwater | No specific distance. Infiltration must not mobilize contaminants. | |||

| Slope | 200 | Recommended | from toe of slope >= 20% | |

| Karst | 1000 up-gradient 100 down-gradient | Requirement1 | active karst | |

1 Required under the Construction Stormwater General Permit

2 Minimum with slopes directed away from the building

3If treating an average of 10,000 gallons per day; otherwise separation distance is 300 feet

Karst

It is HIGHLY RECOMMENDED that infiltration practices not be used in active karst formations without adequate geotechnical testing.

Wellhead Protection Areas

See stormwater and wellhead protection for guidance and recommendations for determining the appropriateness of infiltrating stormwater in a Drinking Water Supply Management Area (DWSMA). For more information on source water protection see Minnesota Department of Health.

Major design elements - Practice and site considerations

If physical attributes of a site do not prohibit infiltration, there are several considerations for the infiltration practice and site.

Conveyance

It is HIGHLY RECOMMENDED that a flow splitter or diversion structure be provided to divert the Water Quality Volume (Vwq) to the infiltration practice and allow larger flows to bypass the practice unless the infiltration practice is sized to retain larger volumes (Channel protection criteria (Vcp), Overbank flood protection criteria (Vp10) or Extreme flood control criteria (Vp100)). Where a flow splitter is not used, it is HIGHLY RECOMMENDED that contributing drainage areas be limited to the appropriate size given the bmp and an overflow be provided within the practice to pass part of the Vwq to a stabilized watercourse or storm drain. It is also HIGHLY RECOMMENDED that overflow associated with the Vp10 or Vp100 storm (depending on local drainage criteria) be controlled such that velocities are non-erosive at the outlet point (to prevent downstream slope erosion), and that when discharge flows exceed 3 cubic feet per second, the designer evaluate the potential for erosion to stabilized areas and infiltration facilities.

An infiltration device can be designed to accommodate a concentrated influent flow; however, an energy dissipater and/or level spreader may be needed. See the pretreatment section for more information on pretreatment devices.

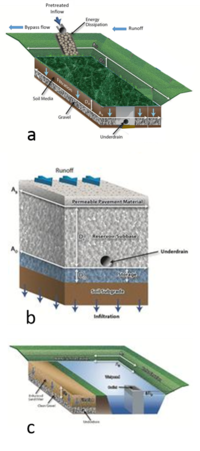

Underdrains

Perforated elevated underdrains are sometimes used to facilitate infiltration. If an infiltration system does not have an underdrain, it should be designed with dewatering provisions in the event of failure. This can be done with underdrain pipe systems that can be pumped out or allowed to gravity drain to the surface.

The following are RECOMMENDED for infiltration practices with underdrains.

- The minimum pipe diameter is 4 inches.

- Install 2 or more underdrains for each infiltration system in case one clogs. At a minimum provide one underdrain for every 1,000 square feet of surface area.

- Include at least 2 observation/cleanouts for each underdrain, one at the upstream end and one at the downstream end. Cleanouts should be at least 4 inches diameter vertical non-perforated schedule 40 PVC pipe, and extend to the surface. Cap cleanouts with a watertight removable cap.

- Construct underdrains with Schedule 40 or SDR 35 smooth wall PVC pipe.

- Install underdrains with a minimum slope of 0.5 percent, particularly in hydrologic soil group D soils (Note: to utilize Manning’s equation the slope must be greater than 0).

- Include a utility trace wire for all buried piping.

- For underdrains that daylight on grade, include a marking stake and animal guard;

- For each underdrain have an accessible knife gate valve on its outlet to allow the option of operating the system as either an infiltration system, filtration system, or both. The valve should enable the ability to make adjustments to the discharge flow so the sum of the infiltration rate plus the underdrain discharge rate equal a 48 hour drawdown time.

- Perforations should be 3/8 inches. Use solid sections of non-perforated PVC piping and watertight joints wherever the underdrain system passes below berms, down steep slopes, makes a connection to a drainage structure, or daylights on grade.

- Spacing of collection laterals should be less than 25 feet.

- Underdrain pipes should have a minimum of 3 inches of washed #57 stone above and on each side of the pipe (stone is not required below the pipe). Above the stone, two inches of choking stone is needed to protect the underdrain from blockage.

- Avoid filter fabric .

- Pipe socks may be needed for underdrains imbedded in sand. If pipe socks are used, then use circular knit fabric.

The procedure to size underdrains is typically determined by the project engineer. An example for sizing underdrains is found in the North Carolina Department of Environment and Natural Resources Stormwater BMP Manual. Underdrain spacing can be calculated using the following spreadsheet, which utilizes the vanSchilfgaarde Equation. The spreadsheet includes an example calculation. File:Underdrain spacing calculation.xlsx

Pretreatment

It is HIGHLY RECOMMENDED that the following pretreatment sizing guidelines be followed:

- Before entering an infiltration practice, stormwater should first enter a pretreatment practice sized to treat a minimum volume of 25 percent of the Vwq.

