Stormwater infiltration and constraints on infiltration combined

This document combines several documents related to Stormwater infiltration and constraints on infiltration. Individual documents can be viewed by clicking on the appropriate link below.

- Karst

- Shallow soils and shallow depth to bedrock

- Shallow groundwater

- Soils with low infiltration capacity

- Potential stormwater hotspots

Contents

- 1 Karst

- 1.1 What is karst?

- 1.2 Why is karst geology a concern?

- 1.3 Where can I get more information on karst in Minnesota?

- 1.4 How to investigate for karst on a site

- 1.5 General stormwater management guidelines for karst areas

- 1.6 How to remediate after a sinkhole appears

- 1.7 Monitoring of BMPs in karst regions

- 1.8 Related pages

- 2 Shallow soils and shallow depth to bedrock

- 3 Shallow groundwater

- 4 Soils with low infiltration capacity

- 5 Potential stormwater hotspots

Karst

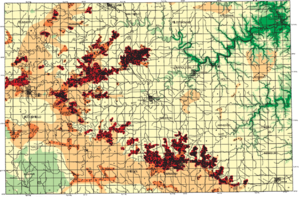

Karst geology makes up approximately 20 percent of the land surface in the United States. It is also found in other parts of the world such as China, Europe, the Caribbean, Australia, and Madagascar (USGS). Karst regions in Minnesota are predominantly found in the southeastern portion of the state. Use of infiltration BMPs in karst regions can be complicated and necessitates additional geotechnical testing, pre-treatment of stormwater runoff, and ponding of runoff. Caution must be used in interpreting the geographic depiction of karst lands as subsurface conditions can change rapidly over very short distances (Karst Working Group, 2009). Generalized maps of active karst will be less accurate than a county-scale map, as demonstrated by the two figures to the right. The following county-level maps have been developed.

In Minnesota there are three classifications of karst lands.

- Active Karst. Active karst is a terrain having distinctive landforms and hydrology created primarily from the dissolution of soluble rocks within 50 feet of the land surface

- Transition Karst. Transition karst is defined as areas underlain by carbonate bedrock with 50 to 100 feet of sediment cover.

- Covered Karst. Covered karst is defined as areas underlain by carbonate bedrock but with more than 100 feet of sediment cover.

A site with Active Karst has the greatest potential for development of a sinkhole below a BMP and the recommendations contained in this section should be considered for all proposed BMPs in areas with Active Karst. For Transitional Karst sites, it is HIGHLY RECOMMENDED that the nature of the overlying soils be evaluated with respect to the potential for catastrophic failure given the increase in hydrostatic pressure created by a BMP.

- Recommended websites pertaining to Minnesota karst

What is karst?

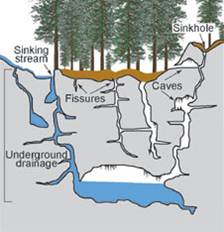

Karst is a landscape formed by the dissolution of a layer or layers of soluble bedrock. The bedrock is usually carbonate rock such as limestone or dolomite but the dissolution has also been documented in weathering resistant rock, such as quartz. The dissolution of the rocks occurs due to the reaction of the rock with acidic water. Rainfall is already slightly acidic due to the absorption of carbon dioxide (CO2), and becomes more so as it passes through the subsurface and picks up even more CO2. Cracks and fissures form as the runoff passes through the subsurface and reacts with the rocks. These cracks and fissures grow, creating larger passages, caves, and may even form sinkholes as more and more acidic water infiltrates into the subsurface (American Rivers).

Subterranean drainage through karst geology limits the presence of surface water in places, explaining the absence of rivers and lakes. Many karst regions display distinctive surface features such as a sinkhole or natural pit (often termed cenotes or dolines), fissures, or caves (USGS, 2012). However, distinctive karst surface features may be completely absent where the soluble rock is below a deep layer of glacial debris (termed mantled), or is below one or more layers of non-soluble rock strata. Some karst regions include thousands of caves, although evidence of caves large enough for human exploration is not a required characteristic of karst.

Presence of sinkholes is an absolute indication of active karst. In these cases, an easement or reserve area should be identified on the development plans for the project so that all future landowners know of the presence of active karst on their property.

The following sources provide additional information on karst in Minnesota.

- Karst in Minnesota - Minnesota Pollution Control Agency

- Karst features of Minnesota - Minnesota Geological Survey

- THE DEVELOPMENT OF A KARST FEATURE DATABASE FOR SOUTHEASTERN MINNESOTA - Alexander and Tipping

Why is karst geology a concern?

Infiltration BMPs in karst settings have the potential of creating sinkholes as a result of the additional weight of water in a structural BMP (termed hydraulic head) and/or water infiltrated from the BMP that can dissolve the carbonate rock (e.g., limestone). These conditions can lead to the erosion of bedrock underneath or adjacent to a BMP. In addition, the pollutants being carried by the stormwater runoff can pass rapidly through the subsurface into the groundwater, creating a greater risk of groundwater contamination than is found in other soil types.

Where karst conditions exist, there are no prescriptive rules or universally accepted management approaches. When underlying karst is known or suspected to be present at the site, stormwater runoff should not be concentrated and discharged into or near known sinkholes. Instead, the following strategies should be employed.

- Runoff should be dispersed

- Runoff should be pretreated and then infiltrated only if subsurface investigations and geotechnical analysis confirm that there are no unstable zones below the BMP

- Additional borings and deeper borings may be warranted to target evaluation of transitional karst zone

- Once ponds are constructed, include contingency plans for cases where karst features open up and impact a pond, including conducting geotechnical borings to appropriate depths trying to identify unstable zones, then target those zones for grouting

- Convey runoff to a collection and transmission system away from the area via vegetated drainageways

Where can I get more information on karst in Minnesota?

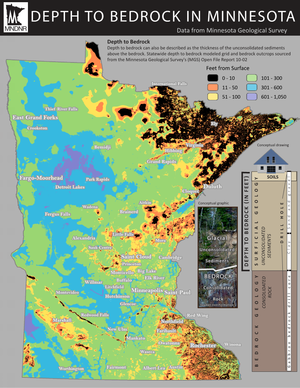

The Minnesota Department of Natural Resources has a relatively new product, Minnesota Regions Prone to Surface Karst Feature Development: GW-01, that shows karst areas in MN. This product can be used to outline such areas in a GIS environment. The GIS coverage is a superposition of Bedrock Geology and Depth to Bedrock maps prepared by the Minnesota Geological Survey (MGS). This dataset is managed by the Ecological and Water Resources Division, County Geologic Atlas Program. For additional information, visit Springs, Springsheds, and Karst on the Minnesota Department of Natural Resources website.

How to investigate for karst on a site

Developers, communities, public works agents, and other stormwater managers should conduct site investigations prior to designing and implementing stormwater BPMs in both active and transitional karst areas. A site with active karst has the greatest potential for development of a sinkhole below a BMP and the recommendations contained in this section should be considered for all proposed BMPs. For transitional karst sites, it is HIGHLY RECOMMENDED that the nature of the overlaying soils be evaluated with respect to the potential for catastrophic failure given the increase in hydrostatic pressure created by a BMP. The level of investigation required will depend on the likelihood of karst being present and the regulatory requirements in the area.

The purpose of the investigation is to identify subsurface voids, cavities, fractures, or other discontinuities which could pose an environmental concern or a construction hazard to an existing or proposed stormwater management facility. Of special concern are the construction hazards posed by karst geology, the formation of sinkholes, and the possibility of a preferential pathway that would provide a direct route for polluted runoff to enter the regional groundwater system. Because of the complexity inherent to active and transitional karst areas, there is no single set of investigatory guidelines that works for every location. Typically, however, the first step is a preliminary investigation that involves analyzing geological and topographic county maps, and aerial photography to determine if active karst is known to be present. Included in the preliminary investigation should be a site visit to perform a visual observation for karst features such as sinkholes. Results of the investigation should be reported to the appropriate agency, including the Department of Natural Resources (DNR), Minnesota Geological Survey (MGS), and local agencies (such as the city, township or county). These known and discovered karst features should be surveyed for specific location and permanently recorded on the property deed.

