Difference between revisions of "Overview for pretreatment screens"

m |

m (→Related pages) |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 97: | Line 97: | ||

*[[Photo gallery for pretreatment]] | *[[Photo gallery for pretreatment]] | ||

| − | [[Category:Pretreatment]] | + | [[Category:Level 3 - Best management practices/Guidance and information/BMP overview]] |

| + | [[Category:Level 3 - Best management practices/Pretreatment practices/Screening and straining devices]] | ||

</noinclude> | </noinclude> | ||

| − | |||

Latest revision as of 18:38, 13 December 2022

NOTE: It is strongly recommended that pretreatment devices be certified through Washington State's TAPE or New Jersey's NJCAT programs, be modeled using SHSAM, or follow guidance in this manual for vegetated filter strips and forebays.

It is important to tailor a pretreatment practice to the specific site and type of receiving structural stormwater BMP. Many factors influence the choice of pretreatment practices, including but not limited to: (1) contributing area characteristics ( contributing drainage area, connected imperviousness, land uses, soils, slopes, dominant vegetation, source controls in place, and availability of public lands ); (2) existing infrastructure (above and below ground); and (3) type of structural stormwater BMP with infiltration/ filtration BMPs having that have the greatest need for removal of solids prior to treatment areas. The following section describes the specific strengths, weaknesses, and applicability of pretreatment screens.

Contents

Processes

Screens provide a very specific and limited function of collecting large pollutants from stormwater runoff at defined sites along the stormwater flow network. Screens do not provide volume reduction, peak flow reduction, sedimentation, infiltration, filtration, sorption and biological processes.

Applicability and suitability

Pretreatment practices are NOT stand-alone treatment practices and should only be installed in conjunction with a treatment practice immediately downstream. The applicability of screens with regard to the cold climate, retrofits, and highly urban and ultra-urban environments is presented below.

Cold Climate suitability

Screens are not suitable for use in cold climates when snow and ice is able to accumulate on the screen, because screens that become frozen often result in short-circuiting (bypass) or backflows. Ice accumulation also often prevents screens from adequately pretreating high runoff volumes and pollutant loads during major thaw and spring snowmelt events in cold climates. Screens also do not provide snow storage capacity.

Retrofit suitability

Screens are often suitable to retrofit with a variety of structural stormwater BMPs due to their small footprint.

Ultra-Urban suitability

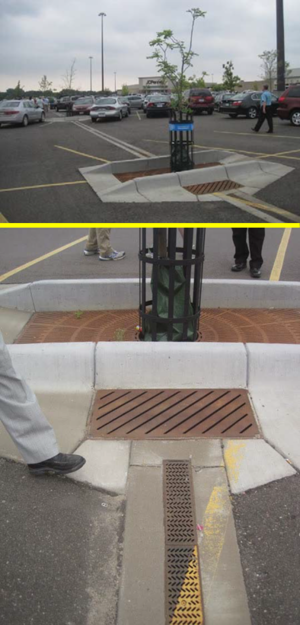

Screens are often effectively used in ultra-urban settings due to their small footprint but above ground screens are often constrained by aesthetics, traffic/safety and cold weather factors.

Applicability to MPCA stormwater permits

If designed properly, this practice meets the intent of the Construction stormwater permit as pretreatment for an infiltration or filtration system.

Advantages and limitations

The advantages and limitations of screens with regard to the pollutant removal capabilities, cost, ease of construction and maintenance, space and other design considerations and compatibility are presented below.

Advantages

Screens are an effective means of pretreatment in certain instances. They screen out sediment and debris efficiently in a small amount of space. The initial costs are often relatively inexpensive because screen systems are not complex. This also allows for simple maintenance which typically requires access to the screen and manual removal of sediment and debris, sometimes including washing with clean water to dislodge collected sediment and debris. Construction consists of installing a screen device in place, with relatively minimal labor costs and often without heavy equipment. Because screens typically have a small footprint, they are suitable for many BMPs and retrofit with many preexisting structures with minimal construction. Screens do provide discrete locations for the interception of large debris thus potentially saving expenses associated with collecting trash from structural stormwater BMPS.