- If the infiltration rate of the native soils exceeds 2 inches per hour a pretreatment practice capable of treating a minimum volume of 50 percent of the Vwq should be installed.

- If the infiltration rate of the native soils exceeds 5 inches per hour a pretreatment practice capable of treating a minimum volume of 100 percent of the Vwq should be installed.

Alternatively, sizing guidelines based on a target particles size to be captured are found here.

It is HIGHLY RECOMMENDED that pretreatment practices be designed such that exit velocities from the pretreatment systems are non-erosive (less than 3 feet per second) and flows are evenly distributed across the width of the practice (e.g., by using a level spreader).

For additional information, see the pretreatment section in the manual.

Treatment

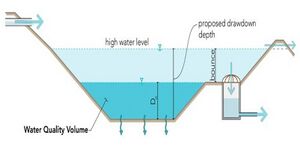

Drawdown time and bounce

For information on assessing the performance of a BMP and determining if it meets the required drawdown time, click here.

Space occupied

Space varies depending on the depth of the practice. Typically, infiltration trenches are 3 to 12 feet deep with a width less than 25 feet. A dry well is essentially a smaller version of an infiltration trench, consistent with the fact that the drainage area to an infiltration trench is typically five times greater (or larger) than that of a dry well. Underground infiltration systems are larger practices that range in depth from approximately 2 to 12 feet. Permeable Pavement systems have an average depth of 2 to 5 feet depending on the pavement and media thickness. The surface area of all infiltration practices is a function of MPCA’s 48-hour drawdown requirement and the infiltration capacity of the underlying soils.

The maximum storage volume statically stored within the infiltration practice must completely drawdown within 48 hours. An emergency spillway and/or backup underdrain should be constructed if the infiltration device is unable to dewater within 48 hours.

Slope of the infiltration practice

It is RECOMMENDED that the bottom of all infiltration practices be flat, in order to enable even distribution and infiltration of stormwater. It is RECOMMENDED that the longitudinal slope range only from the ideal 0 percent up to 1 percent, and that lateral slopes be held at 0 percent.

Side slopes

It is HIGHLY RECOMMENDED that the maximum side slope for an infiltration practice is 3:1 (h:v).

Depth

The depth of an infiltration practice is a function of the maximum drawdown time and the design infiltration rate. When the drawdown time for an infiltration system is 48 hours, the total drawdown depth is 78.2 inches for GW and GP Hydrologic Soil Group (HSG) A soils, 38.4 inches for GM and SW (HSG A) soils; 21.6 inches for SM (HSG B) soils; 14.4 inches for loam, silt loam and MH (HSG B) soils; and 9.6 inches for HSG C soils. If field tested rates for any soil exceeds the rate for A soils in the manual (1.63 inches per hour), the total drawdown depth (water quality volume depth + bounce) must not exceed 6.5 feet. When the drawdown time is 24 hours, the above water quality volume depths are reduced by a factor of 2. Any captured depth (bounce) beyond the water quality volume needs to be removed from the BMP within 48 hours via an emergency spillway designed to overflow at the top of the storage volume and/or a control structure used to limit peak discharge rates.

Aesthetics

Infiltration basins can be effectively integrated into the site planning process, and aesthetically designed as attractive green spaces planted with native vegetation. If vegetation is used, the infiltration practice becomes a bioinfiltration practice. See the Design Criteria for bioinfiltration practices webpage for more information. Infiltration trenches are less conducive to site aesthetics, but the surface of trenches can be designed with turf cover crops if desired.

Concerning infiltration practices with exposed filter media, keep adjacent vegetation from forming an overhead canopy above infiltration practices, in order to keep leaf litter, fruits, and other vegetative materials from clogging the filter media.

Landscaping

Landscaping is critical to the performance and function of vegetated areas of infiltration practices. Therefore, a landscaping plan is HIGHLY RECOMMENDED for vegetated infiltration practices. RECOMMENDED planting guidelines for vegetated practices are as follows.

- Vegetation should be selected based on a specified zone of hydric tolerance. Plants for Stormwater Design - Species selection for the Upper Midwest is a good resource.

- Native plant species should be specified over non-native species. Hardy native species that thrive in our ecosystem without chemical fertilizers and pesticides are the best choices.

- Many vegetated practices feature wild flowers and grasses as well as shrubs and some trees.

- If woody vegetation is placed near inflow locations, it should be kept out of pretreatment devices and be far enough away to not hamper maintenance of pretreatment devices.

- Trees should not be planted directly overtop of underdrain and may be best located along the perimeter of the practice.

- Salt resistant vegetation should be used in locations with probable adjacent salt application, e.g. roadside, parking lot, etc.

