Difference between revisions of "Using the treatment train approach to BMP selection"

m |

m |

||

| Line 159: | Line 159: | ||

*[[Case studies for stormwater treatment trains]] | *[[Case studies for stormwater treatment trains]] | ||

| + | <noinclude> | ||

| + | [[Category:Level 2 - Best management practices/Structural practices]] | ||

| + | </noinclude> | ||

Revision as of 17:04, 25 July 2022

On a watershed scale, the management of stormwater begins with pollution prevention (e.g. pet ordinances, buffer requirements, public education), followed by Source Controls (e.g. sweeping, Illicit Discharge Detection and Elimination), Onsite Stormwater BMPs (e.g. rain gardens, permeable pavement), and Regional BMPs (e.g. constructed pond or stormwater wetlands, large underground infiltration system). All these practices comprise a stormwater management system.

Stormwater treatment implies removal of pollutants or stormwater volume once they have been generated. On-site and regional practices treat stormwater runoff. The term Stormwater Treatment Train has loosely been used since the mid-1980s to represent a multi-BMP approach to managing the quantity and quality of stormwater runoff and has often included prevention and source control practices. In this discussion, treatment train refers to treatment practices.

The concept of treatment trains has been commonly used in the field of wastewater treatment. Professionals in this field will often describe each component of the treatment train in terms of the structure within the plant, i.e. bar screens, grit chambers, primary settling tanks, secondary treatment tanks. For the purpose of stormwater management, the lexicon differs by focusing on the processes utilized within the BMP, rather than the structural feature of a BMP. For the purpose of the Minnesota Stormwater Manual and the information contained in this article, the definitions of practices vs. processes are based on the recommendations contained in Design of Urban Stormwater Controls, published jointly by the Water Environment Federation and American Society of Civil Engineers in 2012. The following approach uses different terminology than developed by WEF, which refers to Practices as Unit Operations. Practice has been selected for this article to parallel the common usage in Minnesota of Best Management Practices (BMPs) and Stormwater Management Practices (SMPs).

A closer look at on-site and regional BMPs shows that each BMP utilizes one or more components that work together to remove pollutants utilizing combinations of hydraulic, physical, biological, and chemical methods. A well-developed stormwater treatment train will combine these processes in a manner that ensures management of all pollutants that have been identified as affecting the receiving water.

Contents

Practice versus process

Stormwater process describes the mechanism by which pollutants are removed. For example, infiltration and evaporation are different processes for managing stormwater volume. Stormwater practices are Best Management Practices. These are the stormwater controls in which the pollutant control process, or multiple processes, takes place. In the stormwater industry, many BMPs have evolved and have been given labels that describe the primary process utilized by that BMP/practice. A key example is the term infiltration, which is used interchangeably as both a process and as a practice.

Physically, each BMP/practice utilizes multiple processes. For example, the practice of a bioinfiltration BMP utilizes the following processes:

- Hydraulic: infiltration, transpiration

- Physical: sedimentation, filtration

- Biological: plant metabolism, nitrification / denitrification, pathogen die-off

- Chemical: adsorption / absorption / ion exchange

- Other: thermal control

The following tables differentiate between stormwater process and practice. To view all the information in these tables in a single Excel file, link here.

- Processes for removing pollutants from stormwater runoff

- Practices for controlling pollutants in stormwater runoff

- Processes utilized by Best Management Practices - Infiltrators

- Processes utilized by Best Management Practices - Swales and Strips

- Processes utilized by Best Management Practices - Filters

- Processes utilized by Best Management Practices - Constructed Basins

- Processes utilized by Best Management Practices - Manufactured Devices

- Processes utilized by Best Management Practices - Storage and Reuse

Typical stormwater treatment train

A stormwater treatment train incorporates at least two processes to maximize the control of pollutants from the runoff. The BMP(s) selected may consist of one or multiple practices, depending on many considerations, including available space, physical conditions at a site, and regulatory requirements. See the tables above for a summary of processes and practices.

Hydraulic and physical processes remove larger solids and associated pollutants during storm events while biological and chemical processes that treat the finer solids and dissolved pollutants occur between storms (Scholes, et. al. 2007, Wong, et. al. 2001). Once complete, a treatment train can (adapted from Strecker, 2005)

- minimize the rate of runoff by utilizing a hydraulic process;

- remove bulk solids by utilizing a physical process;

- remove settleable solids and floatables by utilizing a physical process;

- remove suspended and colloidal solids by utilizing a physical, biological or chemical process; and

- remove colloidal, dissolved, volatile, and pathogens by using a biological or chemical process.

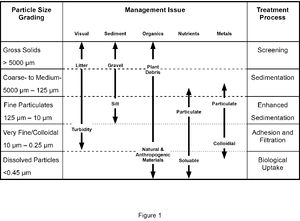

Using this framework for pollutant removal, particulate size of the pollutant(s) of concern should be matched to the stormwater practice best suited to remove that pollutant from stormwater runoff (Wong, et. al. 2002, Strecker, 2005). The figure to the right suggests treatment processes for a range of particulate sizes commonly found in stormwater runoff. Chemical processes are rarely utilized, given the higher capital and operating costs of chemical feeds and controls.