If it is determined that active karst is present, a detailed site investigation, including a subsurface materials investigation should be conducted. The design of any geotechnical investigation should reflect the size and complexity of the proposed project, as well as the local knowledge of the threat posed by the karstic geology. The geotechnical investigation should first assess the subsurface heterogeneity (variability). With this information in-hand, borings or observation wells can then be accurately installed to obtain vertical data surrounding or within karst features or within areas of instability that have the potential for development of karst. The vertical data should be used to determine the nature and thickness of the subsurface materials and needs to include information involving depth to the bedrock and depth to the groundwater table. The investigation will be an iterative process and should be expanded until the desired detailed knowledge of the site is obtained and fully understood (Karst Working Group, 2009). Guidelines for investigating all potential physical constraints to infiltration on a site are presented in a table at this link. These guidelines should not be interpreted as all-inclusive. The size and complexity of the project will drive the extent of any subsurface investigation.

Additional information regarding site investigations in karst areas can be found in Appendix B of the Tennessee Permanent Stormwater Management and Design Guidance Manual (Tennessee Department of Environment and Conservation, 2014). The Tennessee manual provides a flowchart which will guide designers through the investigative process and will help designers determine if any special analysis is required.

Preliminary site investigation

The level of detail required for a site investigation will depend on the likelihood that karst is present and on any local regulations. The preliminary site investigation should include, but not be limited to

- a review of aerial photographs, geological literature, sinkhole maps, previous soil borings, existing well data, and municipal wellhead or aquifer protection plans;

- a site reconnaissance, including a thorough field examination for features such as limestone pinnacles, sinkholes, closed depressions, fracture traces, faults, springs, and seeps; and

- site observations made under varying weather conditions, especially during heavy rains and in different seasons to identify and map any natural drainageways.

Subsurface material investigation

The investigation should determine the nature and thickness of subsurface materials, including depth to bedrock and the water table. Subsurface data may be acquired by backhoe excavation and/or soil boring. These field data should be supplemented by geophysical investigation techniques deemed appropriate by a qualified professional, which will show the location of karst formations under the surface. This is an iterative process that might need to be repeated until the desired detailed knowledge of the site is obtained and fully understood. The data listed below should be acquired under the direct supervision of a qualified and experienced karst scientist.

- Bedrock characteristics (ex. type, geologic contacts, faults, geologic structure, rock surface configuration)

- Depth to the water table and depth to bedrock

- Type and percent of coarse fragements

- Soil characteristics (ex. color, type, thickness, mapped unit, geologic source/history)

- Photo-geologic fracture trace map

- Bedrock outcrop areas

- Sinkholes and/or other closed depressions

- Perennial and/or intermittent streams, and their flow behavior (ex. a stream in a karst area that loses volume could be a good indication of sinkhole infiltration)

In conducting subsurface investigations, all applicable State regulations must be met. For more information, see Minnesota Department of Health's Wells and Borings website.

Location of soil borings

The local variability typical of karst areas could mean that a very different subsurface could exist close by, perhaps as little as 6 inches away. To accommodate this variability, the number and type of borings must be carefully assessed. If the goal is to locate a boring down the center of a sinkhole, the previous geophysical tests or excavation results can show the likely single location to achieve that goal. If the goal is to “characterize” the entire site, then an evaluation needs to occur to determine the number and depth needed to adequately represent the site. Again, the analyst must acknowledge the extreme variability and recognize that details can easily be missed. Some general guidance for locating borings include:

- getting at least 1 boring in each distinct major soil type present, as mapped in soil surveys;

- placing an adequate number near on-site geologic or geomorphic indications of the presence of sinkholes or related karst features;

- locating along geologic fracture traces;

- locating adjacent to bedrock outcrop areas;

- locating a sufficient number to adequately represent the area under any proposed stormwater facility; and

- documenting any areas identified as anomalies from any existing geophysical or other subsurface studies.

Exploratory borings must comply with Minnesota statutes, 4727.0100

Number and depth of soil borings

The number and depth of borings depends upon the results of the subsurface evaluation obtained from the observational, geophysical, and excavation studies, as well as other borings. There are no prescriptive guidelines to determine the number and depth of borings. These will have to be determined by the qualified staff conducting the BMP management evaluation and will be based upon the data needs of the installation. The borings must extend well below the bottom elevation of the designed BMP to ensure there are no karst features that will be encountered or impacted as a result of the installation.

At least 1 subsurface cross section should be provided for the BMP installation, showing confining layers, depth to bedrock, and water table (if encountered). It should extend through a central portion of the proposed installation, using the actual geophysical and boring data. A sketch map or formal construction plan indicating the location and dimension of the proposed practice and line of cross section should be included for reference, or as a base map for presentation of subsurface data.

Abandoning soil borings

Under Minnesota law all soil borings must be sealed by a licensed well contractor or a licensed well sealing contractor. A property owner may not seal any well or boring. See Minnesota Statutes, Chapter 103I For more information see these Minnesota Department of Health websites.

Identification of material

All material identified by the excavation and geophysical studies and penetrated by the boring should be identified, as follows.

- Provide descriptions, logging, and sampling for the entire depth of the boring.

- Note any stains, odors, or other indications of environmental degradation.

- Perform laboratory analysis on a minimum of 2 soil samples, representative of the material penetrated, including potential limiting soil horizons, with the results compared to the field descriptions.

- Identify soil characteristics including color, mineral composition, grain size, shape, sorting, and degree of saturation.

- Log any indications of water saturation to include both perched and groundwater table levels; include descriptions of soils that are mottled or gleyed. Be aware that ground water levels in karst can change dramatically in short periods of time and will not necessarily leave mottled or gleyed evidence.

- Record water levels in all borings over a time-period reflective of anticipated water level fluctuation, noting that water levels in karst geology can vary dramatically and rapidly. Borings should remain fully open to a total depth reflective of these variations and over a time that will accurately show the variation. Be advised that to get a complete picture, this could be a long-term period. Measurements could of course be collected during a period of operation of a BMP, which could be adjusted based on the findings of the data collection.

- Estimate soil engineering characteristics, including “N” or estimated unconfined compressive strength, when conducting a standard penetration test (SPT).

Evaluation of findings

At least 1 figure showing the subsurface soil profile cross section through the proposed practice should be provided, showing confining layers, depth to bedrock, and water table (if encountered). It should extend through a central portion of the proposed practice, using the actual or projected boring data. A sketch map or formal construction plan indicating the location and dimension of the proposed practice and line of cross section should be included for reference, or as a base map for presentation of subsurface data.

Geophysical and dye techniques

Stormwater managers in need of subsurface geophysical surveys are encouraged to obtain the services of a qualified geophysicist experienced in karst geology. Some of the geophysical techniques available for use in karst terrain include: seismic refraction, ground-penetrating radar, and electric resistivity. The surest way to determine the flow path of water in karst geology is to inject dye into the karst feature (sinkhole or fracture) and watch to see where it emerges, usually from a spring. The emergence of a known dye from a spring grants certainty to a suspicion that ground water moves in a particular pattern. Dye tracing can vary substantially in cost depending upon the local karst complexity, but it can be a reasonably priced alternative, especially when the certainty is needed.

For good basic information on use of dye techniques in karst settings, see the United States EPA document, Application of Dye-tracing techniques for Determining Solute-transport Characteristics of Ground Water in Karst Terranes (1988).

General stormwater management guidelines for karst areas

In karst settings there are special considerations and potentially additional constraints needed prior to implementing most structural BMPs. A growing emphasis is being placed on the implementation of strategies that preserve the pre-development hydrology and maintain critical vegetated areas. This is based on the idea that, in a pre-development setting, the runoff was spread across the landscape rather than directed to a certain area, which often results when there is a high concentration of pervious surfaces. When stormwater is concentrated in one area, it can lead to a more rapid dissolution of the underlying rock.