- Plugs, bare root plants or potted plants are RECOMMENDED over seed for herbaceous plants, shrubs, and trees. Erosion control mats pre-vegetated with herbaceous perennial plants are also acceptable. For turf, sod is recommended over seed. (NOTE: Fluctuating water levels following seeding (prior to germination) can cause seed to float and be transported, resulting in bare areas that are more prone to erosion and weed invasion than vegetated areas. Seed is also difficult to establish through mulch, a common surface component of vegetated practices. It may take more than two growing seasons to establish the function and desired aesthetic of mature vegetation via seeding.)

- Vegetated practices should be operated offline for 1 year or, within the first year, until vegetation is established.

- Example target plant coverage includes

- at least 50 percent of specified vegetation cover at end of the first growing season;

- at least 90 percent of specified vegetation cover at end of the third growing season;

- supplement plantings to meet project specifications if cover targets are not met; and

- tailoring percent coverage targets to project goals and vegetation. For example, percent cover required for turf after 1 growing season would likely be 100 percent, whereas it would likely be lower for other vegetation types.

- Vegetated areas should be integrated into the site planning process, and aesthetic considerations should be taken into account in their siting and design.

Operation and maintenance of vegetated practices is critical to meeting these landscape recommendations and targets. For more information on operation and maintenance, see the section on operation and maintenance of stormwater infiltration practices.

Safety

Dry wells, infiltration trenches and subsurface infiltration systems do not pose any major safety hazards. Infiltration basins should have similar side slope considerations as ponds and wetlands.

Additional information on safety for construction sites is available from OSHA.

Maximum flow path

Flow path length is important only if high flows are not bypassed. Below are recommendations from other states or localities.

- North Carolina: The geometry of the cell shall be such that width, length, or radius are not less than 10 feet. This is to provide sufficient space for plants.

- Virginia: Length of shortest flow path to overall length is 0.3 for Level 1 Design and 0.8 for Level 2 Design

- Dakota County Soil and Water Conservation District: Where offline designs are not achievable, bioretention practices shall be designed to route high flows on the shortest flow path across the cell to provide the least disturbance and displacement of the Water Quality Volume to be treated. Energy dissipation to avoid high flow velocity turbulence is required.

Use of multiple cells

In comparison to multiple cells, one large bioretention or infiltration cell will often perform just as well as multiple smaller cells if sized and designed appropriately. One large cell is generally less costly than multiple smaller cells. This is due to the simpler geometry and grading requirements of one large cell, as well as a reduction in piping and outlet structures. Multiple smaller cells do however provide greater redundancy, i.e. if one large cell fails, more function is lost than if just one of multiple cells fail. Multiple cells are also more feasible than one large cell in steep terrain (slopes greater than 5 percent), where they can be terraced to match the existing grade. Provided access is maintained to each cell, multiple cells typically results in less and easier maintenance.

Snow considerations

Considering management of snow, the following are recommended.

- Plan a plow path during design phase and tell snowplow operators where to push the snow. Plan trees around (not in) plow path, with a 16 foot minimum between trees.

- Plan for snow storage (both temporary during construction and permanent). Don’t plow into raingardens (bioretention) routinely. Raingardens should be a last resort for snow storage (i.e. only for very large snow events as “emergency overflow”.

- Snow storage could be, for example, a pretreatment moat around a raingarden, i.e. a forebay for snow melt.

For more information and example photos, see the section on snow and ice management.

Materials specifications

Specifications for infiltration basin, infiltration trench, dry well, and underground infiltration practices are provided below. The table below shows a comparison of different material specifications for infiltration practices. To view this information in an Excel file, link here.

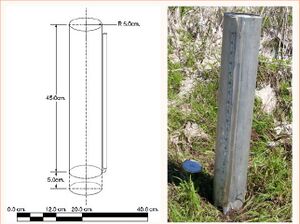

Observation well

Infiltration practices should include an observation well, consisting of an anchored 4- to 6-inch diameter perforated PVC pipe fitted with a lockable cap installed flush with or above the ground surface. See MNDOT Manual Section 3248 for design guidance on PVC pipes. It is recommended to install one well per 50 feet of length in the infiltration practice. For permeable pavement systems with greater than 10,000 square feet of contributing drainage area, the observation well should be placed at the downstream end of the practice.

The purpose of the observation well is to monitor water drainage in the infiltration practice. Check observation wells within the specified drawdown time (24 or 48 hours) after a storm event. Standing water in the well is an indication of clogging of the infiltration system. Observation wells should not be used for water quality monitoring since monitoring wells extend into underlying groundwater.

A detail of a typical infiltration cross-section, which includes an observation well, can be found at this link. This detail includes construction sequencing and other design information.