Limitations

Screens should be inspected after each storm, until a site-specific, seasonal maintenance routine is developed. For most screen materials and design, pollutant removal is limited to trash, debris and coarse sediments while all other pollutants will pass through to the structural stormwater BMP. If the screen diameters are too small, collected material will clog the screen and increase cleaning frequency. Some seasons (e.g., spring snowmelt, spring leaf-out debris, autumn deciduous leaf-fall) or contributing areas (e.g., heavily wooded residential areas without street sweeping, commercial businesses with plastic bags, etc.) often produce a substantial amount of large sediment and debris, resulting in the need for inspections to determine an effective maintenance protocol. Screen systems often do not have much collection capacity and thus reduce in effectiveness or clog after a series of storm events. Without frequent maintenance, this ultimately diminishes the overall effectiveness of the system and thus careful consideration of screen design (size, diameter of openings, contributing area) is required to treat the range of expected seasonal flows and solids load.

Water quantity treatment

Stormwater volume reduction is not provided by pretreatment screens because water flowing into the device exits after the screen removes the sediment and large debris.

Water quality treatment

Screens used for stormwater pretreatment provide screening, or physical straining, of sediment, trash and debris from stormwater. Screens are not to be confused with filters, which refer to the passing of stormwater through a media to remove pollutants. Screens used for stormwater pretreatment are typically manufactured devices that are placed at stormwater inlets.

Points to consider when choosing a screen include the size of the screen openings, the anticipated flow rate through the screen, and the debris holding capacity of the device.

Screens may provide a reduction in nutrients, bacteria, or hydrocarbons if those pollutants are attached to trash or debris captured by the screen. For example, leaf litter can be a large source of nutrients in stormwater runoff, and effectively managing leaf litter has been used by communities to control phosphorus loads in stormwater (City of Madison, 2015). Another reason it is important to clean screens out regularly is to avoid the possibility of nutrients being leached out over time, which reduces the overall effectiveness of nutrient removal by screens. Capture of trash such as food containers, diapers and pet waste may also reduce bacteria (USEPA, 2012). Screens that capture trash and other debris should be cleaned and maintained regularly to prevent accumulation of trash, which may become a pollution source if not properly removed (USEPA, 2014).

Performance of pretreatment screens

The following discussion provides a summary of information found in the literature. The information provides a general summary and indication of the range of pollutant removal and should not be used for design purposes.

A pilot study in the state of California found that catch basin inserts with five-millimeter (mm) openings captured 100 percent of trash in runoff generated by a one-year, one-hour storm (Burns, 2014). Larger openings in the screen may allow small debris such as wrappers or cigarette butts to pass through the screen. The District Department of Environment captured 17,000 pounds of trash in 2012 using trash traps as a part of their TMDL implementation strategy (DDOE, 2013).

Related pages

- Pretreatment selection tool

- Overview and methods of pretreatment

- Overviews for different types of pretreatment practices

- Information for specific types of pretreatment practices

- Design, construction, operation and maintenance specifications for pretreatment vegetated filter strips

- Pretreatment - Hydrodynamic separation devices

- Pretreatment - Screening and straining devices, including forebays

- Pretreatment - Above ground and below grade storage and settling devices

- Pretreatment - Filtration devices and practices

- Pretreatment - Other pretreatment water quality devices and practices

- To see the above pages as a single page, link here

Pretreatment sizing for basins and filters strips

Guidance for managing sediment and wastes collected by pretreatment practices

Tables

- Pretreatment tables - link to tabled information for pretreatment practices

- Hydrodynamic separator tables

- Screening and straining devices tables

- Above ground and below grade storage and settling tables

- Filtration tables

- Other water quality devices tables

Other information and links

This page was last edited on 13 December 2022, at 18:38.