The uncertainty related to the actual presence of karst, the presence of unstable materials that have the potential for development of karst, and the water movement through karst terrain dictates the level of additional field information to be collected before proceeding with BMP design and construction in Active Karst and Transitional Karst classifications. The following guidelines are based on adaptations from a handful of communities (e.g., Carroll County, MD (2004a and b); St. Johns River Water Management District, FL (2010); Jefferson County, WV (Laughland 2003); Tennessee Permanent Stormwater Management and Design Guidance Manual – Appendix B (2014); and other documents (Chesapeake Stormwater Network, Karst Working Group, 2009; West Virginia Stormwater Management & Design Guidance Manual).

The following guidelines do not contain substantial prescriptive information because of the variability inherent to karst geology in Minnesota.

- Conduct a thorough geotechnical investigation in areas with suspected or documented active karst. Karst geology can change rapidly over very short distances so additional soil borings may be required in comparison to geotechnical investigations for shallow groundwater or bedrock.

- Investigate non-infiltration BMPs on sites where infiltration is not allowed under requirements of the CGP (i.e. where the BMP would be “within 1,000 feet up-gradient or 100 feet down-gradient of active karst features”).

- Preserve the maximum length of natural swales as possible at the site to increase the infiltration and accommodate flows from extreme storms.

- Minimize the area of impervious surfaces at the site. This will reduce the volume and velocity of the stormwater runoff. Consult with a geotechnical engineer prior to the design and construction of a BMP.

- Capture the runoff in a series of small runoff reduction practices where sheet flow is present. This technique will help keep the stormwater runoff from becoming channelized and will disperse the flow over a broad area. Practices such as swales, bioretention with underdrains, media filters, and vegetated filters should be considered first at a site. However, not all sites lend themselves to this type of management approach. Adequate precautions should be taken to assure that runoff water is adequately pretreated.

- Design BMPs to be off-line such that volumes of runoff greater than the capacity of the BMP are bypassed around the BMP. This approach will limit the volume through the BMP to a quantity that is manageable in the karst.

- Install multiple small BMPs instead of a centralized BMP. Centralized BMPs are defined as any practice that treats runoff from a contributing drainage area greater than 20,000 square feet, and/or has a surface ponding depth greater than 3 feet. Centralized practices have the greatest potential for karst- related failure, and will require costly geotechnical investigations and a more complex design.

- Direct discharge from stormwater BMPs to surface waters and not to the nearest sinkhole. Because karst areas can be quite large in Minnesota, discharges should be routed to a baseflow stream via a pipe or lined ditch or channel to redirect the flow away from the karst, provided the stream does not disappear into a karst feature.

- Design ponds and wetlands with a properly engineered synthetic liner. It is HIGHLY RECOMMENDED that a professional geotechnical engineer investigate and recommend the depth of unconsolidated material between the bottom of the pond and the surface of the bedrock. A minimum of 3 feet of unconsolidated soil material is the minimum separation; however an expert may recommend 10 feet or greater. Pond and wetland depths should be fairly uniform and limited to no more than 10 feet in depth.

- Minimize site disturbance during BMP construction. Seek the recommendations of a geotechnical engineer for management of heavy equipment, temporary storage of materials, changes to the soil profile - including cuts, fills, excavation and drainage alteration - on sites that have been found to contain a karst feature.

- Report sinkholes as soon as possible after the first observation of sinkhole development. The sinkhole(s) should then be repaired or the stormwater management facility abandoned, adapted, managed and/or observed for future changes, whichever of these is most appropriate.

- Develop a contingency plan for how to manage the stormwater should a BMP fail as a result of the development of a karst feature.

- If a karst feature is encountered report to the appropriate state agency, such as the Department of Natural Resources (DNR), Minnesota Geological Survey (MGS), and local agencies (such as the city, township or county). These known occurrences should be surveyed for specific location and permanently recorded on the property deed. For transition karst areas, local discretion and the likelihood of karstic features should be used to determine the amount of geotechnical investigation. An easement or reserve area should be identified on the development plats for the project so that all future landowners know of the presence of active karst on their property.

- Incorporate additional precautions where infiltration practices are used. For example, infiltration of stormwater from stormwater hoptspots is discouraged unless pollutant concentrations can be significantly reduced through pretreatment practices.

Stormwater BMP selection in karst settings. Sources Karst Working Group, 2009; Minnesota Stormwater Wiki; Tennessee Permanent Stormwater Management and Design Guidance.

Link to this table

| BMP | Suitability in karst regions | Karst considerations | Construction stormwater permit restriction1 |

|---|---|---|---|

| Impervious area disconnect | Preferred |

|

No |

| Bioretention with underdrain (biofiltration) | Preferred |

|

No |

| Rain tank/cistern | Preferred |

|

No |

| Rooftop disconnect | Preferred |

|

No |

| Green roofs | Preferred |

|

No |

| Dry swale or grassed channel | Preferred |

Warning: If the CSW permit applies, Section 16.20 prohibits permittees from constructing infiltration systems in areas within 1,000 feet upgradient or 100 feet downgradient of active karst

|

Yes if designed for infiltration |

| Media filter | Preferred |

|

No |

| Vegetative filter | Preferred |

|

No |

| Soil compost amendment | Adequate | No | |

| Small scale infiltration/micro-bioinfiltration | Adequate |

Warning: If the CSW permit applies, Section 16.20 prohibits permittees from constructing infiltration systems in areas within 1,000 feet upgradient or 100 feet downgradient of active karst

|

Yes |

| Permeable pavement | Adequate | Warning: If the CSW permit applies, Section 16.20 prohibits permittees from constructing infiltration systems in areas within 1,000 feet upgradient or 100 feet downgradient of active karst |

Yes if designed for infiltration (no underdrain) |

| Infiltration trench or basin | Adequate |

Warning: If the CSW permit applies, Section 16.20 prohibits permittees from constructing infiltration systems in areas within 1,000 feet upgradient or 100 feet downgradient of active karst

|

Yes |

| Constructed wetlands | Adequate |

Warning: If the CSW permit applies, liners are required in areas of active karst

|

No |

| Dry extended detention (ED) ponds and wet ponds | Adequate |

Warning: If the CSW permit applies, liners are required in areas of active karst |

No |

| Wet swale | Discouraged | Not feasible | No |

| Large scale infiltration | Discouraged |

Warning: If the CSW permit applies, Section 16.20 prohibits permittees from constructing infiltration systems in areas within 1,000 feet upgradient or 100 feet downgradient of active karst

|

Yes |

1Section 16.20 of the CSW Permit prohibits prohibits permittees from constructing infiltration systems in areas within 1,000 feet upgradient or 100 feet downgradient of active karst features.

How to remediate after a sinkhole appears

There are several approaches to sinkhole remediation if such an approach is desirable. Sinkhole sealing involves investigation, stabilization, filling, and final grading. In the investigation phase, the areal extent and depth of the sinkhole(s) should be determined. The investigation may consist of excavation to bedrock, soil borings, and/or geophysical studies. Sealing small-sized sinkholes is normally achieved by digging out the sinkhole to bedrock, plugging the hole with concrete, installing several impermeable soil layers interspersed with plastic or geotextile, and crowning with an impermeable layer and topsoil. For moderate sinkholes, an engineered subsurface structure is usually required.

It is often not feasible to seal large sinkholes so other remediation options must be pursued. These could include construction of a low-head berm around the sinkhole, clean-out of the sinkhole to make sure all potentially contaminating materials are removed, landscaping and conversion of land use in the sinkhole to open space or recreation, provided it can be done in a manner that provides adequate safety. In any of these cases, pre-treatment of any stormwater entering the sinkhole is imperative. Final grading of sinkholes in open space settings should include the placement of low permeability topsoil or clay and a vegetative cover, with a positive grade maintained away from the sinkhole location to avoid ponding or infiltration, if feasible.