Emergency overflow structure

- Infiltration trench and infiltration basin

- All infiltration beds should be designed with overflow spillway for extreme storm events

- Properly designed vegetated filters are required from the overflow of all infiltration systems

- Dry well

- A surcharge pipe should be constructed as an emergency overflow device for dry wells which receive runoff directly from a roof leader

High flow bypass structure

- Infiltration trench and infiltration basin

- A high flow bypass or diversion structure should be included to safely convey high flows from large storm events

- Control in beds is usually provided as an outlet control structure

- Modified inlet box with internal concrete weir (or weir plate) and low-flow orifice is common

- High flows must be bypassed within 48 hours and allow the infiltration practice to meet the 48 hour drawdown requirement

- Underground infiltration

- A flow bypass structure should be located upgradient of the infiltration structure to convey high flows around the structure

- High flows must be bypassed within 48 hours and allow the infiltration practice to meet the 48 hour drawdown requirement

Buffer vegetation

- Infiltration basin, underground infiltration, dry well

- Keep adjacent vegetation from forming overhead canopy above infiltration practices. This keeps leaf litter, fruits, and other vegetative material from clogging stone

- For infiltration basins, trees may be planted along side slopes but must be 15 ft away from pipes and 25 ft away from risers.

- Infiltration trench

- Grass strip or other vegetated buffer at least 20 feet wide should be maintained around trenches accepting surface runoff as sheet flow

- Slope of filter strip should be approximately 1% along entire length and 0% across width

Surface cover

- Infiltration basin

- For stone cover: apply a two inch layer of pea gravel or river stone

- Infiltration trench

- 3-inch layer of river stone or pea gravel with filter fabric and additional aggregate on top

- Underground infiltration

- Permeable topsoil and planted with grass

- Deep-rooted plants, such as prairie grass, should be used to increase infiltration capacity

- Bottom and side slopes of basin should be planted with dense water-tolerant grass (such as fescues)

- Soil cover (12 - 18 inches) should be maintained above infiltration bed to allow for a healthy vegetative cover

- Overly infiltration bed with native grasses, meadow mix, or other low-growing, dense vegetation

- In place of turf, use basin liner of 6 to 12 inches of fill material (coarse sand)

- Dry well

- Covered by a minimum of 12 inches of topsoil

Filter bed (stone)

- Infiltration basin

- 1 to 3-foot thick layer of double-washed, uniform ( uniformity coefficient of 2 or smaller with a void ratio of 0.40) aggregate between 1.5 and 3.0 inch diameter

- MNDOT Coarse Aggregate Bedding (Section 3149 G.2) ranging 1-2 inch in gradation

- Infiltration trench

- 1 to 4-foot thick layer of double-washed, uniform (uniformity coefficient of 2 or smaller with a void ratio of 0.40) aggregate between 1.5 and 3.0 inch diameter

- MNDOT Coarse Aggregate Bedding (Section 3149 G.2) ranging 1-2 inch in gradation

- Underground infiltration

- 1 to 4-foot thick layer of double-washed, uniform (uniformity coefficient of 2 or smaller with a void ratio of 0.40) aggregate between 1.5 and 3.0 inch diameter

- MNDOT Coarse Aggregate Bedding (Section 3149 G.2) ranging 1-2 inch in gradation

- Dry well

- Double-washed, uniform (uniformity coefficient of 2 or smaller with a void ratio of 0.40) aggregate between 1.5 and 3.0 inch diameter

- MNDOT Coarse Aggregate Bedding (Section 3149 G.2) ranging 1-2 inch in gradation

Filter fabric

- Infiltration basin

- Top of geotextile should be 6-12 inches below upper surface of drainage media with 12 inch overlap of fabric seams

- Fabric should be placed between side walls and between stone and gravel layers but not on the basin bottom

- Geotextile must meet MNDOT Type I Non-woven geotextile

- Examples: Mirafi 140N, Amoco 4547, and Geotex 451

- Infiltration trench

- Surround fill on sides with filter fabric with 12 inch overlap of fabric seams. A separate piece should be used for the top layer to act as a failure plane

- Fabric should be placed between side walls and between stone and gravel layers but not on the trench bottom

- Geotextile must meet MNDOT Type I non-woven geotextile

- Examples: Mirafi 140N, Amoco 4547, and Geotex 451

- Underground infiltration

- Surround fill on sides with filter fabric with 12 inch overlap of fabric seams

- Geotextile must meet MNDOT Type I non-woven geotextile

- Examples: Mirafi 140N, Amoco 4547, and Geotex 451

- Dry well

- Geotextile on trench sides and top keyed into drywell

- Geotextile must meet MNDOT Type I non-woven geotextile

- Examples: Mirafi 140N, Amoco 4547, and Geotex 451

Bottom

- Infiltration basin, infiltration trench, underground infiltration, dry well

- Any of the following can be used on the bottom:

- 6 to 8 inch clean sand (1-2 percent fines or less)

- 3/8 inch pea gravel

- 6-12 inch layer of MNDOT Fine Filter Aggregate (Section 3149 J.2)

- 12 inch of gravel or sand (good for cold climates)

In-situ soils

- Infiltration basin, infiltration trench, underground infiltration, dry well

- NRCS Type A and B soils are the most efficient soils for proper infiltration. Type C soils are acceptable of the infiltration practice meets the required 48 hour drawdown period

Miscellaneous considerations

- All material must be placed such that compaction is avoided. See the Construction Specifications webpage for more details

- For infiltration trench and underground infiltration, plastic, aluminum, or concrete gallery frames can be inserted to increase the runoff capture storage volume.

