Pretreatment practices combined single page

This page combines information from the following pages into a single page:

- Hydrodynamic separation devices

- Screening and straining devices, including forebays

- Above ground and below grade storage and settling devices

- Filtration devices and practices

- Other pretreatment water quality devices and practices

Contents

Hydrodynamic separation devices

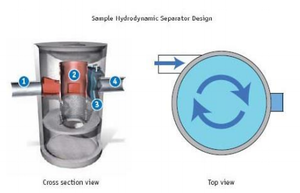

Hydrodynamic separators are flow-through, often proprietary structures that establish a high-speed rotating flow within a cylindrical chamber. Larger particles in the rotating stream have greater density than smaller particles to follow the tight curve of the stream, and thus strike the outside wall, falling to the bottom of the chamber where they can be later removed. While this means of settling does not always occur in this manner, generally the larger, more dense particles well settle to the bottom of these devices.

Some devices include other treatment and removal mechanisms such as the ability to trap floatables and/or provide a higher level of filtration or screening. These units are typically installed underground, frequently in existing sump manhole.

Hydrodynamic separation devices - system design

Many hydrodynamic separators are well-suited for use in or retrofitting existing manholes that service small to moderate-sized catchments (<5 acres). Devices are available in a variety of sizes and corresponding flow capacities. For some devices, the different models and corresponding dimensions can be accessed using the hyperlinks shown in this table.

System and Component Sizing

The sizing of a hydrodynamic separation system can be estimated using various tools, formulae, or guidance documents. Most manufacturers have a design tool or calculator for determining the size of device that may be needed; however modeled flow rates or the Rationale Method can be used to estimate the runoff flow rates. Additionally, guidance from the State of New Jersey Department of Environmental Protection and Washington State Department of Ecology provide additional considerations based on performance of these devices. In addition, SHSAM (Sizing Hydrodynamic Separators And Manholes) is a computer program for predicting the amount of suspended sediments removed from stormwater runoff by a given hydrodynamic separator/standard sump over a given period of time. SHSAM uses a continuous runoff model and sediment removal responses to predict the removal efficiency of the hydrodynamic separator device.

Most important for the sizing is the anticipated frequency of operation and maintenance as well as the protection of downstream BMPs and receiving water. Sizing is usually based on design flow rather than design flow. Most have configurations to bypass additional flow without resuspending solids. Some devices have “enhancements” that can provide other treatment mechanisms beyond pretreatment. These can provide an additional level of treatment such as filtration, skimming (in addition to settling or screening), chemical treatment/ sorption, or biodegradation. This is denoted table on system and component sizing.

Installation and Maintenance Recommendations

Proprietary hydrodynamic separators are generally designed to be easy to measure solids accumulation with access for maintenance from the street level. Manufactures often recommend more frequent inspections for a period after installation in order to gauge sediment and debris accumulation rates that may depend on factors such as nearby construction, winter or rainy conditions, street sanding, or a highly erosive drainage area. The information gained during this time is the primary indicator for how often inspections and cleanings may require to be scheduled. An initial estimate is usually available from the manufacturer. Manufacturers also have maintenance manuals or guides available, which can be accessed in the hyperlink within the table on maintenance recommendations. Generally, hydrodynamic separators are designed for quick and simple, but more frequent, maintenance than other practices. An advantage of hydrodynamic separators is that they are designed to minimize washout and sediment scouring within the system. In many locations, disposal of sediments removed may be handled in the same manner as disposal of sediments from catch basins (see here). Hydrodynamic separators generally are for areas without steep grading.

Links to tables with information on hydrodynamic devices

Below are links to several tables containing information on hydrodynamic separators. To see all tables on a single page, link here. To see the information in a single spreadsheet click on the following link: File:Hydronamic separation table all data.xlsx

- Hydrodynamic separation devices - pollutant removal characteristics

- Hydrodynamic separation devices - system design information

- Hydrodynamic separation devices - system and component sizing

- Hydrodynamic separation devices - installation and maintenance recommendations

Screening and straining devices, including forebays

Screening and straining devices trap trash and coarse debris using smaller apertures such as grates or screens. While many pretreatment devices utilize screening and straining in tandem with their main treatment process, the examples in this category are constrained to those that primarily remove larger particles and sediment by screening or straining. These devices are often visible from ground level as they generally sit above grade or slightly below grade before or just following inlets in order to protect the downstream drainage system/BMP from clogging. This table contains both proprietary and nonproprietary devices, with the proprietary systems often applying the same or similar mechanisms to the nonproprietary systems but with convenient and sometimes easier construction or ease of maintenance.

System design

Screening and straining devices can often be installed in parallel to accommodate larger drainage areas, but in general, each unit is intended for a small drainage area (< 1acre).

System and component sizing

Most important for the sizing is the anticipated frequency of operation and maintenance as well as the considerations of how well the device provides protection of downstream BMPs and receiving waters.

Links to tables with information on screening and straining devices

Below are links to several tables containing information on screening and straining devices. To see all tables on a single page, link here.