Additional information on sinkhole remediation can be found at:

- Problems Associated with the Use of Compaction Grout for Sinkhole Remediation in West-Central Florida (Zisman, 2013). This paper presents information regarding the improper application of compaction grouting in sinkholes.

- The Characterization and Remediation of Sinkholes (Denton, N.D. – PowerPoint Presentation). The PowerPoint presentation presents an overview of karst geology and some common remediation techniques.

- Development Mechanism and Remediation of Multiple Spontaneous Sinkholes: A Case Study (Jammal et al., 2010). This journal article provides information on how to remediate when multiple sinkholes are present.

- Sinkholes and Seepage: Embankment Repair at Hat Creek 1 (Bowers et al., 2013). This article discusses geotechnical investigation and engineering solution regarding a sinkhole that was discovered near a Pacific Gas and Electric Company hydroelectric project.

- Tennessee Permanent Stormwater Management and Design Guidance Manual – Appendix B (2014). This section of Appendix B provides a brief overview of sinkhole notification, investigation, stabilization, and final grading.

Monitoring of BMPs in karst regions

A water quality monitoring system installed, operated, and maintained by the owner/operator is RECOMMENDED, particularly where drinking water supplies are derived from ground water or associated with known sources of contamination. The location of monitoring wells or BMP performance monitoring will depend upon the nature of the BMP and surrounding karst characteristics. This could mean the installation of a monitoring system designed to reflect variable water behavior typical of karst water flow in addition to the monitoring of the performance of the BMP. Monitoring of groundwater and stormwater runoff behavior requires a thorough understanding of the local geology as the hydrology of karst terrains is vastly different from that of non-karst terrains (EPA, 1989).

Below is a list of resources that provide additional information on runoff and/or groundwater monitoring in karst areas.

- Ground-Water Monitoring in Karst Terranes: Recommended Protocols & Implicit Assumptions (EPA, 1989). This report provides information on the monitoring procedures and common monitoring pitfalls in karst areas. It describes where to monitor for pollutants, where to monitor for background water quality, when to monitor the groundwater, and how to do all this reliably and economically.

- Highway Stormwater Runoff in Karst Areas – Preliminary Results of Baseline Monitoring and Design of a Treatment System for a Sinkhole in Knoxville Texas (Stephenson et al., 1999). The authors of this report discuss the use of quantitative dye tracing and hydrograph analyses to monitor stormwater runoff and resulting groundwater flow from runoff from a highway system.

- Evaluating the Effectiveness of Regulatory Stormwater Monitoring Protocols on Groundwater Quality in Urbanized Karst Regions (Nedvidek, 2014). This report looks at monitoring techniques and frequencies. It also discusses how to make these monitoring programs cost effective, while still providing a sufficient amount of information.

BMP failure

In case of BMP failure in karst areas,

- if waters of the state are or may be impacted, contact the state duty officer (651-649-5451 or 800-422-0798; or 651-297-5353 TDD Line/800-627-3529 TDD Watts Line);

- contact appropriate local authorities; and/or

- repair the practice following guidance above.

Related pages

- Overview of stormwater infiltration

- Pre-treatment considerations for stormwater infiltration

- BMPs for stormwater infiltration

- Pollutant fate and transport in stormwater infiltration systems

- Surface water and groundwater quality impacts from stormwater infiltration

- Stormwater infiltration and groundwater mounding

- Stormwater infiltration and setback (separation) distances

- Karst

- Shallow soils and shallow depth to bedrock

- Shallow groundwater

- Soils with low infiltration capacity

- Potential stormwater hotspots

- Stormwater and wellhead protection

- Stormwater infiltrations and contaminated soils and groundwater

- Decision tools for stormwater infiltration

- Stormwater infiltration research needs

- References for stormwater infiltration

Shallow soils and shallow depth to bedrock

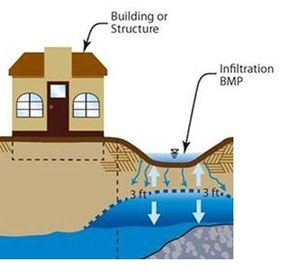

Sites with shallow bedrock are defined as having bedrock within 6 feet or less of the ground surface. Shallow bedrock is found in many portions of the state, but is a particular problem in the northeastern region. When installing an infiltration Best Management Practice (BMP), there must be at least 3 feet of separation between the base of the BMP and the bedrock per the Minnesota Construction General Permit (CGP). Bedrock at the 6 foot depth is a trigger to perform a geotechnical investigation to determine the location of the bedrock in the area in and around the proposed BMP to ensure the 3 foot separation can be achieved.

Why is shallow depth to bedrock a concern?

Shallow bedrock limits the depth of BMPs, reduces the potential for subsurface infiltration, and reduces the depth over which treatment can occur. These sites present challenges to stormwater management; however these challenges can be managed. General guidelines for investigation and management are presented below. Special caution for steep slopes and fractured bedrock is urged.

How to investigate for shallow bedrock

It is important to understand the general depth to bedrock over the entire site, but more specifically it is important to know the depth to bedrock in and around the area of the proposed BMP. Geotechnical investigations are recommended for all proposed stormwater facilities located in regions with shallow bedrock. The purpose of the investigation is to identify subsurface conditions which can pose an environmental concern or a construction hazard to a proposed stormwater management practice. Guidelines for investigating all potential physical constraints to infiltration on a site are presented in a table at this link. These guidelines should not be interpreted as all-inclusive. The size and complexity of the project will drive the extent of any subsurface investigation.

Subsurface material investigation

The investigation is designed to determine the nature and thickness of subsurface materials, including depth to bedrock and to the water table. Subsurface data for depth to groundwater may be acquired by soil boring or backhoe investigation. These field data should be supplemented by geophysical investigation techniques deemed appropriate by a qualified professional, which will show the location of the geologic and groundwater formations under the surface. The data listed below should be acquired under the direct supervision of a qualified geologist, geotechnical engineer, or soil scientist who is experienced in conducting such studies. Pertinent site information should include the following:

- Known groundwater depth or bedrock characteristics (type, geologic contacts, faults, geologic structure, rock surface configuration)

- Soil characteristics (type, thickness, mapped unit)

- Bedrock outcrop areas

Location of soil borings

Borings should be located in order to provide representative area coverage of the proposed BMP facilities. The location of borings should be

- within each distinct major soil type present, as mapped in soil surveys;

- next to bedrock outcrop areas and/or in areas with known shallow groundwater if present;

- near the edges and center of the proposed practice and spaced at equal distances from one another; and

- near any areas identified as anomalies from any existing geophysical studies.

Number of soil borings

The number of recommended borings is described below.

- Infiltration trenches, bioretention, and filters - a minimum of 2 per practice. Note that more borings are recommended for infiltration BMPs greater than 5000 square feet in area. See here for recommendations on number of borings for infiltration BMPs as a function of BMP size.

- Ponds/wetlands - a minimum of 3 per practice, or 3 per acre, whichever is greater.

- Additional borings – as needed to define lateral extent of limiting horizons, or site specific conditions, where applicable.

Depth of soil borings

Borings should be extended to a minimum depth of 5 feet below the lowest proposed grade within the practice unless auger/backhoe refusal is encountered.

Identification of material

All material penetrated by the boring should be identified, as follows.

- Provide descriptions, logging, and sampling for the entire depth of the boring.

- Note any stains, odors, or other indications of environmental degradation.

- Perform a laboratory analysis of a minimum of 2 soil samples, representative of the material penetrated including potential limiting horizons, with the results compared to the field descriptions.

- Identify soil characteristics including, at a minimum: color; mineral composition; grain size, shape, and sorting; and saturation.

- Log any indications of water saturation to include both perched and ground water table levels, and descriptions of soils that are mottled or gleyed (sticky clay soils typically found in waterlogged soils).

- Measure water levels in all borings at the time of completion and again 24 hours after completion. The boring should remain fully open to total depth of these measurements.