Infiltration material specifications

Link to this table. To open this table in Excel format, link here.

| Component | Infiltration basin | Bioinfiltration basin | Infiltration trench | Underground infiltration | Dry well | Dry swale with check dams | Permeable pavement | Tree trench/box/planter |

|---|---|---|---|---|---|---|---|---|

| Observation well |

|

|

|

|||||

| Emergency overflow structure |

|

NA | A surcharge pipe should be constructed as an emergency overflow device for Dry Wells which receive runoff directly from a roof leader. [6] | NA | See Design criteria for permeable pavement | Tree box filters should be designed with an emergency overflow pipe | ||

| High flow bypass structure |

|

|

NA | NA | NA | NA | ||

| Buffer vegetation |

|

|

Keep adjacent vegetation from forming an overhead canopy above infiltration practices. This keeps leaf litter, fruits, and other vegetative material from clogging stone. |

|

NA |

|

||

| Surface cover | For stone cover: apply a two inch layer of pea gravel or river stone |

|

3-inch layer of river stone or pea gravel with filter fabric and additional aggregate on top |

|

Covered by a minimum of 12 inches of topsoil |

|

|

|

| Intermediate layer | NA | NA | NA | NA | NA | NA | Choker Layer: A 2 to 8 inch bedding coarse of Medium Filter Aggregate (MNDOT Section 3149 J.1) is usually placed over the top of the base material to help stabilize the irregular surface | NA |

| Filter bed (stone) |

|

Bioinfiltration engineered soil mix |

|

|

20-30 inch layer of permeable manufactured soil mixture meeting the bioinfiltration soil mix |

|

3' of bioinfiltration Soil Media | |

| Filter fabric |

|

|

|

|

|

|

|

|

| Bottom |

|

|

|

|

Bottom Layer: 4" min depth of .75" crushed stone MNDOT Coarse Aggregate Bedding (Section 3149 G.2) | 2' layer of clean, washed angular gravel 0.75 to 1.5 inch diameter | ||

| in-situ soils | NRCS Type A and B soils are the most efficient soils for proper infiltration. Type C soils are acceptable of the infiltration practice meets the required 48 hour drawdown period | |||||||

| Miscellaneous | All material must be placed such that compaction is avoided. See the Construction Specifications webpage for more details | To increase the runoff capture storage volume of trenches, plastic, aluminum or concrete gallery frames can be inserted All material must be placed such that compaction is avoided. See the Construction Specifications webpage for more details |

|

|||||

1Thickness will vary depending on traffic conditions.Typically, thicker configurations are needed for heavier traffic loads.

Materials specifications - filter media

Infiltration practices do not typically use engineered filter media. If engineered media is used, all media should meet the specifications listed in the design criteria for bioretention basin webpage. Links are provided below.

Design procedure - design steps

The following steps outline a recommended design procedure for infiltration practices in compliance with the MPCA Construction Stormwater General Permit for new construction. Design recommendations beyond those specifically required by the permit are also included and marked accordingly.

When riser pipe outlets are used in infiltration basins, it is HIGHLY RECOMMENDED that they be constructed with manholes that either have locks or are sufficiently heavy to prevent easy removal.

Fencing of dry wells and infiltration trenches is neither necessary nor desirable. Infiltration basins may warrant fencing in some situations.

Step 1. Make a preliminary judgment

Make a preliminary judgment as to whether site conditions are appropriate for the use of an infiltration practice, and identify the function of the practice in the overall treatment system.

A. Consider basic issues for initial suitability screening, including:

- site drainage area (See the summary of infiltration practices for given drainage areas in the table below);

- site topography and slopes;

- soil infiltration capacity;

- regional or local depth to groundwater and bedrock;

- site location/ minimum setbacks; and

- presence of active karst.

B. Determine how the infiltration practice will fit into the overall stormwater treatment system.

- Decide whether the infiltration practice is the only bmp to be employed, or if are there other BMPs addressing some of the treatment requirements.

- Decide where on the site the infiltration practice is most likely to be located.