- Screening and straining devices - general information

- Screening and straining devices - system design information

- Screening and straining devices - system and component sizing

- Screening and straining devices - installation and maintenance recommendations

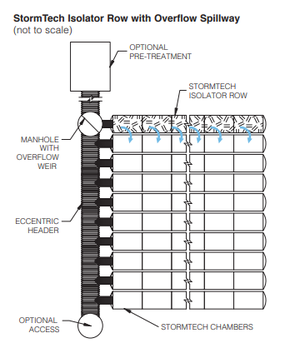

Above ground and below grade storage and settling devices

Above ground and below grade storage and settling systems are typically below grade vaults, specialized structures, or similar practices that are designed to promote gravitational settling in a liquid-filled system. These devices may also be outfitted with additional structures to also trap trash, oil, and other floatables. The devices presented below are a mix of proprietary and nonproprietary systems. The proprietary entries are examples that utilize one or more of the nonproprietary functionalities. Manholes with sumps have the space underneath the manhole’s lowest outlet (the sump) for sediment and debris collection and storage. The practice itself is nonproprietary, though proprietary outlet structures are available for enhanced performance.

Forebays are small bodies of water positioned just upstream of a larger pretreatment or treatment area. They slow the water allowing for settling of larger sediment. While these can be installed in front of vegetative filter strips, ponds, or other practices, each of which maintains its own specifications and recommendations, the forebays in this table are examples of the most common and general applications.

System Design

The underground settling vaults often come in pre-cast sizes from the manufacturer as an alternative to designing a custom unit. This is often a cost-effective approach with the designer selecting a larger size if manufacturer does not have the exact size based on calculations or sizing tables. Design and sizing tables may be available on a manufacturer’s website and are often accessible through the hyperlinks.

For forebays, the design is most often based on required capacity. Other specifications such as those listed under “Materials” often help to make maintenance easier.

System and Component Sizing

The sizing of an underground settling system can be estimated using various tools, formulae, or guidance documents. Most manufacturers have a tool or calculator for determining the size of device that may be needed, however modeled flow rates or the rational equation can be used to estimate the runoff flow rates. Additionally, guidance from the State of New Jersey Department of Environmental Protection and Washington State Department of Ecology provide additional considerations based on performance of these devices. Many sumped manholes can also use SHSAM (Sizing Hydrodynamic Separators And Manholes) for predicting the amount of suspended sediments removed from stormwater runoff over a given period of time. SHSAM is comprised of a continuous runoff model and sediment removal responses to predict the removal efficiency of the device. Most important for the sizing is the anticipated frequency of operation and maintenance as well as the protection of downstream BMPs and receiving waters.

Specifically regarding forebays, the capacity is determined by the flow received from its impervious drainage area. Then the shape of the basin and positioning of its inlets and outlets ensure that adequate settling occurs. Some devices have “enhancements” that can provide treatment mechanisms beyond the primary pretreatment mechanism. These can provide an additional level of treatment such as filtration, skimming (in addition to settling or screening), chemical treatment/sorption, or biodegradation. This is denoted by the Y or N in the table indicating this ability to perform additional mechanisms.

Links to tables with information on above ground and below grade storage and settling

Below are links to several tables containing information on above ground and below grade storage and settling. To see all tables on a single page, link here.

- Above ground and below grade storage and settling - pollutant removal information

- Above ground and below grade storage and settling - system design information

- Above ground and below grade storage and settling - system and component sizing

- Above ground and below grade storage and settling - installation and maintenance recommendations

Filtration devices and practices

Filtration pretreatment practices include proprietary and non-proprietary devices that remove particles by filtration or sieving through media (gravel, sand or other), vegetation, geotextile or fabric material, metal or plastic screen, or other material. The filtration devices presented in this table are classified as pretreatment due to the nature of the filtration, placement in the treatment train, or built-in additional pretreatment mechanisms. The filtration methods are widely varied from biological to mechanical. They seek to remove not only larger sediments and debris, but also heavy metals, nutrients, and other fine contaminants. The natural or engineered biological systems are, by nature, above ground.

System Design

Some filtration pretreatment methods require a larger footprint than other pretreatment options due to the slower flow through rate and surface-area-based effectiveness. Most drainage area references refer to impervious area.

System and Component Sizing

Sizing is largely based on drainage area and estimated runoff volumes for different design storms or intensities. Most important for the sizing is the anticipated frequency of operation and maintenance as well as protection of downstream BMPs and receiving water. Some devices have “enhancements” that can provide treatment mechanisms beyond the primary pretreatment mechanism. These can provide an additional level of treatment such as filtration, skimming (in addition to settling or screening), chemical treatment/sorption, or biodegradation. This is denoted by the Y or N in the table indicating this ability to perform additional mechanisms.

Links to tables with information on filtration

Below are links to several tables containing information on filtration. To see all tables on a single page, link here. To see the information in a single spreadsheet click on the following link: [[File:]]

- Filtration - pollutant removal information

- Filtration - system design information

- Filtration - system and component sizing

- Filtration - installation and maintenance recommendations

Other pretreatment water quality devices and practices

Links to tables with information on other water quality devices

Below are links to several tables containing information on other water quality devices. To see all tables on a single page, link here. To see the information in a single spreadsheet click on the following link: [[File:]]

- Other water quality devices - pollutant removal information

- Other water quality devices - system design information

- Other water quality devices - installation and maintenance recommendations