- Estimate soil engineering characteristics, including “N” or estimated unconfined compressive strength, when conducting a standard penetration test (SPT).

Evaluation of findings

At least one (1) figure showing the subsurface soil profile cross section through the proposed practice should be provided, showing confining layers, depth to bedrock, and water table (if encountered). It should extend through a central portion of the proposed practice, using the actual or projected boring data. A sketch map or formal construction plan indicating the location and dimension of the proposed practice and line of cross section should be included for reference, or as a base map for presentation of subsurface data.

References for conducting geotechnical investigations

The following references provide useful information for conducting geotechnical investigations. Note that some of these documents were written for investigations at contaminated sites.

- CHECKLIST AND GUIDELINES FOR REVIEW OF GEOTECHNICAL REPORTS AND PRELIMINARY PLANS AND SPECIFICATIONS

- Geotechnical Investigations

- GUIDELINES FOR PLANNING AND IMPLEMENTING GROUNDWATER CHARACTERIZATION OF CONTAMINATED SITES

- How to Read and Understand a Geotechnical Report

What are general stormwater management guidelines for areas with shallow bedrock?

The following investigations and guidelines are HIGHLY RECOMMENDED for infiltration and other BMPs proposed to be located in areas with shallow depth to bedrock.

- Conduct thorough geotechnical investigations in areas with suspected or documented shallow bedrock. Perform site geotechnical analysis similar to karst.

- Consider a non-infiltration BMP or moving the BMP to a location on site with sufficient depth to bedrock if the required 3-foot separation cannot be achieved. It may be possible to move the infiltration BMP to another location in order to achieve this separation.

- Consider shallow ponding depths up to 12 inches for filters, swales, and bioretention.

- Conclude that infiltration of stormwater runoff from stormwater hotspots is not feasible due to potential for connections with bedrock fracture zones.

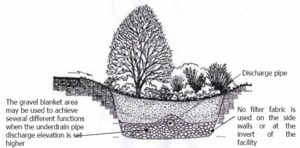

- Consider stormwater wetlands which have shallower ponding depths than stormwater ponds. The disadvantage is that the shallow depths result in basins with large footprints which may not be feasible on small sites.

The following table provides an overview of shallow bedrock and soil related design considerations for different structural practice groups. Guidelines for investigating all potential physical constraints to infiltration on a site are presented in the table at the bottom of this page.

Recommendations for structural BMP use in settings with shallow soils and shallow depth to bedrock.

Link to this table

| BMP | Shallow soil and shallow depth to bedrock considerations |

|---|---|

| Bioretention | Should be constructed with an underdrain or liner if minimum separation distance of three (3) feet is not present between practice bottom and bedrock.1 |

| Media filter |

|

| Vegetative filter |

|

| Infiltration trench or basin |

|

| Stormwater ponds |

|

| Constructed wetlands |

|

1A liner is required under the Construction Stormwater General Permit.

Related pages

- Overview of stormwater infiltration

- Pre-treatment considerations for stormwater infiltration

- BMPs for stormwater infiltration

- Pollutant fate and transport in stormwater infiltration systems

- Surface water and groundwater quality impacts from stormwater infiltration

- Stormwater infiltration and groundwater mounding

- Stormwater infiltration and setback (separation) distances

- Karst

- Shallow soils and shallow depth to bedrock

- Shallow groundwater

- Soils with low infiltration capacity

- Potential stormwater hotspots

- Stormwater and wellhead protection

- Stormwater infiltrations and contaminated soils and groundwater

- Decision tools for stormwater infiltration

- Stormwater infiltration research needs

- References for stormwater infiltration

Shallow groundwater

Shallow groundwater is a condition where the seasonal high groundwater table, or saturated soil, is less than 3 feet from the land surface. There is a large portion of the state (more than 50 percent) where the seasonal high water table is located less than 3 feet from the surface. In these areas it may be impossible to get the 3 feet of separation from the bottom of an infiltration practice to the seasonal high water table REQUIRED under the Construction General Permit (CGP). Non-infiltration BMPs, such as lined filtration or settling practices, should be considered in areas with shallow groundwater.

Why is shallow groundwater a concern?

Removal of some pollutants (e.g., bacteria) can occur in the vadose zone beneath the base of the BMP. Pollutant removal in the vadose zone is attained via biological activity, chemical degradation, adsorption of pollutants to soil, and plant uptake. Shallow groundwater reduces the depth of the unsaturated soil available for treatment, leading to an increased likelihood of groundwater contamination. The vadose zone is further reduced when a groundwater mound forms. These sites present challenges to stormwater management, however these challenges can be managed. General guidelines for investigation and management are presented in the following sections.

How to investigate for shallow groundwater

Investigations are recommended for all proposed stormwater facilities located on sites with a suspected shallow groundwater table. The investigation should be two-fold. First, appropriate screening tools such as soil surveys, geologic atlases, or well records should be used to determine the likelihood that the groundwater table is shallow. If a shallow groundwater table is present, a geotechnical investigation should be conducted.

Geotechnical investigations are recommended for all proposed stormwater facilities located on sites where it is suspected that the 3 foot vertical separation between the base of the BMP and the groundwater table might not be achievable. This is needed to show that requirements of the CGP have been met. The guidelines for how to investigate for shallow groundwater are summarized below. Guidelines for investigating all potential physical constraints to infiltration on a site are presented in a table at this link. These guidelines should not be interpreted as all-inclusive. The size and complexity of the project will drive the extent of any subsurface investigation. Regardless of the results of the initial site screening, soils borings and infiltration tests should be performed to verify site soil conditions.

Subsurface material investigation

The investigation is designed to determine the nature and thickness of subsurface materials, including depth to bedrock and to the water table. Subsurface data for depth to groundwater may be acquired by soil boring or studying existing wells on the site, if present. These field data should be supplemented by geophysical investigation techniques deemed appropriate by a qualified professional, which will show the location of the groundwater formations under the surface. The data listed below should be acquired under the direct supervision of a qualified geologist, geotechnical engineer, or soil scientist who is experienced in conducting such studies. Pertinent site information should include the following:

- Known groundwater depth or bedrock characteristics (type, geologic contacts, faults, geologic structure, rock surface configuration)

- Soil characteristics (type, thickness, mapped unit)

- Bedrock outcrop areas

Location of soil borings

Borings should be located in order to provide representative area coverage of the proposed BMP facilities. The location of borings should be:

- within each distinct major soil type present, as mapped in soil surveys;

- next to bedrock outcrop areas and/or in areas with known shallow groundwater if present;

- near the edges and center of the proposed practice and spaced at equal distances from one another; and

- near any areas identified as anomalies from any existing geophysical studies.

Number of soil borings

The number of recommended borings is described below.

- Infiltration trenches, bioretention, and filters - a minimum of 2 per practice. Note that more borings are recommended for infiltration BMPs greater than 5000 square feet in area. See here for recommendations on number of borings for infiltration BMPs as a function of BMP size.

- Ponds/wetlands - a minimum of 3 per practice, or 3 per acre, whichever is greater.

- Additional borings – as needed to define lateral extent of limiting horizons, or site specific conditions, where applicable.

Depth of soil borings

Borings should be extended to a minimum depth of 5 feet below the lowest proposed grade within the practice unless auger/backhoe refusal is encountered.

Identification of material

All material penetrated by the boring should be identified, as follows.

- Provide descriptions, logging, and sampling for the entire depth of the boring.

- Note any stains, odors, or other indications of environmental degradation.

- Perform a laboratory analysis of a minimum of 2 soil samples, representative of the material penetrated including potential limiting horizons, with the results compared to the field descriptions.

- Identify soil characteristics including, at a minimum: color; mineral composition; grain size, shape, and sorting; and saturation.

- Log any indications of water saturation to include both perched and ground water table levels, and descriptions of soils that are mottled or gleyed (sticky clay soils typically found in waterlogged soils).

- Measure water levels in all borings at the time of completion and again 24 hours after completion. The boring should remain fully open to total depth of these measurements.