Stormwater infiltration BMPs - contributing drainage area

Link to this table

| Stormwater BMP | Recommended contributing area | Notes |

|---|---|---|

| Infiltration Basin | 50 acres or less | A natural or constructed impoundment that captures, temporarily stores and infiltrates the design volume of water into the surrounding naturally permeable soil over several days. In the case of a constructed basin, the impoundment is created by excavation or embankment. |

| Bioinfiltration Basin | 5 acres or less | Bioinfiltration basins must meet the required 48 hour drawdown time and must be sized in order to allow for adequate maintenance. It is HIGHLY RECOMMENDED that bioinfiltration basins be designed to prevent high levels of bounce as submerging vegetation may inhibit plant growth. A maximum wet storage depth of 1.5 feet is HIGHLY RECOMMENDED. |

| Infiltration Trench | 5 acres or less | |

| Dry Well Synonym: Infiltration Tube, French Drain, Soak‐Away Pits, Soak Holes | 1 acre or less (rooftop only) | |

| Underground Infiltration | 10 acres or less | Though feasible, larger underground infiltration systems may cause groundwater contamination as water is not able to infiltrate through a surface cover. In addition, wind flocculation, UV degradation, and bacterial degradation, which provide additional treatment in surface systems, do not occur in underground systems. Because performance research is lacking for larger features, it is HIGHLY RECOMMENDED that the contributing drainage area to a single device not exceed 10 acres. |

| Dry Swale with Check Dams | 5 acres or less | |

| Permeable Pavement | It is RECOMMENDED that external contributing drainage area not exceed the surface area of the permeable pavement. It is HIGHLY RECOMMENDED that external contributing drainage area not exceed twice the surface area of the permeable pavement | It is RECOMMENDED that external drainage area be as close to 100% impervious as possible. Field experience has shown that drainage area (pervious or impervious) can contribute particulates to the permeable pavement and lead to clogging. Therefore, sediment source control and/or pretreatment should be used to control sediment run-on to the permeable pavement section. |

| Tree Trench/Tree Box | up to 0.25 acres per tree |

References: Virginia, North Carolina, West Virginia, Maine, Lake Tahoe, Connecticut, Massachusetts, New York, Wisconsin, Vermont, New Hampshire, Ontario, Pennsylvania

Step 2. Confirm design criteria and applicability

Determine whether the infiltration practice must comply with the MPCA Construction Stormwater General (CSW) Permit. Check with local officials, Watershed management Organizations (WMOs), and other agencies to determine if there are any additional restrictions and/or surface water or watershed requirements that may apply.

- areas that receive discharges from vehicle fueling and maintenance;

- areas with less than three (3) feet of separation distance from the bottom of the infiltration system to the elevation of the seasonally saturated soils or the top of bedrock;

- areas that receive discharges from industrial facilities which are not authorized to infiltrate industrial stormwater under an NPDES/SDS Industrial Stormwater Permit issued by the MPCA;

- areas where high levels of contaminants in soil or groundwater will be mobilized by the infiltrating stormwater;

- areas of predominately Hydrologic Soil Group D (clay) soils;

- areas within 1,000 feet up‐gradient, or 100 feet down‐gradient of active karst features;

- areas within a Drinking Water Supply Management Area (DWSMA) as defined in Minn. R. 4720.5100, subp. 13., if the system will be located:

- in an Emergency Response Area (ERA) within a DWSMA classified as having high or very high vulnerability as defined by the Minnesota Department of Health; or

- in an ERA within a DWSMA classified as moderate vulnerability unless a regulated MS4 Permittee performed or approved a higher level of engineering review sufficient to provide a functioning treatment system and to prevent adverse impacts to groundwater; or

- outside of an ERA within a DWSMA classified as having high or very high vulnerability, unless a regulated MS4 Permittee performed or approved a higher level of engineering review sufficient to provide a functioning treatment system and to prevent adverse impacts to groundwater; and

- areas where soil infiltration rates are more than 8.3 inches per hour unless soils are amended to slow the infiltration rate below 8.3 inches per hour.

Step 3. Perform field verification of site suitability

16.10. Permittees must provide at least one soil boring, test pit or infiltrometer test in the location of the infiltration practice for determining infiltration rates.

Designers should evaluate soil properties during preliminary site layout with the intent of installing infiltration practices on soils with the highest infiltration rates ( hydrologic soil group A and B). Preliminary planning for the location of an infiltration device may be completed using a county soil survey or the NRCS Web Soil Survey. These publications provide HSG information for soils across Minnesota. To ensure long-term performance, however, field soil measurements are desired to provide site-specific data.

If the initial evaluation indicates that an infiltration practice would be a good BMP for the site, it is RECOMMENDED that soil borings or pits be dug within the proposed boundary of the infiltration practice to verify soil types and infiltration capacity characteristics and to determine the depth to groundwater and bedrock. Soil borings for building structural analysis are not acceptable. In all design scenarios, a minimum of one soil boring (two are recommended) shall be completed to a depth 5 feet below the bottom of the proposed infiltration Stormwater Control Measure (SCM or BMP) (Dakota County Soil and Water Conservation District, 2012) per ASTM D1586 (ASTM, 2011). For infiltration SCMs with surface area between 1000 and 5000 square feet, two borings shall be made. Between 5000 and 10000 square feet, three borings are needed, and for systems with greater than 10000 square feet in surface area, 4 or more borings are needed. For each additional 2500 square feet beyond 12,500 square feet, an additional soil boring should be made. Soil borings must be undertaken during the design phase (i.e. prior to the commencement of construction) to determine how extensive the soil testing will be during construction. Borings should be completed using continuous split spoon sampling, with blow counts being recorded to determine the level of compaction of the soil. Soil borings are needed to understand soil types, seasonally high groundwater table elevation, depth to karst, and bedrock elevations.