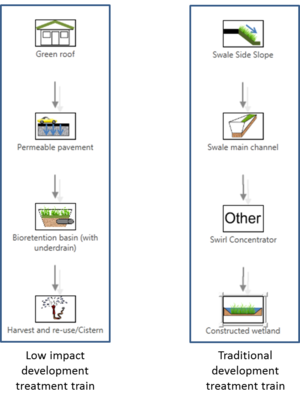

The resulting stormwater treatment train may result in a single BMP, such as a stormwater wetland, that utilizes multiple treatment train processes and by definition can be considered a stand-alone stormwater treatment train. Or it could become a multi-BMP treatment train with BMPs operating in series or parallel to each other. Low Impact Development (LID) and Traditional development are two typical configurations of treatment trains currently utilized by site designers that meet the definition of stormwater treatment trains. The focus of LID is to keep the raindrop as close to it's source as possible utilizing techniques such as infiltration and capture/storage/reuse. Traditional development typically employs filtration and sedimentation practices such as swales and constructed ponds and wetlands. These practices may or may not treat rainwater close to its source but generally have minor impacts on stormwater volume. Where feasible, LID practices are favored from a stormwater management practice as they reduce both stormwater volume and pollutant loading. LID practices, however, are often constrained by site factors, such as shallow depth to bedrock, soil or groundwater contamination, and space limitations (e.g. ultra-urban settings).

Examples of these two types of treatment trains are provided below and illustrated in the schematic to the right. In the LID example, water falling on a rooftop is filtered through a green roof, which stores some water for eventual uptake by plants and routes the remaining water to a permeable pavement and then to an infiltration BMP. The traditional configuration routes water off-site through a swale, which provides some treatment, before the water is discharged to a regional system.

- Example treatment train configuration for Low Impact Development site

- Green roof

- Hydraulic: transpiration, attenuation

- Biological: plant metabolism

- Permeable pavement

- Hydraulic: infiltration

- Physical: filtration

- Bioretention

- Hydraulic: infiltration, transpiration

- Physical: filtration, sedimentation

- Biological: plant metabolism, pathogen die-off, nitrification / denitrification

- Cistern for irrigation

- Hydraulic: diversion

- Example treatment train configuration for traditional development

- Swales

- Hydraulic

- Physical: sedimentation, filtration

- Swirl concentrator

- Hydraulic: vortex separation

- Stormwater wetland

- Hydraulic: peak flow attenuation

- Physical: skimming, sedimentation

- Biological: plant metabolism, pathogen die-off

Benefits and Disadvantages

On-site treatment trains that have been found to be the most effective are those that maintain runoff onsite while allowing sufficient time for hydraulic, physical, biological, and chemical processes to take place (Rushton, 2004). This has been demonstrated to be true in multiple case studies, as well as in Minnesota case studies including the Empire Wastewater Treatment Plant project owned and operated by the Metropolitan Council.

On a larger catchment area or watershed scale the pollution reduction of treatment train BMPs is effective, but less so than on an on-site basis. Generally, the highest level of pollutant reduction is achieved in the first BMP, with each successive BMP becoming less effective. The theory of why this occurs is based on the concept of irreducible pollutants. For more information on irreducible concentration, link here. Essentially the second, third, etc. BMPs in the treatment train are receiving runoff that has considerably less concentration of pollutants and which at some point are below the theoretical irreducible concentration for the BMP. One recommended approach to adjust for the uncertainties of pollutant removals would be to create a prioritized list of BMPs that are listed or ranked according to the pollutant removal effectiveness for each pollutant. Modelers utilizing this technique are advised to adjust the pollutant concentrations and kinetic uptake factor (k) for each pollutant being assessed by the model (Scholes, et al, 2007).

Costs

A review of literature did not find any studies that assessed the cost effectiveness of stormwater treatment trains. It is assumed that the cost considerations for a stormwater treatment train would parallel these cost considerations for individual stormwater BMPs.

- Cost comparisons should assess the cost through the life cycle of the BMP (WEF, 2012, Strecker, 2005).

- Larger projects typically have a better economy of scale (WEF, 2012).

- Retrofits are more expensive than installation of BMPs in new construction projects (WEF, 2012, Watershed Protection Techniques). The cost to retrofit is 1.5 to 4.0 times the cost of BMP installation in new construction (CWP, 2007).

- Most BMP studies report the construction costs, only. An additional 25 to 32 percent should be added to the capital budget to accommodate design, permitting, and contingency costs (Strassler, 1999)

- Land costs have the greatest impact on stormwater facility costs (Strecker, 2005).

- Cost per volume (gallon, cubic foot, etc) is more reliable than cost per area (acre) when comparing BMP options (Strecker, 2005, Weigand, 1986).

- O&M costs can be calculated as a percentage of construction costs (Strassler, 1999).

Stormwater treatment train approach

General considerations

A stormwater management system begins at the point that the rainfall hits the ground and becomes runoff. Site owners, maintainers, designers, etc. that are establishing a stormwater management system should consider non-structural practices as well as structural BMPs. A comprehensive stormwater management system includes

- practices that control the development of runoff;

- practices that prevent generation of pollutants, (Pollution Prevention and Education Practices);

- practices that remove pollutants before contact with rainfall (Source Controls); and

- BMPs that utilize multiple processes that remove pollutants in stormwater runoff.