- Estimate soil engineering characteristics, including “N” or estimated unconfined compressive strength, when conducting a standard penetration test (SPT).

Evaluation of findings

At least one (1) figure showing the subsurface soil profile cross section through the proposed practice should be provided, showing confining layers, depth to bedrock, and water table (if encountered). It should extend through a central portion of the proposed practice, using the actual or projected boring data. A sketch map or formal construction plan indicating the location and dimension of the proposed practice and line of cross section should be included for reference, or as a base map for presentation of subsurface data.

References for conducting geotechnical investigations

The following references provide useful information for conducting geotechnical investigations. Note that some of these documents were written for investigations at contaminated sites.

- CHECKLIST AND GUIDELINES FOR REVIEW OF GEOTECHNICAL REPORTS AND PRELIMINARY PLANS AND SPECIFICATIONS

- Geotechnical Investigations

- GUIDELINES FOR PLANNING AND IMPLEMENTING GROUNDWATER CHARACTERIZATION OF CONTAMINATED SITES

- How to Read and Understand a Geotechnical Report

What are general stormwater management guidelines for areas with shallow groundwater?

The following investigations and design variants are HIGHLY RECOMMENDED for infiltration BMPs proposed to be located in areas of shallow groundwater:

- Conduct thorough geotechnical investigations with geotechnical analyses similar to those recommended for karst regions.

- Conclude the site to be infeasible for infiltration BMPs where a minimum 3 foot separation between the bottom of the BMP and groundwater cannot be achieved. The CGP prohibits infiltration BMPs when the separation distance is less than 3 feet.

- Consider stormwater wetlands which require a shallower ponding depth than stormwater ponds. The disadvantage of stormwater wetlands is that the shallow depth of the wetlands often creates footprints that are larger than ponds.

- Consider a stormwater pond that will intercept the groundwater table. This approach requires close examination of the land uses to assess the potential for stormwater hotspot or other highly concentrated runoff sources that would contribute excess pollutants to the groundwater. If the area is a potential stormwater hotspot and there is less than 3 feet of separation from the seaonally high water table, or if the area is a confirmed stormwater hotspot, a Level 1 liner is recommended to protect against groundwater contamination.

MPCA is often asked why it allows a sedimentation pond (no liner) to be constructed that may intercept the water table, but require a minimum of 3 feet of separation from the bottom of any constructed infiltration practice and the water table. The treatment processes for these two practices are very different and may help to explain the requirements. A stormwater pond achieves pollutant removal through the process of settling of suspended solids. If the basin is large enough, contains vegetation, and has a long detention time, additional treatment through biological uptake and microbial action can also occur. An infiltration practice removes pollutants through filtering that occurs in the minimum 3 foot unsaturated soil layer beneath the practice along with the biologic and microbial activity that takes place in the layer under aerobic conditions.

Related pages

- Overview of stormwater infiltration

- Pre-treatment considerations for stormwater infiltration

- BMPs for stormwater infiltration

- Pollutant fate and transport in stormwater infiltration systems

- Surface water and groundwater quality impacts from stormwater infiltration

- Stormwater infiltration and groundwater mounding

- Stormwater infiltration and setback (separation) distances

- Karst

- Shallow soils and shallow depth to bedrock

- Shallow groundwater

- Soils with low infiltration capacity

- Potential stormwater hotspots

- Stormwater and wellhead protection

- Stormwater infiltration and contaminated soils and groundwater

- Decision tools for stormwater infiltration

- Stormwater infiltration research needs

- References for stormwater infiltration

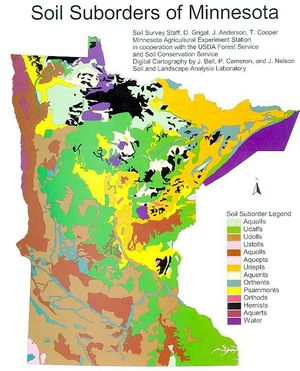

Soils with low infiltration capacity

Soils with low infiltration capacity (tight soils) are defined as soils with steady-state infiltration rates equal to or less than 0.06 inches per hour. County soil surveys are useful for initial screening to identify soils that may have low infiltration rates. Most county soil surveys are available digitally from the NRCS (National Resources Conservation Service). These surveys are not accurate enough to determine site-specific characteristics suitable for infiltration systems but are useful for initial screening. If there is a potential for slowly infiltrating soils to exist on a site, a detailed site analysis should be performed for all proposed infiltration BMPs (Susilo, 2009). Additional information on soils can be found here.

Stormwater management limitations in areas with tight soils generally preclude large-scale infiltration and ground water recharge (infiltration that passes into the ground water system). These soils will typically be categorized under Hydrologic Soil Group (HSG) D. The table below provides a general summary of infiltration rates for different soils. These are conservative estimates of long-term, sustainable infiltration rates that have been documented in Minnesota. They are based on in-situ measurement within existing infiltration practices in Minnesota, rather than national numbers or rates based on laboratory columns.

The Construction General Permit (CGP) prohibits infiltration when an infiltration system will be constructed in areas of predominately Hydrologic Soil Group D (clay) soils.

Design infiltration rates, in inches per hour, for A, B, C, and D soil groups. Corresponding USDA soil classification and Unified soil Classifications are included. Note that A and B soils have two infiltration rates that are a function of soil texture.*

The values shown in this table are for uncompacted soils. This table can be used as a guide to determine if a soil is compacted. For information on alleviating compacted soils, link here. If a soil is compacted, reduce the soil infiltration rate by one level (e.g. for a compacted B(SM) use the infiltration rate for a B(MH) soil).

Link to this table

| Hydrologic soil group | Infiltration rate (inches/hour) | Infiltration rate (centimeters/hour) | Soil textures | Corresponding Unified Soil ClassificationSuperscript text |

|---|---|---|---|---|

| Although a value of 1.63 inches per hour (4.14 centimeters per hour) may be used, it is Highly recommended that you conduct field infiltration tests or amend soils.b See Guidance for amending soils with rapid or high infiltration rates and Determining soil infiltration rates. |

gravel |

GW - Well-graded gravels, fine to coarse gravel GP - Poorly graded gravel |

||

| 1.63a | 4.14 |

silty gravels |

GM - Silty gravel |

|

| 0.8 | 2.03 |

sand |

SP - Poorly graded sand |

|

| 0.45 | 1.14 | silty sands | SM - Silty sand | |

| 0.3 | 0.76 | loam, silt loam | MH - Elastic silt | |

| 0.2 | 0.51 | Sandy clay loam, silts | ML - Silt | |

| 0.06 | 0.15 |

clay loam |

GC - Clayey gravel |

|

1For Unified Soil Classification, we show the basic text for each soil type. For more detailed descriptions, see the following links: The Unified Soil Classification System, CALIFORNIA DEPARTMENT OF TRANSPORTATION (CALTRANS) UNIFIED SOIL CLASSIFICATION SYSTEM

- NOTE that this table has been updated from Version 2.X of the Minnesota Stormwater Manual. The higher infiltration rate for B soils was decreased from 0.6 inches per hour to 0.45 inches per hour and a value of 0.06 is used for D soils (instead of < 0.2 in/hr).