Recommended number of soil borings, pits or permeameter tests for bioretention design. Designers select one of these methods.

Link to this table

| Surface area of stormwater control measure (BMP)(ft2) | Borings | Pits | Permeameter tests |

|---|---|---|---|

| < 1000 | 1 | 1 | 5 |

| 1000 to 5000 | 2 | 2 | 10 |

| 5000 to 10000 | 3 | 3 | 15 |

| >10000 | 41 | 41 | 202 |

1an additional soil boring or pit should be completed for each additional 2,500 ft2 above 12,500 ft2

2an additional five permeameter tests should be completed for each additional 5,000 ft2 above 15,000 ft2

It is HIGHLY RECOMMENDED that soil profile descriptions be recorded and include the following information for each soil horizon or layer (Source: Site Evaluation for Stormwater Infiltration, Wisconsin Department of Natural Resources Conservation Practice Standards 2004):

- thickness, in inches or decimal feet;

- Munsell soil color notation;

- soil mottle or redoximorphic feature color, abundance, size and contrast;

- USDA soil textural class with rock fragment modifiers;

- soil structure, grade size and shape;

- soil consistence, root abundance and size;

- soil boundary; and

- occurrence of saturated soil, impermeable layers/lenses, ground water, bedrock or disturbed soil.

It is RECOMMENDED that a standard soil boring form be used. A good example is File:Boring Pit Log form.docx. The NRCS Field Book for Describing and Sampling Soils provide detailed information for identifying soil characteristics. Munsell color charts can be found here.

It is HIGHLY RECOMMENDED that the field verification be conducted by a qualified geotechnical professional.

Step 4. Compute runoff control volumes

The design techniques in this section are meant to maximize the volume of stormwater being infiltrated. If the site layout and underlying soil conditions permit, a portion of the Channel Protection Volume (Vcp), Overbank Flood Protection Volume (Vp10), and the Extreme Flood Volume (Vp100) may also be managed in the infiltration practice.

Step 5. Determine infiltration type and size practice

Once the physical suitability evaluation is complete (Step 3), it is HIGHLY RECOMMENDED that the designer apply the better site design principles in sizing and locating the infiltration practice(s) on the development site.

Select design variant

After following the steps outlined above, the designer will presumably know the location of naturally occurring permeable soils, the depth to the water table, bedrock or other impermeable layer, and the contributing drainage area. Given the steps performed in the physical suitability evaluation (Step 3), identify the most suitable location for the infiltration practice. Given the water quality volume and the drainage area, select the appropriate infiltration practice for the first iteration of the design process. See the section on BMPs for stormwater infiltration for more information.

Note: Information collected during the site suitability evaluation (see Steps 1 and 3) should be used to explore the potential for multiple infiltration practices versus relying on a single infiltration facility. The use of smaller infiltration practices dispersed around a development is usually more sustainable than a single regional facility that is more likely to have maintenance and groundwater mounding problems (Source: Stormwater post-construction technical standards, Wisconsin Department of Natural Resources Conservation Practice Standards. See Using the treatment train approach to BMP selection for more information on selecting multiple BMPs at a site.

Experience has demonstrated that, although the drawdown period is 48 hours, there is often some residual water pooled in the infiltration practice after 48 hours. This residual water may be associated with reduced head, water gathered in depressions within the practice, water trapped by vegetation, and so on. The drawdown period is therefore defined as the time from the high water level in the practice to 1 to 2 inches above the bottom of the facility. This criterion was established to provide the following: wet-dry cycling between rainfall events; unsuitable mosquito breeding habitat; suitable habitat for vegetation; aerobic conditions; and storage for back-to-back precipitation events. This time period has also been called the period of inundation.

Determine site infiltration rates (for facilities with infiltration and/or recharge)

For design purposes, there are two ways of determining the soil infiltration rate. The first, and preferred method, is to field-test the soil infiltration rate using appropriate methods described below. The other method uses the typical infiltration rate of the most restrictive underlying soil (determined during soil borings).

If infiltration rate measurements are made, a minimum of one infiltration test in a soil pit must be completed at the elevation from which exfiltration would occur (i.e. interface of gravel drainage layer and in situ soil). When the SCM surface area is between 1000 and 5000 square feet, two soil pit measurements are needed. Between 5000 and 10000 square feet of surface area, a total of three soil pit infiltration measurements should be made. Each additional 5000 square feet of surface area triggers an additional soil pit.