Treatment train implies treatment or removal of stormwater volume or pollutants. Prevention and source control practices are therefore not treatment practices. The remainder of this section therefore details the process of developing the structural practices, or treatment portion, of the stormwater management system.

Developing a stormwater treatment train

Development of a stormwater treatment train is an iterative process that balances site constraints, project goals, and available budget. The following steps lay out the process for establishing a stormwater treatment train. The results of one of the steps may cause designers to reconsider earlier decisions on sizing, siting, etc., as the project progresses.

- Step 1 - Review project goals and site conditions

The site conditions, regulatory requirements, and project purpose will vary from site to site and from city to city. Information to assemble includes:

- Project goals – is the project intended to solve a drainage problem, meet regulatory requirements, or both? The answer to this question determines whether the goals are related to runoff volume or water quality. If the objectives are related to water quality, the pollutants of concern need to be identified.

- Regulatory requirements – are there any regulatory requirements that will influence the stormwater system?

- Site conditions: collect information on impervious surface, drainage area, runoff quality, soils, topography

- Step 2 - Review pollutant removal processes and identify potential practices

The purpose of this step is to create a list of BMPs that work together to remove the pollutants of concern identified in Step 1.

- Select processes required to manage pollutants

- Identify combination(s) of BMPs that include the processes required to manage the identified pollutants

To make these determinations, use this table, which provides a summary of processes and practices.

- Step 3 - Determine site constraints that affect BMP placement and sizing

Site constraints will affect the sizing, location, and performance of the BMPs identified in Step 2. The purpose of this step is to narrow down the BMP options based on such site constraints as:

- Available space

- Access for maintenance

- Limitations on infiltration related to soil type, soil contamination, depth to groundwater, presence of structures, utility conflicts, and/or depth to bedrock

- Regulatory requirements that affect the BMP volume or footprint

- Compatibility with other site uses, including green space requirements, public spaces, structures, etc.

- Step 4 - Select individual BMPs and evaluate range of performance

Review each BMP identified in Step 3 to confirm that each pollutant removal process identified in Step 2 is present in the combination of BMPs selected in Step 3. If not, then Step 3 should be reviewed and alternative BMPs proposed.

- Step 5 - Size BMPs and assess performance

Size the BMP and use the MIDS calculator or other technique detailed in the Credits section of the MN Stormwater Manual to assess the performance. Review results against goals set in Step 1. If goals are not fully achieved, then resize the BMPs or return to Step 3 to select alternative BMPs.

- Step 6 - Review construction and operation criteria

Designers should assess construction and operation considerations that need to be incorporated into the construction plans and/or the Operations and Maintenance Manual that are necessary to ensure the BMP operates as designed and is properly maintained.

References

- Rushton, Betty. 2002. Enhanced parking lot design for stormwater treatment. In Proc. of 9th International Conference on Urban Drainage, September 8-13, 2002 EWRI/IWA/ASCE.

- Scholes, Lian, D. Michael Revitt, and J. Bryan Ellis. 2008. A systematic approach for the comparative assessment of stormwater pollutant removal potentials. Journal of Environmental Management 88: no. 3: 467-478.

- Schueler, Thomas R. 2000. The economics of stormwater treatment: An update. Article 68: 401-405.

- Schueler, Thomas R., and Jennifer Zielinski. 2007. Urban stormwater retrofit practices. Center for Watershed Protection.

- Strassler, Eric, Jesse Pritts, and Kristen Strellec. 1999. Preliminary data summary of urban storm water best management practices. United States Environmental Protection Agency, Office of Water.

- Strecker, Eric. 2006. Critical Assessment of Stormwater Treatment and Control Selection Treatment.

- Water Environment Federation. 2012. Design of urban stormwater controls (2nd ed.). New York: McGraw-Hill Professional.

- Wiegand, Cameron, Thomas Schueler, Wendy Chittenden, and Debra Jellick. 1986. Cost of urban runoff quality controls. In Urban Runoff Quality@ sImpact and Quality Enhancement Technology, pp. 366-380. ASCE.

- Wong, Tony HF. 2001. A changing paradigm in Australian urban stormwater management. In 2nd South Pacific Stormwater Conference, pp. 1-18. 2001.

- Wong, Tony HF, Tim D. Fletcher, Hugh P. Duncan, John R. Coleman, and Graham A. Jenkins. 2002. A model for urban stormwater improvement conceptualization. Global Solutions for Urban Drainage (2002): 8-13.

Related articles

- Using the treatment train approach to BMP selection

- Scenario for developing a stormwater treatment train for a parking lot

- Scenario for developing a stormwater treatment train for an ultra-urban setting

- Scenario for developing a stormwater treatment train for a site with limited infiltration capacity

- Scenario for developing a stormwater treatment train for a retrofit site

- Scenario for developing a stormwater treatment train for constructed ponds in new development

- Case studies for stormwater treatment trains