Source: Thirty guidance manuals and many other stormwater references were reviewed to compile recommended infiltration rates. All of these sources use the following studies as the basis for their recommended infiltration rates: (1) Rawls, Brakensiek and Saxton (1982); (2) Rawls, Gimenez and Grossman (1998); (3) Bouwer and Rice (1984); and (4) Urban Hydrology for Small Watersheds (NRCS). SWWD, 2005, provides field documented data that supports the proposed infiltration rates. (view reference list)

aThis rate is consistent with the infiltration rate provided for the lower end of the Hydrologic Soil Group A soils in the Stormwater post-construction technical standards, Wisconsin Department of Natural Resources Conservation Practice Standards.

bThe infiltration rates in this table are recommended values for sizing stormwater practices based on information collected from soil borings or pits. A group of technical experts developed the table for the original Minnesota Stormwater Manual in 2005. Additional technical review resulted in an update to the table in 2011. Over the past 5 to 7 years, several government agencies revised or developed guidance for designing infiltration practices. Several states now require or strongly recommend field infiltration tests. Examples include North Carolina, New York, Georgia, and the City of Philadelphia. The states of Washington and Maine strongly recommend field testing for infiltration rates, but both states allow grain size analyses in the determination of infiltration rates. The Minnesota Stormwater Manual strongly recommends field testing for infiltration rate, but allows information from soil borings or pits to be used in determining infiltration rate. A literature review suggests the values in the design infiltration rate table are not appropriate for soils with very high infiltration rates. This includes gravels, sandy gravels, and uniformly graded sands. Infiltration rates for these geologic materials are higher than indicated in the table.

References: Clapp, R. B., and George M. Hornberger. 1978. Empirical equations for some soil hydraulic properties. Water Resources Research. 14:4:601–604; Moynihan, K., and Vasconcelos, J. 2014. SWMM Modeling of a Rural Watershed in the Lower Coastal Plains of the United States. Journal of Water Management Modeling. C372; Rawls, W.J., D. Gimenez, and R. Grossman. 1998. Use of soil texture, bulk density and slope of the water retention curve to predict saturated hydraulic conductivity Transactions of the ASAE. VOL. 41(4): 983-988; Saxton, K.E., and W. J. Rawls. 2005. Soil Water Characteristic Estimates by Texture and Organic Matter for Hydrologic Solutions. Soil Science Society of America Journal. 70:5:1569-1578.

Why are soils with a low infiltration capacity a concern?

Sites with low infiltration capacity soils may limit the type, location, number and/or sizing of infiltration BMPs that can be used for stormwater management. Low infiltration rates result in extended surface ponding of water, which may damage vegetation, lead to mosquito breeding, damage soil structure, and reduce pollutant treatment by the BMP. Certain watershed organizations in Minnesota do not allow the use, or strongly discourage the use, of infiltration BMPs where soil infiltration capacity is low. This does not mean, however, that these soils do not have any infiltration and recharge capabilities. It may be possible for sites to partially or fully meet infiltration objectives as long as appropriate design modifications have been incorporated, such as amending the soil with compost or sand, or incorporating an underdrain into the practice.

The following table provides an overview of design considerations for several groups of structural practices.

This table shows structural BMP use in soil with low infiltration capacity

Link to this table

| BMP | Low infiltration capacity soil considerations |

|---|---|

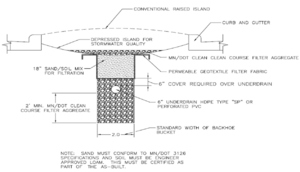

| Bioretention, dry swale, permeable pavement, tree trench/box | Should be constructed with an underdrain. Recharge criteria, if applicable, can be met by modifying the design to include an infiltration gallery below the underdrain, so long as it is appropriately sized. |

| Media filter | Recommended practice in tight soils. Some design variants can be modified to incorporate an infiltration gallery that can help meet recharge criteria, if properly sized. |

| Infiltration trench or basin |

|

| Stormwater ponds | Acceptable practice with tight soils. Soils should help maintain permanent pool. |

| Constructed wetlands |

|

How to investigate soils with low infiltration capacity

Soil tests to determine infiltration capacity of soil should be performed at all proposed stormwater facilities that plan to have a recharge or infiltration component to their design. The purpose of the testing is to identify and confirm the soil characteristics and determine suitability, if any, for infiltration BMPs. Guidelines for investigating all potential physical constraints to infiltration on a site are presented in a table at this link. These guidelines should not be interpreted as all-inclusive. The size and complexity of the project will drive the extent of any subsurface investigation.

Subsurface material investigation

Soil testing is recommended for all proposed stormwater facilities that plan to have a recharge or infiltration component to their design. Testing can be less rigorous than that for karst areas or sites with shallow bedrock and groundwater. The investigation is designed to identify and confirm the soil characteristics and determine their suitability, if any, for infiltration practices.

Location of soil borings

Borings should be located in order to provide representative area coverage of the proposed BMP facilities. The location of borings should be:

- within each distinct major soil type present, as mapped in soil surveys;

- near the edges and center of the proposed practice and spaced at equal distances from one another; and

- near any areas identified as anomalies from any existing geophysical studies.

Number of soil borings

The number of recommended borings is described below.

- Infiltration trenches, bioretention, and filters - a minimum of 2 per practice. Note that more borings are recommended for infiltration BMPs greater than 5000 square feet in area. See here for recommendations on number of borings for infiltration BMPs as a function of BMP size.

- Ponds/wetlands - a minimum of 3 per practice, or 3 per acre, whichever is greater.

- Additional borings – as needed to define lateral extent of limiting horizons, or site specific conditions, where applicable.

Depth of soil borings

Borings should be extended to a minimum depth of 5 feet below the lowest proposed grade within the practice unless auger/backhoe refusal is encountered.

Identification of material

All material penetrated by the boring should be identified, as follows:

- Provide descriptions, logging, and sampling for the entire depth of the boring.

- Note any stains, odors, or other indications of environmental degradation.

- Perform a laboratory analysis of a minimum of 2 soil samples, representative of the material penetrated including potential limiting horizons, with the results compared to the field descriptions.

- Identify soil characteristic including, at a minimum: color; mineral composition; grain size, shape, and sorting; and saturation.

- Log any indications of water saturation to include both perched and ground water table levels, and descriptions of soils that are mottled or gleyed (sticky clay soils typically found in waterlogged soils).

- Measure water levels in all borings at the time of completion and again 24 hours after completion. The boring should remain fully open to total depth of these measurements.

References for conducting geotechnical investigations

The following references provide useful information for conducting geotechnical investigations. Note that some of these documents were written for investigations at contaminated sites.

- CHECKLIST AND GUIDELINES FOR REVIEW OF GEOTECHNICAL REPORTS AND PRELIMINARY PLANS AND SPECIFICATIONS

- Geotechnical Investigations

- GUIDELINES FOR PLANNING AND IMPLEMENTING GROUNDWATER CHARACTERIZATION OF CONTAMINATED SITES

- How to Read and Understand a Geotechnical Report

Infiltration rate testing

Soil permeability should be determined in the field using the procedures described here.

What are general stormwater management guidelines for sites with low infiltration capacity soils?

- Local soil surveys should be used for preliminary determination of infiltration capacity of the soils on site; if the soil survey suggests soils with very low infiltration capacities, then alternative BMPs such as filters, wet sedimentation basins, etc. should be considered. If the survey suggests the potential for infiltration, the on-site soil testing should be done to accurately characterize site soils. The testing should be conducted in the most restrictive layer of soil that is found within 5-feet below the bottom of the proposed BMP.

- Soil compost amendments should be considered for lawns and other pervious surfaces to increase pervious area storage and/or decrease pervious surface runoff. Designers should also consider disconnection of impervious surfaces, by draining rooftops and other impervious surface runoff to compost amended pervious surfaces before collection and discharge into a structural BMP.

- Where volume reduction is a primary objective for a site (e.g., required by permit, potentially a receiving water-based goal due to channel erosion, nuisance flooding, or inadequate infrastructure capacity), emphasis should be placed on practices that promote runoff reuse and evapotranspiration such as cisterns, rain barrels, green roofs, and biofiltration in order to maximize volume reduction.

- A mounding analysis should be conducted to ensure that any groundwater mound that develops under a BMP will not extend into the BMP. This mounding analysis is especially important for soils with low permeability since such soils cannot efficiently dissipate groundwater through the soil column.