Recommended number of soil borings, pits or permeameter tests for bioretention design. Designers select one of these methods.

Link to this table

| Surface area of stormwater control measure (BMP)(ft2) | Borings | Pits | Permeameter tests |

|---|---|---|---|

| < 1000 | 1 | 1 | 5 |

| 1000 to 5000 | 2 | 2 | 10 |

| 5000 to 10000 | 3 | 3 | 15 |

| >10000 | 41 | 41 | 202 |

1an additional soil boring or pit should be completed for each additional 2,500 ft2 above 12,500 ft2

2an additional five permeameter tests should be completed for each additional 5,000 ft2 above 15,000 ft2

The median measured infiltration rate should be utilized for design. Soil pits should be dug during the design phase and should be a minimum of two feet in diameter for measurement of infiltration rate. Infiltration testing in the soil pit can be completed with a double-ring infiltrometer or by filling the pit with water and measuring stage versus time. If the infiltration rate in the first pit is greater than 2 inches per hour, no additional pits shall be needed.

Alternatively, a Modified Philip-Dunne permeameter can be used to field test infiltration rate. Modified Philip-Dunne permeameter tests may be made in conjunction with soil borings or may be completed using a handheld soil auger. Borings should be lined with a plastic sleeve to prevent infiltration from the sides of the borehole (i.e. restrict flow to vertical infiltration). Soil borings should be filled with water. The time for the borehole to drain should be recorded and divided by the initial ponding depth in the borehole to provide an infiltration rate measurement. The design infiltration rate should be the lower of the median soil pit infiltration rate or the median borehole method infiltration rate. For information on conducting soil borings see Understanding and interpreting soils and soil boring reports for infiltration BMPs.

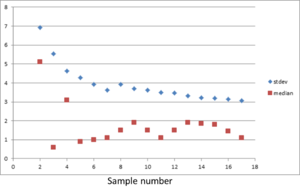

NOTE: In the table above, the recommended number of permeameter tests increases by 5 tests per each additional 5000 square feet of surface area. For larger sites, this can result in a very large number of samples. There may be situations where fewer permeameter tests may be used (5 is the minimum) . For example, in situations where the variability in saturated hydraulic conductivity between measurements is not great, fewer samples may be taken. One method for determining the number of samples is to plot standard deviation versus number of samples. Measurements may be halted when the standard deviation becomes relatively constant from one sample to the next. In the example to the right the standard deviation flattens at about 7 to 10 samples. Therefore, 7 to 10 samples would be an appropriate number of samples for this situation.

For information on conducting soil infiltration rate measurements, see Determining soil infiltration rates.

If the infiltration rate is not measured, use the table below to estimate an infiltration rate for the design of infiltration practices. These infiltration rates represent the long-term infiltration capacity of a practice and are not meant to exhibit the capacity of the soils in the natural state.

Design infiltration rates, in inches per hour, for A, B, C, and D soil groups. Corresponding USDA soil classification and Unified soil Classifications are included. Note that A and B soils have two infiltration rates that are a function of soil texture.*

The values shown in this table are for uncompacted soils. This table can be used as a guide to determine if a soil is compacted. For information on alleviating compacted soils, link here. If a soil is compacted, reduce the soil infiltration rate by one level (e.g. for a compacted B(SM) use the infiltration rate for a B(MH) soil).

Link to this table

| Hydrologic soil group | Infiltration rate (inches/hour) | Infiltration rate (centimeters/hour) | Soil textures | Corresponding Unified Soil ClassificationSuperscript text |

|---|---|---|---|---|

| Although a value of 1.63 inches per hour (4.14 centimeters per hour) may be used, it is Highly recommended that you conduct field infiltration tests or amend soils.b See Guidance for amending soils with rapid or high infiltration rates and Determining soil infiltration rates. |

gravel |

GW - Well-graded gravels, fine to coarse gravel GP - Poorly graded gravel |

||

| 1.63a | 4.14 |

silty gravels |

GM - Silty gravel |

|

| 0.8 | 2.03 |

sand |

SP - Poorly graded sand |

|

| 0.45 | 1.14 | silty sands | SM - Silty sand | |

| 0.3 | 0.76 | loam, silt loam | MH - Elastic silt | |

| 0.2 | 0.51 | Sandy clay loam, silts | ML - Silt | |

| 0.06 | 0.15 |

clay loam |

GC - Clayey gravel |

|

1For Unified Soil Classification, we show the basic text for each soil type. For more detailed descriptions, see the following links: The Unified Soil Classification System, CALIFORNIA DEPARTMENT OF TRANSPORTATION (CALTRANS) UNIFIED SOIL CLASSIFICATION SYSTEM

- NOTE that this table has been updated from Version 2.X of the Minnesota Stormwater Manual. The higher infiltration rate for B soils was decreased from 0.6 inches per hour to 0.45 inches per hour and a value of 0.06 is used for D soils (instead of < 0.2 in/hr).