Related pages

- Overview of stormwater infiltration

- Pre-treatment considerations for stormwater infiltration

- BMPs for stormwater infiltration

- Pollutant fate and transport in stormwater infiltration systems

- Surface water and groundwater quality impacts from stormwater infiltration

- Stormwater infiltration and groundwater mounding

- Stormwater infiltration and setback (separation) distances

- Karst

- Shallow soils and shallow depth to bedrock

- Shallow groundwater

- Soils with low infiltration capacity

- Potential stormwater hotspots

- Stormwater and wellhead protection

- Stormwater infiltration and contaminated soils and groundwater

- Decision tools for stormwater infiltration

- References for stormwater infiltration

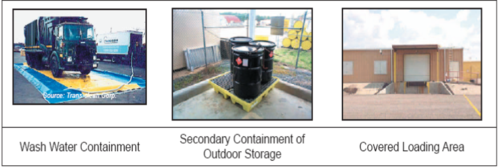

Potential stormwater hotspots

Potential Stormwater Hotspots (PSHs) are activities or practices that have the potential to produce relatively high levels of stormwater pollutants. Designation as a PSH does not imply that a site is a hotspot, but rather that the potential to generate high pollutant runoff loads or concentrations exists. PSHs include locations where there is a potential risk for spills, leaks, or illicit discharges. Stormwater hotspots may also be areas which produce higher concentrations of pollutants than normally found in urban runoff. Because stormwater hotspots are found in a variety of land uses, there is no common pollutant for any type of hotspot. Instead the pollutants tend to be a unique mixture of pollutants (CWP, 2005). Hotspots can be classified as Regulated, subject to state or federal permits, or Unregulated. In Minnesota Regulated hotspots are subject to the NPDES Multi-Sector General Permit for Industrial Activity, and/or local ordinances.

Pollutant generating operations and activities

The potential for hotspots is related to the activities on the site more than the land use or category of operation. The table below summarizes the most common pollutants generated at stormwater hotspots based on common operations at a site. These operations are discussed in greater detail below.

Pollutants of Concern from Operations (adapted from CWP, 2005).

Link to this table.

| Pollutant of concern | Vehicle operations | Waste management | Site maintenance practices | Outdoor materials | Landscaping |

|---|---|---|---|---|---|

| Nutrients | X | X | X | ||

| Pesticides | X | X | |||

| Solvents | X | X | |||

| Fuels | X | ||||

| Oil and grease | X | X | |||

| Toxic chemicals | X | X | |||

| Sediment | X | X | X | X | |

| Road salt | X | X | |||

| Bacteria | X | X | |||

| Trace metals | X | X | |||

| Hydrocarbons | X | X |

Vehicle operations

Vehicle operations include maintenance, repair, recycling, fueling, washing, and long-term parking. Vehicle operations can be a significant source of trace metals, oil, grease, and hydrocarbons, and are the first operations inspected during a hotspot source investigation. Vehicle maintenance and repair operations often produce waste oil, fluids and other hazardous products, particularly if work areas are connected to the storm drain system. Routing protective rooftop runoff through a fueling area has become a common practice in Minnesota; simple re-routing of runoff away from a potential fuel wash-off location could eliminate this from the hotspot list. Examples of pollutant-generating activities associated with vehicle operations include the following.

- Improper disposal of fluids down shop and storm drains

- Spilled fuel, leaks and drips from wrecked vehicles

- Hosing of outdoor work areas

- Wash water from cleaning

- Uncovered outdoor storage of liquids/oils/batteries/spills

- Pollutant wash-off from parking lots

Outdoor materials

Improper handling or storage of materials outdoors can create stormwater problems. Techniques for properly handling materials outdoors include inventorying the type and hazard level of materials at the site, examining loading and unloading areas to see if materials are exposed to rainfall and/or are connected to the storm drain system, and investigating any materials stored outdoors that could potentially be exposed to rainfall or runoff. Public and private road salt and sand storage areas are of particular concern. Examples of pollutant-generating activities associated with outdoor materials include the following.

- Spills at loading areas

- Hosing/washing of loading areas into shop or storm drains

- Wash-off of uncovered bulk materials and liquids stored outside, of particular concern in MN are road salt storage areas

- Leaks and spills

Waste management

Every business generates waste as part of its daily operations, most of which is temporarily stored at the site pending disposal. The manner in which waste products are stored and disposed of at a site, particularly in relation to the storm drain system, determine the likelihood of becoming a hotspot. In some sites, simple practices such as dumpster management can reduce pollutants, whereas other sites may require more sophisticated spill prevention and response plans. Examples of pollutant-generating activities associated with waste management include the following.

- Spills and leaks of fluids

- Dumping into storm drains

- Leaking dumpsters

- Wash-off of dumpster spillage

- Accumulation of particulate deposits

Physical plant maintenance

Plant maintenance relates to practices used to clean, maintain or repair the physical plant, which includes the building, outdoor work areas and parking lots. Routine cleaning and maintenance practices can cause runoff of sediment, nutrients, paints, and solvents from the site. Sanding, painting, power-washing, and resealing or resurfacing roofs or parking lots are activities that can result in increased pollutant loading or concentrations, especially when performed near storm drains. Examples of pollutant-generating activities associated with plant maintenance include the following.

- Discharges from power washing and steam cleaning

- Wash-off of fine particles from painting/sandblasting operations

- Rinse water and wash water discharges during cleanup

- Temporary outdoor storage

- Runoff from degreasing and re-surfacing

Turf and landscaping

Many commercial, institutional and municipal sites hire contractors to maintain turf and landscaping, apply fertilizers or pesticides, and provide irrigation. Current landscaping practices should be thoroughly evaluated at each site to determine whether they are generating runoff of nutrients, pesticides, organic carbon, or are producing non-target irrigation flows. Examples of pollutant-generating activities associated with turf and landscaping include the following.

- Non-target irrigation

- Runoff of nutrients and pesticides

- Deposition and subsequent washoff of soil and organic matter on impervious surfaces

Determining if a PSH is a hotspot

As stated previously, the designation of PSH does not mean a site is a hotspot, only that activities have the potential to generate higher pollution runoff loads or concentrations compared to the land uses in which they occur. When designing a stormwater management system at these sites, it is important to determine if the PSH is an actual hotspot. If it is a hotspot, additional stormwater management controls may be needed. A recommended process for determining whether a PSH is a hotspot is as follows.

- Step 1: Consider where the activities take place. If all activities using hazardous materials occur inside a building and no materials can be tracked outside, then the site is not a hotspot. The various activities involving hazardous materials should be monitored at regularly scheduled intervals to ensure that nothing changes that would cause the hazardous materials to come in contact with stormwater runoff.

- Step 2: Review the Stormwater Pollution Prevention Plan/Program (SWPPP), if present. Sites subject to NPDES requirements through the Industrial Multi-Sector Permit or the MS4 Municipal General Permit may have created SWPPPs that guide the operations and housekeeping at sites where the potential exists for increased concentrations of certain pollutants in the runoff.

- Step 3: Conduct a site inspection. The Center for Watershed Protection (CWP) has developed inspection forms that can be used to record physical operations and observations at a site to assess whether the site should be designated as a hotspot. For sites with a SWPPP, the inspection should include whether the site is operated in compliance with the requirements in the SWPPP. The CWP form includes an overall assessment of whether to designate the site as a hotspot. To access the CWP information go to this link and find Urban Subwatershed Restoration Manual Series Manual 8: Pollution Source Control Practices to open the document as a pdf. Hotspot prevention profile sheets are found on pages 109-158. A discussion of stormwater hotspots is found on pages 13-24.

- Step 4: Sample collection and analysis. Further analysis may be required to determine if the PSH is a hotspot. Samples of the stormwater runoff at the site should be collected and analyzed for the pollutants of concern. Samples need to be collected from the runoff that is in contact with the waste to ensure that there is accurate site characterization. There is no specific criteria for concluding a location is a stormwater hotspot, although concentrations in runoff may be compared to water quality criteria to make this determination. See surface water quality standards or drinking water standards. Recommendations for design adjustments are included in the following section.

The U.S. EPA developed a hotspot inspection checklist that can be used to score a site to determine the likelihood that it is a stormwater hotspot.

General guidelines for managing stormwater at a PSH